Panels & Furniture Asia March/April 2024

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ENVIRONMENTAL REPORT<br />

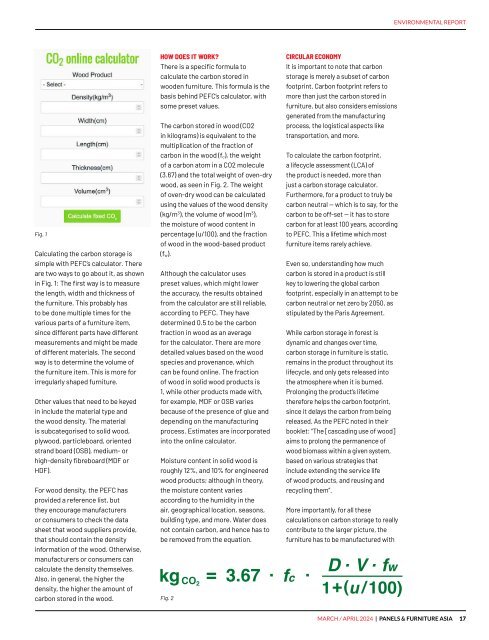

Fig. 1<br />

Calculating the carbon storage is<br />

simple with PEFC’s calculator. There<br />

are two ways to go about it, as shown<br />

in Fig. 1: The first way is to measure<br />

the length, width and thickness of<br />

the furniture. This probably has<br />

to be done multiple times for the<br />

various parts of a furniture item,<br />

since different parts have different<br />

measurements and might be made<br />

of different materials. The second<br />

way is to determine the volume of<br />

the furniture item. This is more for<br />

irregularly shaped furniture.<br />

Other values that need to be keyed<br />

in include the material type and<br />

the wood density. The material<br />

is subcategorised to solid wood,<br />

plywood, particleboard, oriented<br />

strand board (OSB), medium- or<br />

high-density fibreboard (MDF or<br />

HDF).<br />

For wood density, the PEFC has<br />

provided a reference list, but<br />

they encourage manufacturers<br />

or consumers to check the data<br />

sheet that wood suppliers provide,<br />

that should contain the density<br />

information of the wood. Otherwise,<br />

manufacturers or consumers can<br />

calculate the density themselves.<br />

Also, in general, the higher the<br />

density, the higher the amount of<br />

carbon stored in the wood.<br />

HOW DOES IT WORK?<br />

There is a specific formula to<br />

calculate the carbon stored in<br />

wooden furniture. This formula is the<br />

basis behind PEFC’s calculator, with<br />

some preset values.<br />

The carbon stored in wood (CO2<br />

in kilograms) is equivalent to the<br />

multiplication of the fraction of<br />

carbon in the wood (f c), the weight<br />

of a carbon atom in a CO2 molecule<br />

(3.67) and the total weight of oven-dry<br />

wood, as seen in Fig. 2. The weight<br />

of oven-dry wood can be calculated<br />

using the values of the wood density<br />

(kg/m 3 ), the volume of wood (m 3 ),<br />

the moisture of wood content in<br />

percentage (u/100), and the fraction<br />

of wood in the wood-based product<br />

(f w).<br />

Although the calculator uses<br />

preset values, which might lower<br />

the accuracy, the results obtained<br />

from the calculator are still reliable,<br />

according to PEFC. They have<br />

determined 0.5 to be the carbon<br />

fraction in wood as an average<br />

for the calculator. There are more<br />

detailed values based on the wood<br />

species and provenance, which<br />

can be found online. The fraction<br />

of wood in solid wood products is<br />

1, while other products made with,<br />

for example, MDF or OSB varies<br />

because of the presence of glue and<br />

depending on the manufacturing<br />

process. Estimates are incorporated<br />

into the online calculator.<br />

Moisture content in solid wood is<br />

roughly 12%, and 10% for engineered<br />

wood products; although in theory,<br />

the moisture content varies<br />

according to the humidity in the<br />

air, geographical location, seasons,<br />

building type, and more. Water does<br />

not contain carbon, and hence has to<br />

be removed from the equation.<br />

Fig. 2<br />

CIRCULAR ECONOMY<br />

It is important to note that carbon<br />

storage is merely a subset of carbon<br />

footprint. Carbon footprint refers to<br />

more than just the carbon stored in<br />

furniture, but also considers emissions<br />

generated from the manufacturing<br />

process, the logistical aspects like<br />

transportation, and more.<br />

To calculate the carbon footprint,<br />

a lifecycle assessment (LCA) of<br />

the product is needed, more than<br />

just a carbon storage calculator.<br />

Furthermore, for a product to truly be<br />

carbon neutral — which is to say, for the<br />

carbon to be off-set — it has to store<br />

carbon for at least 100 years, according<br />

to PEFC. This a lifetime which most<br />

furniture items rarely achieve.<br />

Even so, understanding how much<br />

carbon is stored in a product is still<br />

key to lowering the global carbon<br />

footprint, especially in an attempt to be<br />

carbon neutral or net zero by 2050, as<br />

stipulated by the Paris Agreement.<br />

While carbon storage in forest is<br />

dynamic and changes over time,<br />

carbon storage in furniture is static,<br />

remains in the product throughout its<br />

lifecycle, and only gets released into<br />

the atmosphere when it is burned.<br />

Prolonging the product’s lifetime<br />

therefore helps the carbon footprint,<br />

since it delays the carbon from being<br />

released. As the PEFC noted in their<br />

booklet: “The [cascading use of wood]<br />

aims to prolong the permanence of<br />

wood biomass within a given system,<br />

based on various strategies that<br />

include extending the service life<br />

of wood products, and reusing and<br />

recycling them”.<br />

More importantly, for all these<br />

calculations on carbon storage to really<br />

contribute to the larger picture, the<br />

furniture has to be manufactured with<br />

MARCH / APRIL <strong>2024</strong> | PANELS & FURNITURE ASIA 17