Design Strategies IMPULSE - Sustainable Facades Vol 2

Report Winter Semester 2023/24

Report Winter Semester 2023/24

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

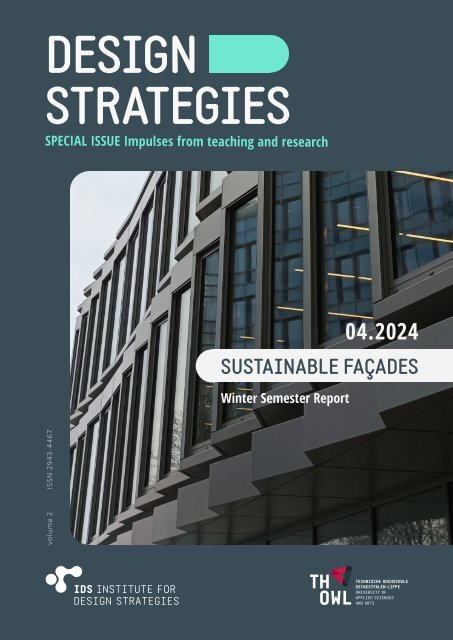

DESIGN<br />

STRATEGIES<br />

SPECIAL ISSUE Impulses from teaching and research<br />

Winter Semester Report<br />

04.2024<br />

SUSTAINABLE FAÇADES<br />

volume 2 ISSN 2943-4467

EDITORIAL<br />

Welcome to the second edition of <strong>Sustainable</strong> Façades, a Special Issue of the<br />

<strong>Design</strong> <strong>Strategies</strong> Magazine produced by the Institute for <strong>Design</strong> <strong>Strategies</strong> (IDS)<br />

of TH OWL in Detmold, Germany. We are happy to be back, this time reporting<br />

the activities of the Winter Semester 2023-2024. We are grateful that over 1400<br />

people downloaded the previous issue between between November 2023 and<br />

April 2024.<br />

<strong>Sustainable</strong> Façades was originally intended as a digital-only resource. However,<br />

further actions were taken after the successful realization of the first issue as a<br />

proof of concept, and the encouraging feedback obtained at it‘s public release<br />

during the European Façade Network Conference in Detmold, on November<br />

2023. <strong>Sustainable</strong> Façades was developed into an indexed magazine, and in<br />

January 2024, 150 issues were printed and distributed at the IDS, providing a<br />

printed issue to every contributor and the rest offered free of charge at the front<br />

desk of the IDS until they run out. The release of digital and printed media will be<br />

repeated in this second edition or "volume 2".<br />

We hope this issue will resonate with our readers and we extend the invitation<br />

for contributions and feedback to expand our outreach, fine-tune our processes<br />

and grow our network for the next issues of <strong>Sustainable</strong> Façades.<br />

Alvaro Balderrama & Daniel Arztmann<br />

EDITORIAL VORWORT<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

3

CONTENTS<br />

1. INTRODUCTION<br />

7<br />

4. MID DESIGN CONCEPTS<br />

62 – JTI Headquarters, Switzerland<br />

Meltem Durmus, Hiruy Tekeste, Abdelrahman Badr<br />

2. LATEST RESEARCH<br />

66– Montparnasse, France<br />

Ahmet Faruk Çakır, Murat Gül<br />

3. ARTICLES<br />

10 – Values-Based Governance and<br />

Intervention Framework for Mass<br />

Housing Neighbourhoods<br />

Anica Dragutinovic<br />

13 – A Guide to Biodegradable<br />

Materials in Envelope <strong>Design</strong><br />

Shashi Karmaker<br />

29 – Energy Efficiency of a Timber<br />

Frame House in Detmold<br />

Mina Kherad<br />

5. EVENTS<br />

70 – 35XV, USA<br />

Priyanka Bamble, Najmeh Najafpour<br />

74 – Dockland Office Building, Germany<br />

Aysegül Gürleyen, Rodolph Naalabend<br />

78 – One World Trade Center, USA<br />

Ghazaleh Valipour, Lama Ibrahim<br />

82 – 20 Fenchurch Street, England<br />

Amrani Chemseddine, Harishankar Kallepalli<br />

87 – Past events<br />

37 – Preliminary Observation<br />

for the Structural Performance of<br />

Timber Façade Mullion and Transom<br />

Connection with Large Glass Dead<br />

Load<br />

Hiruy Gebremariam Tekeste<br />

6. IMPRINT<br />

91 – Upcoming events<br />

92<br />

40 – Façade Acoustics and<br />

Soundscape Assessment Workshops:<br />

Implementing Soundscape Criteria in<br />

Façade Education<br />

Alvaro Balderrama<br />

53 – Solar Façade: Energy<br />

Generation with 2.500 m2 of BIPV<br />

Melicia Planchart, Stefan Grünsteidl, Augustin Rohr<br />

4 CONTENTS CONTENTS<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024 <strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

5

1. INTRODUCTION<br />

As the title <strong>Sustainable</strong> Façades declares, the focus<br />

of this report is on “façades”, which generally refer<br />

to the vertical surfaces of the building envelope,<br />

including the walls, doors, windows, balustrades,<br />

balconies, parapets and depending on the case,<br />

possibly parts of the roof (Knaack et al., 2007; Klein,<br />

2013), and how they impact the people inside and<br />

outside of buildings, as well as the environment<br />

and the economy. <strong>Sustainable</strong> practices can be<br />

integrated into multiple stages of projects, including<br />

the design, construction, use, maintenance, and<br />

end-of-life stage of buildings. However, determining<br />

the sustainability of a project is a complex task,<br />

given its wide-ranging implications.<br />

The cover of this magazine shows the façade of the<br />

Schüco One building in Bielefeld designed by 3XN<br />

Architects, the first building in the world to receive<br />

all three sustainability certifications from the LEED,<br />

BREEAM and DGNB labels. This sets a precedent<br />

in the construction industry but also highlights<br />

some conceptual differences between labels. For<br />

example, the BREAM category “pollution” differs<br />

from the LEED v.4.1. scorecard for Building <strong>Design</strong><br />

and Construction, which is the most popular<br />

worldwide (Chomsky, 2023) since LEED doesn’t<br />

account for potential unintended by-products of<br />

the building, showing how BREAM is more flexible<br />

to unexpected circumstances.<br />

The controversial case of the 20 Fenchurch Street<br />

skyscraper – the “walkie talkie” in London can<br />

exemplify how the BREAM covers an aspect that<br />

could be neglected by other labels. As it became<br />

well known, the concave façade acted as a mirror<br />

reflecting sunbeams to the street, leading to<br />

material damage (Smith-Spark, 2013). The project<br />

was applying for BREAM certification, and it was<br />

put on hold until the developers solved the issue<br />

by installing a brise-soleil to diffuse the reflected<br />

sunlight and prevent further damage. Afterwards,<br />

the certification was restored and it has since then<br />

become an iconic project in the skyline of London.<br />

When focusing on the requirements for adequate<br />

façade performance it is clear that the criteria<br />

are probably not the same in every project,<br />

therefore façade performance is contextdependent.<br />

According to Bianchi et al. (2024)<br />

façade performance can be classified into<br />

three main performance categories: Functional,<br />

Environmental, and Financial. These categories<br />

correspond to the three pillars of the triple<br />

bottom line (Society, Environment, Economy).<br />

Therefore, raising the idea that for a façade to<br />

be sustainable, it should perform adequately in<br />

those three aspects. The functional performance<br />

category includes structural safety, human comfort<br />

(including air quality, thermal, acoustic and visual<br />

comfort), and durability as the main criteria.<br />

Environmental performance includes energy and<br />

material efficiency, considering not only energy<br />

demand, generation and storage, but also carbon<br />

footprint and biodiversity impacts. The financial<br />

performance category is focused on the initial,<br />

operational and end-of-life costs. This overview of<br />

performance criteria helps identify the potential<br />

performance of a specific project, however,<br />

this classification does not exclude overlapping<br />

between categories.<br />

Considering these issues, as explained in the<br />

first edition of <strong>Sustainable</strong> Façades, the goal of<br />

this report is to explore the possible meanings<br />

of sustainability within the built environment,<br />

examining façades as intrinsic elements of every<br />

building and every city. This introduction is followed<br />

by the next sections:<br />

Section 2 | Latest Research is a showcase of<br />

recent publications by members of the academic<br />

network of TH OWL. In this edition, we have<br />

a summary of the PhD thesis of Dr.-Ing. Anica<br />

Dragutinovic, focused on the deterioration and<br />

management challenges of post-war mass housing<br />

neighborhoods, exemplified by New Belgrade<br />

Blocks. It explores how ownership changes and<br />

community dynamics affect these areas. The study<br />

applied participatory methods to develop a valuesbased<br />

intervention framework for these spaces,<br />

promoting inclusive heritage management, and<br />

contributing to residents‘ sense of belonging.<br />

Section 3 | Articles presents original work<br />

developed recently that has not been published<br />

elsewhere. This section includes two Master<br />

6<br />

INTRODUCTION<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

7

2. LATEST RESEARCH<br />

thesis summaries, providing the opportunity<br />

to communicate the theses more effectively,<br />

and perhaps serve as a stepping stone towards<br />

publication elsewhere (e.g. conference or journal).<br />

One thesis provides a catalog of biodegradable<br />

materials for façades, and the other thesis analyzed<br />

the thermal and energy performance of the façades<br />

of a “Fachwerkhaus” (timber frame house) built in<br />

Detmold more than 100 years ago. Then, a short<br />

article examines the impact of large glass dead<br />

loads on the structural performance of the timber<br />

mullion and transom façade of the Riegel building<br />

at the campus of TH OWL in Detmold. Finally, a<br />

research article regarding the implementation of<br />

soundscape criteria in façade design education is<br />

presented.<br />

Section 4 | MID <strong>Design</strong> Concepts provides a<br />

summary of six projects developed by the students<br />

of the class “Materials, Surfaces and Security”,<br />

where complex existing façade projects were<br />

analyzed, describing façade details.<br />

Section 5 | Events closes the report with a<br />

summary of recent activities, like the Detmold<br />

Conference Week 2023, which held the European<br />

Façade Network Conference, and a handson<br />

workshop at Schüco for MID FD students.<br />

Regarding the upcoming Summer Semester 2024,<br />

information about the Detmolder Räume and the<br />

Detmold <strong>Design</strong> Week, as well as an introductory<br />

course of ArcGIS, is presented.<br />

References:<br />

Bianchi, S., Andriotis, C., Klein, T., Overend, M. (2024).<br />

Multi-criteria design methods in façade engineering:<br />

State-of-the-art and future trends. https://doi.<br />

org/10.1016/j.buildenv.2024.111184<br />

Chomsky, R. (2023). Top Green Building Certifications.<br />

https://sustainablereview.com/top-green-buildingcertifications/<br />

Klein, T. (2013) Integral Facade Construction. Towards<br />

a new product architecture for curtain walls. A+BE |<br />

Architecture and the Built Environment. ISBN 978-<br />

9461861610<br />

Knaack, U., Klein, T., Bilow, M., Auer, T. (2007), Façades:<br />

Principles of Construction. Birkhäuser Basel. https://<br />

doi.org/10.1007/978-3-7643-8281-0<br />

Smith-Spark, L., CNN (2013). Reflected light from<br />

London skyscraper melts car. https://edition.cnn.<br />

com/2013/09/03/world/europe/uk-london-buildingmelts-car/index.html<br />

8 INTRODUCTION<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

9

Latest Research<br />

Values-Based Governance and Intervention Framework for Mass<br />

Housing Neighbourhoods<br />

Summary of the PhD Dissertation of Anica Dragutinovic published by TU Delft:<br />

Dragutinovic, A. (2023). Mass Housing Neighbourhoods and Urban Commons: Values-based Governance<br />

and Intervention Framework for New Belgrade Blocks. TU Deflt. https://doi.org/10.7480/abe.2023.15<br />

Anica Dragutinovic 1,2<br />

1. Faculty of Architecture and the Built Environment, TU Delft, P.O. Box 5043, 2600GA, Delft, the Netherlands<br />

2. Detmold School of <strong>Design</strong>, TH OWL, Emilienstrße 45, D-32756 Detmold, Germany<br />

from the theoretical and contextual frameworks<br />

and empirical studies, this research develops a<br />

values-based intervention framework for reuse<br />

and governance of the common spaces in the New<br />

Belgrade Blocks, aimed at improving devalued,<br />

conserving and reinforcing the sustained, and<br />

adding new values. Although based on contextspecific<br />

argumentation, selections and decisions,<br />

the developed framework is possibly adaptable<br />

to another set of issues. Its methodology,<br />

and the principles it enhances, such as selforganisation,<br />

participation, multi-scale networks,<br />

stakeholders’ engagement, collaboration, etc.,<br />

contribute to the democratisation of the urban<br />

heritage governance processes.<br />

The doctoral research has established a specific<br />

methodology for studying contemporary issues<br />

of urban heritage, in particular related to mass<br />

housing neighbourhoods. This research has<br />

been conducted by (1) combining critical and<br />

correlational analysis in exploring deterioration<br />

of New Belgrade Blocks and their common<br />

spaces; (2) socio-spatial analysis including<br />

empirical, place-based and participatory<br />

methods in assessing their current condition; and<br />

(3) „design-polemical theory“ (abstract thought,<br />

speculation) in developing an intervention<br />

framework and a set of guidelines for valuesbased<br />

governance and reuse of the common<br />

spaces of New Belgrade Blocks. Throughout<br />

the three main parts, the doctoral research<br />

develops various findings and perspectives,<br />

and provides different levels of knowledge on<br />

approaches for integrated conservation, urban<br />

planning and governance of urban heritage, and<br />

in particular mass housing neighbourhoods. It<br />

shows co-dependence of those fields and offers<br />

an integrative and cross-disciplinary approach.<br />

The results represent a valuable contribution<br />

to architecture, urban planning and especially<br />

heritage studies, in particular for governance<br />

and heritage management of complex sites, as<br />

mass housing neighbourhoods are. Besides the<br />

scientific and academic impact, the research<br />

achieves a societal and cultural impact through<br />

an engaging research approach conducted<br />

with society. It emphasizes the importance of<br />

engagement of local communities, but also<br />

the importance of cross-sectoral and interinstitutional<br />

communication and collaboration<br />

in urban planning, including the civil sector.<br />

Summary<br />

The post-war mass housing neighbourhoods<br />

are one of the most widespread typologies of<br />

the modern architecture and urbanism, and<br />

represent one of the most significant legacies<br />

of the twentieth century. Nevertheless, their<br />

deterioration and devaluation are major<br />

challenges, both in the field of heritage<br />

conservation and management and in urban<br />

planning and design. The mass housing<br />

neighbourhoods encapsulate a greater<br />

complexity of issues compared to single, iconic<br />

buildings, which have been more extensively<br />

addressed in the heritage sector. The reasons for<br />

their deterioration are different and interlinked<br />

with the socio-cultural discourse, as well as the<br />

spatial characteristics of these neighbourhoods,<br />

or how they were planned, built, lived and<br />

governed. This doctoral research addresses the<br />

challenges of those neighbourhoods, focusing<br />

on the New Belgrade Blocks, which are part of<br />

this larger cultural phenomenon, yet strongly<br />

tied into a very specific contextual framework.<br />

New Belgrade is one of the largest modernist<br />

post-war mass housing areas in Europe. As<br />

the legacy of both modernism and socialism,<br />

it represents a symbol of collectiveness and<br />

participatory planning and governance, though<br />

with contradictions in practice. Following the<br />

gradual transformation of the urban landscape of<br />

modernity in parallel with different socio-spatial<br />

factors—such as transformed ownership and<br />

governance relations, suppressed importance<br />

of community, as well as the modernist planning,<br />

or rather performance of the plans, and later<br />

urban practices—this research investigates the<br />

correlation between deterioration and previously<br />

mentioned factors. It identifies common spaces<br />

of the blocks as the most neglected components<br />

of the blocks that are at the same time crucial to<br />

their quality, vitality and preservation of values.<br />

Moreover, the specific Yugoslav housing policy<br />

and collective self-management from the postwar<br />

period, although neglected over the time,<br />

represent a valuable intangible heritage that<br />

can contribute to the contemporary discussions<br />

on commons, linking historical forms of<br />

decentralized governance and contemporary<br />

discourses on urban commons.<br />

After understanding and clarifying the specific<br />

socio-spatial setting, the research explores<br />

and assesses the common spaces of the blocks<br />

through a multi-level socio-spatial analysis<br />

including different participatory methods for<br />

exploration, assessment and eventually codesign<br />

of the strategies for their improvement.<br />

The common spaces are crucial for the actual<br />

implementation or manifestation of the heritage<br />

management shift from the expert-led and<br />

authoritarian procedures towards more inclusive<br />

practices. They enable spatialisation of the right<br />

to the city, allowing for bottom-up initiatives,<br />

reactive actions and proactive practices. The<br />

common spaces have a potential to facilitate<br />

bottom-up governance and direct democracy<br />

in the city, enabling ’defence’ of the common<br />

interest in urban development. Collating findings<br />

Figure. Cover of the PhD Dissertation | Block 23, New Belgrade, 2020. Photograph taken by Ivona<br />

Despotovic for the student workshop “Reuse of Common Spaces of New Belgrade Blocks: Co-designing<br />

the Urban Commons”, Belgrade, September 2020.<br />

10<br />

LATEST RESEARCH<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

LATEST RESEARCH<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

11

3. ARTICLES<br />

Article<br />

A Guide to Biodegradable Materials in Envelope <strong>Design</strong><br />

Summary of the Master Thesis presented for the Master of Integrated <strong>Design</strong> -<br />

Façade <strong>Design</strong> specialization (2023).<br />

Shashi Karmaker 1<br />

Supervisor 1. Prof. Dipl.-Ing. Daniel Arztmann 1,2 ; Supervisor 2. M.Eng. Alvaro Balderrama 1,2,3<br />

1. MID Façade <strong>Design</strong>, Detmold School of Architecture and Interior Architecture, Technische Hochschule Ostwestfalen-Lippe, Emilienstraße 45, 32756 Detmold, Germany<br />

2. Schüco International KG, Karolinenstraße 1-15, 33609 Bielefeld, Germany<br />

3. Architectural Façades and Products Research Group, Department of Architectural Engineering and Technology, Faculty of Architecture and the Built Environment, TU<br />

Delft, Julianalaan, 134, 2628 BL Delft, The Netherlands<br />

Abstract<br />

This research explores the potential of biodegradable materials in building envelopes, with an emphasis<br />

on design principles and performance characteristics. Physical qualities and performance in areas such<br />

as thermal resistance, acoustic properties, and weather resistance will be used to assess the materials. A<br />

database of product lists and design methods for each material will also be established to encourage and<br />

ease their usage in building construction. The main research question is- What design guidelines need to be<br />

considered for biodegradable materials used in building envelopes? Ultimately, this research aims to contribute<br />

to the advancement of eco-friendly construction and encourage the use of biodegradable materials in building<br />

envelopes<br />

1. Introduction<br />

In recent years, there has been increasing pressure<br />

on the construction sector to embrace sustainable<br />

practices and lessen their environmental effect.<br />

The use of biodegradable materials in building<br />

envelopes is one area of attention since it may<br />

assist in decreasing waste and enhance the overall<br />

sustainability of the building. Biodegradable<br />

materials decay naturally without affecting the<br />

environment, and they have various advantages<br />

over standard building materials like concrete, steel,<br />

and plastic.<br />

Some criteria for a material to be biodegradable<br />

include Chemical Composition, Decomposition time,<br />

Environmental Impact, Diversity of degradation, and<br />

Disposal method. According to the research of Eleni<br />

Sgouropoulou [1], there are seven categories of<br />

biodegradable materials, among them five categories<br />

of materials that have already been utilized as<br />

building materials and can be sourced from natural<br />

resources like earth, plants, animals‘ hair, and trees.<br />

The other two categories include materials that are<br />

either in the process of development or derived from<br />

emerging technologies that hold potential for the<br />

future use. The selection of materials for this research<br />

was influenced by the potential of the materials that<br />

may be employed as cladding or as construction<br />

components of the wall. Some products made from<br />

these materials may also fit infill areas which has also<br />

been discussed while creating the design manual.<br />

The chosen materials are Unfired earth products,<br />

Rammed-earth products, Straw products, Hemplime<br />

products, and Cork products. These materials<br />

can be split into three groups: (1) Earthen products<br />

- products derived from the earth (soil), (2) Plants<br />

fibrous products - products made from fibrous<br />

plants, and (3) By-or recycled derived products -<br />

products derived from recycled materials.<br />

2. Unfired Earth products<br />

Around 30% of the world’s population lives in earthmade<br />

construction [2]. There is very wide use of<br />

such products in New Mexico and Arizona (America),<br />

Africa, and Asia [3]. However, their use is also<br />

beginning to spread once again in Europe.<br />

12 LATEST RESEARCH<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

ARTICLES<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

13

Figure 1. Criteria of a biodegradable material<br />

Production technique<br />

Raw earth, straw, and water are combined to form<br />

the adobe bricks that make up the structure of the<br />

adobe home. These bricks are then dried in the<br />

sun after being pressed into molds. The Adobe<br />

construction style is ideal for owner-builders since<br />

no expensive tools or equipment are required, and<br />

the skills needed can be quickly gained at a training<br />

session and through hands-on experiences.<br />

<strong>Design</strong> guidelines<br />

• Orientation and room arrangement: To make<br />

use of the thermal mass of earth walls, adequate<br />

direct sunshine should be allowed to penetrate<br />

an earth structure, especially in winter.<br />

Compressed earth bricks may or may not be<br />

stabilized. However, they are usually stabilized by<br />

cement or lime. As a result, they are now known as<br />

Compressed Stabilized Earth Blocks (CSEB)<br />

Equipment<br />

Today, there are manual presses that are light or<br />

heavy, as well as motorized presses that provide<br />

compression energy via an engine. There are also<br />

mobile machines that combine a crusher and a<br />

mixer in the same equipment. The Impact 2001A<br />

CEB machine from the business AECT Earth block<br />

is seen in Figure 8. This automated machine makes<br />

300 CEBs every hour.<br />

Figure 3. Biodegradable material<br />

• Large eaves are required to protect from<br />

weather damage.<br />

Figure 2. List and category of<br />

discussed materials<br />

• In cold climates, at least the south walls are<br />

insulated. Wool insulation with cladding might<br />

be an excellent alternative since wool is a natural<br />

insulation material with low embodied energy<br />

and hygroscopic properties like earth [8].<br />

Strength:<br />

• In earthquake-prone areas, the structural<br />

design may necessitate vertical and horizontal<br />

reinforcing of earth walls.<br />

• The drying of Unfired earth products requires<br />

less energy input in comparison to fired earth<br />

brick [4].<br />

• Extremely low embodied energy (0.011-0.051<br />

MJ/kg)<br />

• Fire resistance is high (Euroclass fire testing rate<br />

A1-B2)<br />

• Products mixed with straw and other fibrous<br />

materials, usually have lots of thermal mass.<br />

• A CEB wall of 150mm thickness can be resistant<br />

to airborne sound [5].<br />

• Capable to construct self-supporting walls if<br />

their compressive strength is more than 2 MPa.<br />

Weakness:<br />

• Should not be exposed to water for a long<br />

period.<br />

• CEBs may need extra exterior wall insulation for<br />

U-value, despite their high thermal mass in cold<br />

climates [6].<br />

• Stabilizers can affect the final product’s<br />

biodegradability and recyclability, but they are<br />

needed for water resistance and compressive<br />

strength.<br />

• It is advisable to avoid using Adobe Brick for<br />

constructing houses with more than one story [7].<br />

Available products of Unfired Earth are Adobe, CEB,<br />

and 3D-printed walls.<br />

2.1 Adobe bricks<br />

Figure 4. Unfired earth (CEB)<br />

Adobe brick building is an ancient technique<br />

common in the Americas and the Middle East.<br />

In nations with high demand, adobe bricks<br />

are manufactured mechanically at industrial<br />

brickyards, or they can be made on-site by<br />

renting a brick-making machine. According to the<br />

manufacturers, the usual size of an adobe brick<br />

can be 40*20*10 cm<br />

Soil selection<br />

The soil must include between 15% and 30% clay<br />

to provide a suitable binding to the dough. When<br />

using soil with more than 30% clay, adobe brick<br />

will shrink (during sun-drying) and crack, whereas<br />

soil with less than 15% clay will disintegrate.<br />

Furthermore, it is advised that the soil be used<br />

from a depth of 50 cm, eliminating the presence of<br />

organic components such as rotting leaves, plant,<br />

and animal remnants, or roots that may interfere<br />

with the quality of the brick.<br />

• Earth constructions require stable sites. The<br />

site should not flood and, preferably, should not<br />

be exposed to strong rains.<br />

2.2 Compressed Earth Block (CEB)<br />

CEBs began in 19th-century Europe with handmade<br />

blocks. The fi rst steel press in Colombia<br />

improved upon adobe by creating denser, stronger,<br />

and more water-resistant bricks. This technique<br />

has since spread to Africa, South America, India,<br />

and South Asia with the development of advanced<br />

machinery and soil expertise.<br />

Soil selection<br />

Not every soil is ideal for earth construction,<br />

particularly CEB. Topsoil and organic soils are not<br />

permitted. The soil condition and project needs<br />

will influence the choice of a stabilizer. Cement<br />

will be preferred for sandy soils and achieving a<br />

higher strength rapidly. Lime will be utilized for<br />

particularly clayey soil; however, it will take longer<br />

to solidify and provide sturdy blocks.<br />

Production technique<br />

The raw or stabilized soil for a compressed<br />

earth block is slightly moistened before being<br />

poured into a steel press and compacted with<br />

either a manual or automated press. CEB may<br />

be compacted into a variety of forms and sizes.<br />

Figure 5. Typical reinforced adobe wall construction<br />

Figure 6. Adobe Bricks<br />

Figure 7. CEB<br />

14<br />

ARTICLES<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024 <strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

ARTICLES<br />

15

<strong>Design</strong> guidelines<br />

CEB structures require a base that is at least 45 cm<br />

broad and 60 cm deep. Reinforced concrete, rubble<br />

masonry, or stone masonry should be used for the<br />

foundation.<br />

For CEB structures, the required wall thickness is<br />

300 mm for load-bearing walls and 200 mm for nonload-bearing<br />

walls.<br />

CEBs should be set in a stretcher bond with a mortar<br />

joint of 10 mm.<br />

When constructing a double-layer wall, the CEB layer<br />

must be put on the interior side when the room<br />

is primarily inhabited during the day and on the<br />

outside side when the room is primarily occupied at<br />

night [9].<br />

CEB walls, unlike adobe, have great compressive<br />

strength and can withstand seismic stresses,<br />

making them appropriate for usage in earthquakeprone<br />

locations.<br />

2.3 3D-Printed clay wall<br />

3D printed earth walls are a newer building method<br />

that employs 3D printing processes to construct<br />

earth walls. The technique of 3D printing earth<br />

walls requires the use of a specialized printer that<br />

creates blocks out of a mixture of earth and water,<br />

which are then piled and cemented together to form<br />

a wall. The printer can generate blocks of various<br />

sizes and shapes and an entire wall. One benefit<br />

Figure 9.: CEB wall section<br />

Figure 10. Variety of CEB blocks<br />

the composition of the earth mixture adapts to<br />

local climatic circumstances, and the envelope<br />

filling is parametrically tuned to balance<br />

thermal mass, insulation, and ventilation based<br />

on climate demands.<br />

While 3D printing has given the possibility to<br />

create complex geometries, the intelligence<br />

of the design comes from the optimization<br />

strategies, and the creation of performative<br />

shapes becoming easier to achieve for<br />

example, the TerraPerforma project by IAAC.<br />

However, there are certain obstacles involved<br />

with 3D-printed earth walls, such as ensuring<br />

that the earth mixture used in the printing<br />

process is of uniform quality and addressing<br />

any moisture management and waterproofing<br />

issues. Furthermore, the technology is still in its<br />

early stages, and additional study is required to<br />

properly comprehend its long-term durability<br />

and sustainability.<br />

Recycle and reuse<br />

Unfired earth products like adobe, earth walls,<br />

and compressed earth blocks can be sustainably<br />

recycled and reused. They can be crushed into<br />

aggregate for construction projects, used as<br />

soil or soil additives, repurposed as decorative<br />

elements, or rebuilt in a new location. If none of<br />

these options work, they can be used as fill material<br />

in other construction projects. The provider<br />

says that it is feasible to recover about 90% of<br />

the waste material throughout the demolition<br />

process. As a result, the remaining 10% goes to<br />

waste (e.g., small broken components, demolition<br />

dust, etc.) that is left on the construction site.<br />

Since the product is primarily formed of dirt,<br />

returning it to the natural environment has no<br />

substantial impact.<br />

• It absorbs vibrations very well and reduces<br />

airborne sound by 40-50 decibels<br />

Weakness:<br />

• The performance of in-situ rammed-earth<br />

constructions is weather-dependent.<br />

• In cold climates, a wall thickness of more<br />

than 700 mm is required to be able to fulfill<br />

the thermal requirements of the Building<br />

Regulations. But this will increase cost and<br />

reduce usable area.<br />

• It is preferable to construct rammed earth<br />

walls with 200–350 mm thickness and to<br />

provide greater thermal insulation to the wall.<br />

There are two ways that rammed-earth walls may<br />

be built: on-site or as prefabricated heavyweight<br />

façade and wall components produced by specific<br />

construction companies.<br />

Figure 12. TECLA Construction<br />

3. Rammed-earth products<br />

Figure 13. Project TerraPerforma<br />

Figure 11. Types of Bonding Patterns<br />

of 3D-printed earth walls is that they can be<br />

built fast and efficiently because the printing<br />

process is automated and needs little physical<br />

effort. When compared to typical building<br />

processes, this can result in considerable cost<br />

reductions. Another advantage of 3D-printed<br />

earth walls is their strength and longevity.<br />

Rammed earth walls are a sustainable construction<br />

method where a mixture of soil, gravel, sand, and<br />

other materials is compressed into solid blocks<br />

or walls. This ancient technique, recently revived,<br />

involves wetting the soil mixture and compacting<br />

it manually or mechanically with wooden or metal<br />

forms. After compaction, the material cures and<br />

solidifi es before being used for construction.<br />

Rammed earth walls have been historically used<br />

in various climate zones, from the Himalayan<br />

Mountains to the deserts of North Africa.<br />

Figure 8. The Impact 2001A<br />

WASP, an Italian company, is an expert in 3D<br />

printing and green building. Their unique 3D<br />

printing method can be used to construct<br />

massive earth-based structures like dwellings.<br />

The first TECLA (Technology and Clay)<br />

construction was in Italy and was 3D printed<br />

using Crane WASP (the most recent WASP 3D<br />

printer), which used a blend of natural materials<br />

soil, and rice straw to make the walls, roof, and<br />

other structural components. Furthermore,<br />

Strength:<br />

• Because of their high thermal mass, these<br />

buildings require low energy for heating<br />

and cooling [10].<br />

• According to CSIRO testing, Fire resistance is<br />

high, a 250 mm thick rammed earth wall had<br />

a fi re-resistance rating of 4 hours, whereas a<br />

150 mm thick wall had a rating of 3 hours and<br />

41 minutes<br />

Figure 14. : Rammed Earth wall<br />

16<br />

ARTICLES<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024 <strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

ARTICLES<br />

17

3.1 On-site rammed earth wall<br />

On-site rammed earth wall construction<br />

involves building walls directly at the intended<br />

location. The process starts with constructing<br />

formwork, temporary structures that shape<br />

and support the wall. Typically made of wood,<br />

the formwork helps achieve the desired size<br />

and shape. Soil, aggregates, and stabilizers<br />

are then compacted into the formwork using<br />

mechanical or hydraulic rammers until the<br />

desired wall height is reached. Once completed,<br />

the formwork is removed to reveal the finished<br />

rammed earth wall.<br />

This method offers benefits such as reduced<br />

transportation costs as materials are usually<br />

locally sourced and flexibility in wall design.<br />

However, it requires skilled labor and takes<br />

longer to complete. External surface protection,<br />

water resistance, shrinkage, and strength<br />

are addressed by adding stabilizers like lime,<br />

cement, or pozzolan. Stabilizers also allow for<br />

thinner walls, speeding up construction and<br />

requiring less surface preparation.<br />

Building process<br />

‚Rammed earth enterprises‘ outlines<br />

constructing rammed earth walls using steel<br />

formwork wrapped in plyboard for an ‚Off<br />

Form Finish‘. Water is added to an earth/<br />

cement mix for ideal moisture. Hand-shoveled<br />

into formwork in 150mm increments, it‘s<br />

compressed with pneumatic tampers. T-Bar<br />

lintels support earth above openings, while<br />

metal rods create tie-downs for a wooden top<br />

plate. Electrical conduits are integrated for<br />

outlets and switches. After drying overnight,<br />

formwork is removed, and the wall detailed.<br />

<strong>Design</strong> consideration<br />

• Potential soils should be examined before<br />

usage. To establish whether stabilizers are<br />

required, and which ones are best for the kind<br />

of soil, collect samples of compact soil and<br />

contact trustworthy sources.<br />

• The better the formwork, the faster and more<br />

precisely the building will go. Forms must be<br />

able to withstand the strong forces used to<br />

push the dirt within a while. Reusable forms can<br />

help to reduce the cost.<br />

• It is crucial to carefully plan mechanical systems<br />

and wall openings for structures since changing<br />

the walls can be a time-consuming procedure. It<br />

is advised to build conduits within the walls for<br />

running services rather than opening them to<br />

allow for future upgrades or repairs.<br />

• The roof needs to have been sufficiently hung<br />

to allow water to flow to the ground without<br />

damaging the wall.<br />

• An appropriate coating of the wall is also required.<br />

existing structures/framing. Steel clips provided<br />

by the manufacturer secure the panels to the<br />

structural wall, preventing forward movement.<br />

• Hiding seam lines: Color-matched sanded<br />

grout is recommended to create a seamless<br />

appearance between panels and soften the 1/4“<br />

seam lines.<br />

• Stacking panels: The maximum panel height is<br />

5 feet. For stacks taller than 20 feet, a carrier<br />

plate must be integrated into the structure to<br />

support the weight of additional panels.<br />

3.3 Insulated rammed earth panel<br />

SIREWALL, established in 1992, pioneered<br />

the method of integrating an insulative core<br />

into rammed earth walls to enhance thermal<br />

insulation, particularly in regions with extremely<br />

low temperatures. In 2008, they became the first<br />

company globally to consistently produce rammed<br />

earth with high compression strengths suitable<br />

for structural construction. Their innovative wall<br />

system allows for the construction of curved<br />

structures and imposing load-bearing walls up<br />

to 50 feet tall. Previously limited to residential<br />

buildings, SIREWALL‘s technology now enables<br />

tall, load-bearing commercial applications,<br />

exemplified by projects like Telenor’s head office<br />

in Pakistan.<br />

Installation process<br />

400mm to 450mm thickness, with options<br />

for a 50mm, 75mm, or 100mm Styrofoam<br />

core to achieve an R-value of up to 4.3.<br />

• Thickness of insulated rammed earth<br />

panels should consider desired R-value,<br />

structural strength, and wall opening size.<br />

• Minimum thickness and insulation - R<br />

ratings for rammed earth, structural, and<br />

non-structural walls are provided in a<br />

table, serving as baseline requirements<br />

that can be adjusted based on specific<br />

project needs and wall heights.<br />

Recycle and reuse<br />

When structures with rammed earth walls are<br />

demolished, the walls can be broken down and the<br />

soil mixture repurposed for other construction<br />

projects such as roads or new walls. Crushed<br />

walls can serve as soil amendments or fertilizers<br />

in agriculture, while crushed stone can be used<br />

for landscaping or pavement foundations.<br />

The walls themselves can be reused for new<br />

construction, serving as retaining or garden<br />

walls, or incorporated into projects for aesthetic<br />

appeal. Rammed earth panels can be carefully<br />

Figure 15.: On site Rammed Earth wall construction<br />

3.2 Prefabricated rammed earth panel<br />

In 1986, Nicolas Meunier introduced a prefabricated<br />

rammed earth method, refining traditional<br />

techniques to suit modern European economic and<br />

social conditions. This approach offers enhanced<br />

quality control, uniformity, and shorter construction<br />

times for panels. Prefabricated rammed earth panels<br />

can incorporate insulation and waterproofing for<br />

durability and energy efficiency. Additionally, they<br />

can be finished with various materials like paint or<br />

plaster to achieve desired aesthetics.<br />

Prefabricated rammed earth panel guide<br />

Provider Like ‘Rammed Earth Work’ shares insightful<br />

information regarding their panels, which are-<br />

• Panel sizes: Standard panels measure 12’ L x 5’<br />

H and around 3” thick, but custom sizes up to<br />

13’ or smaller are available.<br />

• Panel weight: A standard panel weighs<br />

approximately 2200 lbs., inclusive of the steel<br />

frame mounted on the back.<br />

• Mounting method: Panels are floor-mounted,<br />

featuring a steel frame for attachment to<br />

Secured reusable forms are used as the<br />

foundation of the SIREWALL System, and they are<br />

filled with a moist earth mixture. When the soil<br />

mixture is compacted, it forms sturdy rammed<br />

earth walls that won‘t require any maintenance<br />

for many lifetimes. They have created a unique<br />

additive called SIREWALL Base Admixture<br />

(SBA). It is used all over the wall because of its<br />

hydrophobic qualities and ability to reduce<br />

efflorescence. Most frequently, but not always,<br />

polyiso foam serves as the concealed core of<br />

insulation in the wall‘s middle.<br />

<strong>Design</strong> guideline<br />

Rammed Earth Tasmania, a specialized in rammed<br />

earth wall construction, has compiled design<br />

considerations for building a rammed earth wall.<br />

These include:<br />

• Insulated Rammed Earth walls are<br />

recommended for areas with winter shadowing,<br />

with a suggested thickness of 450mm for harsh<br />

winter conditions.<br />

• North-facing walls exposed to sunlight in<br />

winter can use non-insulated 300mm thick<br />

walls, which absorb heat during the day<br />

and release it at night.<br />

• Insulated earth walls typically range from<br />

Figure 16. Prefabricated Rammed Earth panel<br />

Figure 17. : Insulated Rammed Earth panel<br />

18<br />

ARTICLES<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024 <strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

ARTICLES<br />

19

deconstructed and reused in new structures,<br />

crushed for landscaping or road building, or<br />

pulverized into a binder for manufacturing fresh<br />

stabilized rammed earth panels.<br />

4. Straw products<br />

Straw, a natural raw material harvested from<br />

crops like wheat, rice, and barley, serves various<br />

purposes in agriculture and construction. It is<br />

used for bedding and soil enrichment, while<br />

its fibers reinforce earth buildings like adobe<br />

constructions [11]. In modern buildings, straw<br />

finds applications as load-bearing wall elements,<br />

infill, partition walls, and as a component<br />

in rammed earth and adobe constructions.<br />

Notably, it offers energy efficiency and has a low<br />

environmental impact.<br />

Strength:<br />

• When local straw bales are used to build<br />

walls, straw has a low embodied energy.<br />

Because the heating and compression of<br />

the straw used in prefabricated compressed<br />

straw slabs uses a considerable amount of<br />

energy.<br />

• Straw plastered on both sides could<br />

withstand fire for two hours and fifteen<br />

minutes. In contrast Loose straw is highly<br />

flammable [12].<br />

• Quick, easy, and cheap to build.<br />

Weakness:<br />

Figure 18.: Comparison of compressive strength of different rammed earth wall<br />

• It takes a lot of space to build a straw bale house<br />

since straw walls are usually 450 mm thick [3].<br />

• Should not be exposed to internal/external<br />

sources of water when handling straw<br />

• Recommended to use breathable plaster to<br />

prevent moisture from getting trapped in<br />

the straw.<br />

• Very vulnerable to pest infestations, To prevent<br />

the attraction of insects or rodents, it‘s<br />

important for the straw used in construction to<br />

be dry and free of seeds [13].<br />

Building products of straw include straw bales<br />

bounded with two or three strings, prefabricated<br />

compressed straw products like straw boards,<br />

and blocks, and structural insulating panels (SIP).<br />

4.1 Strawbale<br />

In straw bale wall construction, the size of straw<br />

bales used varies based on building design and<br />

construction style. Typically, three stringers<br />

measure 24′′ wide X 16′′ high X 48′′ long, while two<br />

stringers are around 18′′ wide X 14‘‘ high X 36′′ long.<br />

Two-stringers are preferred for smaller structures<br />

to maximize internal floor area, while three-stringers<br />

are better suited for larger constructions. Three<br />

stringers offer a higher R-value in cold climates<br />

but are heavier (up to 80 lbs.), while two stringers<br />

provide a lower R-value but are lighter (around 45<br />

lbs.), making transportation easier.<br />

There are four types of straw bale construction.<br />

Which are-1. Load-bearing construction type 2. Infill<br />

straw bale construction 3. Prefabricated cassettes<br />

4. Rehabilitation with straw bales<br />

i) Load-bearing construction<br />

In the load-bearing building method using straw<br />

bales, the bales are stacked like large stretcherbonded<br />

bricks and secured with sticks or lashing<br />

straps. This method, often termed „Nebraska style,“<br />

involves crushing the bales from above with weight<br />

or straps. Wall thickness can reach up to 500mm<br />

depending on the number of bales used. Currently,<br />

there are no standardized models for calculating the<br />

structural characteristics of straw bales, and their<br />

usage as load bearers may be limited due to varying<br />

regulations requiring construction estimates for<br />

building permission.<br />

<strong>Design</strong> consideration<br />

• Roof loads must be distributed uniformly across<br />

all walls. Roof loads on the bales should not be<br />

greater than 22kN/m2.<br />

• The wall height-to-wall thickness ratio should<br />

not exceed 6:1. However, if the wall is braced<br />

against buckling using horizontal bracing, the<br />

ratio can be surpassed.<br />

• Windows should have relatively small openings<br />

but be taller than broad.<br />

• The straw wall should begin at least 300mm<br />

above ground level. The plinth must be<br />

protected against moisture from the outside<br />

and rising moisture from the earth with a waterresistant<br />

covering.<br />

• Straw bales must be properly pressed before<br />

being utilized for construction. The bales are<br />

squeezed even further when put in the wooden<br />

wall compartments. Straw density in the built-in<br />

condition must be 100 kg/m3, with a margin of<br />

error of 15 kg/m3.<br />

ii) Infill straw bale construction<br />

Infill straw bale building utilizes a frame structure<br />

filled with straw bales for insulation. Two methods<br />

are used for achieving proper wall compression: 1)<br />

Placing bales in the frame and tightening the wall<br />

plate to compress them, and 2) Inserting bales and<br />

crushing the second-to-last layer to accommodate<br />

the final layer. This approach relies on the primary<br />

structure to support loads, allowing for larger spans<br />

and openings.<br />

iii) Prefabricated cassettes<br />

Prefabricated cassettes or panels, utilizing straw<br />

and wood properties, offer a quick assembly, wellinsulated,<br />

low-energy, and sustainable building<br />

solution. Manufactured off-site, they minimize<br />

material waste and ensure tight dimension tolerances.<br />

These panels can serve structurally, eliminating the<br />

need for lintels and foundation plates, potentially<br />

reducing overall costs. Transported and installed by<br />

manufacturers like ModCell, they come in various<br />

depths and types, including braced panels, lintels,<br />

sills, and inclined gable wall components, adaptable<br />

to different structural requirements. Made of double<br />

hardwood, they can support multiple floors and are<br />

suitable for ceilings, roofs, or facades. <strong>Design</strong>ed to<br />

prevent thermal bridges, breakout access spaces<br />

allow for installation of various components within<br />

the panel, with the option of using other materials<br />

for insulation if needed.<br />

iv) Rehabilitation with straw bales<br />

Straw bales are commonly repurposed for<br />

construction renovations to enhance thermal<br />

insulation. In retrofitting projects, small bales<br />

are placed outside existing walls to improve<br />

insulation. Restorations prioritize healthy<br />

environments devoid of hazardous materials,<br />

utilizing wood frameworks and straw bales coated<br />

in earth mortars and lime for walls. Incorporating<br />

substantial overhangs is essential to shield new<br />

walls from rain damage.<br />

Finishing and Truth window<br />

Straw bale buildings can last 100+ years, but<br />

exposure to water affects durability. Moisture above<br />

20% can lead to straw cellulose breakdown by<br />

fungal enzymes. To prevent rot, create a waterproof,<br />

breathable wall with finishes like lime stucco. Clay<br />

Figure 19. PStrawbale<br />

Figure 20. Infill straw bale construction<br />

Figure 21. Prefabricated cassettes<br />

20<br />

ARTICLES<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024 <strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

ARTICLES<br />

21

its production, providing strong thermal qualities,<br />

while lime binder adds mechanical capabilities,<br />

making it fire, rot, and insect-resistant. Although<br />

it can possess favorable compressive strength,<br />

hempcrete is not suitable for load-bearing<br />

structures but is commonly used as infill in<br />

construction [3].<br />

Strength:<br />

shifted upwards, leaving an overlap to prevent<br />

spillage. Hempcrete walls are framed with 2×4s at<br />

24-inch spacing, with potential wood use reduction<br />

under engineer‘s guidance. Once cured, lime plaster<br />

is applied internally and externally, with fiberglass<br />

mesh reinforcing the exterior. Additional rain<br />

protection may include a face brick splash guard on<br />

a zinc shelf at the bottom, topped with flashing for a<br />

seamless joint with plaster.<br />

Figure 22. Rehabilitation with straw bales<br />

• High rot, and insect resistance<br />

• Hemp-lime buildings may collect roughly<br />

165 kg of CO2 per m3. (manufacturers ‘Lime<br />

Technology Ltd and Technichanvre)<br />

• There are no solid wastes generated during<br />

construction.<br />

• Structural element, good thermal and<br />

acoustic insulation, can be cast into any<br />

shape.<br />

5.3 Prefab hempcrete panel<br />

Using prefabricated hemp panels for construction<br />

offers a more efficient and faster alternative to<br />

traditional on-site builds, reducing construction<br />

time and eliminating the 45-day curing period<br />

required for cast hempcrete buildings. These<br />

panels, filled with hempcrete mixture, utilize 3-ft by<br />

Weakness:<br />

plaster is ideal for interior finishes, regulating indoor<br />

moisture. Builders often include a „Truth Window“ to<br />

showcase straw bale construction, revealing a piece<br />

of straw within the wall.<br />

Recycle and Reuse<br />

Straw bale walls and panels offer environmentally<br />

friendly building materials that can be recycled<br />

and reused in various ways. Recycling begins<br />

with careful deconstruction, separating<br />

straw from extraneous components like<br />

plaster or wood framework. The straw can be<br />

repurposed for animal bedding, mulch, or soil<br />

amendment, while the plaster and wood can<br />

also be recycled. If in good condition, straw<br />

bales may be reused for earth-building like<br />

Adobe construction.<br />

5. Hemp-lime products<br />

Figure 23. Truth window<br />

Hemp-lime, also known as „hempcrete,“ is a<br />

bio-composite material made from lime-based<br />

binders and hemp shiv. It offers strength, thermal<br />

efficiency, and versatility, suitable for monolithic<br />

walls or insulating bricks and blocks. Originating<br />

in France, about 15% of hemp shives are used in<br />

• The material must be well sheltered from<br />

frost and severe rain during construction,<br />

and the outside temperature must not drop<br />

below 5°C.<br />

• Protective clothing, gloves, and other gear<br />

are necessary when handling hemp-lime due<br />

to its skin and eye irritant properties, as well<br />

as the potential to cause burns when damp.<br />

• To maintain proper plaster coating and wall<br />

finishes, maintenance is frequently required.<br />

Hemp-lime products come in blocks, precast<br />

elements, and in situ cast forms. In-situ<br />

application involves molding or spraying it<br />

around the building‘s structural frame. Blocks<br />

are available in structural and thermal varieties,<br />

while precast panels are filled with hemp-lime<br />

and hung on steel, timber, or concrete frames,<br />

providing insulation and an airtight enclosure for<br />

buildings.<br />

5.1 The hempcrete block<br />

‚Isohemp‘ provides hemp blocks, a non-loadbearing<br />

glued masonry product suitable for<br />

various construction purposes such as residential<br />

houses, wall doubling, industrial partitioning, and<br />

apartments. They offer two types: solid blocks and<br />

machined blocks. Solid hemp blocks are 60cm by<br />

Figure 24. Hempcrete blocks<br />

30cm, and available in thicknesses from 6 to 36cm.<br />

Machined blocks include holed and U-shaped<br />

blocks with thicknesses of 30 and 36cm.<br />

Hempro System<br />

The Hempro System by ‚Isohemp‘ utilizes two types<br />

of 30cm thick hemp blocks: solid and machined.<br />

Machined blocks serve as insulating lost formwork<br />

within the building envelope for pouring reinforced<br />

concrete structural frames. Holed blocks form<br />

column formwork, while U-blocks facilitate beam<br />

pouring to support floors and roofs. Additional<br />

hemp block layers of varying thicknesses can be<br />

added for enhanced thermal performance.<br />

5.2 The hempcrete formwork<br />

On-site hempcrete walls are constructed by<br />

blending hemp hurd (the woody core of the hemp<br />

plant), a binder (such as lime or cement), and water.<br />

This mixture produces a durable and lightweight<br />

material suitable for both load-bearing and nonload-bearing<br />

walls in construction.<br />

Construction Process<br />

Figure 25. : Hempro system<br />

‘Hempstone,‘ a professional hempcrete installer,<br />

outlined the construction process for Hempcrete<br />

Formwork. To prevent moisture absorption from the<br />

ground, plastic membrane strips are placed directly<br />

on the slab with spray foam insulation sealing any<br />

cracks. Small PVC conduits on 2” x 4” studs create<br />

an interior barrier, acting as spacers for plywood<br />

formwork. T1-11 siding serves as the outer barrier,<br />

secured with 5-inch<br />

screws into studs, forming a 6.5-inch cavity for<br />

hempcrete. After filling the mold with<br />

hempcrete mix, the formwork is unscrewed and<br />

Figure 26. Hempcrete formwork<br />

Figure 27. Prefab hempcrete panel<br />

22<br />

ARTICLES<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024 <strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

ARTICLES<br />

23

8-ft wood frames and come in thicknesses of 9 and<br />

12 inches. After curing for 30 days, they are shipped<br />

to the building site and can be easily installed,<br />

offering various finishing options. <strong>Design</strong>ed by<br />

‚Dunagro Prefab Hemp Construction,‘ these panels<br />

can adapt to any desired home design, suitable for<br />

low-rise and high-rise structures, from tiny huts to<br />

major commercial complexes. While suitable for up<br />

to six-story buildings, design experts should assess<br />

hempcrete‘s suitability for larger projects covered<br />

by relevant code provisions.<br />

Finishing<br />

To achieve resilient hemp-lime walls, it is imperative<br />

to select low-permeability finishes and utilize a<br />

two-coat plaster system such as BioLime over<br />

hemp-based substrates. Additionally, treating wood<br />

surfaces to prevent cracking during plastering is<br />

essential. Moreover, plaster should only be applied<br />

in temperatures above 5°C and below 32°C. Lastly,<br />

it is crucial to use exclusively breathable external<br />

paints to ensure durability and longevity.<br />

Recycle and Reuse<br />

Hempcrete‘s ecological soundness spans its entire<br />

life cycle, starting from its creation using natural<br />

waste products to its eventual reuse or recycling in<br />

case of demolition. At the Tuorla Agricultural School,<br />

hemp structures were crushed and found to be<br />

degradable, improving soil structure and allowing<br />

for hemp cultivation to resume. According to Mike<br />

Lawrence of the University of Bath, UK, at the end<br />

of a building‘s life, hemp lime can be repurposed<br />

as mulch, preventing weed growth, conserving<br />

water, and promoting plant growth. Over time, it<br />

decomposes into plant fertilizer.<br />

6. Cork products<br />

Cork, sourced from the spongy bark of Cork Oaks,<br />

is a renewable material harvested every 9 to 11<br />

years. The trees are left undisturbed for 25 years<br />

before harvesting. During hot summers, the cork<br />

dries out and cracks, facilitating manual removal<br />

of the bark. Cork for building products is sourced<br />

sustainably or repurposed from wine bottlestoppers.<br />

Recent studies indicate that debarked<br />

cork oaks store three to fi ve times more CO2 than<br />

those left unharvested [14].<br />

Strength:<br />

• Very light material, weights only 0.16gm/cm3<br />

[15].<br />

• Cork contains a natural substance called<br />

Suberin, which is a mixture of organic acids that<br />

coats the walls and prevents water and gases<br />

from passing through.<br />

• The material is fire retardant and does not emit<br />

any toxic gases during a fire.<br />

• Has very good sound insulation quality [14].<br />

• Naturally unaffected by mice or termites and<br />

maintenance-free [15].<br />

Weakness:<br />

• Its products have an intense smell during the<br />

first few months of use.<br />

• Cork is expensive and can only be harvested in<br />

a limited amount each time.<br />

Available products from cork are Cork tile and Cork<br />

board.<br />

6.1 Cork tile<br />

Wall-cladding cork tiles are crafted by bonding thin<br />

layers of cork to a backing material or adhesive,<br />

retaining cork‘s natural texture, warmth, and<br />

sound-absorbing qualities. These tiles offer ease of<br />

installation and come in diverse sizes, shapes, and<br />

patterns for creative design options. They can be<br />

affixed to prepared walls using screws, adhesive,<br />

or peel-and-stick backing. Installation may require<br />

cutting tiles to fit precise dimensions and arranging<br />

them for aesthetic appeal.<br />

Cladding Process<br />

Cork has garnered global attention as a versatile<br />

cladding material due to its high insulation values<br />

and exceptional acoustic performance, making it<br />

favored by designers worldwide.<br />

Before installation, it is imperative to ensure the<br />

surface is clean and sturdy, free from any dust,<br />

grease, or other substances that could compromise<br />

adhesion. Precise measurements and markings<br />

are essential to accurately position the first tile.<br />

Adhesive application, whether using a water-based<br />

or latex-based primer for absorbent surfaces,<br />

should adhere strictly to manufacturer instructions,<br />

ensuring optimal settings and drying times. Liquid<br />

adhesive is then evenly applied to both the wall and<br />

the back of the cork tile, utilizing a new, high-quality<br />

microfiber roller with a short pile. The initial tile is<br />

carefully placed as marked, with subsequent tiles<br />

following suit, ensuring close alignment of edges for<br />

a seamless finish.<br />

For MD Façade Cork Board, a glue fixation method is<br />

recommended to maximize energy efficiency, owing to<br />

its low thermal conductivity of 0.043 W/m.K, contributing<br />

to both environmental and economic savings.<br />

Additionally, mechanical fixation of MD Façade<br />

boards can be achieved through hidden mechanical<br />

fastening directly to metal or other supports using a<br />

shiplap system.<br />

<strong>Design</strong> consideration<br />

• Selection of high-quality cork tailored for<br />

outdoor use is pivotal for durability and weather<br />

resistance.<br />

• Regular maintenance routines, including<br />

cleaning and resealing, are vital to uphold the<br />

facade‘s appearance and structural integrity.<br />

• Cork‘s warmth, diverse finishes, colors, and<br />

textures offer versatility for captivating facade<br />

designs.<br />

• Whether as the primary cladding material<br />

or in combination with other architectural<br />

elements, cork allows for visually striking exterior<br />

expressions.<br />

• Prioritizing sustainably sourced cork and ecofriendly<br />

manufacturing practices aligns with<br />

environmental responsibility and ensures longterm<br />

viability.<br />

• Adherence to prescribed installation procedures,<br />

with expert guidance as needed, is crucial for<br />

establishing enduring and reliable cork facades.<br />

• Attention to detail during installation, particularly<br />

in joints, connections, and sealing, is imperative for<br />

structural integrity and effective water resistance.<br />

Recycle and Reuse<br />

Figure 28 : Cork facade<br />

Figure 29. Cork tile<br />

Figure 30. Glued fixation of MD corkboard<br />

Companies like ReCork and Cork Forest Conservation<br />

Alliance specialize in recycling corks to create new<br />

products. However, due to the high cost, recycling<br />

small quantities of cork may not be practical. ReCork<br />

offers a solution for disposing of large quantities by<br />

shredding and repurposing cork as filler in other<br />

materials. Cork tiles or boards in good condition can<br />

be salvaged and reused for interior wall cladding<br />

or creative projects like furniture or artwork.<br />

Improperly dismantled cork can biodegrade in<br />

landfills over time, as it is a natural material.<br />

7. Comparative analysis of the biodegradable<br />

materials<br />

The selected 5 biodegradable materials which<br />

were described already are now compared with<br />

each other with charts, tables, and graphs. The<br />

comparisons will be made based on parameters<br />

like density, thermal conductivity, mechanical<br />

and acoustic properties, embodied energy, and<br />

CO2 emission which have been collected from<br />

different manufacturer’s websites, research<br />

papers, and design manuals. These results will<br />

finally help users to understand the difference<br />

Figure 31. Mechanical fixation of MD corkboard<br />

and identify suitable material for a project.<br />

Thermal conductivity measures a material‘s<br />

heat conductivity, with lower values indicating<br />

better insulation. Fig 33 displays two categories<br />

of materials, with straw and cork showing<br />

the lowest thermal conductivity. Earthen<br />

products vary widely due to density and<br />

composition, ranging from 0.5-1.5 W/m*K (Fig<br />

32). Generally, higher density correlates with<br />

higher conductivity, implying denser materials<br />

are poorer insulators.<br />

Heat capacity, or thermal capacity, measures<br />

the amount of heat energy needed to change<br />

an object‘s temperature. Specific heat capacity<br />

(J/kg K) is heating capacity per unit mass.<br />

Fig 34 shows cork, straw, and hemp-lime<br />

products with the highest heat capacity, while<br />

earth-based products have the lowest. These<br />

materials‘ significant mass contributes to their<br />

thermal mass, allowing them to accumulate,<br />

store, and re-emit heat, influencing indoor<br />

temperatures.<br />

24<br />

ARTICLES<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024 <strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

ARTICLES<br />

25

Figure 32. Density<br />

Figure 36. Summary of comparative analysis<br />

Figure 33. Thermal Conductivity<br />

Figure 34. Heat Capacity<br />

Figure 35. Compressive strength<br />

Figure 35. Sound reduction (dB)<br />

The U-value, expressed in W/m²K, represents<br />

the overall heat transfer coefficient of a building<br />

element or product. It‘s calculated using the<br />

equation U-value = thermal conductivity (λ) /<br />

thickness (d). This value indicates the rate at which<br />

heat is transferred through one square meter<br />

of the structure, divided by the temperature<br />

difference across the structure.<br />

Compressive strength is the strength of a<br />

material loaded in compression. For load-bearing<br />

structures (1-2 stories) a compressive strength<br />

of 0.1-0.2MPa is sufficient, but for safety reasons<br />

and after the safety factors are applied, the<br />

compressive strength should be ca. 2-2.5 MPa [2].<br />

As Fig 35 shows unfi red earthen products,<br />

rammed earth and cork present the highest values<br />

of compressive strength, while hemp lime product<br />

presents a slightly lower value of compressive<br />

strength but still a sufficient compressive strength<br />

of more than 2 MPa. On the other hand, straw<br />

products have very low values, less than 1 MPa<br />

which means they are not suitable as load-bearing<br />

materials.<br />

Fig 36 represents the sound reduction capability<br />

of the materials. From this graph, it is noticed that<br />

Rammed earth and Hemp lime products present<br />

the highest sound reduction. In a project where<br />

acoustic performance has a high priority, these<br />

materials can be a better choice.<br />

Different comparative analyses result that<br />

different materials may belong to multiple<br />

categories depending on their applications<br />

(Fig 37), each offering unique benefi ts and<br />

considerations. While biodegradable materials<br />

require careful design to avoid moisture issues,<br />

cork stands out for its water resistance, alongside<br />

stabilized earthen structures. Conversely, straw<br />

products necessitate robust water protection due<br />

to susceptibility to rot. Despite this, straw remains<br />

cost-effective and widely available, boasting<br />

favorable thermal and mechanical properties,<br />

ideal for eco-friendly construction projects.<br />

8. Conclusion<br />

This study provides valuable insights into the<br />

practical implementation of biodegradable<br />

materials in envelope design, equipping<br />

architects, engineers, and builders with informed<br />

decision-making tools. Biodegradable materials<br />

offer numerous benefits, including renewability,<br />

reduced environmental impact, and compatibility<br />

with circular economy principles,<br />

while also enhancing structural integrity and<br />

indoor environmental quality. „Building for the<br />

Future: A Guide to Biodegradable Materials<br />

in Envelope <strong>Design</strong>“ aims to inspire industry<br />

professionals and researchers to embrace<br />

these materials for a more sustainable future,<br />

leveraging advancing technology to further<br />

enhance their performance and unlock their full<br />

potential in sustainable construction endeavors.<br />

26<br />

ARTICLES<br />

<strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024 <strong>Design</strong> <strong>Strategies</strong> <strong>IMPULSE</strong> – <strong>Sustainable</strong> Façades 04.2024<br />

ARTICLES<br />

27

9. References:<br />

1- Sgouropoulou, E. (2013). Possibilities of applying<br />

biodegradable materials in solid building envelopes<br />

in the Netherlands. MSc thesis. TU Delft, Faculty of<br />

Architecture, page: 43<br />

2- Houben H. and Guillaud H. (1994). Earth<br />

construction; a comprehensive guide. France:<br />

practical action publishing, page: 152-153<br />

3- Halliday S, 2008 Halliday, S. (2008) <strong>Sustainable</strong><br />

Construction. Butterworth-Heinemann, page.148<br />

4- Lyons A., 2010 Lyons, A. (2010) Materials for<br />

architects and builders. (4th edition) Elsevier,<br />

page:17<br />

5- Keefe L., 2005 Keefe, L. (2005) Earth building<br />

methods and materials, repair and conservation.<br />

USA and Canada: Taylor & Francis, page: 96<br />

6- Roaf, S. et al (2013) Ecohouse; a design guide (4th<br />

edition), Routledge: page: 286<br />

7- Paul G. McHenry, Jr. McHenry and Co. Albuquerque,<br />

NM. Appropriate building codes and specifications<br />

for Adobe construction, page: 429<br />

8- Solid Earth Adobe Buildings, https://www.<br />

solidearth.co.nz/earthbuilding-information/earthbuilding-design/<br />

9- Césaire Hema (2020) Impact of the <strong>Design</strong> of Walls<br />

Made of Compressed Earth Blocks on the Thermal<br />