Trade fairs - Lenze

Trade fairs - Lenze

Trade fairs - Lenze

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ting work. The system is capable of<br />

changing a tool holder for different<br />

models fully automatically. It detects<br />

which component has arrived, and<br />

brings the appropriate tool holder into<br />

position accordingly.<br />

Time is money – and changes have<br />

to be made quickly. This is no easy task,<br />

especially since the rotary table can<br />

weigh 17 tonnes including its load. But<br />

in spite of its mass, the table requires<br />

just six to seven seconds for a half rotation.<br />

The asynchronous geared motor<br />

from <strong>Lenze</strong> which turns the carousel has<br />

a maximum drive power of 22 kW and<br />

delivers the necessary torque of 7,800<br />

Newton metres.<br />

Strength, however, is not all that is<br />

required. Precision is also necessary<br />

when accelerating and braking, since<br />

narrow tolerances must be observed<br />

when the component moves from the<br />

tool holder to the welding station. Four<br />

sensors are attached to the rotary table<br />

for monitoring the positions. A 9400<br />

Servo Drive with a power output of 30 kW<br />

controls the motor and its positioning.<br />

Motion profiles are stored on a pluggable<br />

module. Separating the hardware<br />

The C-Class is the best-seller in the Mercedes-Benz range.<br />

and software in this way has the advantage<br />

that the system can be restarted<br />

very quickly after replacing a controller,<br />

without the new unit requiring lengthy<br />

programming. When the system requires<br />

servicing, this module considerably<br />

reduces expensive downtimes.<br />

<strong>Lenze</strong> drive technology was also<br />

used in the Turnflex’s internal conveyor<br />

technology which moves the tool holders<br />

in and out. A 10 kW synchronous servo<br />

motor combined with an 11 kW 9400<br />

Servo Drive powers a conveyor belt on<br />

the linear sections. Precise movements<br />

are once again necessary to ensure that<br />

the tool holder hooks exactly into the<br />

belt’s lock, enabling it to be transported<br />

safely.<br />

Safety considerations were high on<br />

the list of priorities when the Turnflex’s<br />

drive technology was designed. Regulations<br />

governing the protection of<br />

persons are very strict. <strong>Lenze</strong> has<br />

designed its series of controllers in a<br />

modular form, which enables the necessary<br />

safety categories to be fulfilled<br />

easily and reliably using plug-in safety<br />

modules. Their functions satisfy the<br />

demands of IEC 61508 SIL3, and have<br />

Cover story<br />

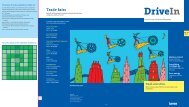

Servo Drives 9400<br />

The controllers in the 9400 Servo Drive<br />

series are designed as Single Drives and<br />

Multi Drives. The Single Drives combine<br />

mains feed, DC bus and inverter in a single<br />

unit. Integrated filter elements and a brake<br />

chopper facilitate autonomous operation<br />

within decentralised installations. The<br />

Multi Drives have been optimised for centralised,<br />

compact multi-axis installations<br />

with all the benefits of a shared DC bus.<br />

The dimensions of the power section<br />

combined with the intelligent management<br />

of switching frequencies enables peak<br />

currents of up to four times more than the<br />

drive continuous current. The drives support<br />

feedback-based and encoder-free control<br />

processes. The assembly equipment and<br />

drive electronics are kept separate up to a<br />

motor output of 11 kW. This makes them<br />

easier to assemble and install. The mounting<br />

base incorporates all of the power<br />

connections such as mains supply, motor<br />

connections and busbars for the DC bus in<br />

Multi Drives. The series covers an overall<br />

power range of 0.37 to 400 kW.<br />

Servo Drives 9400.<br />

9