Finishing - September-October 2023

As we reach the end of summer which has not been the greatest in terms of weather it will be interesting to see which way the wind is blowing in regard to the environment as the next general election approaches. I live close to London and the ULEZ extension has been on top of the agenda for many people. The statistics on London’s air quality are extremely worrying with the WHO saying that air pollution far exceeds limits. Do we ignore the evidence and continue to put lives at risk? I would imagine we would not like a polluting business near our home or place of work and it is impressive that finishing companies are stepping up and taking on board their environmental responsibilities. We are all aware that there is a cost involved, but it seems a small price to pay for a healthy future. John Hatcher, Editor

As we reach the end of summer which has not been the greatest in terms of weather it will be interesting to see which way the wind is blowing in regard to the environment as the next general election approaches.

I live close to London and the ULEZ extension has been on top of the agenda for many people. The statistics on London’s air quality are extremely worrying with the WHO saying that air pollution far exceeds limits. Do we ignore the evidence and continue to put lives at risk? I would imagine we would not like a polluting business near our home or place of work and it is impressive that finishing companies are stepping up and taking on board their environmental responsibilities.

We are all aware that there is a cost involved, but it seems a small price to pay for a healthy future.

John Hatcher, Editor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

14 ENERGY<br />

On the HangOn website you can compare<br />

the numbers of different coating cost<br />

calculations in standard scenarios in five<br />

standard coating lines. You can also fill in the<br />

blanks with your own numbers if you like, to<br />

check the facts.<br />

A great way for validation of the numbers<br />

your own coating facility, Törefors says.<br />

Using the energy wisely by<br />

increasing hanging density<br />

No matter what, there will be energy losses<br />

in the outer surfaces, ventilation, and heat<br />

leakages through openings. So, Törefors says,<br />

you need to be smart and use the energy<br />

wisely:<br />

– By hanging the goods in a more efficient<br />

way you can cut your costs up to 75 percent if<br />

you count the cost of energy consumption per<br />

coated detail.<br />

Hanging the goods is mainly a task that is<br />

handled on the workshop floor, but this matter<br />

should be addressed all the way up to<br />

management, according to Petter Törefors.<br />

Because the question of hanging density<br />

makes a difference, not only on reducing costs<br />

and increasing profit, but it definitely makes a<br />

difference in reducing energy consumption<br />

and thereby contributing to a greener coating<br />

industry.<br />

You can actually cut costs up to 48 percent<br />

on the coating process as a whole, going from<br />

0,28 kWh per coated product down to 0,07<br />

kWh per coated product if you choose to<br />

increase the hanging density. This is really<br />

important for the decision makers to<br />

understand, Törefors says.<br />

A Green Effect with enormous<br />

hidden potential<br />

So, lets juggle a few more numbers. A<br />

medium sized automatic coating line with a<br />

conveyor speed of 2 metres per minute and a<br />

conveyor length of 293 metres and an object<br />

size of 3000 x 600 x 1500 mm (LxWxH) that<br />

transports about 850 kg goods per hour uses<br />

about 470 kWh per hour. Of this the pretreatment<br />

uses about 200 kWh, the drying<br />

oven about 85 kWh, the powder application<br />

around 40 kWh and the curing oven 145<br />

kWh.<br />

Running the coating line with HQC-hanging<br />

and a density of 3 550 kg per hour of painted<br />

goods instead, it would use 580 kWh per<br />

hour.<br />

A full year of running a medium sized<br />

coating line in 3-shift with daisy-chain<br />

hanging, amounts to about 2,5 million kWh<br />

per year. With dense HQC-hanging you can<br />

paint the same amount of goods while using<br />

about 800 000 kWh per year, Törefors says.<br />

Numbers that make a huge difference on<br />

the last line of accounting with energy prices<br />

skyrocketing all over Europe.<br />

– The energy saved by this would be<br />

enough to supply 170 average EU households<br />

with energy for a whole year.<br />

And if you take this further to a global<br />

scale, there is an enormous hidden potential to<br />

save energy and make the coating industry<br />

greener.<br />

This is what we at HangOn call the double<br />

Green Effect, Törefors says.<br />

Real numbers in real life<br />

Realizing that the numbers might sound<br />

overly positive, Petter Törefors takes the Swedish<br />

company Skeppshult as an example. This is one<br />

of Sweden´s most well-known bicycle brands<br />

that has taken capacity utilization to a whole<br />

new level. All manufacturing has been done in<br />

their own workshop in southern Sweden since<br />

1911, and to make their production even more<br />

sustainable they wanted to increase efficiency in<br />

their coating process with special hangers. In<br />

one specific coating case they went from 54 pcs<br />

per hour to 180 pcs per hour with the new<br />

solution. The green effect was summed up in<br />

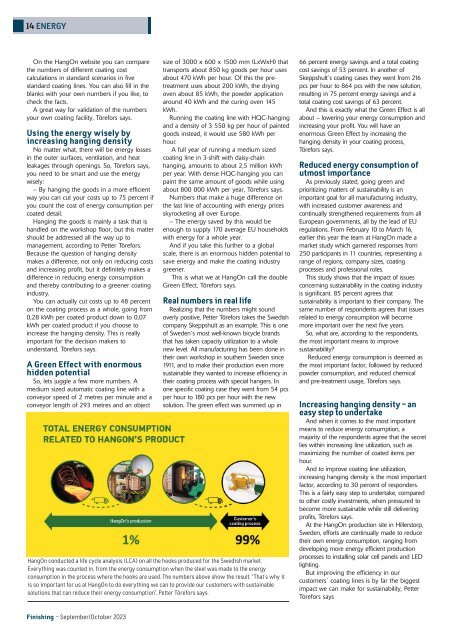

HangOn conducted a life cycle analysis (LCA) on all the hooks produced for the Swedish market.<br />

Everything was counted in, from the energy consumption when the steel was made to the energy<br />

consumption in the process where the hooks are used. The numbers above show the result. “That´s why it<br />

is so important for us at HangOn to do everything we can to provide our customers with sustainable<br />

solutions that can reduce their energy consumption”, Petter Törefors says.<br />

66 percent energy savings and a total coating<br />

cost savings of 53 percent. In another of<br />

Skeppshult´s coating cases they went from 216<br />

pcs per hour to 864 pcs with the new solution,<br />

resulting in 75 percent energy savings and a<br />

total coating cost savings of 63 percent.<br />

And this is exactly what the Green Effect is all<br />

about – lowering your energy consumption and<br />

increasing your profit. You will have an<br />

enormous Green Effect by increasing the<br />

hanging density in your coating process,<br />

Törefors says.<br />

Reduced energy consumption of<br />

utmost importance<br />

As previously stated, going green and<br />

prioritizing matters of sustainability is an<br />

important goal for all manufacturing industry,<br />

with increased customer awareness and<br />

continually strengthened requirements from all<br />

European governments, all by the lead of EU<br />

regulations. From February 10 to March 16,<br />

earlier this year the team at HangOn made a<br />

market study which garnered responses from<br />

250 participants in 11 countries, representing a<br />

range of regions, company sizes, coating<br />

processes and professional roles.<br />

This study shows that the impact of issues<br />

concerning sustainability in the coating industry<br />

is significant. 85 percent agrees that<br />

sustainability is important to their company. The<br />

same number of respondents agrees that issues<br />

related to energy consumption will become<br />

more important over the next five years.<br />

So, what are, according to the respondents,<br />

the most important means to improve<br />

sustainability?<br />

Reduced energy consumption is deemed as<br />

the most important factor, followed by reduced<br />

powder consumption, and reduced chemical<br />

and pre-treatment usage, Törefors says.<br />

Increasing hanging density – an<br />

easy step to undertake<br />

And when it comes to the most important<br />

means to reduce energy consumption, a<br />

majority of the respondents agree that the secret<br />

lies within increasing line utilization, such as<br />

maximizing the number of coated items per<br />

hour.<br />

And to improve coating line utilization,<br />

increasing hanging density is the most important<br />

factor, according to 30 percent of responders.<br />

This is a fairly easy step to undertake, compared<br />

to other costly investments, when pressured to<br />

become more sustainable while still delivering<br />

profits, Törefors says.<br />

At the HangOn production site in Hillerstorp,<br />

Sweden, efforts are continually made to reduce<br />

their own energy consumption, ranging from<br />

developing more energy efficient production<br />

processes to installing solar cell panels and LED<br />

lighting.<br />

But improving the efficiency in our<br />

customers´ coating lines is by far the biggest<br />

impact we can make for sustainability, Petter<br />

Törefors says<br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2023</strong>