DAM IMPRESSIVE

DAM IMPRESSIVE

DAM IMPRESSIVE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

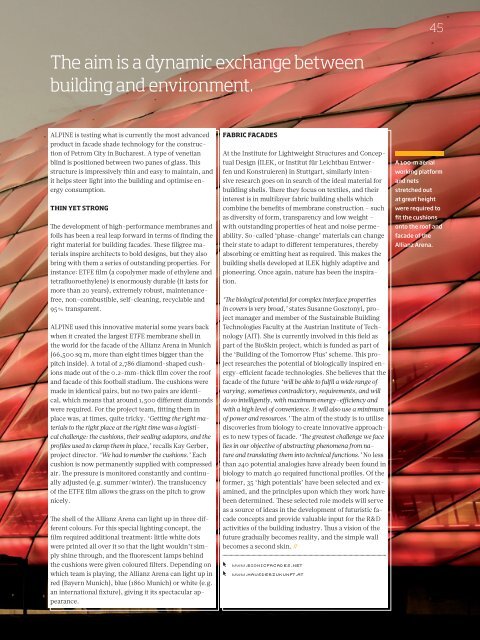

the aim is a dynamic exchange between<br />

building and environment.<br />

ALPINE is testing what is currently the most advanced<br />

product in facade shade technology for the construction<br />

of Petrom City in Bucharest. A type of venetian<br />

blind is positioned between two panes of glass. This<br />

structure is impressively thin and easy to maintain, and<br />

it helps steer light into the building and optimise energy<br />

consumption.<br />

thin Yet StRong<br />

The development of high-performance membranes and<br />

foils has been a real leap forward in terms of finding the<br />

right material for building facades. These filigree materials<br />

inspire architects to bold designs, but they also<br />

bring with them a series of outstanding properties. For<br />

instance: ETFE film (a copolymer made of ethylene and<br />

tetrafluoroethylene) is enormously durable (it lasts for<br />

more than 20 years), extremely robust, maintenancefree,<br />

non-combustible, self-cleaning, recyclable and<br />

95% transparent.<br />

ALPINE used this innovative material some years back<br />

when it created the largest ETFE membrane shell in<br />

the world for the facade of the Allianz Arena in Munich<br />

(66,500 sq m, more than eight times bigger than the<br />

pitch inside). A total of 2,786 diamond-shaped cushions<br />

made out of the 0.2-mm-thick film cover the roof<br />

and facade of this football stadium. The cushions were<br />

made in identical pairs, but no two pairs are identical,<br />

which means that around 1,500 different diamonds<br />

were required. For the project team, fitting them in<br />

place was, at times, quite tricky. ‘Getting the right materials<br />

to the right place at the right time was a logistical<br />

challenge: the cushions, their sealing adaptors, and the<br />

profiles used to clamp them in place,’ recalls Kay Gerber,<br />

project director. ‘We had to number the cushions.’ Each<br />

cushion is now permanently supplied with compressed<br />

air. The pressure is monitored constantly and continually<br />

adjusted (e.g. summer/winter). The translucency<br />

of the ETFE film allows the grass on the pitch to grow<br />

nicely.<br />

The shell of the Allianz Arena can light up in three different<br />

colours. For this special lighting concept, the<br />

film required additional treatment: little white dots<br />

were printed all over it so that the light wouldn’t simply<br />

shine through, and the fluorescent lamps behind<br />

the cushions were given coloured filters. Depending on<br />

which team is playing, the Allianz Arena can light up in<br />

red (Bayern Munich), blue (1860 Munich) or white (e.g.<br />

an international fixture), giving it its spectacular appearance.<br />

fabRiC faCadeS<br />

At the Institute for Lightweight Structures and Conceptual<br />

Design (ILEK, or Institut für Leichtbau Entwerfen<br />

und Konstruieren) in Stuttgart, similarly intensive<br />

research goes on in search of the ideal material for<br />

building shells. There they focus on textiles, and their<br />

interest is in multilayer fabric building shells which<br />

combine the benefits of membrane construction – such<br />

as diversity of form, transparency and low weight –<br />

with outstanding properties of heat and noise permeability.<br />

So-called ‘phase-change’ materials can change<br />

their state to adapt to different temperatures, thereby<br />

absorbing or emitting heat as required. This makes the<br />

building shells developed at ILEK highly adaptive and<br />

pioneering. Once again, nature has been the inspiration.<br />

‘The biological potential for complex interface properties<br />

in covers is very broad,’ states Susanne Gosztonyi, project<br />

manager and member of the Sustainable Building<br />

Technologies Faculty at the Austrian Institute of Technology<br />

(AIT). She is currently involved in this field as<br />

part of the BioSkin project, which is funded as part of<br />

the ‘Building of the Tomorrow Plus’ scheme. This project<br />

researches the potential of biologically inspired energy-efficient<br />

facade technologies. She believes that the<br />

facade of the future ‘will be able to fulfil a wide range of<br />

varying, sometimes contradictory, requirements, and will<br />

do so intelligently, with maximum energy-efficiency and<br />

with a high level of convenience. It will also use a minimum<br />

of power and resources.’ The aim of the study is to utilise<br />

discoveries from biology to create innovative approaches<br />

to new types of facade. ‘The greatest challenge we face<br />

lies in our objective of abstracting phenomena from nature<br />

and translating them into technical functions.’ No less<br />

than 240 potential analogies have already been found in<br />

biology to match 40 required functional profiles. Of the<br />

former, 35 ‘high potentials’ have been selected and examined,<br />

and the principles upon which they work have<br />

been determined. These selected role models will serve<br />

as a source of ideas in the development of futuristic facade<br />

concepts and provide valuable input for the R&D<br />

activities of the building industry. Thus a vision of the<br />

future gradually becomes reality, and the simple wall<br />

becomes a second skin. //<br />

Ü www.bionicfacades.net<br />

Ü www.hausderzukunft.at<br />

45<br />

A 100-m aerial<br />

working platform<br />

and nets<br />

stretched out<br />

at great height<br />

were required to<br />

fit the cushions<br />

onto the roof and<br />

facade of the<br />

Allianz Arena.