Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ducati’s approach is to develop internally the<br />

technologies to be introduced on its motorcycles,<br />

together with its suppliers, simultaneously<br />

creating know-how within the Company. Concrete<br />

examples are the close collaboration with Pirelli,<br />

Brembo, Bosch and other suppliers with which<br />

the Bologna-based manufacturer participates in<br />

the development of components which are first<br />

mounted on the Ducati bikes. This approach is<br />

even more valuable when it comes to electronics<br />

because it allows Ducati to have full control over<br />

the technologies implemented, thus being able<br />

to customize them without constraints depending<br />

on the application, from the Panigale V4 to the<br />

Scrambler via the Streetfighter, Diavel, DesertX<br />

and the Multistrada V4, which represents the<br />

maximum expression of Ducati electronic<br />

technology.<br />

ELECTRICAL & ELECTRONIC SYSTEMS:<br />

DEVELOPMENT AND CREATION OF<br />

EXPERTISE<br />

The drive towards innovation in electronics goes<br />

hand in hand with the growth of the Electrical &<br />

Electronic Systems department, which has seen<br />

its resources quadruple in just over ten years.<br />

Through the work of this department, which<br />

is part of R&D, Ducati studies, develops and<br />

introduces new and often innovative systems<br />

into series production, obviously also drawing on<br />

experience from racing competition. The constant<br />

work of developing and refining the technical<br />

and technological solutions has introduced<br />

a very broad range of functions and devices<br />

across the entire range, which today varies from<br />

the state-of-the-art available on the Panigale V4<br />

and Multistrada V4, to systems such as Ride-bywire,<br />

Traction Control, Quickshift, Riding Mode,<br />

Cornering ABS and TFT instruments also on more<br />

accessible models such as the Scrambler.<br />

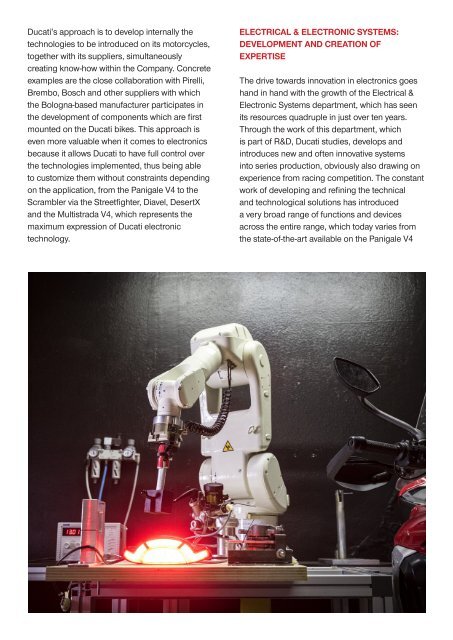

Ducati innovation also involves new working<br />

methods. In addition to developing new<br />

technologies internally, Ducati has had several<br />

internal laboratories within the company for several<br />

years to carry out tests during the development<br />

phase, without necessarily having to rely on<br />

external resources or suppliers. One of these is<br />

Electrical & Electronic Testing which is responsible<br />

for testing the electrical and electronic components<br />

of the bikes in the range, putting them to the test<br />

to measure their quality and duration over time.<br />

The purpose of this activity is twofold: to quickly<br />

solve the problems that may arise during the<br />

development phases and to monitor the quality of<br />

the already existing models.<br />

Among the tests that are carried out by highly<br />

specialized personnel in the Electrical & Electronic<br />

Testing laboratory there are those for verifying the<br />

functioning of the components in extreme thermal<br />

and environmental conditions, made possible<br />

thanks to the use of cells capable of replicating<br />

temperatures ranging from –40°C to 180°C and<br />

atmospheric events such as heavy rain or salt<br />

mist. The components are also put under stress<br />

by means of robots which repeat operations<br />

thousands of times, such as, for example, the<br />

rotation of the handlebar to check the correct<br />

reliability of the wiring, or other operations such as<br />

the brake lever to turn on the brake light, in order<br />

to verify its resilience in real conditions of use.