sponge iron industry –past-present-future - SIMA

sponge iron industry –past-present-future - SIMA

sponge iron industry –past-present-future - SIMA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

led to more than 50 gaustec ® - WHIMS sold in five<br />

years only.<br />

And now with the new model capacities per unit have<br />

doubled at almost the same footprint, the same<br />

weight, the same energy consumption and the same<br />

efficiency, of course:<br />

The new gaustec ® - GX 3600 with capacities from<br />

360 to 800 tph¹).<br />

At the Itaminas plant the new gaustec ® -GX 3600 is<br />

fed with hematite <strong>iron</strong> ore < 1 mm with a feed grade<br />

of about 54 % Fe and 23 % SiO 2 at a rate of 700<br />

tph, 50 % solids. The product of this cobber stage is<br />

further upgraded in a second, already existing<br />

gaustec ® -G 3600 to a final product of plus 66 % Fe<br />

and less than 3.0 % SiO 2 . The tailings of the cobber<br />

stage are fed to a gaustec ® - GHP 150, which works<br />

as a scavenger, producing tailings with about 18 %<br />

Fe and 60 % SiO2. With the <strong>future</strong> introduction of a<br />

grinding circuit for better liberation it is expected that<br />

the <strong>iron</strong> in the tailings can be reduced to less than<br />

10 % Fe, since by now only natural <strong>iron</strong> ore fines are<br />

processed.<br />

In addition to the general features of gaustec ® -<br />

WHIMS like<br />

l Independently adjustable magnetic fields of the<br />

rotors of up to 15.000 Gauss<br />

l Easy access to rotors for maintenance<br />

l Controlled feed distribution through improved<br />

feed box design<br />

l Optimized spray boxes for product washing of<br />

higher efficiency at less water consumption<br />

The gaustec ®<br />

-GX 3600 offers even more technical<br />

and economical advantages:<br />

l Lower specific CAPEX and OPEX per ton of feed<br />

l Less ancillary equipment required<br />

l Simplified processing flow sheet and plant layout<br />

That´s why the X in the new gaustec ® -WHIMS not<br />

only symbolizes the new pole arrangement but leads<br />

the way to increased benefits for the mineral <strong>industry</strong><br />

by making use of the high capacity gaustec ® - GX<br />

technology.<br />

¹) figures for <strong>iron</strong> ore, depending on feed<br />

characteristics, to be confirmed by test work<br />

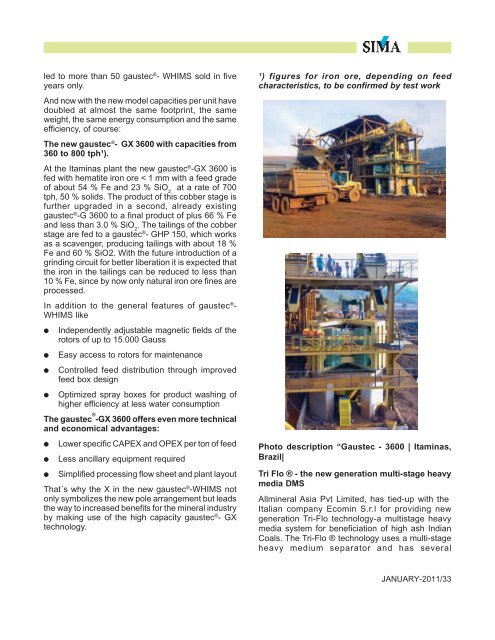

Photo description “Gaustec - 3600 | Itaminas,<br />

Brazil|<br />

Tri Flo ® - the new generation multi-stage heavy<br />

media DMS<br />

Allmineral Asia Pvt Limited, has tied-up with the<br />

Italian company Ecomin S.r.l for providing new<br />

generation Tri-Flo technology-a multistage heavy<br />

media system for beneficiation of high ash Indian<br />

Coals. The Tri-Flo ® technology uses a multi-stage<br />

heavy medium separator and has several<br />

JANUARY-2011/33