Autumn 2023 EN

The German Biogas Association presents its autumn 2023 issue of the English BIOGAS journal.

The German Biogas Association presents its autumn 2023 issue of the English BIOGAS journal.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>EN</strong>GLISH ISSUE<br />

BIOGAS JOURNAL | AUTUMN_<strong>2023</strong><br />

Accumulated wheat after no-till sowing into a harvested maize field.<br />

On the day of sowing, a knife roller ran at the front of the tractor to<br />

control the maize borer.<br />

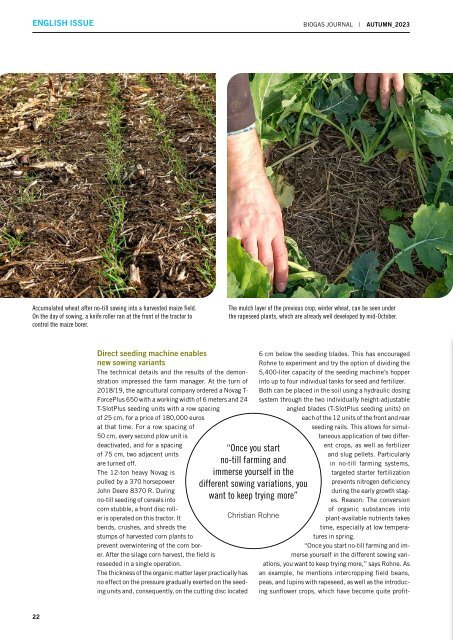

The mulch layer of the previous crop, winter wheat, can be seen under<br />

the rapeseed plants, which are already well developed by mid-October.<br />

Direct seeding machine enables<br />

new sowing variants<br />

The technical details and the results of the demonstration<br />

impressed the farm manager. At the turn of<br />

2018/19, the agricultural company ordered a Novag T-<br />

ForcePlus 650 with a working width of 6 meters and 24<br />

T-SlotPlus seeding units with a row spacing<br />

of 25 cm, for a price of 180,000 euros<br />

at that time. For a row spacing of<br />

50 cm, every second plow unit is<br />

deactivated, and for a spacing<br />

of 75 cm, two adjacent units<br />

are turned off.<br />

The 12-ton heavy Novag is<br />

pulled by a 370 horsepower<br />

John Deere 8370 R. During<br />

no-till seeding of cereals into<br />

corn stubble, a front disc roller<br />

is operated on this tractor. It<br />

bends, crushes, and shreds the<br />

stumps of harvested corn plants to<br />

prevent overwintering of the corn borer.<br />

After the silage corn harvest, the field is<br />

reseeded in a single operation.<br />

The thickness of the organic matter layer practically has<br />

no effect on the pressure gradually exerted on the seeding<br />

units and, consequently, on the cutting disc located<br />

“Once you start<br />

no-till farming and<br />

immerse yourself in the<br />

different sowing variations, you<br />

want to keep trying more”<br />

Christian Rohne<br />

6 cm below the seeding blades. This has encouraged<br />

Rohne to experiment and try the option of dividing the<br />

5,400-liter capacity of the seeding machine’s hopper<br />

into up to four individual tanks for seed and fertilizer.<br />

Both can be placed in the soil using a hydraulic dosing<br />

system through the two individually height-adjustable<br />

angled blades (T-SlotPlus seeding units) on<br />

each of the 12 units of the front and rear<br />

seeding rails. This allows for simultaneous<br />

application of two different<br />

crops, as well as fertilizer<br />

and slug pellets. Particularly<br />

in no-till farming systems,<br />

targeted starter fertilization<br />

prevents nitrogen deficiency<br />

during the early growth stages.<br />

Reason: The conversion<br />

of organic substances into<br />

plant-available nutrients takes<br />

time, especially at low temperatures<br />

in spring.<br />

“Once you start no-till farming and immerse<br />

yourself in the different sowing variations,<br />

you want to keep trying more,” says Rohne. As<br />

an example, he mentions intercropping field beans,<br />

peas, and lupins with rapeseed, as well as the introducing<br />

sunflower crops, which have become quite profit-<br />

22