Africa Automotive July-August issue 2022

Africa Automotive prides itself to be the ONLY Africa’s leading and MOST authoritative magazine for the automotive industry in Africa with printed copies for the automotive industry decision makers in both government, NGO’s and private sector. The Bi-monthly magazine offers cost effective advertising services that get results and improves growth in the auto B2C and B2B sector, keeping an eye on latest technologies in Africa and across the world, the magazine predominately covers the developments in the Africa auto industry.

Africa Automotive prides itself to be the ONLY Africa’s leading and MOST authoritative magazine for the automotive industry in Africa with printed copies for the automotive industry decision makers in both government, NGO’s and private sector. The Bi-monthly magazine offers cost effective advertising services that get results and improves growth in the auto B2C and B2B sector, keeping an eye on latest technologies in Africa and across the world, the magazine predominately covers the developments in the Africa auto industry.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technology<br />

<strong>July</strong>-<strong>August</strong> <strong>issue</strong> l <strong>2022</strong><br />

SAF TRAKr regenerative<br />

braking axle goes into<br />

production<br />

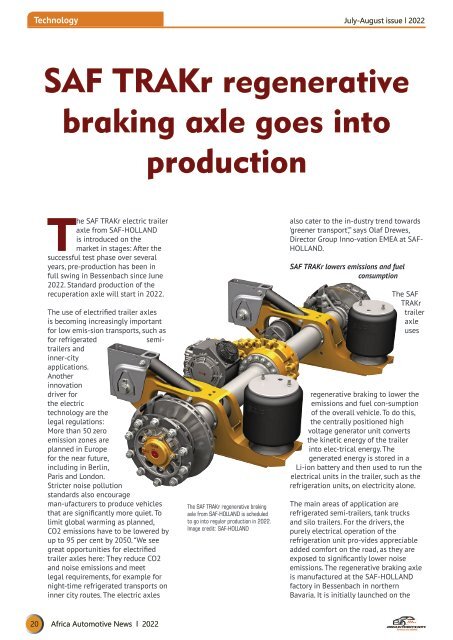

The SAF TRAKr electric trailer<br />

axle from SAF-HOLLAND<br />

is introduced on the<br />

market in stages: After the<br />

successful test phase over several<br />

years, pre-production has been in<br />

full swing in Bessenbach since June<br />

<strong>2022</strong>. Standard production of the<br />

recuperation axle will start in <strong>2022</strong>.<br />

The use of electrified trailer axles<br />

is becoming increasingly important<br />

for low emis-sion transports, such as<br />

for refrigerated<br />

semitrailers<br />

and<br />

inner-city<br />

applications.<br />

Another<br />

innovation<br />

driver for<br />

the electric<br />

technology are the<br />

legal regulations:<br />

More than 50 zero<br />

emission zones are<br />

planned in Europe<br />

for the near future,<br />

including in Berlin,<br />

Paris and London.<br />

Stricter noise pollution<br />

standards also encourage<br />

man-ufacturers to produce vehicles<br />

that are significantly more quiet. To<br />

limit global warming as planned,<br />

CO2 emissions have to be lowered by<br />

up to 95 per cent by 2050. “We see<br />

great opportunities for electrified<br />

trailer axles here: They reduce CO2<br />

and noise emissions and meet<br />

legal requirements, for example for<br />

night-time refrigerated transports on<br />

inner city routes. The electric axles<br />

The SAF TRAKr regenerative braking<br />

axle from SAF-HOLLAND is scheduled<br />

to go into regular production in <strong>2022</strong>.<br />

Image credit: SAF-HOLLAND<br />

also cater to the in-dustry trend towards<br />

‘greener transport’,” says Olaf Drewes,<br />

Director Group Inno-vation EMEA at SAF-<br />

HOLLAND.<br />

SAF TRAKr lowers emissions and fuel<br />

consumption<br />

The SAF<br />

TRAKr<br />

trailer<br />

axle<br />

uses<br />

regenerative braking to lower the<br />

emissions and fuel con-sumption<br />

of the overall vehicle. To do this,<br />

the centrally positioned high<br />

voltage generator unit converts<br />

the kinetic energy of the trailer<br />

into elec-trical energy. The<br />

generated energy is stored in a<br />

Li-ion battery and then used to run the<br />

electrical units in the trailer, such as the<br />

refrigeration units, on electricity alone.<br />

The main areas of application are<br />

refrigerated semi-trailers, tank trucks<br />

and silo trailers. For the drivers, the<br />

purely electrical operation of the<br />

refrigeration unit pro-vides appreciable<br />

added comfort on the road, as they are<br />

exposed to significantly lower noise<br />

emissions. The regenerative braking axle<br />

is manufactured at the SAF-HOLLAND<br />

factory in Bessenbach in northern<br />

Bavaria. It is initially launched on the<br />

20 <strong>Africa</strong> <strong>Automotive</strong> News l <strong>2022</strong>