Atlas Copco Air Motors

Atlas Copco Air Motors

Atlas Copco Air Motors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Par<br />

[100%]<br />

100<br />

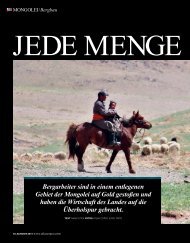

Introducing the air<br />

motor<br />

The air motor is one of the toughest and most<br />

versatile power units available to today´s<br />

design engineer. It is easy to control over a<br />

wide speed range, and it produces maximum<br />

torque where it is often most needed – at start<br />

up.<br />

The performance of an air motor is dependant on the inlet<br />

pressure. At a constant inlet pressure, ungoverned air<br />

motors exhibit the characteristic linear output torque/speed<br />

relationship. Figure 1.<br />

However, by simply regulating the air supply, using the<br />

techniques of throttling or pressure regulation, the output of<br />

an air motor can be easily modified.<br />

The free speed and torque can be regulated down to 50%<br />

for an LZB air motor. The free speed for an LZL can be regulated<br />

down to 10% and the torque can be regulated down to<br />

20%. The shaded areas in figure 2 illustrate this.<br />

50<br />

Par<br />

[Nm]<br />

50 100<br />

Velocidad [100%]<br />

Par<br />

[100%]<br />

100<br />

Velocidad [r/min]<br />

10 50 100<br />

Velocidad [100%]<br />

LZB LZL<br />

6 AT L A S C O P C O A I R M O T O R S<br />

50<br />

20<br />

Figure 1<br />

Figure 2<br />

It should be noted that all vane air motors produce a variable<br />

starting torque, due to the position of the vanes in the motor<br />

when it is started. The variation differs between motor types<br />

and must be checked on an individual basis.<br />

The power that an air motor produces is a function of torque<br />

and speed. All ungoverned air motors produce the same characteristic<br />

power curve, with maximum power occurring at<br />

around 50% of the free speed. The torque produced at this<br />

point is often referred to as ”torque at maximum output.”<br />

The performance curves for an ungoverned air motor operating<br />

at a constant air pressure are illustrated in figure 3.<br />

Par<br />

[Nm]<br />

Par de<br />

ahogo<br />

Par de<br />

arranque<br />

mín.<br />

The use of gear units<br />

Par<br />

Potencia<br />

Velocidad [r/min]<br />

Figure 3<br />

<strong>Air</strong> motors operate at high speed and, although they can be<br />

controlled over a wide speed range, the output characteristics<br />

are not always suitable for the application. To achieve the<br />

required output an appropriate gear unit can be selected. The<br />

ability to change the output by use of a gear unit is illustrated<br />

in figure 4.<br />

Par<br />

[Nm]<br />

4:1<br />

2:1<br />

The planetary and helical gear units used by <strong>Atlas</strong> <strong>Copco</strong><br />

have a high level of efficiency that can be assumed to be<br />

100%. The power output remains virtually unchanged also<br />

when gears are used.<br />

Note. The above does not apply to worm drive gear units, which can have<br />

high frictional losses and, therefore, loss of power output.<br />

1:1<br />

Par<br />

Potencia<br />

1:1, 2:1, 4:1 = relaciones de engrane<br />

Velocidad [r/min]<br />

Figure 4