EUROMAINTENANCE JOURNAL - DNV Germany

EUROMAINTENANCE JOURNAL - DNV Germany

EUROMAINTENANCE JOURNAL - DNV Germany

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CONFERENCE WORKSHOPS<br />

MAINTENANCE KEY PERFORMANCE INDICATORS<br />

THE WORLD’S FIRST PRESENTATION OF THE<br />

SMRP - EFNMS HARMONISED INDICATORS<br />

Many companies use KPI’s in<br />

maintenance to compare the<br />

current maintenance performance<br />

with that of others, to communicate<br />

maintenance performance<br />

improvement to management and<br />

maintenance staff and to support<br />

their business strategies with predefi<br />

ned goals.<br />

Euromaintenance has programmed<br />

a full day workshop, that will provide<br />

training and practice in the<br />

calculation and understanding of the<br />

indicators for measuring maintenance,<br />

reliability and availability performance.<br />

The workshop will be the premiere of the<br />

Harmonised indicators, set up by SMRP<br />

(the Society for Maintenance and Reliability<br />

Professionals) and the EFNMS<br />

(the European Federation of National<br />

Maintenance Societies). The trick in<br />

benchmarking is to clearly defi ne what<br />

is included in the different components of<br />

the KPI’s. That is why the workshop will<br />

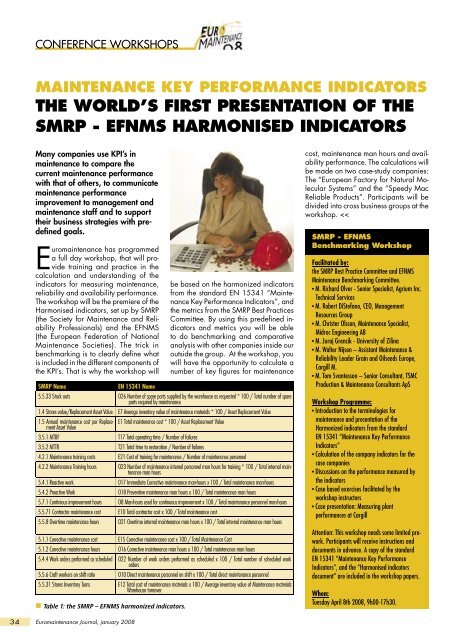

n Table 1: the SMRP – EFNMS harmonized indicators.<br />

34 Euromaintenance Journal, january 2008<br />

be based on the harmonized indicators<br />

from the standard EN 15341 “Maintenance<br />

Key Performance Indicators”, and<br />

the metrics from the SMRP Best Practices<br />

Committee. By using this predefi ned indicators<br />

and metrics you will be able<br />

to do benchmarking and comparative<br />

analysis with other companies inside our<br />

outside the group. At the workshop, you<br />

will have the opportunity to calculate a<br />

number of key fi gures for maintenance<br />

SMRP Name EN 15341 Name<br />

5.5.33 Stock outs O26 Number of spare parts supplied by the warehouse as requested * 100 / Total number of spare<br />

parts required by maintenance<br />

1.4 Stores value/Replacement Asset Value E7 Average inventory value of maintenance materials * 100 / Asset Replacement Value<br />

1.5 Annual maintenance cost per Replacement<br />

Asset Value<br />

E1 Total maintenance cost * 100 / Asset Replacement Value<br />

3.5.1 MTBF T17 Total operating time / Number of failures<br />

3.5.2 MTTR T21 Total time to restoration / Number of failures<br />

4.2.1 Maintenance training costs E21 Cost of training for maintenance / Number of maintenance personnel<br />

4.2.2 Maintenance Training hours O23 Number of maintenance internal personnel man hours for training * 100 / Total internal maintenance<br />

man hours<br />

5.4.1 Reactive work 017 Immediate Corrective maintenance man-hours x 100 / Total maintenance man-hours<br />

5.4.2 Proactive Work O18 Preventive maintenance man hours x 100 / Total maintenance man hours<br />

5.7.1 Continious improvement hours O8 Man-hours used for continuous improvement x 100 / Total maintenance personnel man-hours<br />

5.5.71 Contractor maintenance cost E10 Total contractor cost x 100 / Total maintenance cost<br />

5.5.8 Overtime maintenance hours O21 Overtime internal maintenance man hours x 100 / Total internal maintenance man hours<br />

5.1.1 Corrective maintenance cost E15 Corrective maintenance cost x 100 / Total Maintenance Cost<br />

5.1.2 Corrective maintenance hours O16 Corrective maintenance man hours x 100 / Total maintenance man hours<br />

5.4.4 Work orders performed as scheduled O22 Number of work orders performed as scheduled x 100 / Total number of scheduled work<br />

orders<br />

5.5.6 Craft workers on shift ratio O10 Direct maintenance personnel on shift x 100 / Total direct maintenance personnel<br />

5.5.31 Stores Inventory Turns E12 Total cost of maintenance materials x 100 / Average inventory value of Maintenance materials<br />

Warehouse turnover<br />

cost, maintenance man hours and availability<br />

performance. The calculations will<br />

be made on two case-study companies:<br />

The “European Factory for Natural Molecular<br />

Systems” and the “Speedy Mac<br />

Reliable Products”. Participants will be<br />

divided into cross business groups at the<br />

workshop.