EUROMAINTENANCE JOURNAL - DNV Germany

EUROMAINTENANCE JOURNAL - DNV Germany

EUROMAINTENANCE JOURNAL - DNV Germany

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

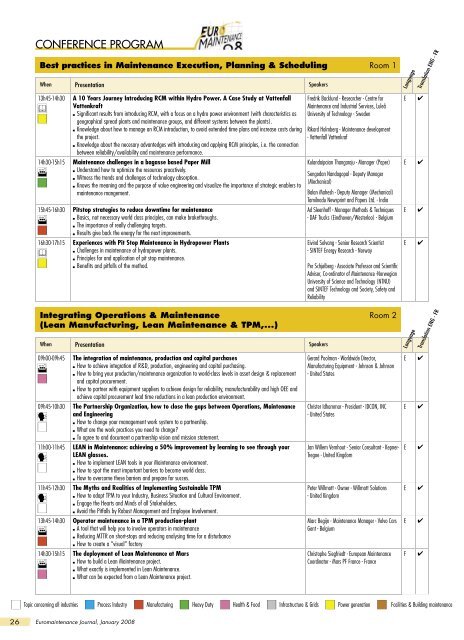

CONFERENCE PROGRAM<br />

Best practices in Maintenance Execution, Planning & Scheduling Room 1<br />

When Presentation Speakers<br />

13h45-14h30 A 10 Years Journey Introducing RCM within Hydro Power. A Case Study at Vattenfall<br />

Vattenkraft<br />

n Signifi cant results from introducing RCM, with a focus on a hydro power environment (with characteristics as<br />

geographical spread plants and maintenance groups, and different systems between the plants).<br />

n Knowledge about how to manage an RCM introduction, to avoid extended time plans and increase costs during<br />

the project.<br />

n Knowledge about the necesary advantedges with introducing and applying RCM principles, i.e. the connection<br />

between reliability/availability and maintenance performance.<br />

14h30-15h15 Maintenance challenges in a bagasse based Paper Mill<br />

n Understand how to optimize the resources proactively.<br />

n Witness the trends and challenges of technology absorption.<br />

n Knows the meaning and the purpose of value engineering and visualize the importance of strategic enablers to<br />

maintenance mangement.<br />

15h45-16h30 Pitstop strategies to reduce downtime for maintenance<br />

n Basics, not necessary world class principles, can make brakethroughs.<br />

n The importance of really challenging targets.<br />

n Results give back the energy for the next improvements.<br />

16h30-17h15 Experiences with Pit Stop Maintenance in Hydropower Plants<br />

n Challenges in maintenance of hydropower plants.<br />

n Principles for and application of pit stop maintenance.<br />

n Benefi ts and pitfalls of the method.<br />

Topic concerning all industries<br />

26 Euromaintenance Journal, January 2008<br />

Process Industry Manufacturing Heavy Duty Health & Food Infrastructure & Grids<br />

Fredrik Backlund - Researcher - Centre for<br />

Maintenance and Industrial Services, Luleå<br />

University of Technology - Sweden<br />

Rikard Holmberg - Maintenance development<br />

- Vattenfall Vattenkraf<br />

Kulandaipaian Thangaraju - Manager (Paper)<br />

Sengodan Nandagopal - Deputy Manager<br />

(Mechanical)<br />

Balan Mahesh - Deputy Manager (Mechanical)<br />

Tamilnadu Newsprint and Papers Ltd. - India<br />

Ad Sleenhoff - Manager Methods & Techniques<br />

- DAF Trucks (Eindhoven/Westerloo) - Belgium<br />

Eivind Solvang - Senior Research Scientist<br />

- SINTEF Energy Research - Norway<br />

Per Schjølberg - Associate Professor and Scientifi c<br />

Advisor, Co-ordinator of Maintenance -Norwegian<br />

University of Science and Technology (NTNU)<br />

and SINTEF Technology and Society, Safety and<br />

Reliability<br />

Integrating Operations & Maintenance Room 2<br />

(Lean Manufacturing, Lean Maintenance & TPM,...)<br />

When Presentation Speakers<br />

09h00-09h45 The integration of maintenance, production and capital purchases<br />

n How to achieve integration of R&D, production, engineering and capital purchasing.<br />

n How to bring your production/maintenance organization to world-class levels in asset design & replacement<br />

and capital procurement.<br />

n How to partner with equipment suppliers to achieve design for reliability, manufacturability and high OEE and<br />

achieve capital procurement lead time reductions in a lean production environment.<br />

09h45-10h30 The Partnership Organization, how to close the gaps between Operations, Maintenance<br />

and Engineering<br />

n How to change your management work system to a partnership.<br />

n What are the work practices you need to change?<br />

n To agree to and document a partnership vision and mission statement.<br />

11h00-11h45 LEAN in Maintenance: achieving a 50% improvement by learning to see through your<br />

LEAN glasses.<br />

n How to implement LEAN tools in your Maintenance environment.<br />

n How to spot the most important barriers to become world class.<br />

n How to overcome these barriers and prepare for succes.<br />

11h45-12h30 The Myths and Realities of Implementing Sustainable TPM<br />

n How to adapt TPM to your Industry, Business Situation and Cultural Environment.<br />

n Engage the Hearts and Minds of all Stakeholders.<br />

n Avoid the Pitfalls by Robust Management and Employee Involvement.<br />

13h45-14h30 Operator maintenance in a TPM production-plant<br />

n A tool that will help you to involve operators in maintenance<br />

n Reducing MTTR on short-stops and reducing analysing time for a disturbance<br />

n How to create a “visual” factory<br />

14h30-15h15 The deployment of Lean Maintenance at Mars<br />

n How to build a Lean Maintenance project.<br />

n What exactly is implemented in Lean Maintenance.<br />

n What can be expected from a Lean Maintenance project.<br />

Gerard Poolman - Worldwide Director,<br />

Manufacturing Equipment - Johnson & Johnson<br />

- United States<br />

Christer Idhammar - President - IDCON, INC<br />

- United States<br />

Jan Willem Vernhout - Senior Consultant - Kepner-<br />

Tregoe - United Kingdom<br />

Peter Willmott - Owner - Willmott Solutions<br />

- United Kingdom<br />

Marc Begijn - Maintenance Manager - Volvo Cars<br />

Gent - Belgium<br />

Christophe Siegfriedt - European Maintenance<br />

Coordinator - Mars PF France - France<br />

Language<br />

E 4<br />

E 4<br />

E 4<br />

E 4<br />

Language<br />

E 4<br />

E 4<br />

E 4<br />

E 4<br />

E 4<br />

F 4<br />

Translation ENG - FR<br />

Translation ENG - FR<br />

Power generation Facilities & Building maintenance