Finishing - September-October 2023

As we reach the end of summer which has not been the greatest in terms of weather it will be interesting to see which way the wind is blowing in regard to the environment as the next general election approaches. I live close to London and the ULEZ extension has been on top of the agenda for many people. The statistics on London’s air quality are extremely worrying with the WHO saying that air pollution far exceeds limits. Do we ignore the evidence and continue to put lives at risk? I would imagine we would not like a polluting business near our home or place of work and it is impressive that finishing companies are stepping up and taking on board their environmental responsibilities. We are all aware that there is a cost involved, but it seems a small price to pay for a healthy future. John Hatcher, Editor

As we reach the end of summer which has not been the greatest in terms of weather it will be interesting to see which way the wind is blowing in regard to the environment as the next general election approaches.

I live close to London and the ULEZ extension has been on top of the agenda for many people. The statistics on London’s air quality are extremely worrying with the WHO saying that air pollution far exceeds limits. Do we ignore the evidence and continue to put lives at risk? I would imagine we would not like a polluting business near our home or place of work and it is impressive that finishing companies are stepping up and taking on board their environmental responsibilities.

We are all aware that there is a cost involved, but it seems a small price to pay for a healthy future.

John Hatcher, Editor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

12 ENERGY<br />

Are you ready for the green effect?<br />

With energy prices skyrocketing all over<br />

Europe the question of lowering your<br />

energy consumption has never been<br />

more urgent. But there might be an easy<br />

solution with an enormous hidden potential –<br />

cutting costs and increasing profit while at the<br />

same time making the coating industry<br />

greener.<br />

The coating industry is very energy<br />

demanding. This is a fact that has been<br />

known to us for long, but we never knew<br />

exactly how much energy that escapes during<br />

the process. Now we know.<br />

We are meeting up with Petter Törefors,<br />

CEO and owner of HangOn AB, a Swedish<br />

developer and manufacturer of solutions for<br />

hanging, masking, and handling, solutions that<br />

today are distributed to more than 40<br />

countries around the world. For starters the<br />

business idea was mostly about helping<br />

customers to increase efficiency and<br />

profitability in their coating process, a mission<br />

in which they have succeeded. But the<br />

question that has been eating away during the<br />

last couple of years, ever since HangOn<br />

conducted a life cycle analysis (LCA) on their<br />

own products 20 years ago, is the question of<br />

sustainability. All while visiting customers and<br />

exploring their needs for further development.<br />

– And it is obvious that finding the right<br />

solutions for sustainability in the coating<br />

industry by increasing hanging density is the<br />

most important thing we can do for our<br />

customers, Törefors says.<br />

Sustainability – a top priority<br />

In the coating industry for the last decades,<br />

sustainability has been a top priority when it<br />

comes to limit emissions, preventing air and<br />

water pollution and putting effort to<br />

reformulate and produce environment-friendly<br />

coatings. Furthermore, the coating industry<br />

has gone long ways to explore the<br />

development of bio-renewable technologies to<br />

reduce the carbon footprint. An array of<br />

certified environmentally preferable paints and<br />

coatings are available, which all together have<br />

much lower levels of toxicity, while also<br />

having recyclable content. Some of these<br />

paints are not only environmentally friendly,<br />

but also more cost-effective than conventional<br />

paints.<br />

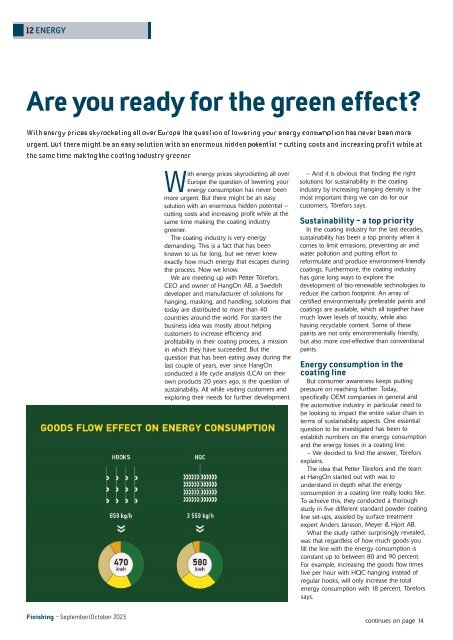

Energy consumption in the<br />

coating line<br />

But consumer awareness keeps putting<br />

pressure on reaching further. Today,<br />

specifically OEM companies in general and<br />

the automotive industry in particular need to<br />

be looking to impact the entire value chain in<br />

terms of sustainability aspects. One essential<br />

question to be investigated has been to<br />

establish numbers on the energy consumption<br />

and the energy losses in a coating line.<br />

– We decided to find the answer, Törefors<br />

explains.<br />

The idea that Petter Törefors and the team<br />

at HangOn started out with was to<br />

understand in depth what the energy<br />

consumption in a coating line really looks like.<br />

To achieve this, they conducted a thorough<br />

study in five different standard powder coating<br />

line set-ups, assisted by surface treatment<br />

expert Anders Jansson, Meyer & Hjort AB.<br />

What the study rather surprisingly revealed,<br />

was that regardless of how much goods you<br />

fill the line with the energy consumption is<br />

constant up to between 80 and 90 percent.<br />

For example, increasing the goods flow times<br />

five per hour with HQC-hanging instead of<br />

regular hooks, will only increase the total<br />

energy consumption with 18 percent, Törefors<br />

says.<br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2023</strong><br />

continues on page 14