International Aquafeed Directory 2023-24

Welcome to the 27th edition of the International Aquafeed Directory & Buyers’ Guide 2023/24, the essential guide for everyone involved in the global aquafeed industry. Last year I wrote about the effects of the war, and the challenges resulting from rising fuel costs, but the industry showed great resilience. The impact of inflation and reduced consumer spending dampened growth in the market at the beginning of the year, but an expected increase in aquaculture production will compensate for a mall decline in wild catches. This edition contains information relating to 450+ businesses and over 850 products, coupled with useful and practical information including the extruder and expander guide. We would like to take this opportunity to thank all the businesses that have contributed to the completion of this directory. I also hope that all of our readers across the world remain safe and well.

Welcome to the 27th edition of the International Aquafeed Directory & Buyers’ Guide 2023/24, the essential guide for everyone involved in the global aquafeed industry.

Last year I wrote about the effects of the war, and the challenges resulting from rising fuel costs, but the industry showed great resilience. The impact of inflation and reduced consumer spending dampened growth in the market at the beginning of the year, but an expected increase in aquaculture production will compensate for a mall decline in wild catches.

This edition contains information relating to 450+ businesses and over 850 products, coupled with useful and practical information including the extruder and expander guide.

We would like to take this opportunity to thank all the businesses that have contributed to the completion of this directory. I also hope that all of our readers across the world remain safe and well.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

28<br />

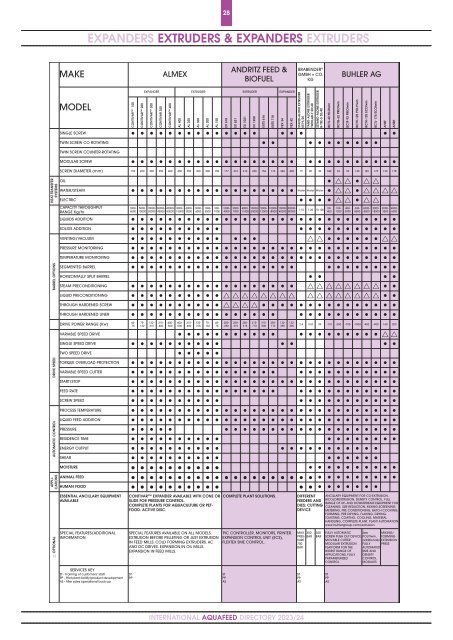

EXPANDERS EXTRUDERS & EXPANDERS EXTRUDERS<br />

MAKE<br />

ALMEX<br />

ANDRITZ FEED &<br />

BIOFUEL<br />

BRABENDER ®<br />

GMBH + CO.<br />

KG<br />

BUHLER AG<br />

HEAT TRANSFER<br />

SYSTEMS<br />

BARREL OPTIONS<br />

DRIVE SPEED<br />

AUTOMATIC CONTROL<br />

APPLI-<br />

CATIONS<br />

MODEL<br />

CONTIVAR 150<br />

CONTIVAR 200<br />

EXPANDER EXTRUDER EXTRUDER EXPANDER<br />

CONTIVAR 300<br />

CONTIVAR 350<br />

CONTIVAR 400<br />

AL 400<br />

AL 350<br />

AL 300<br />

AL 200<br />

AL 150<br />

EX 618<br />

SINGLE SCREW<br />

• • • • • • • • • • • • • • • • • • •<br />

TWIN SCREW CO ROTATING<br />

• • • • • • • • • •<br />

TWIN SCREW COUNTER-ROTATING<br />

MODULAR SCREW<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

SCREW DIAMETER (mm) 150 200 300 350 400 400 350 300 200 150 177 210 210 250 156 176 340 420 19 20 30 342 62 93 125 125 175 133 178<br />

OIL<br />

• r r • r r<br />

WATER/STEAM<br />

• • • • • • • • • • • • • • • • • • • r r • r r r r<br />

Water Water Water<br />

ELECTRIC<br />

• • • • r r • r r<br />

CAPACITY THROUGHPUT<br />

RANGE Kg/hr<br />

1000-<br />

6000<br />

5000-<br />

10000<br />

10000-<br />

30000<br />

30000-<br />

45000<br />

45000-<br />

80000<br />

8000-<br />

15000<br />

6000-<br />

8000<br />

3500-<br />

6000<br />

1000-<br />

3500<br />

500-<br />

1000<br />

1000-<br />

4000<br />

EX 621<br />

3000-<br />

7000<br />

EX 1021<br />

4000-<br />

11000<br />

EX 1250<br />

10000-<br />

20000<br />

EXTS 616<br />

5000-<br />

12000<br />

EXTS 718<br />

10000-<br />

18000<br />

FEX 34<br />

10000-<br />

40000<br />

FEX 42<br />

30000-<br />

80000<br />

STAND-ALONE EXTRUDER<br />

KE19/25<br />

TAND-ALONE EXTRUDER<br />

TWINLAB-F 20/40<br />

SSTAND-ALONE EXTRUDER<br />

B-TSE-S 30/40<br />

1-10 1-20 10-100<br />

LIQUIDS ADDITION<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

SOLIDS ADDITION<br />

• • • • • • • • • • • • • • • • • • • • •<br />

VENTING/VACUUM<br />

• • • • • • • • • • • • • r r • • • • • • r r<br />

PRESSURE MONITORIING<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

TEMPERATURE MONITORING<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

SEGMENTED BARREL<br />

• • • • • • • • • • • • • • • • • • • • • • • • • •<br />

HORIZONTALLY SPLIT BARREL<br />

• • • •<br />

STEAM PRECONDITIONING<br />

• • • • • • • • • • • • • • • • • • r r r r r r r r • •<br />

LIQUID PRECONDITIONING<br />

• • • • • • • • • • r r r r r r r r r r r r r r r r • •<br />

THROUGH HARDENED SCREW<br />

• • • • • • • • • • r r r r • • • • • • • • • • • • • • •<br />

THROUGH HARDENED LINER<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

DRIVE POWER RANGE (Kw)<br />

45-<br />

75<br />

75-<br />

132<br />

132-<br />

315<br />

315-<br />

400<br />

400-<br />

500<br />

400-<br />

500<br />

315-<br />

400<br />

132-<br />

315<br />

75-<br />

132<br />

45-<br />

75<br />

200-<br />

250<br />

250-<br />

315<br />

250-<br />

315<br />

315-<br />

710<br />

315-<br />

500<br />

355-<br />

710<br />

132-<br />

355<br />

132-<br />

355<br />

BCTL-42 PILOtwin<br />

50-<br />

400<br />

BCTG-62 PRIOtwin<br />

BCTF-93 PRIOtwin<br />

400-<br />

3000<br />

BCTH-125 POLYtwin<br />

600-<br />

8000<br />

BCTH-125 ECOtwin<br />

6000-<br />

8000<br />

BCTJ-175 ECOtwin<br />

2000-<br />

18000<br />

AHSF<br />

100-<br />

1200<br />

2000-<br />

3500<br />

AHSH<br />

4000-<br />

6000<br />

2.4 10.0 39 -110 -250 -700 -1500 -450 -900 160 200<br />

VARIABLE SPEED DRIVE<br />

• • • • • • • • • • • • • • • • • • • • r r<br />

SINGLE SPEED DRIVE<br />

• • • • • • • • • • • • • •<br />

TWO SPEED DRIVE<br />

• • • • •<br />

TORQUE OVERLOAD PROTECTION<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

VARIABLE SPEED CUTTER<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

START/STOP<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

FEED RATE<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

SCREW SPEED<br />

• • • • • • • • • • • • • • • • • • • • •<br />

PROCESS TEMPERATURE<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

LIQUID FEED ADDITION<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

PRESSURE<br />

• • • • • • • • • • • • • • • • • • • • • • • •<br />

RESIDENCE TIME<br />

• • • • • • • • • • • • • • • • • •<br />

ENERGY OUTPUT<br />

• • • • • • • • • • • • • • • • • • • • •<br />

SHEAR<br />

• • • • • • • • • • • • • • • •<br />

MOISTURE<br />

• • • • • • • • • • • • • • • • • • • •<br />

ANIMAL FEED<br />

• • • • • • • • • • • • • • • • • • • • • • • • • • • • •<br />

HUMAN FOOD<br />

• • • • • • • • • • • • • • • • • • •<br />

ESSENTIAL ANCILLARY EQUIPMENT<br />

AVAILABLE<br />

CONTIVAR EXPANDER AVAILABLE WITH CONE OR<br />

SLIDE FOR PRESSURE CONTROL.<br />

COMPLETE PLANTS FOR AQUACULTURE OR PET-<br />

FOOD. ACTIVE DISC.<br />

COMPLETE PLANT SOLUTIONS.<br />

DIFFERENT ANCILLARY EQUIPMENT FOR CO-EXTRUSION,<br />

BICOLOREXTRUSION, DENSITY CONTROL, FULL<br />

FEEDERS AND<br />

RANGE OF UP- AND DOWNSTREAM EQUIPMENT FOR<br />

DIES; CUTTING CLEANING, SIZE REDUCTION, MIXING,SCREENING,<br />

DEVICE METERING, PRE CONDITIONING, BATCH COOKING,<br />

FORMING, PRE DRYING, FLAKING, DRYING,<br />

TOASTING, COATING, COOLING, MATERIAL<br />

HANDLING, COMPLETE PLANT, PLANT AUTOMATION<br />

www.buhlergroup.com/extrusion<br />

r OPTIONAL<br />

SPECIAL FEATURES/ADDITIONAL<br />

INFORMATION<br />

SPECIAL FEATURES AVAILABLE ON ALL MODELS.<br />

EXTRUSION BEFORE PELLETING OR JUST EXTRUSION<br />

IN FEED MILLS. COLD FORMING EXTRUDERS. AC<br />

AND DC DRIVES. EXPANSION IN OIL MILLS.<br />

EXPANSION IN FEED MILLS.<br />

PIC CONTROLLER, MONITORS, PRINTER.<br />

EXPANSION CONTROL UNIT (ECS),<br />

FLEXTEX SME CONTROL.<br />

MAX 350<br />

PRES- BAR<br />

SURE<br />

700<br />

BAR<br />

350<br />

BAR<br />

FULLY AUTOMATIC See MIXING/<br />

SCREW PUSH OUT DEVICE, POLYtwin, FORMING<br />

MOVABLE CUTTER, additionally: EXTRUSION<br />

MODULAR EXTRUSION FULLY PRESS<br />

PLATFORM FOR THE AUTOMATED<br />

WIDEST RANGE OF SME AND<br />

APPLICATIONS, FULLY DENSITY<br />

PARAMETERIZED CONTROL<br />

CONTROL<br />

MODULES<br />

SERVICES KEY<br />

ST - Training of customers’ staff<br />

PP - Pilot plant facility/product development<br />

AS - After sales operational back-up<br />

ST<br />

PP<br />

ST<br />

PP<br />

AS<br />

ST<br />

PP<br />

AS<br />

ST<br />

PP<br />

AS<br />

INTERNATIONAL AQUAFEED DIRECTORY <strong>2023</strong>/<strong>24</strong>