You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2/2000<br />

<strong>Mercedes</strong>-<strong>Benz</strong><br />

UNIMOG<br />

JOURNAL<br />

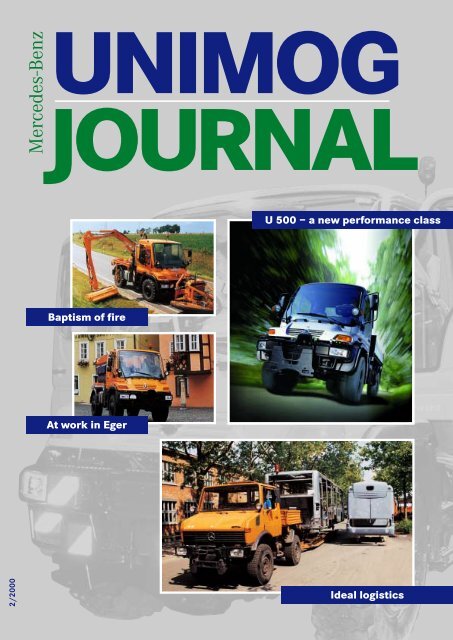

Baptism of fire<br />

At work in Eger<br />

U 500 – a new performance class<br />

Ideal logistics

Unimog-System-Partnerships agreed 4-5<br />

U 500 – A new performance class 6<br />

Star of the demonstration track 7<br />

The baptism of fire 8-9<br />

50 years of Unimog in 2001 17<br />

New U 300 for Gaggenau’s public works department 17<br />

Unimog Used Vehicle Center on the Internet 18<br />

Versatility is in demand 18<br />

New Unimog book/ Rally power with the Unimog 19<br />

50 years of Herold 19<br />

Publisher:<br />

DaimlerChrysler AG, Unimog Division<br />

Publisher’s responsibility:<br />

Dieter Sellnau, Unimog Division<br />

Coordination:<br />

Martin Adam, Unimog Division<br />

Editorial committee:<br />

Martin Adam, Erwin Kirschner, Dieter Mutard, Karin Weidenbacher<br />

Contributors to this issue:<br />

Texts: Michael Brettnacher, Stefan Loeffler,<br />

Dieter Mutard, Christine Karras<br />

Photos: DWM Pressebüro und Verlag, Michael Brettnacher,<br />

Unimog Division<br />

Editorial office address:<br />

DaimlerChrysler AG, Produktbereich Unimog<br />

Vertrieb Marketing, 76568 Gaggenau, Germany<br />

Production:<br />

Dieter Mutard DWM Pressebüro und Verlag,<br />

Ringstrasse 11, 89081 Ulm, Germany. Phone +49 731/9 62 89-0, Fax +49<br />

731/96289-30<br />

The next issue will be published in the spring of 2001.<br />

The publisher assumes no responsibility for voluntarily submitted texts and<br />

photographs. Printed on paper bleached without the use of chlorine.<br />

P U B L I S H E R ’ S D A T A<br />

Editorial<br />

A new quality of cooperation 3<br />

The new Unimog Generation<br />

U nimog International<br />

Premiere in Austria 11<br />

Convincing technical superiority 12-13<br />

Sales organisation<br />

Ideal vehicle logistics with special trailers 14-16<br />

UNISCOPE<br />

Printed in the Federal Republic of Germany<br />

WWW<br />

UNIMOG HOMEPAGE:<br />

www.mercedes-benz.com/d/ecars/<strong>unimog</strong>/default.htm<br />

Cover photographs<br />

The local authorities in the<br />

Eger district operates the<br />

Unimog, and the<br />

management appreciates<br />

its technical superiority<br />

most of all<br />

Company stamp<br />

The 58th IAA Commercial<br />

Vehicle Exhibition in Frankfurt<br />

am Main is the stage<br />

for the first appearance of<br />

the Unimog U 500, which<br />

can pull trailer loads of over<br />

24 tonnes with ease<br />

High volumes of transport and chronic<br />

lack of space at the bus factory in Mannheim<br />

are no problem for the Unimog.<br />

It is a convincing towing vehicle thanks<br />

to its manoeuvrability and power<br />

The State Highways<br />

Institute in Saxony has<br />

been testing a U 400.<br />

Conclusion: this newgeneration<br />

vehicle withstood<br />

its baptism of fire

The Unimog-System-Partnership:<br />

A new quality of cooperation<br />

Dear reader,<br />

In the last edition of the UNIMOG JOUR-<br />

NAL we described the main aspects of<br />

Unimog-System-Partnership in connection<br />

with the report on our official launch event<br />

for the new Unimog generation in Mainz.<br />

I would like to take the opportunity here to<br />

present in more detail the aims and general<br />

conditions of this new quality of cooperation<br />

with regional or international implement<br />

manufacturers.<br />

Some of you may quite rightly object:<br />

implement partnership at Unimog — this<br />

is nothing new! DaimlerChrysler AG s<br />

Unimog Division has maintained close<br />

cooperation with selected implement<br />

manufacturers throughout the world for<br />

many years. We have actively utilized or<br />

implemented the knowledge gained in<br />

almost half a century in developing the<br />

new U 300 - U 500 equipment carriers.<br />

The end product was and is a sign that<br />

the direction/design of the Unimog implement<br />

strategy has changed, and now<br />

pursues the following core objectives:<br />

•To fulfil customer requirements as<br />

effectively as possible<br />

•The vehicle plus implement<br />

must prove its efficiency<br />

in operation and<br />

permit quick implement<br />

changeovers<br />

and last but not least<br />

•A major improvement in<br />

the cost/performance<br />

ratio of the vehicle plus<br />

implement system.<br />

You may realise from these specifications<br />

that we set a very high standard for<br />

ourselves. How could these aims best be<br />

achieved?<br />

A major success factor here was the fact<br />

that we developed and tested the vehicle<br />

and its implement from the very outset in<br />

close cooperation with our implement System-Partners,<br />

in order to match the drive<br />

concepts and interfaces perfectly together.<br />

Some of the experts discussion groups<br />

lasted well into the night! But the effort<br />

was worth it. Numerous innovative systems<br />

have resulted or are in the offing, to the<br />

advantage of the customer and with major<br />

improvements in their cost-performance<br />

ratio compared with previous solutions.<br />

You can identify this innovation in our<br />

system partners communications documents<br />

by the logo illustrated here, which<br />

at the same time confirms acceptance of<br />

the implement system for the new U 300 -<br />

U 500.<br />

The new quality of cooperation with regional<br />

or international operating equipment<br />

manufacturers is being vouched for<br />

and promoted by further sales activities:<br />

¥ Mutual presence at specialist trade<br />

fairs, demonstrations and special events<br />

(see our article on pages 4/5)<br />

•Joint presentation of the vehicle plus<br />

implement system under the Unimog-<br />

System-Partner quality seal<br />

•Regular co-ordination when producing<br />

communication media<br />

Editorial<br />

Hans-Jürgen Wischhof: “Close cooperation<br />

with our implement System-Partners is a<br />

major success factor for the new Unimog<br />

generation.”<br />

•Co-ordinated support and service<br />

•Joint training programs<br />

and above all<br />

•Availability of the Unimog plus implement<br />

system from a single source<br />

through our Unimog sales organization.<br />

As you can see, the new Unimog-System-Partnership<br />

represents a central element<br />

in our future marketing. A unique<br />

alliance to your advantage as our valued<br />

Unimog customers.<br />

Yours truly,<br />

Hans-Jürgen Wischhof<br />

UNIMOG<br />

JOURNAL<br />

3

The Unimog Division<br />

exhibition at the<br />

International Specialist Trade<br />

Fair for Recycling and<br />

Disposal (ENTSORGA), held<br />

in June in Cologne, Germany<br />

Unimog-System-Partnerships agreed<br />

In Hall 14.2 at the exhibition the new<br />

Unimog U 300/U 400 model lines with<br />

system solutions for mowing, cleaning<br />

and winter services were on display. The<br />

new product range is enduring proof from<br />

<strong>Mercedes</strong>-<strong>Benz</strong> that the Unimog represents<br />

an efficient operating system throughout<br />

the year for towns and cities, road and<br />

motorway maintenance departments and<br />

private companies. Three of the new-gen-<br />

➀ ➁ ➂<br />

eration Unimog equipment carriers were<br />

shown in exemplary fashion at the<br />

ENTSORGA: a Unimog U 300 with a Mulag-<br />

Schmidt HSK 1200 hedge clipping head on<br />

the SB 500 boom, with which Product<br />

Manager Erich Rid demonstrated live to<br />

numerous specialist visitors the technical<br />

innovations and subtleties; a Unimog U 400<br />

with Faun AK 451 attachable sweeper and<br />

a Unimog U 400 with VECTOR MS 33<br />

There was a large<br />

crowd of visitors<br />

to the <strong>Mercedes</strong>-<br />

<strong>Benz</strong> stand at the<br />

International<br />

Specialist Trade<br />

Fair ENTSORGA in<br />

Cologne<br />

snowplough and STRATOS B27-21 silo<br />

spreading device from Schmidt Winterdienst<br />

und Kommunaltechnik.<br />

All these combinations were developed<br />

and tested together with these Unimog-<br />

System-Partners. And the divisional managers<br />

used the trade fair platform to officially<br />

seal other partnerships. At a joint event,<br />

Hans-Jürgen Wischhof, Head of the Unimog<br />

Product Division, and Sales Director Winfried<br />

Blum handed over the certificates for<br />

the implement System-Partnership. At the<br />

meeting, which took place in an informal<br />

atmosphere, Joachim Oechsner, Managing<br />

Director of Schmidt Winterdienst- und<br />

Kommunaltechnik GmbH and Managing<br />

Director Michael Leistikow of Joachim<br />

Leistikow GmbH signed the relevant contracts.<br />

Michael Häusermann, Managing<br />

Director of the Automotive Division of<br />

Bucher-Industries AG, and the Managing<br />

Director of Faun Umwelttechnik GmbH

Advertisement<br />

➍<br />

& Co., Dr. Armin Vogel, strengthened future<br />

cooperation with their signatures. All of<br />

those present were in agreement with<br />

Hans-Jürgen Wischhof that the Unimog-<br />

System-Partnership , which we introduced<br />

you to briefly in the last edition of UNIMOG<br />

JOURNAL, represents a new quality in over<br />

fifty years of cooperation with leading implement<br />

manufacturers at home and abroad.<br />

This will be of valuable assistance to you,<br />

our customers, in the choice of practical<br />

1 Winfried Blum (left) and Hans-Jürgen<br />

Wischhof (2nd from right) with the General<br />

Managers of Faun Umwelttechnik<br />

GmbH & Co., Dr. Armin Vogel (2nd from<br />

left) and Dr. Johannes F. Kirchhoff<br />

2 Hans-Jürgen Wischhof with company<br />

founder Joachim Leistikow (right) and<br />

Managing Director Michael Leistikow<br />

3 Hans-Jürgen Wischhof with Michael<br />

Häusermann, Managing Director of the<br />

Automotive Division of Bucher-<br />

Industries AG<br />

4 Left to right: Winfried Blum, Joachim<br />

Oechsner, Managing Director of Schmidt<br />

Winterdienst und Kommunaltechnik<br />

GmbH, Hans-Jürgen Wischhof and<br />

Schmidt’s Sales Manager Klaus Drescher<br />

system solutions and also of financial significance,<br />

since a much-improved cost/<br />

performance ratio for the combination of<br />

Unimog plus implement can be achieved<br />

through this close cooperation.<br />

The four companies that received these<br />

certificates in Cologne all have many years<br />

of experience in the field of local-authority<br />

utility technology. For example, Schmidt<br />

Winterdienst und Kommunaltechnik with<br />

its head offices in St. Blasien, manufactures<br />

The new Unimog generation<br />

add-on implements for both winter and<br />

summer requirements. Leistikow GmbH,<br />

based in Niederdorfelden in the Federal<br />

German State of Hesse, has been working<br />

together with the Unimog Division for<br />

many years now and specializes in highpressure<br />

cleaning technology. Lower<br />

Saxony s Bucher-Schörling GmbH, manufacturer<br />

of interchangeable roadsweeping<br />

machines and Faun Umwelttechnik GmbH<br />

& Co., a manufacturer of refuse disposal<br />

vehicles and roadsweeping machines based<br />

in Lower Saxony s Osterholz-Scharmbeck,<br />

are both new partners.<br />

UNIMOG<br />

JOURNAL<br />

5

U500<br />

The 58th IAA Commercial Vehicle Exhibition in Frankfurt am Main was the platform for the<br />

first public appearance of the Unimog U 500. In contrast to the Unimog U 300 and U 400,<br />

which were introduced in the spring, this implement carrier with up to 280 horsepower on<br />

tap and a gross weight limit of 16 tonnes is, thanks to its operating profile, also a versatile<br />

specialist when the need arises.<br />

The European market for implement<br />

carriers is a hard-fought battleground.<br />

For success here one needs<br />

products that comply with the customers<br />

demand for a major improvement in the<br />

cost/performance ratio. For this reason<br />

the new, big U 500 also offers interesting<br />

technical solutions such as a Telligent<br />

gear shift or powerful Euro 3 standard sixcylinder<br />

engines from the 906 model line.<br />

On top of this it has a comprehensive<br />

standard package with no fewer than 83<br />

features extending from storage facilities<br />

and lockers to additional side turn-indicator<br />

repeaters.<br />

Advantages compared with trucks<br />

The question as to what operating purposes<br />

a Unimog of this size (230 to 280<br />

horsepower and 16 tonnes gross weight<br />

limit) can fulfil that a medium-size allwheel<br />

drive truck could not carry out<br />

satisfactorily was naturally asked within<br />

the DaimlerChrysler Group, the largest<br />

commercial vehicle manufacturer in the<br />

world, but is, however, quickly answered.<br />

The successor to the heavy Unimog<br />

U2100 to 2450 model line is a highly versatile<br />

implement carrier for municipal<br />

6 UNIMOG<br />

JOURNAL<br />

U 500 – a new performance class<br />

services, trade and industry and the construction<br />

and energy-supply industries. It<br />

has conceptual advantages compared with<br />

its truck competitors, which can largely be<br />

explained in the following points:<br />

— integrated implement carrier/tractor<br />

— optimal drive and attachment facilities<br />

— high torque and pulling power with the<br />

Unimog 4x4 driveline concept<br />

— high pulling power for winter clearing<br />

— mechanical power take-off shaft at the<br />

front with 150 kW power output<br />

— 20 to 30 percent more front-axle load<br />

available than a comparable truck<br />

— semi-forward control design permits a<br />

very good view of the appliances and<br />

attachments.<br />

Developed for multi-purpose operations<br />

The new Unimog U 300 - U 500 models<br />

have been developed for multi-purpose<br />

operations. The U 500 on the other hand,<br />

is a new vehicle dimension with regard to<br />

its power and strength in heavy duty<br />

operations. This can be seen from the snow<br />

clearing work carried out by road and<br />

motorway maintenance departments,<br />

which use heavy equipment with high grit<br />

and road salt carrying volumes on a daily<br />

basis. But even with an add-on road<br />

sweeper with a body of up to 6 cubic metres<br />

in volume, the U 500 is in a new performance<br />

category.<br />

Heavy loads are no problem<br />

Compact and manoeuvrable tractors<br />

for heavy duty transport work are a special<br />

type of commercial vehicle that is<br />

constantly in demand in the industry. The<br />

U 500 with its immense pulling power<br />

has no problems here and the standard<br />

all-wheel drive and differential locks are<br />

significant plus points. In addition, the<br />

short tractor is ideal for the movement of<br />

extra-long material.<br />

In the construction and energy industries,<br />

the requirements are above all for<br />

heavy implement operation, frequently in<br />

off-road environments or confined areas.<br />

The U 500 s compact dimensions and its<br />

high payload of up to 9 tonnes are for instance<br />

ideal when erecting mobile cranes<br />

with load capacities of up to 40 tm. Trailer<br />

loads of over 24 tonnes are also no<br />

problem for this new-generation vehicle.

The new Unimog model<br />

lines also prove their worth<br />

in agriculture.<br />

The Unimog Division<br />

demonstrated this at the<br />

DLG open-air event near<br />

Magdeburg<br />

Rottmersleben from 20th to 22nd June<br />

2000. This location near Magdeburg<br />

was the showground for the Deutsche<br />

Landwirtschafts-Gesellschaft (DLG)’s openair<br />

event on these dates and is an information<br />

platform for trends and the latest developments<br />

in crop cultivation and protection.<br />

The Unimog Division was among the exhibitors<br />

and, as well as the familiar Unimog<br />

all-wheel tractor program, presented with<br />

various implement companies, demonstrated<br />

the new Unimog U 300 for the first<br />

time to almost 18,000 specialist visitors<br />

with a Dammann sprayer attachment.<br />

The response was overwhelming. With<br />

its handling, excellent all-round vision<br />

from the spacious, well-designed driver cab<br />

and the low level of background noise,<br />

the Unimog U 300 with Dammann sprayer<br />

and exemplary linkage control was the star<br />

of the demonstrations.<br />

The Unimog Division displayed various<br />

practical combinations of operating implement<br />

with this supplement to the all-wheel<br />

drive tractor program. <strong>Mercedes</strong>-<strong>Benz</strong><br />

Unimogs are predestined for use in largescale<br />

agricultural operations by reason of<br />

their design as well as their powerful technology<br />

. This is equally true of machine<br />

cooperatives and private companies, who<br />

value the power and the excellent implement<br />

properties just as much as the rapid<br />

deployment from location to location. The<br />

implement carrier from Gaggenau is a<br />

purposeful and above all an economical<br />

alternative.<br />

The Unimog Division<br />

and the Herbert<br />

Dammann company<br />

from Buxtehude-<br />

Hedendorf present<br />

their product range<br />

Star of the<br />

demonstrations<br />

Incereasingly in demand recently are<br />

once again Unimog s universal implement<br />

operating facilities in large-scale agricultural<br />

areas and in operations by the Agro-<br />

Service Associations in the new German<br />

Federal states. There is also demand from<br />

farmers who, as a source of additional<br />

Advertisement<br />

Practical operation before<br />

a large crowd of visitors.<br />

The new Unimog U 300<br />

demonstrated its strengths<br />

for agricultural use most<br />

impressively at this DLG<br />

open-air event<br />

income, accept commissions from the<br />

Ministry of Agriculture, landscape protection<br />

commissions, water authorities or<br />

industrial companies, as well as by private<br />

persons who perform countryside maintenance<br />

or winter road clearing work.<br />

Technology that grabs you!<br />

The Type<br />

M 215<br />

Quick-action<br />

Excavator<br />

Attachment<br />

UNIMOG<br />

JOURNAL<br />

40<br />

7

The baptism of fire<br />

Tests on the edge of the Erzgebirge mountains. Under the<br />

supervision of the Saxon State Highway Construction<br />

Institute, a U 400 with mowing implement was tested by<br />

the Chemnitz Highways Department<br />

The Central Implement Service Section<br />

at the State Institute is responsible<br />

among other things for the<br />

purchasing of all vehicles and implement<br />

and the maintenance and operation of<br />

Federal motorways and Federal and State<br />

roads in the Free State of Saxony. Emphasis<br />

is placed on the testing of new products<br />

as a means of assessment. For this<br />

reason, a U 400 in combination with the<br />

Mulag-Schmidt MHU 800<br />

mowing attachment was<br />

comprehensively tested for<br />

an initial period of six<br />

weeks from May this year<br />

onwards by the highway<br />

maintenance depot in<br />

Gornau on the edge of the<br />

Middle Erz Mountains,<br />

not far from Chemnitz. The<br />

U 400 is very near in its<br />

specification to a tender in-<br />

vitation that a U 1600 would<br />

formerly have fulfilled, but<br />

with major design changes:<br />

• The mowing implements<br />

8 UNIMOG<br />

JOURNAL<br />

The Mulag-Schmidt<br />

mowing attachment is<br />

controlled by a joystick<br />

and keyboard<br />

is no longer driven via the rear power<br />

take-off shaft but via a power hydraulic<br />

system. The rear power take-off shaft is no<br />

longer utilized.<br />

• Thanks to the new transmission design<br />

with Telligent gear shift, a double clutch<br />

is no longer required for operating heavy,<br />

front-driven appliances; the power take-off<br />

shaft is switched on and off electrically,<br />

independent of the clutch.<br />

• The panorama door and the<br />

rotating seat for operating the<br />

mowing implements are not for<br />

retrofitting but can be ordered<br />

ex-works from Gaggenau.<br />

• With the VarioPilot interchangeable<br />

steering it is possible<br />

to control and drive the<br />

Unimog conventionally from<br />

the left or — after a quick<br />

swap — from the right for improved<br />

implement operation.<br />

After a successful invitation<br />

to tender, the Saxon Highways<br />

Administration will buy<br />

seventeen U 400s of almost<br />

the same design. Not all the vehicles will<br />

be equipped with VarioPilot¤, however. In<br />

view of the large number of roads needing<br />

maintenance, the Unimog with two mowing<br />

implements and a two-person crew is<br />

more efficient. The Mulag-Schmidt attachable<br />

mowing implements is matched to the<br />

new Unimog. It has an outreach of 7.3 metres,<br />

CAN bus control and M htronic ,<br />

with which the boom is automatically relieved<br />

of load when meeting obstacles.<br />

As a result, an average working speed of<br />

5 km/h can be reached.<br />

The U 400 also has a hydrostatic drive<br />

which enables very low working speeds,<br />

that can be precisely maintained both in<br />

mowing and in winter road clearing with<br />

a rotary snow blower or snow tiller.<br />

The Saxon State Highways Institute’s<br />

decision to buy the U 400 was not an easy<br />

one, although it has already had a good<br />

deal of experience with the Unimog midrange<br />

and large model lines. Testing the<br />

U 400 also served to define the specifications<br />

for other Unimog vehicles in close<br />

cooperation with Unimog-Agency Henne<br />

Unimog GmbH in Wiedemar and the KLMV<br />

customer service station in Rodewisch.<br />

Result: the new Unimog has passed the<br />

baptism of fire. And the driver is happy as<br />

well with the latest developments!

Advertisement<br />

Roadside grass can be maintained<br />

in a one-man operation; the<br />

U 400’s technology relieves the<br />

driver of a large number of tasks<br />

(above)<br />

Comprehensive tests in road<br />

operations were carried out with<br />

a U 400 all around the town of<br />

Gornau in Saxony (photo left)<br />

The new Unimog generation<br />

The mowing door and the<br />

rotating seat give the operator<br />

an excellent view of<br />

the Mulag mowing attachment<br />

(above)<br />

The mowing unit is supported<br />

directly above the rear<br />

axle to dampen suspension-related<br />

movement<br />

UNIMOG<br />

JOURNAL<br />

9

Advertisements<br />

10 UNIMOG<br />

JOURNAL<br />

E-Mail: <strong>unimog</strong>.ugc@mercedes-benz.de • www.<strong>unimog</strong>-ugc.de

Premiere in Austria<br />

The new Unimog U 300/U 400 model ranges were on<br />

display on 15th and 16th June at the Commercial Vehicle<br />

Center of Georg Pappas Automobil AG in Vienna-Neudorf<br />

There was enormous interest even before<br />

the official presentation: over 600<br />

visitors came to the Commercial Vehicle<br />

Center to gain a first impression of the<br />

Advertisement<br />

Always at maximum<br />

It’s so easy with the CLUTCHMATE<br />

Less strain on the driver, less wear on the machine<br />

• Because it reduces physical strain and protects<br />

knees and backs<br />

• It is ideal when stuck in traffic jams and city traffic<br />

• It works like a “semi-automatic” transmission<br />

• It allows drivers to concentrate more on the traffic<br />

and the job in hand<br />

new Unimog generation, and more than<br />

200 test drives were undertaken. Guests<br />

were welcomed by the owner of the Center,<br />

Magister Georges König, member of the<br />

CLUTCHMATE protects man and machine<br />

• It is quick and easy to fit<br />

• It requires no modifications to existing mechanisms<br />

• It does not affect the licensing of the vehicle in any way<br />

• It has no effect on any mechanical auxiliaries or hydraulics<br />

• It is ideal for use with implements and attachments<br />

• It might even allow a disabled person to be employed<br />

U nimog International<br />

Executive Board of Georg Pappas Automobil<br />

AG, Unimog Sales Director at Daimler-<br />

Chrysler AG, Winfried Blum, and Anton<br />

Bucek, Unimog Sales director in Austria.<br />

In the course of the event there was a<br />

press conference on the new Unimog generation<br />

where specialist Austrian journalists<br />

— after the first presentation in March<br />

at the DaimlerChrysler headquarters in<br />

Stuttgart-Möhringen — were able to obtain<br />

a detailed overview.<br />

As well as numerous customers, such<br />

as the Ministry of Transport, state governments<br />

and lord mayors, a delegation from<br />

Hungary also attended the presentation.<br />

TÜV approved<br />

Have you ever thought about how much strain is put on a Unimog driver’s left knee,<br />

and how often it happens?<br />

Depending on the type of work he might have to press the clutch up to three thousand times a<br />

day.<br />

And because human knees vary in strength and load capacity, serious injuries are always occurring.<br />

Sometimes it means that a driver is off work for a while, but it could even lead to<br />

permanent incapacity.<br />

Why choose CLUTCHMATE?<br />

Supply and installation by Unimog distributors only:<br />

T.C. Systems bv, Schelmseweg 1, 6816 PA Arnhem NL<br />

Tel: +31/2 64 42 23 43 Fax: +31/2 64 45 8136 Automatic coupling<br />

UNIMOG<br />

JOURNAL<br />

11

Convincing technical superiority<br />

If proof were needed that the Unimog is<br />

appreciated at the highways administration<br />

department of the Czech local<br />

authority of Eger in beautiful Bohemia,<br />

the crew of Director Radomil Havrda has<br />

certainly delivered it in a convincing way.<br />

Within a month — October 1999 — the<br />

workshop employees restored and made<br />

operational a U 900, which was left standing<br />

in a corner of the yard in an almost<br />

scrap-like condition.<br />

Today the shiny as-new U 900 complements<br />

the vehicle park of Správa a Údrzba<br />

Silnic Cheb (SUS) — Eger s Highways Administration<br />

and Maintenance Department —<br />

and is being fitted with implements such<br />

as a rotary snow plough and add-on<br />

spreader or Schmidt s road-sign cleaning<br />

unit and roadside mowing system. A total<br />

of six Unimogs are in service, along with a<br />

<strong>Mercedes</strong>-<strong>Benz</strong> SK 1824 and an Atego<br />

1824 with drain cleaning system, which<br />

will be delivered soon.<br />

There are 72 highway administration<br />

departments in the Czech Republic, some<br />

are using Unimogs but none are so well<br />

equipped with them as Eger. This fact is<br />

astonishing and is making some speci-<br />

The <strong>Mercedes</strong>-<strong>Benz</strong> fleet at the Eger<br />

Highways Maintenance department<br />

12 UNIMOG<br />

JOURNAL<br />

alists amongst Radomil Havrda’s colleagues<br />

rather envious. In a country such<br />

as the Czech Republic, where there are<br />

four domestic manufacturers — Tatra, Liaz,<br />

Karosa and Praga, all of whom have made<br />

a name for themselves in the all-wheel<br />

truck sector, it is extremely difficult to<br />

find arguments for premium foreign products<br />

such as the <strong>Mercedes</strong>-<strong>Benz</strong> Unimog<br />

or other truck brands. But for Radomil<br />

Havrda it is simply the technical superiority<br />

of the products from the Black Forest and<br />

the truck factory in W rth in municipal<br />

work and road maintenance that counts .<br />

Even the Department of Transport in<br />

Prague, the highest authority of the highways<br />

administration departments in the<br />

Czech Republic, has accepted Havrda’s<br />

Four-lane motorways, main roads and even<br />

the historical market square in Eger,<br />

the Bohemian town rich in history, are part<br />

of the Unimog U 400’s operating area<br />

Eger<br />

Karlsbad<br />

Marienbad<br />

Prag<br />

Tschechien Tschechien<br />

Budweis<br />

Mährisch-Ostrau<br />

Brünn<br />

opinion in the meantime. We could undoubtedly<br />

save money at first if we bought<br />

a competitor s product , says the Head of<br />

the Highways Administration, but in<br />

terms of performance, payloads and axle<br />

loads, add-on implements, lifespan and<br />

universal applicability we would have to<br />

reinvest several times over the amount we<br />

saved on the purchase in the course of the<br />

vehicle s operating life. The Unimogs are<br />

therefore a convincing argument with<br />

their economical lifecycle costs and it s<br />

really no wonder then that under these<br />

conditions the first new-generation Unimog<br />

U 400 has now been put into service.<br />

At the official handover, Radomil Havrda<br />

remembers that at the beginning of the<br />

Unimog era in Eger one of the fitters remarked<br />

on the sheer versatility of the Unimog.<br />

I was fascinated because I d never<br />

seen anything like it before. Today nothing<br />

can surprise him anymore in this area.<br />

The new Unimog generation offers a<br />

great deal technically and ergonomically<br />

that relieves the driver, but also improves<br />

the vehicle s operational diversity. I was<br />

impressed immediately by this equipment<br />

carrier and its facilities, he explains.<br />

The U 400 in a<br />

historic setting in<br />

Eger, where Albrecht<br />

von Wallenstein was<br />

murdered in 1634<br />

(photo at top)<br />

The oldest U 900<br />

Unimog is 26 years<br />

old, and poses here<br />

with the new U 400<br />

pose as a symbol of<br />

26 years of Unimog<br />

presence in Eger<br />

(centre photo)

Features such as the VarioPilot® steering<br />

and the power hydraulics pay for themselves<br />

very quickly in regular operation.<br />

The U 400 that the Eger Highway Administration<br />

has now put into service is<br />

equipped with the new Schmidt Stratos<br />

spreader, but for year-round use other<br />

attachments will naturally be added too.<br />

The Eger region s road network that<br />

the SUS cares for is 615 kilometres long.<br />

Throughout the year, the most frequently<br />

used appliances are for mowing and winter<br />

road clearing.<br />

In this respect, the often hard winters affect<br />

roads in particular that in some cases<br />

reach altitudes of over 900 metres. The<br />

fact that four border crossings to Germany<br />

(Schirnding, Selb, Waldsassen (Bavaria)<br />

and Sch nberg (Saxony) are part of the<br />

operating area requires constant readiness<br />

in the interests of troublefree cross-border<br />

traffic.<br />

Another unusual aspect is in the fact<br />

that 70 percent of all the roads pass<br />

through water conservation areas (with<br />

Advertisement<br />

Maximilian Prinz von Croy (right), Head of<br />

the Czech Unimog general agency, hands<br />

over the keys to SUS Director Radomil<br />

Havrda (left). In the center is Ing. Ladislav<br />

Vybíral, co-proprietor of the general agency<br />

the famous spa towns of Karlsbad and<br />

Marienbad very near). The Highways<br />

Maintenance Department therefore has to<br />

be very careful with road salt: only the<br />

most modern spreading technology brings<br />

about the desired environmental effect.<br />

U nimog International<br />

HOCH- UND NIEDERDRUCKTECHNIK<br />

FÜR DIE NEUEN UNIMOG-BAUREIHEN<br />

U 300 / U 400<br />

Unser Unimog-Lieferprogramm:<br />

✻ Universal-Hochdruckreinigungsgeräte<br />

für den Front- und Heckanbau<br />

✻ Hochdruckflächenreinigungsgeräte<br />

auch in Kombination mit<br />

Frontanbaukehrmaschinen<br />

✻ Hochdruckkanalspülgeräte zum<br />

Aufbau auf den Pritschenhilfsrahmen<br />

✻ Kombinierte Saug- und Spülbehälter<br />

bis 7.000 l Gesamtvolumen<br />

✻ Kommunale Schlammsaugewagen bis<br />

8.000 l Gesamtvolumen<br />

✻ Wasserbehälter bis 7.000 l<br />

✻ Sonderaufbauten nach Wunsch<br />

(z.B. Niederdruckgeräte, Gießarme,<br />

Heißwassergeräte)<br />

Specialists in the workshop<br />

Every vehicle is only as good as its servicing,<br />

according to an old saying. This is<br />

equally true in the Czech Republic and in<br />

Eger. SUS is a demanding customer, as<br />

Maximilian Prinz von Croy, Head of the Unimog<br />

general agency for the Czech Republic<br />

in Rakovnik near Prague and his partner<br />

Ing. Ladislav Vybíral will confirm. It s<br />

also the reason why the experienced service<br />

team at the general agency take<br />

familiarisation with the new vehicle very<br />

seriously. In Eger they always meet with a<br />

team that is hungry for knowledge and<br />

that understands technical information.<br />

The 35 technicians amongst the total of 115<br />

SUS employees are specialists. This is an<br />

important factor, says Vladislav Holy, Deputy<br />

Head of the Highways Administration:<br />

The Unimog also succeeded with us because<br />

we have a workshop team that cares<br />

for these vehicles extremely well and thus<br />

enhances the Unimog s qualitative<br />

strengths.<br />

Joachim Leistikow GmbH<br />

Altkönigstraße 2<br />

D-61138 Niederdorfelden<br />

Tel. (0) 6101 / 5364-0<br />

Fax. (0) 6101 / 33461<br />

Internet: http://www.leistikow-gmbh.de<br />

E-Mail: Vertrieb@leistikow-gmbh.de<br />

UNIMOG<br />

JOURNAL<br />

13

Sales organisation<br />

14 UNIMOG<br />

JOURNAL<br />

Efficient and perfectly<br />

designed production<br />

processes call for trouble-<br />

free logistics. For this<br />

reason, Unimogs are also in<br />

transport service at the<br />

DaimlerChrysler plants in<br />

Bremen, Mannheim and<br />

Ludwigsfelde. Their unique-<br />

ness is in the special imple-<br />

ment features that are finely<br />

tuned for transport tasks<br />

Ideal logistic vehicles with special trailers<br />

It would be altogether too easy for<br />

DaimlerChrysler production plants to<br />

buy Unimogs simply so this Division<br />

could improve its sales figures! In fact, internal<br />

competition is too tough, since the<br />

<strong>Mercedes</strong>-<strong>Benz</strong> Truck Division can offer a<br />

variety of transport vehicles and hauling<br />

These pictures show two features specific<br />

to the factory’s vehicles. The platform body<br />

(left) has been optimised for a better field<br />

of view when uncoupling and manoeuvring.<br />

The radio data terminal (above) is a module<br />

in the TESS computer transport control<br />

system at the Bremen plant<br />

machines. Quite the opposite: the logistics<br />

managers check the potential applications<br />

scrupulously, for their sectors too are measured<br />

in terms of functionality and efficiency.<br />

The Unimog is very frequently the<br />

ideal logistics vehicle when used with<br />

special trailers. As a model for the many<br />

other Group automobile production facilities,<br />

we present here the internal Unimog<br />

operations at the Bremen, Mannheim and<br />

Ludwigsfelde plants.<br />

Bremen<br />

The transportation in the Logistics and<br />

Communications Department (LVW/TW)<br />

at the Bremen plant operates with a staff of<br />

150 persons in three shifts to ensure an<br />

all-encompassing transportation system.<br />

Bremen is one of the most up-to-date car<br />

plants in the world. 16,000 people work<br />

here on a site with an area of 1,300,000<br />

square metres. The production program<br />

includes the <strong>Mercedes</strong>-<strong>Benz</strong> C Class cars,<br />

the SLK, the CLK and the CLK convertible,<br />

the C Class T models and the fabulous<br />

SL Roadster.

High transport volumes and chronic<br />

lack of space at the bus plant in<br />

Mannheim are no problem for the<br />

Unimog. It is thoroughly at home here<br />

as a tractor due to its manoeuvrability<br />

and power<br />

In view of this extensive program and a<br />

production volume of 1,000 cars a day,<br />

much of the daily transport work that has to<br />

be carried out involves movements from<br />

outside storage facilities to the assembly<br />

supply of engines, removal of empty material,<br />

delivering material to and removing it<br />

from the press shop and the assembly lines<br />

and moving tools and fixtures to where they<br />

are required. Holger Ahrendt, Transport<br />

Manager at the Bremen plant, emphasises<br />

the importance of the 14 Unimogs that are<br />

utilized as tractors: We have excellent results<br />

from all our Unimogs so far. They re<br />

ideal for these short-distance movements<br />

too, and help us to cope when the supply<br />

situation changes. Everything has to<br />

reach the assembly point just in time , so<br />

absolute flexibility is what counts.<br />

Short journeys or not, the Unimogs at<br />

the Bremen plant average 2,600 kilometres<br />

a week. Thanks to the Transport Operating<br />

and Control System (TESS), they perform<br />

45,000 individual transport tasks every<br />

month, a third of these involving towing<br />

work. Holger Ahrendt sums up the importance<br />

of the Unimog for transport tasks at<br />

the Bremen plant in the following unequivocal<br />

terms: The plant logistics continue to<br />

change, and so we have tried to achieve a<br />

practicable mix between the various transport<br />

systems. We shall certainly need the<br />

Unimogs in the future as well, because for<br />

certain types of load handling there s<br />

simply no alternative to these vehicles!<br />

The bodies in white from<br />

the cathodic dip painting<br />

process wait in front of<br />

the omnibus paintshop in<br />

Mannheim for further<br />

processing<br />

Manoeuvrability and<br />

the ability to shunt are<br />

essentials when “parking”<br />

the body in white of a<br />

15 m long, six-wheel<br />

<strong>Mercedes</strong>-<strong>Benz</strong> Citaro<br />

urban bus. The load can be<br />

rolled off without any<br />

problems by the driver<br />

using the hydraulic lift on<br />

the fifth wheel<br />

The “Bremen Unicat”: a<br />

U 2450 mit Zikun heavy<br />

duty semi-trailer is used<br />

to transport press tools<br />

weighing up to 26 tonnes<br />

Mannheim<br />

Sales organisation<br />

At the Mannheim plant, where DaimlerChrysler<br />

buses are traditionally manufactured,<br />

the experts from the General<br />

Engineering department who are responsible<br />

for plant logistics are convinced of<br />

the Unimog‘s advantages. Let‘s hear what<br />

Michael Krügel, Transport Team Manager,<br />

has to say about the U 1400, U 1100 and<br />

U90 models which he operates: They’ re<br />

manoeuvrable and strong. We also need<br />

their four-wheel drive, their power hydraulics<br />

and their high braking power,<br />

UNIMOG<br />

JOURNAL<br />

15

Combined rail-road Unimogs for shunting<br />

rail freight cars, and the combined lift railvehicle<br />

system developed by <strong>Mercedes</strong>-<strong>Benz</strong>,<br />

make sure that all the different components<br />

arrive on the essambly line when needed<br />

because we have loads of up to 17 tons to<br />

shift. The bus bodies-in-white are moved<br />

on special semi-trailers made for us by the<br />

Zikun company. These are designed for rapid<br />

unloading with the aid of the hydraulic<br />

fifth-wheel coupling, which can also be<br />

tilted to one side.<br />

Two-shift production every day means<br />

that up to 100 bus movements are needed.<br />

The buses have to be manoeuvred skilfully<br />

through the narrower parts of the plant s<br />

road system: from the body fabrication<br />

area to the cathodic-dip coating unit, from<br />

the interior fitting zone to the final assembly<br />

line, but also after cathodic dip coating<br />

directly to the rail sidings, because bodyshells<br />

are also delivered to other bus<br />

assembly plants in Ulm/Neu-Ulm, Ligny<br />

(Lorraine) and Samano in Spain.<br />

16 UNIMOG<br />

JOURNAL<br />

The delivery van plant in Ludwigsfelde (top<br />

right) also uses the Unimog as a supply and<br />

removal vehicle. The painted bodies of Vario<br />

delivery vans are brought to the assembly<br />

line in special trailers (above)<br />

This specially designed drawbar (below)<br />

enables the driver to attach and remove<br />

the loaded or empty delivery-van trailers<br />

quickly<br />

Ludwigsfelde<br />

The commercial vehicle plant in Brandenburg<br />

builds the Vario delivery van<br />

range and, starting next year, will also be<br />

manufacturing the new “Vaneo”, a small<br />

city delivery van. Much has changed at<br />

this plant since it was taken over in 1990,<br />

and the tasks now facing it call for numerous<br />

changes in internal logistics.<br />

Dietmar Felgentreu from the Logistics<br />

and Transport department strongly approves<br />

of the Type U 1200, U 1000 and<br />

U 90 Unimogs he has in operation, particularly<br />

because they are normally available<br />

without restriction all the year round. He<br />

explains: There are quite a few gradients<br />

inside our plant, and when the first snow<br />

falls we would have problems and possibly<br />

production delays if it weren t for the<br />

Unimogs. Loading pressings for cathodic<br />

dip paint coating, moving painted bodies to<br />

the assembly area, keeping the production<br />

lines supplied with parts and removing<br />

waste material — it s fair to say that the<br />

Vario, the plant s end-product, depends a<br />

lot on the reliability of the Unimog.

U·N·I·S·C·O·P·E<br />

50 years Unimog<br />

in 2001<br />

It will soon be time to look back — so let s look<br />

ahead first to 2001, when production of the Unimog<br />

in Gaggenau celebrates its 50th anniversary. A<br />

long weekend from June 8 to 10 will be devoted to a<br />

three-day celebration event at the factory in Southwest<br />

Germany s Murg Valley, with a retrospect of<br />

the major successes in half a century s successful<br />

history. This informal survey will be accompanied<br />

by a presentation of the very latest generation of<br />

Unimog models.<br />

For many of those who have formed a lasting<br />

friendship with this eternally young utility vehicle,<br />

DaimlerChrysler AG is organising a long list of<br />

other activities, including a display of historic vehicles<br />

and the popular rally. The production facilities<br />

in Gaggenau will also be opening their doors to<br />

visitors, who will be able to see where not only the<br />

Unimogs themselves but also transmissions, axles<br />

and other vehicle components are produced. The<br />

whole event promises to be a journey back in time<br />

to 1951, and a chance for visitors to see how everything<br />

was done then and how things have changed<br />

since.<br />

See our next issue for further information on<br />

this event — and make a note of the date!<br />

Advertisement<br />

New U 300 for the city<br />

of Gaggenau<br />

Gaggenau is a name that springs to mind immediately in connection<br />

with the Unimog. The town owes much of its reputation as a motor-vehicle<br />

manufacturing centre to this world-famous utility vehicle. With the<br />

local press in attendance, one of the latest models was recently supplied<br />

to the local authorities. Erich Mahler, Unimog Western Sales Region<br />

Manager, recently handed over the U 300 to Mayor Gerrit Grosse and<br />

members of the staff.

Versatility is in demand<br />

The town of Schwarzenberg in the Erzgebirge mountains of Eastern Germany<br />

celebrated its 850th anniversary last August. Activities included a procession in<br />

which a new U 400 took part. The local authorities of the town, which looks after<br />

more than 250 kilometres of roads and tracks around Schwarzenberg, operates a<br />

fleet of Unimogs including a U 1400 with crane bought in 1991, a U 1650 with a<br />

Schmidt SK 340 road sweeper and a U 2150 L that was purchased in 1994 and is<br />

mainly used for transport work. Since the department is also incharge of forestry<br />

activities, another U 1000 is used for work on the forest and woodland path network.<br />

All of these Unimogs are needed in the winter for snow clearing, with a plough<br />

and a salt gritter. Günter Wezel, who has worked for the town authorities in<br />

Schwarzenberg for 31 years, manages this variety of tasks with a staff of 26; he<br />

has identified the advantages of the Unimog system and relies on its strengths<br />

for the work that has to be carried out all the year round.<br />

Unimog Used-vehicle Centre<br />

on the Internet<br />

The new UnimogGebrauchtCenter<br />

(Unimog Used-vehicle Centre) is located in<br />

Martinsrieth in the Harz Mountains region<br />

of Germany. On its Internet page it presents<br />

the various services and Unimog<br />

vehicles for sale, secondhand or<br />

from the rental pool. By calling<br />

the address www.<strong>unimog</strong>-ugc.de<br />

the specifications of a variety of Unimog<br />

bargains can be checked out directly, and<br />

the user can find all of this information he<br />

needs.<br />

U·N·<br />

www.<strong>unimog</strong>-ugc.de

I·S·C·O·P·E<br />

New Unimog book<br />

It s a must for every Unimog fan:<br />

Das Buch vom Unimog , published<br />

in German by the Franckh-Kosmos-<br />

Verlag in Stuttgart and selling at<br />

39.80 Marks. Author Ralf Maile has<br />

compiled a complete Unimog history<br />

from 1946 until the present day. His<br />

book is richly illustrated: 250 photographs<br />

show just about every Unimog<br />

type there has ever been, and also<br />

many different versions of this utility<br />

vehicle, some of them highly exotic<br />

in character.<br />

With full technical details and tables,<br />

the book is also an excellent source of<br />

reference. Commercial-vehicle fans<br />

wont regret making space available<br />

on their bookshelves for Das Buch<br />

vom Unimog .<br />

Rally power with the Unimog<br />

Held again at the end of last June, the<br />

legendary Berlin-Breslau Rally crossed<br />

Germany and Poland in seven daily stages<br />

including some 1,500 difficult kilometres<br />

over land used for exercises by Poland‘ s<br />

military forces. This year again the Hanover<br />

driver Peter Cordey and his navigator<br />

Dirk Petrich were entered for this adventure<br />

trip, with support from Unimog General<br />

Agent C. Wiesner. Among their competitors<br />

were 14 rough-terrain trucks, 80<br />

passenger cars and 70 motorcycles. After<br />

the first few days the Unimog team led the<br />

truck category. Immediately following the<br />

introductory run through an area devoted<br />

to open-cast coal mining, the standard-<br />

50th anniversary of Herold<br />

Established in 1950, the Unimog general agency<br />

Ing. Kurt Herold currently has 28 employees and is<br />

managed by Dieter Herold and his sister Annett Herold-<br />

Behl. Since the firm began to trade, it can proudly claim<br />

to have taken on 74 trainees. Such basic and follow-up<br />

training is regarded by the Herold team as a matter of<br />

course and part of the expert and competent service<br />

that it offers its customers. Herold supplies every<br />

aspect of the service expected of a Unimog general<br />

agency: regular official vehicle inspection dates, for instance,<br />

but also safety checks, work on hydraulic pumps<br />

and systems and a variety of conversion and installation<br />

work. In an emergency, Herold s teams are on call<br />

24 hours a day to assist the customer.<br />

specification U 1300 L confirmed its lead<br />

by climbing an unbelievably steep gradient<br />

that very few of the other entrants could<br />

master. From the third day on, mudholes,<br />

swampland and soft sandy tracks took over.<br />

Wiesner s Unimog team helped a number<br />

of other participants out of the deep pools<br />

of mud and because of this was obliged to<br />

surrender the lead again, but finished nevertheless<br />

sixth in the truck category and<br />

37th overall. Cordey and Petrich collected<br />

a large number of bonus points for fairness<br />

and for their willingness to help others, and<br />

the Unimog itself withstood all this tough<br />

treatment without causing any problems.<br />

For more details, see: www.berlin-breslau.de