please click here for the pdf-version - RECYCLING magazin

please click here for the pdf-version - RECYCLING magazin

please click here for the pdf-version - RECYCLING magazin

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

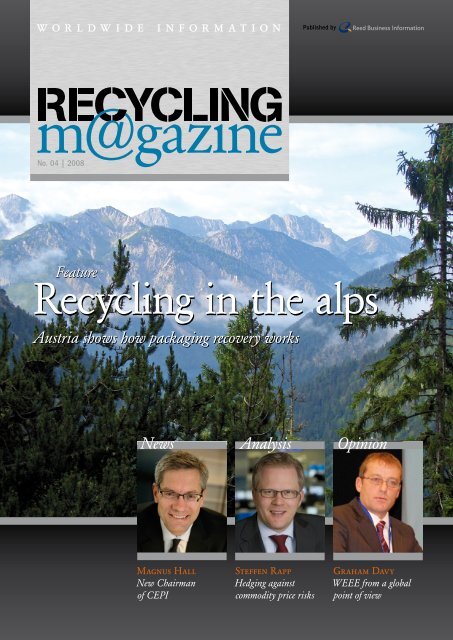

w�������� i����������<br />

No. 04 | 2008<br />

Feature<br />

Recycling in <strong>the</strong> alps<br />

Austria shows how packaging recovery works<br />

News Analysis<br />

M����� H���<br />

New Chairman<br />

of CEPI<br />

S������ R���<br />

Hedging against<br />

commodity price risks<br />

Opinion<br />

G����� D���<br />

WEEE from a global<br />

point of view

Contents<br />

Editorial 3<br />

News 4<br />

Feature | Different ways 8<br />

Analysis | Risks in primary materials 16<br />

Opinion | Graham Davy 20<br />

Market | Survey of <strong>for</strong>ecasts 22<br />

Data | International markets 24<br />

M�������<br />

Publisher:<br />

Reed Business In<strong>for</strong>mation GmbH<br />

Gabrielenstraße 9, D-80636 Munich, Germany<br />

Editor in Chief:<br />

Stephan Peter Krafzik<br />

Ph.: +49 (89) 89817-371; email: spk@rbi.de<br />

Editorial Office:<br />

Walter Henkes (whe)<br />

Ph.: +49 (89) 89817-372; email: whe@rbi.de<br />

Kerstin Bendix (kbe)<br />

Ph.: +49 (89) 89817-374; email: kbe@rbi.de<br />

Andreas Schleinkofer (asc)<br />

Ph.: +49 (89) 89817-373; email: asc@rbi.de<br />

2<br />

Editorial Assistant:<br />

Sabine Hatzfeld (sha, deputising)<br />

Management:<br />

Hans-Jürgen Kuntze, Ph.: +49 (89) 89817-303;<br />

email: hjk@rbi.de<br />

Sales Manager:<br />

Jürgen Pfister, Ph.: +49 (89) 89817-325; email: jp@rbi.de<br />

Advertising Sales / Scheduling:<br />

Christa Manghard (ma)<br />

Ph.: +49 (89) 89817-352<br />

Fax: +49 (89) 89817-350; email: ma@rbi.de<br />

Art Direction: Es<strong>the</strong>r Zillner<br />

Publishing Company Address:<br />

P. O. Box 201663, D-80016 Munich<br />

Ph. +49 (89) 89817-0 (exchange)<br />

Fax: +49 (89) 89817-350<br />

Sole managing partner (100%) of Reed Business In<strong>for</strong>mation<br />

GmbH is Reed Elsevier Deutschland GmbH, Munich, a fullyowned<br />

subsidiary of Reed Elsevier Overseas B.V., Amsterdam<br />

This publication is issued under <strong>the</strong> German Press Law.

Editorial<br />

Cheaper –<br />

even without<br />

competition?<br />

Germany as a pioneer in packaging recycling<br />

Whenever discussion turns to recycling packaging waste,<br />

<strong>the</strong> word Germany often comes up. T<strong>here</strong> was <strong>the</strong> birth-<br />

place of <strong>the</strong> ‘Grüne Punkt’ (Green Dot) in 1990, which<br />

has been adopted by many o<strong>the</strong>r countries in <strong>the</strong> meantime<br />

and is considered <strong>the</strong> hallmark <strong>for</strong> recycling of household<br />

packaging waste. In Germany, packaging recovery is<br />

mainly organised by Duale System Deutschland AG – but<br />

<strong>for</strong> how long is <strong>the</strong> question, as t<strong>here</strong> is now a number of<br />

competitors who are trying to capture shares in <strong>the</strong> market<br />

from DSD.<br />

Comparing German and Austrian systems<br />

The fact that Germany is now experiencing stronger<br />

competition within <strong>the</strong> dual systems is <strong>the</strong> result of appeals<br />

by <strong>the</strong> Federal Cartel Office to create competition- friendly<br />

structures. However, interestingly enough, this increased<br />

competition does not seem to be making a big impression<br />

on disposal costs, at least not in comparison with <strong>the</strong><br />

neighbouring country of Austria.<br />

The CEO of <strong>the</strong> Austrian company ARA AG, Christian<br />

Stiglitz, offers a startling explanation of <strong>the</strong> situation: in a<br />

comparison of both countries, <strong>the</strong> Austrian system comes<br />

off as <strong>the</strong> much more cost-efficient – even though, unlike<br />

Germany, it is not competition-oriented or profit-seeking.<br />

While disposal of a yoghurt carton costs 90 cents in<br />

Germany, in Austria it costs less than half (Euro 0.42). “It<br />

seems that although prices have been reduced over <strong>the</strong><br />

past few years, German systems should still be able to offer<br />

even lower prices to <strong>the</strong>ir customers,” says Stiglitz in his article<br />

<strong>for</strong> Recycling m@gazine. And a fur<strong>the</strong>r point: in Germany,<br />

<strong>the</strong> licence fee <strong>for</strong> disposal is only paid <strong>for</strong> two out of three<br />

pieces of packaging; in Austria, it is at 90 per cent.<br />

Hedging against price risks<br />

A very different topic is <strong>the</strong> issue of how to effectively hedge<br />

against price risks. This particularly affects traders in <strong>the</strong><br />

metals market and material recyclers. Between purchasing<br />

<strong>the</strong> materials and selling <strong>the</strong> recycled products t<strong>here</strong> is often<br />

a period of several months – long enough <strong>for</strong> metal prices<br />

to plummet on <strong>the</strong> stock market. For Recycling m@gazine,<br />

Steffen Rapp of Deutsche Bank analyses hedging options<br />

which offer greater protection against such price risks.<br />

Yours sincerely<br />

Stephan Peter Krafzik<br />

Editor in Chief<br />

spk@rbi.de<br />

3

News<br />

v A new system <strong>for</strong> detection of<br />

banned polybrominated substances<br />

ANNECY | Alcatel Vacuum Technology is introducing a new<br />

technology to confirm <strong>the</strong> absence of polybrominated diphenyl<br />

e<strong>the</strong>rs (PBDE) and polybrominated biphenyls (PBB) in<br />

electrical or electronic products using Ion Attachment Mass<br />

spectrometry (IA-Mass). IA-Mass allows <strong>the</strong> analysis of<br />

samples at a rate that is consistent with a manufacturing<br />

environment. No special lab or highly trained technician is<br />

required <strong>for</strong> IA-Mass. The IA-Mass instrument can be operated<br />

by a regular technician and can take place alongside a<br />

manufacturing line.<br />

The RoHS (Restriction of Hazardous Substances) directive<br />

and its application releases in all European States stipulates<br />

that manufacturers must guarantee that <strong>the</strong>se (PBDE,<br />

PBB) restricted substances are not present in <strong>the</strong>ir products.<br />

The number of samples requiring analysis will reach tens of<br />

thousands each year. Based on AVT, <strong>the</strong> novel IA-Mass method<br />

to check PBB and PBDE in plastics is extremely easy to<br />

use and can obtain co<strong>here</strong>nt results in line with those provided<br />

with GC/MS in a greatly reduced time. z<br />

v Oahu’s Recycling Numbers Down<br />

HONOLULU | Residents of Oahu are recycling and reusing<br />

less waste, fur<strong>the</strong>r burdening <strong>the</strong> Waimanalo Gulch landfill.<br />

State officials say <strong>the</strong> island kept 35 per cent of its waste<br />

out of <strong>the</strong> landfill in fiscal year 2004 and 41 per cent in<br />

2005. But that number dropped to about 31 per cent last<br />

year when <strong>the</strong> island produced nearly 1.8 million tonnes of<br />

solid waste and reused or recycled little more than 500,000<br />

tonnes.<br />

Officials say <strong>the</strong>y are not sure why less waste is being diverted<br />

from <strong>the</strong> landfill, although <strong>the</strong>y add that large construction<br />

or public works projects can push recycling numbers<br />

down because much of <strong>the</strong>ir waste cannot be recycled<br />

or reused. Environmentalists say Oahu residents need to<br />

change <strong>the</strong>ir attitudes about recycling. z<br />

4<br />

v Call <strong>for</strong> urgent action on Ireland’s<br />

waste is too late<br />

DUBLIN | The Irish waste sector has warned that a call from<br />

<strong>the</strong> Environmental Protection Agency (EPA) <strong>for</strong> ‘urgent action’<br />

<strong>for</strong> Ireland to meet its EU 2010 landfill targets could be too<br />

late. A published discussion paper entitled Hitting <strong>the</strong> targets<br />

<strong>for</strong> biodegradable municipal waste: Ten targets <strong>for</strong> change<br />

said that <strong>the</strong> outcome currently being achieved with biodegradable<br />

municipal waste (BMW) is ‘less than satisfactory’.<br />

The EPA’s National Waste Report revealed that 1.4 million<br />

tonnes of BMW were landfilled in 2006. “As recycling rates in<br />

Ireland are now reaching <strong>the</strong> best in Europe — averaging from<br />

40 to 50 per cent — and substantial residual waste remains<br />

to be managed, t<strong>here</strong> is now an inescapable requirement <strong>for</strong><br />

waste to energy to reduce landfill rates to 20 per cent or less<br />

in accordance with nor<strong>the</strong>rn European norms.” Commenting<br />

on <strong>the</strong> EPA report, Green Party environment minister, John<br />

Gormley, said: “This report makes a very welcome contribution<br />

to finding solutions to obstacles in our path.” EPA said<br />

that 92 per cent of BMW was landfilled in 2006 and suggested<br />

ten areas to encourage landfill di<strong>version</strong>. z<br />

v Nucor acquiring DJJ<br />

CINCINNATI | Nucor Corp. has signed a purchase agreement<br />

to acquire <strong>the</strong> stock of SHV North America Corporation,<br />

which owns 100 per cent of <strong>the</strong> David J. Joseph Company<br />

(DJJ), its related affiliates and real estate, <strong>for</strong> around<br />

US-Dollar 1.44 billion. DJJ will be a wholly owned subsidiary<br />

of Nucor Corporation and will maintain its headquarters in<br />

Cincinnati.<br />

DJJ is one of <strong>the</strong> leading U.S. scrap companies. The acquisition<br />

of DJJ will bring a variety of benefits to Nucor. In addition<br />

to DJJ’s scrap operations and expertise, its extensive<br />

brokerage operations provide Nucor with global sourcing of<br />

many key steel-making raw materials. DJJ’s rail services and<br />

logistics capabilities will allow Nucor to leverage <strong>the</strong> largest<br />

private railcar fleet in North America dedicated to scrap<br />

transportation. The addition of DJJ to Nucor’s current scrap<br />

processing capabilities will allow <strong>the</strong> company to process<br />

about four million tonnes of ferrous scrap annually. z

Editorial<br />

v Stena enters <strong>the</strong> Romanian waste<br />

management market<br />

BUCHAREST | The Swedish recycling company Stena has<br />

acquired a majority stake in <strong>the</strong> Romanian company DTM<br />

Waste Recycling SRL. The new name of <strong>the</strong> company after<br />

<strong>the</strong> acquisition is Stena DTM SRL. The main focus of <strong>the</strong><br />

company’s operations will be <strong>the</strong> processing of hazardous<br />

waste and recycling of waste from electrical and electronic<br />

equipment in accordance with <strong>the</strong> European Union’s WEEE<br />

directive.<br />

Stena DTM SRL holds a dominant position in <strong>the</strong> field of<br />

electronics recycling and processing of hazardous waste.<br />

DTM Waste Recycling SRL was set up as late as 2006 and<br />

has rapidly gained <strong>the</strong> respect of its customers by providing<br />

a high and professional quality level of services in waste<br />

management, a fast developing field in <strong>the</strong> Romanian economic<br />

sector.<br />

The new company Stena DTM SRL will have three operating<br />

locations in Romania – Jilava, Ilfov County; Darmanesti,<br />

Bacau County; and Apahida, Cluj County. Its headquarters<br />

will be in Jilava.<br />

The Stena Metall Group is <strong>the</strong> Nordic leader in recycling and<br />

environmental services with operations in 250 locations and<br />

12 countries. For more in<strong>for</strong>mation on Stena Metall Group,<br />

<strong>please</strong> visit www.stenametall.com/English z<br />

v South Africa companies<br />

called to recycle waste<br />

JOHANNESBURG | Collect-a-Can has called <strong>for</strong> companies<br />

to recycle <strong>the</strong>ir waste as a contribution to <strong>the</strong> 2008 Green<br />

Year initiative. The purpose of <strong>the</strong> corporate challenge initiative<br />

is to challenge organisations to embark on a <strong>for</strong>mal<br />

recycling campaign within <strong>the</strong>ir premises. It will involve educating<br />

employees about separating waste at work and home.<br />

“The corporate world can contribute a lot to <strong>the</strong> management<br />

of waste; just think of all those people employed within<br />

large public and private organisations and <strong>the</strong> amount of<br />

waste that is generated daily. The impact on our environment<br />

and landfills will be phenomenal if each of <strong>the</strong>se individuals<br />

recycles <strong>the</strong>ir waste from home and <strong>the</strong> office,” Collect-a-<br />

Can Managing Director Funani Mojono said.<br />

He said waste discharged in <strong>the</strong> environment has negative<br />

impacts, while an integrated waste and environmental management<br />

system curbs <strong>the</strong> quantity of waste discharged<br />

through recycling. Cans are <strong>the</strong> most recycled <strong>for</strong>m of packaging<br />

in Africa, making a major contribution to preserving<br />

<strong>the</strong> natural environment and tourist attractions.<br />

According to figures from <strong>the</strong> Department of Water Affairs<br />

and Forestry, more than 42 million cubic metres of waste is<br />

generated in South Africa every year. The largest proportion,<br />

42 per cent, is generated in Gauteng. z<br />

5

News<br />

v Converted Organics acquires United<br />

Organic Products and Waste Recovery<br />

BOSTON | Converted Organics Inc. (NASDAQ: COIN) has<br />

acquired <strong>the</strong> assets of United Organic Products, LLC of<br />

Gonzales, CA, as well as <strong>the</strong> assets, including <strong>the</strong> intellectual<br />

property, of Waste Recovery Industries, LLC of Paso Robles,<br />

CA. These acquisitions make Converted Organics <strong>the</strong><br />

owner of <strong>the</strong> proprietary technology and process known<br />

as <strong>the</strong> High Temperature Liquid Composting (HTLC) system,<br />

which processes various biodegradable waste products into<br />

liquid and solid organic-based fertiliser and feed products.<br />

Converted Organics has also acquired a leading liquid fertiliser<br />

product line, as well as a state-of-<strong>the</strong>-art production<br />

facility that services a strong West Coast agribusiness customer<br />

base through established distribution channels.<br />

In addition to acquiring assets and technology, Converted<br />

Organics also announced that <strong>the</strong> employees of United<br />

Organic Products, LLC will join Converted Organics. COIN has<br />

also announced an agreement with Rhode Island Resource<br />

Recovery Corporation to build an organic fertiliser facility. z<br />

v ERP celebrates five years<br />

and looks <strong>for</strong>ward<br />

BRUSSELS | The European Recycling Plat<strong>for</strong>m announced<br />

that it has celebrated its five year anniversary — a milestone<br />

in its evolution from an alternative to national compliance<br />

schemes to a leading pan-European provider of WEEE<br />

solutions. ERP can look back with satisfaction on <strong>the</strong> last<br />

five years and is anxious to continue its strong growth trend<br />

in <strong>the</strong> coming years. With over 1,200 members and over<br />

250,000 tonnes of WEEE collected and treated, it is clear<br />

ERP has launched a winning business model. Each of <strong>the</strong><br />

countries w<strong>here</strong> <strong>the</strong>y are directly operational boast impressive<br />

numbers <strong>for</strong> tonnage collected. In Germany, <strong>for</strong> example,<br />

ERP consistently collects over 4,000 tonnes of WEEE each<br />

month. Even operations that are relatively new on <strong>the</strong> market,<br />

such as ERP UK, collect upwards of 3,000 tonnes per<br />

month. ERP’s market share ranges from 10 to 25 per cent in<br />

each country. This growth has been overseen by <strong>the</strong>ir senior<br />

management team, including Umberto Raiteri (CEO), Christophe<br />

Pautrat (COO) and Nicola Magaraggia (CFO). z<br />

6<br />

v New CEPI Chairman:<br />

Magnus Hall, Holmen CEO<br />

BRUSSELS | The Confederation of<br />

European Paper Industries (CEPI) is<br />

<strong>please</strong>d to announce <strong>the</strong> appointment<br />

of Magnus Hall as <strong>the</strong> new CEPI Chairman.<br />

Hall started his chairmanship in <strong>the</strong><br />

beginning of January and will hold <strong>the</strong> post until <strong>the</strong> end of<br />

2009. Frits Beurskens, <strong>for</strong>mer CEPI Chairman, will keep <strong>the</strong><br />

Vice Chairman post <strong>for</strong> <strong>the</strong> next two years to guarantee a<br />

smooth transition.<br />

Hall has been <strong>the</strong> President and CEO of Holmen since April<br />

2004. He holds an MSc degree in Industrial Management and<br />

Engineering from Linköping Institute of Technology in Sweden<br />

and was a Fulbright Scholar at Georgetown University in <strong>the</strong><br />

U.S. in 1985. He has been with Holmen since <strong>the</strong>n and has<br />

previously worked as VP Marketing and Sales and President of<br />

<strong>the</strong> Publication Paper division. He is also Chairman of <strong>the</strong> Forest-Based<br />

Sector Technology Plat<strong>for</strong>m (FTP) and Vice Chairman<br />

of <strong>the</strong> Swedish Forest Industries Federation. z<br />

v Divestment of Metso’s panelboard<br />

business to Dieffenbacher finalised<br />

NASTOLA | Metso has finalised <strong>the</strong> divestment of certain<br />

Metso Panelboard operations to Dieffenbacher GmbH + Co.<br />

KG, Germany. The panelboard business in Nastola, Finland,<br />

and part of <strong>the</strong> MDF business in Sundsvall, Sweden, was<br />

transferred to <strong>the</strong> ownership of Dieffenbacher on 1 February.<br />

The transaction, whose value was not disclosed, does not<br />

have a significant impact on Metso’s net income.<br />

The panelboard operations in Finland with all its 60<br />

employees and in Sweden with its 40 employees have<br />

been transferred to Dieffenbacher GmbH. The refiner-related<br />

operations in Sundsvall, Sweden, will remain in Metso’s<br />

ownership and are not included in <strong>the</strong> transaction. After <strong>the</strong><br />

divestment, <strong>the</strong> panelboard business will not be reported as<br />

a separate business line, but <strong>the</strong> unit will continue to supply<br />

fibre preparation technology to <strong>the</strong> global MDF industry as<br />

part of Metso Paper. Metso is a global engineering and technology<br />

corporation with 2006 net sales of approximately €5<br />

billion. z

Editorial<br />

v BOV environment conference<br />

to focus on waste management<br />

MALTA | Bank of Valletta, in conjunction with <strong>the</strong> Malta<br />

Business Bureau incorporating Malta Federation of Industry,<br />

Malta Chamber of Commerce and Enterprise and Malta<br />

Hotels and Restaurants Association, is organising a conference<br />

entitled “Tackling waste toge<strong>the</strong>r – turning obligations<br />

into an opportunity”. The conference will be held on Wednesday<br />

at <strong>the</strong> San Gorg Corinthia Hotel in St Julian’s. Bringing<br />

toge<strong>the</strong>r a panel of both international and local speakers,<br />

<strong>the</strong> conference will address <strong>the</strong> issue of waste management<br />

and legislation regarding commercial waste. The conference<br />

will also discuss <strong>the</strong> opportunities available <strong>for</strong> reducing <strong>the</strong><br />

financial burden <strong>for</strong> industry, as well as EU funding opportunities.<br />

As such, it is of particular interest to manufacturers<br />

and o<strong>the</strong>r organisations involved in commercial activities.<br />

Participants wishing to attend can apply through BOV’s<br />

Customer Service Centre by e-mail to csc@bov.com, or from<br />

any BOV branch. The price is €35/Lm15. The rate <strong>for</strong> MBB<br />

members and students is €25/Lm10.73 (VAT incl.). z<br />

v International stainless steel course<br />

now available in Korean<br />

BRUSSELS | The course, offered globally by <strong>the</strong> Internation-<br />

al Stainless Steel Forum (ISSF), is a 16-module programme<br />

covering all aspects of stainless steel. Its focus is to improve<br />

<strong>the</strong> knowledge of all individuals and companies who work<br />

with stainless steel. “Increasing knowledge across all levels<br />

of staff ultimately improves productivity <strong>for</strong> companies and<br />

minimises errors,” ISSF Secretary General Staffan Malm said.<br />

Following agreement with <strong>the</strong> Korean Iron and Steel Association<br />

(KOSA), six of <strong>the</strong> modules available via e-learning were<br />

translated into Korean, enabling students to complete an<br />

intermediate certificate in <strong>the</strong>ir local language. The e-learning<br />

approach offers interactive flash presentations with images,<br />

animations and video, almost halving <strong>the</strong> time of study<br />

compared with <strong>the</strong> more traditional methods of study. “The<br />

e-learning delivery method makes <strong>the</strong> learning rich, fast and<br />

exciting,” says Malm. Sung Joon Pak from KOSA expressed<br />

his delight at <strong>the</strong> arrangement and <strong>the</strong> ability <strong>for</strong> students to<br />

enhance <strong>the</strong>ir knowledge of <strong>the</strong> material. z<br />

v Caterpillar ® equipment systems to<br />

be standard in Europe and Turkey<br />

EUROPE | Caterpillar will equip most of its Core, Mining &<br />

Paving machines with EquipmentManager and Product Link<br />

— <strong>the</strong> remote asset management solution by Caterpillar. The<br />

remote tracking and management system will be a standard<br />

feature in <strong>the</strong> European and Turkish markets. Caterpillar<br />

will deliver <strong>the</strong>se capabilities as an integral part of most<br />

core Caterpillar machines. Product Link will be available as<br />

an option <strong>for</strong> Caterpillar machines. Caterpillar will phase in<br />

EquipmentManager / Product Link throughout <strong>the</strong> first quarter<br />

2008, after which Product Link will come as standard<br />

equipment, along with a three-year subscription to Asset<br />

Watch, <strong>the</strong> remote asset management portion of EquipmentManager.<br />

This is a system that provides <strong>the</strong> full depth<br />

of asset management, maintenance and health in<strong>for</strong>mation<br />

required by equipment managers to effectively manage <strong>the</strong>ir<br />

fleets. EquipmentManager is a secure, web-based application<br />

that uses key indicators from equipment such as hours,<br />

location and diagnostic codes. Combined with powerful<br />

tools such as mapping, maintenance scheduling and troubleshooting<br />

instructions, EquipmentManager quickly sorts<br />

through machine data to identify events that require attention<br />

and delivers in<strong>for</strong>mation in a meaningful and actionable<br />

manner. Using satellite technology, Product Link is <strong>the</strong> hardware<br />

that enables in<strong>for</strong>mation flow between on-board systems<br />

and <strong>the</strong> web-based application. The remote management<br />

system provides machine location and hours as well<br />

as time and geo-fencing capabilities. z<br />

USED MACHINES FOR SALE<br />

Eldan HG129 granulator<br />

Year 2000, 90kW without control box<br />

recently renovated € 40.000<br />

Rapid GK 1000<br />

75kW without control box € 15. 000<br />

Well maintained paper<br />

shredder BOA AG 550-100<br />

55kW with control box € 28.000<br />

ARP– ARP scandinavia.com<br />

Telefon: +45 9823 3511<br />

jf@arp-scandinavia.com,<br />

www.arp-scandinavia.com<br />

7

Feature | Separation System<br />

Different ways<br />

Outstanding per<strong>for</strong>mance by Austrian’s packaging recovery system<br />

Since <strong>the</strong>ir foundation, <strong>the</strong> recovery systems in Austria<br />

and Germany developed in parallel and were role models<br />

<strong>for</strong> most recovery systems in o<strong>the</strong>r European countries.<br />

However, a few years ago <strong>the</strong>y began showing diverging<br />

development. While <strong>the</strong> Austrian system <strong>for</strong> <strong>the</strong> most part<br />

is acting <strong>the</strong> same by still following <strong>the</strong> principles of non-<br />

profit, <strong>the</strong> German system has chosen ano<strong>the</strong>r path to fol-<br />

low. Instead of <strong>the</strong> non-profit orientation with sustainable<br />

low prices, a profit-oriented competition of international<br />

waste groups fight <strong>for</strong> customers.<br />

Fur<strong>the</strong>rmore, <strong>the</strong> German government installed a deposit<br />

system <strong>for</strong> disposable beverage packaging in 2003 which<br />

failed completely to reach <strong>the</strong> goal of promoting reusable<br />

packaging. These two major developments led to different<br />

results <strong>for</strong> customers, consumers and <strong>the</strong> environment.<br />

The Austrian Solution<br />

“Since <strong>the</strong> beginning of <strong>the</strong> ARA System close cooperation<br />

with all stakeholders was one of <strong>the</strong> major facts <strong>for</strong> our success,”<br />

says Christian Stiglitz, CEO of <strong>the</strong> Austrian ARA AG.<br />

8<br />

Christian Stiglitz<br />

“For us it was clear that sustainable change of behav-<br />

iour was only possible when all <strong>the</strong> involved groups w<strong>here</strong><br />

willing to contribute <strong>the</strong>ir share. We invested a lot of ef<strong>for</strong>t in<br />

educating trade, industry an municipalities affected by <strong>the</strong><br />

Austrian Packaging Ordinance. we also spent a lot of time<br />

searching <strong>for</strong> strong partners in waste management. Last but<br />

not least <strong>the</strong> consumers needed to recognise <strong>the</strong> purpose<br />

and advantages of separating packaging and to be trained<br />

on how to collect it properly.”<br />

This experience was reached by looking at <strong>the</strong> already<br />

existing collection systems in Germany and France. But this<br />

wasn’t <strong>the</strong> only lesson learned. The Austrian legislators also<br />

not only analysed already existing packaging laws but also<br />

improved some of <strong>the</strong> regulations. For example, <strong>the</strong> Austri-<br />

an packaging ordinance includes regulations <strong>for</strong> household<br />

packaging and commercial and industrial packaging.<br />

Distinctively favourable tariffs in Austria<br />

As a privately run stock company, ARA was founded in 1993<br />

and is owned by Altstoff Recycling Austria Verein – an asso-<br />

ciation that also functions as <strong>the</strong> sole shareholder. Every<br />

company that manufactures, imports or distributes packaged<br />

products can become a member of this association<br />

and participate in <strong>the</strong> decision-making process as ARA coowner.<br />

Only companies belonging to <strong>the</strong> waste management<br />

industry are excluded from membership to avoid conflict of<br />

interest. At <strong>the</strong> moment, some 200 leading companies are<br />

members of <strong>the</strong> association. The mission given to ARA by <strong>the</strong><br />

owners association has remained unchanged since 1993: to<br />

fulfil <strong>the</strong> collection and recycling quotas at <strong>the</strong> lowest possible<br />

sustainable cost to all customers.<br />

This mission was <strong>the</strong> driving <strong>for</strong>ce during <strong>the</strong> first 15 years<br />

and still is and t<strong>here</strong><strong>for</strong>e it is imperative that all possible<br />

optimisations are implemented in collection and recy-

Editorial<br />

Tariff comparison<br />

license <strong>for</strong> <strong>the</strong> disposal of...<br />

Foto: Franz Pfluegl - FOTOLIA<br />

yogurt container<br />

0,90 0.90 0.42 1.23 1.16 0.16 0.13<br />

DSD (Germany) ARA (Austria)<br />

values in € cents, source: DSD, ARA, price basis 2007<br />

plastic bag crayon box<br />

cling. More than 10 years ago, <strong>the</strong> ARA system was <strong>the</strong><br />

first collection and recycling system in Europe who put out<br />

<strong>the</strong>se services to tender – quite some time be<strong>for</strong>e <strong>the</strong> DG<br />

competition made that mandatory. Since <strong>the</strong>n this process<br />

has been repeated continuously and improvements<br />

implemented permanently.<br />

This persistent procedure has resulted in decreasing tariffs<br />

since 1995 – up to 50 per cent. In fact ARA tariffs have<br />

been below <strong>the</strong> German prices <strong>for</strong> quite a long time.<br />

It is amazing <strong>the</strong>n that in spite of competition between 10<br />

dual systems, German tariffs are still considerably above <strong>the</strong><br />

Austrian prices. For instance <strong>the</strong> licence fee <strong>for</strong> a yoghurt<br />

pot costs at <strong>the</strong> German DSD EUR 0.90 per year; at ARA<br />

EUR 0.42. The costs <strong>for</strong> a plastic bag amounted to EUR 1.23<br />

(DSD) and EUR 1.16 (ARA). “It seems that although prices<br />

were reduced in <strong>the</strong> past years, German systems could offer<br />

even lower prices <strong>for</strong> <strong>the</strong>ir customers. But since profit is <strong>the</strong><br />

centre stage <strong>for</strong> <strong>the</strong>ir business, possible reductions are not<br />

passed on in <strong>the</strong>ir entirety. With that kind of business policy,<br />

<strong>the</strong> customers – more precisely German consumers – lose<br />

several hundred millions,” Stiglitz believes.<br />

In contrast to <strong>the</strong> above described situation, ARA system is<br />

acting as a non-profit company. It doesn’t bag surpluses as<br />

profits, but gives it back to <strong>the</strong> supply chain. “We are in debt<br />

to our customers, <strong>the</strong> consumers and <strong>the</strong> environment. Their<br />

interests come first. Compared to that, <strong>the</strong> long standing<br />

In Germany, <strong>the</strong> licencing fees<br />

<strong>for</strong> packaging is consistently<br />

more expensive than Austria.<br />

structure in Germany was broken up bit by bit, <strong>for</strong>ced by a<br />

decision from <strong>the</strong> German Federal Cartel Office. The question<br />

now is: who benefits from this development?” Stiglitz<br />

describes <strong>the</strong> difference between <strong>the</strong> situation in Germany<br />

and Austria.<br />

Impurity quotas in Austria are decreasing<br />

As result of <strong>the</strong> close cooperation with <strong>the</strong> Austrian<br />

municipalities since 1993, <strong>the</strong> ARA system has succeeded<br />

in motivating <strong>the</strong> Austrian citizens to collect packaging<br />

separately and ensures <strong>the</strong> necessary collection quality.<br />

With this cooperation ARA capitalises on <strong>the</strong> confidence that<br />

citizens place in municipal waste management. Because<br />

waste has always been within <strong>the</strong> responsibility threshold of<br />

<strong>the</strong> municipalities, consumers consider <strong>the</strong>m <strong>the</strong> most trusted<br />

and reliable source <strong>for</strong> in<strong>for</strong>mation on this matter. The<br />

communication workload is carried by so called waste-consultants<br />

who are employees of municipalities or communal<br />

waste management associations. With agreed financial<br />

contribution towards <strong>the</strong> personnel costs of <strong>the</strong>se waste-consultants<br />

ARA is able to make use of this valuable and highly<br />

trusted communication channel. As part of a comprehensive<br />

communication strategy, waste consultants in<strong>for</strong>m citizens<br />

in <strong>the</strong>ir specific region while ARA in<strong>for</strong>ms and motivates <strong>the</strong><br />

consumers by running a nationwide campaign. On <strong>the</strong> one<br />

side, this communication strategy ensures that consum-<br />

9

Feature | Separation System<br />

ers get <strong>the</strong> same message from both <strong>the</strong> municipality and<br />

ARA. On <strong>the</strong> o<strong>the</strong>r side, <strong>the</strong> communication is flexible and<br />

regionally adaptable. Because waste consultants work in<br />

small regions <strong>the</strong>y have a detailed knowledge of <strong>the</strong> local<br />

situation. That is why <strong>the</strong>y are able to react fast and accurately.<br />

The advantage of this regional communication becomes<br />

visible especially <strong>for</strong> local changes in <strong>the</strong> collection systems:<br />

without almost any time and in<strong>for</strong>mation loss adjustments<br />

can be communicated correctly to <strong>the</strong> affected inhabitants.<br />

This was proved recently when <strong>the</strong> collection of lightweight<br />

packaging was changed to plastic bottle collection in several<br />

regions in Austria.<br />

This change was made possible because of landfill ordinance<br />

regulations and was realised in coordination with<br />

<strong>the</strong> local communities. It showed outstanding results shortly<br />

after introduction. Not just <strong>the</strong> quantity of <strong>the</strong> collected<br />

plastic bottles could be raised but also <strong>the</strong> quality of <strong>the</strong><br />

collected material has improved incredibly. More than three<br />

million Austrians are using this new collection system and<br />

<strong>the</strong> amount of impurities within <strong>the</strong> yellow bin <strong>for</strong> lightweight<br />

packaging has decreased. The comparative value averages<br />

to 19 per cent throughout Austria. Even <strong>the</strong> collection in <strong>the</strong><br />

federal capital Vienna reached a quota which never seemed<br />

to be achievable in a city of over a million inhabitants – less<br />

than 15 per cent impurities.<br />

In total, <strong>the</strong> Austrians collect about 740,000 tonnes of<br />

packaging per year. The ARA system provides more than 1.2<br />

million collection bins and additionally 1.4 million households<br />

are serviced by door-to-door-collection <strong>for</strong> lightweight<br />

packaging.<br />

In comparison – <strong>the</strong> competitive situation in Germany leads<br />

in <strong>the</strong> opposite direction. Communication measures towards<br />

<strong>the</strong> consumers have ceased almost completely because<br />

none of <strong>the</strong> collection services is willing to spend money<br />

on something that o<strong>the</strong>r competitors benefit from. As a<br />

10<br />

result <strong>the</strong> quota of impurities within <strong>the</strong> collection is rising<br />

dramatically and bins are removed to reduce costs. But<br />

thinning out <strong>the</strong> collection system causes dissatisfied consumers<br />

who are no longer willing to collect packaging properly.<br />

At <strong>the</strong> moment experts estimate <strong>the</strong> impurity quota of<br />

lightweight-packaging amounts between 40 and 65 per<br />

cent.<br />

90 per cent support <strong>the</strong> separate collection<br />

“In Austria we are on <strong>the</strong> right track. Our customers, <strong>the</strong><br />

public authority and <strong>the</strong> waste co-operatives confirm this.<br />

The consumers also approve of <strong>the</strong> system: <strong>the</strong> excellent<br />

collection morale, <strong>the</strong> good collection quality and <strong>the</strong> high<br />

acceptance prove this,” explains Stiglitz and refers to a<br />

recently conducted survey of <strong>the</strong> Austrian Gallup Institute<br />

on behalf of <strong>the</strong> ARA system. Ninety per cent of <strong>the</strong> interviewed<br />

persons said that <strong>the</strong> collection of recyclable materials<br />

makes sense.<br />

Ninety-five per cent collect packaging separately from<br />

residual waste and six out of ten Austrians don’t see any<br />

additional ef<strong>for</strong>t <strong>for</strong> separate collection. Seventy-six per<br />

cent cannot imagine living without separate collection.<br />

Two reasons <strong>for</strong> acceptance are <strong>the</strong> tight net of collection<br />

containers all over <strong>the</strong> country and <strong>the</strong> knowledge of <strong>the</strong><br />

citizens about <strong>the</strong> value of recyclable materials <strong>for</strong> <strong>the</strong> protection<br />

of natural resources: eight out of ten interviewees<br />

underline that <strong>the</strong> clean disposal of recyclable waste is also<br />

important <strong>for</strong> tourism and a positive public sentiment of<br />

Austria.<br />

“It was always very important to us, to explain to people not<br />

only how to collect but also why. Only if citizens like you and<br />

me understand <strong>the</strong> purpose of <strong>the</strong> separate collection, <strong>the</strong>y<br />

are favourable to it,” Stiglitz describes one factor of success<br />

<strong>for</strong> <strong>the</strong> high acceptance of <strong>the</strong> ARA system by Austrian citizens.

Feature | Separation System<br />

Equal terms of competition <strong>for</strong> all companies<br />

As <strong>the</strong> ARA System is obligated to treat its licensees on<br />

equal terms, <strong>the</strong> conditions <strong>for</strong> <strong>the</strong> economy in Austria are<br />

much more balanced. To guarantee fair competition <strong>for</strong> all<br />

affected companies on <strong>the</strong> market, ARA examines and audits<br />

800 customers per year <strong>for</strong> compliance. By means of mar-<br />

keting and sales ARA also succeeds in keeping <strong>the</strong> number<br />

of participating companies – who partake in both collection<br />

and recovery <strong>for</strong> free – on a low level. This so called free rid-<br />

er quota is estimated to be at 10 to 15 per cent in <strong>the</strong> area<br />

of household packaging. Each year about 850 additional<br />

companies sign contracts with ARA. This means a net growth<br />

of <strong>the</strong> total number of clients of about 300 per year. By <strong>the</strong><br />

end of 2007 ARA serviced approximately 15,000 customers.<br />

In Germany large companies get special conditions. Fur<strong>the</strong>rmore<br />

<strong>the</strong> free rider quota is considerably higher. Experts<br />

estimate that only 60 per cent of <strong>the</strong> obligated companies<br />

in Germany contribute to <strong>the</strong> financing of <strong>the</strong> household collection.<br />

They are t<strong>here</strong><strong>for</strong>e under increasing pressure to cut<br />

costs through non-sustainable measures.<br />

ARA secures <strong>the</strong> market <strong>for</strong> small and medium<br />

sized waste management companies<br />

The ARA system has had positive effects on <strong>the</strong> Austrian<br />

economy: it secures some 3,000 jobs in waste management<br />

and allows a multifarious Austrian waste management<br />

industry to thrive. The ARA system closely cooperates with<br />

more than 200 regional waste management companies,<br />

recycling companies and waste management associations<br />

all over Austria, thus establishing a dense network <strong>for</strong> <strong>the</strong><br />

For <strong>the</strong> competing collection systems, citizen<br />

service and sustainability are not <strong>the</strong> decisive<br />

factors in Germany - cost is. That is why<br />

important in<strong>for</strong>mation and motivation <strong>for</strong><br />

consumers to seperate waste has been omitted.<br />

Containers with low fill rate and high litter<br />

polution rate are disposed of in order to save<br />

costs. The results: <strong>the</strong> motivation of citizens<br />

to seperate <strong>the</strong>ir waste disappears and <strong>the</strong><br />

entire waste disposal system falls apart.<br />

12<br />

efficient and cost-effective collection and recovery of packaging<br />

waste.<br />

In Germany <strong>the</strong> market is dominated by a few multinational<br />

waste management groups and most of <strong>the</strong>m hold <strong>the</strong>ir own<br />

collection and recovery system. It is clear that <strong>the</strong>se collection<br />

systems do not put all services to tender but first use<br />

<strong>the</strong> capacity of <strong>the</strong>ir own facilities. As a result, many small<br />

local waste operators have already disappeared and a takeover<br />

wave led to a reduction of <strong>the</strong> number of companies<br />

offering disposal services.<br />

In Austria <strong>the</strong> collection of packaging is working properly.<br />

More than 70 per cent of PET-bottles are recovered and<br />

more than 50 per cent recycled mechanically. This is one of<br />

<strong>the</strong> reasons why a deposit system <strong>for</strong> disposable beverage<br />

packaging as put into <strong>for</strong>ce in Germany was not implemented.<br />

To <strong>the</strong> contrary: <strong>the</strong> Austrian solution to <strong>the</strong> problem was<br />

a voluntary agreement between <strong>the</strong> Ministry of <strong>the</strong> Environment<br />

and <strong>the</strong> beverage industry – instead of a compulsory<br />

measure. The agenda achieved its aims: <strong>for</strong> instance 80<br />

per cent of <strong>the</strong> beverage packaging <strong>for</strong> consumers becomes<br />

Price war instead of citizen service<br />

Quota <strong>for</strong> Austrian/German collection containers (Gelbe Tonne)<br />

40–65%<br />

19%<br />

Germany Austria<br />

Source: ARA, German media reports (e.g. FAZ from 9.8.2006)

Package Recycling<br />

Editorial<br />

30 *<br />

Yearly Costs per Resident<br />

16<br />

Germany Austria<br />

* € 18 licensing cost + € 12 Cost of Operations <strong>for</strong><br />

<strong>the</strong> disposable beverage packaging deposit system<br />

Source: DSD, Deutsche Pfandsysteme GmbH., ARA calculations, price basis 2005<br />

refilled or recycled. The goal <strong>for</strong> disposable PET bottles is to<br />

recycle at least 50 per cent of <strong>the</strong> amount put in <strong>the</strong> market.<br />

Beyond that a yearly increasing amount of PET has to be<br />

recycled <strong>for</strong> <strong>the</strong> production of new PET beverage bottles – a<br />

bottle-to-bottle recycling. To reach <strong>the</strong>se goals <strong>the</strong> collection<br />

of PET bottles had to be increased by <strong>the</strong> ARA system, first<br />

by changing <strong>the</strong> lightweight packaging to a plastic bottle<br />

collection and second by extending <strong>the</strong> collection at events,<br />

public locations and o<strong>the</strong>r special collections on-site.<br />

Bottle-to-bottle recycling <strong>for</strong> Austria<br />

Since August 2007, Austria’s first bottle-to-bottle<br />

recycling plant is in full operation – less than one year<br />

after construction began. The plant is owned and run by<br />

a partnership between five of Austria’s biggest beverage<br />

producers – Coca-Cola Beverages Austria, Radlberger, Rauch,<br />

Spitz and Vöslauer – and provides ecological recycling of<br />

PET bottles in Austria. Its operation is a prerequisite <strong>for</strong><br />

<strong>the</strong> beverage industry to reach <strong>the</strong> goal of <strong>the</strong> Agenda of<br />

Sustainability. At <strong>the</strong> moment 6,000 tonnes of food-grade<br />

recycled PET are produced annually <strong>for</strong> <strong>the</strong> use in new<br />

bottles. With its Agenda of Sustainability, Austria proves that<br />

t<strong>here</strong> are o<strong>the</strong>r and vastly more efficient ways to protect<br />

<strong>the</strong> environment instead of installing a deposit system <strong>for</strong><br />

disposable beverage packaging at enormous costs.<br />

Including <strong>the</strong> cost of operation of <strong>the</strong> disposable<br />

beverage packaging deposit system, <strong>the</strong><br />

German system <strong>for</strong> used pagaging is twice<br />

that of Austria per capita. In Austria, this<br />

deposit system is not in place.<br />

German deposit system failed<br />

To achieve <strong>the</strong> minimum recovery quota requested by<br />

<strong>the</strong> European Community some countries established a<br />

mandatory deposit <strong>for</strong> disposable beverage packaging. A<br />

study of Roland Berger Strategy Consultants proves that a<br />

deposit is not a sustainable and efficient instrument to fulfil<br />

<strong>the</strong> European packaging directive.<br />

In Germany <strong>the</strong> deposit system was installed <strong>for</strong> a different<br />

reason. The goals were to first stabilise <strong>the</strong> refillable<br />

beverage packaging quota and second to minimise <strong>the</strong><br />

littering problem. The deposit system installed in 2003 by<br />

Germany was a very complex and expensive system. The<br />

existing infrastructure of <strong>the</strong> dual recovery systems was<br />

ignored and a new take back material stream established<br />

through retail outlets, shops, gas stations etc. Installing this<br />

system cost EUR 726 million; to run <strong>the</strong> deposit system <strong>the</strong><br />

German economy pays EUR 793 million per year. Taking into<br />

consideration that only 2.7 per cent of <strong>the</strong> packaging quantities<br />

are disposable beverage packaging, <strong>the</strong> costs of <strong>the</strong><br />

deposit system are immense compared to its ecological<br />

benefits. The deposit system is <strong>the</strong>n triple <strong>the</strong> cost of household<br />

collection.<br />

The deposit system missed <strong>the</strong> environmental goal of <strong>the</strong> German<br />

packaging ordinance spectacularly: after a short positive<br />

effect at <strong>the</strong> start of <strong>the</strong> deposit system <strong>the</strong> quota of reusable<br />

packaging declined. Only beer fulfils <strong>the</strong> politically aimed<br />

quota <strong>for</strong> reusable packaging of 80 per cent. The quota <strong>for</strong><br />

refillable non-alcoholic beverages has been almost free fall:<br />

while it was 57.5 per cent be<strong>for</strong>e <strong>the</strong> mandatory deposit in<br />

2003, it is now at an all time low of 29.9 per cent four years<br />

later – with no end in sight. O<strong>the</strong>r goals such as <strong>the</strong> significant<br />

increase of material recovery and litter reduction were<br />

also missed: recovery went up a mere 10 to 15 per cent and<br />

<strong>the</strong> effect on littering was not measurable.<br />

13

Feature | Separation System<br />

“To invest almost EUR 800 million and accept a yearly cost<br />

of ano<strong>the</strong>r EUR 800 million with <strong>the</strong>se results is not justi-<br />

fied! I ask <strong>the</strong> environmental authorities in all EU member<br />

states to look at this failure be<strong>for</strong>e <strong>the</strong>y decide on mandato-<br />

ry deposit systems in <strong>the</strong>ir country,” says Stiglitz.<br />

The study of Roland Berger Strategy Consultants confirms<br />

that Austria is on <strong>the</strong> right track with its Agenda of Sustain-<br />

ability <strong>for</strong> beverage packaging.<br />

Waste reduction as a new goal<br />

For five years now ARA is also obligated to support waste<br />

avoidance and waste reduction activities. One of <strong>the</strong> first<br />

projects in 2003 was <strong>the</strong> financing of a chair <strong>for</strong> resource<br />

management at <strong>the</strong> Technical University of Vienna. One of<br />

<strong>the</strong> goals was to close <strong>the</strong> loop between waste management<br />

and design plus production by creating a knowledge base.<br />

Students should learn how products should be designed<br />

<strong>for</strong> optimised recycling material streams. O<strong>the</strong>r actions<br />

included setting up an initiative to support small and medium<br />

sized enterprises in <strong>the</strong>ir ef<strong>for</strong>t in waste avoidance. This<br />

major project is run in cooperation with <strong>the</strong> City of Vienna,<br />

<strong>the</strong> province of Lower Austria and <strong>the</strong> Austrian Camber of<br />

Commerce. Small and medium sized enterprises can apply<br />

<strong>for</strong> investment grants that are directed towards waste avoidance.<br />

If <strong>the</strong> submitted project fulfils <strong>the</strong> guidelines of this<br />

In Germany, licensing fees <strong>for</strong> disposal<br />

in a dual system (DSD) is<br />

only paid <strong>for</strong> two out of three pieces<br />

of packaging. Two-thirds of <strong>the</strong> company<br />

t<strong>here</strong><strong>for</strong>e carry <strong>the</strong> entire costs<br />

of disposal of packaging through <strong>the</strong><br />

packaging disposal container (Gelbe<br />

Tonne). In Austria, thanks to intensive<br />

cooperation between business,<br />

municipalities and communities<br />

and under <strong>the</strong> supervision of ARA,<br />

90 per cent of <strong>the</strong> amounts disposed<br />

of within <strong>the</strong> packaging life cycle are<br />

licensed with <strong>the</strong> ARA by <strong>the</strong> producers<br />

of <strong>the</strong> waste and in accordance<br />

with <strong>the</strong> rules.<br />

14<br />

initiative, one third of <strong>the</strong> investment cost will be covered.<br />

ARA also is very active in <strong>the</strong> waste management of large<br />

events. Besides setting up an optimised collection system<br />

<strong>for</strong> large events, ARA supports organisers in planning waste<br />

avoidance measures. During <strong>the</strong> event, ARA experts teach<br />

visitors how to avoid waste and how to separate packaging<br />

properly.<br />

Competition in <strong>the</strong> household sector<br />

must not endanger achievements<br />

Recently <strong>the</strong> household packaging sector in Austria was discovered<br />

as a new market by <strong>the</strong> new entrepreneurs in Germany.<br />

Of course ARA will take up this challenge; after all<br />

competition in trade and industrial sectors has exists since<br />

1996 and ARA managed quite well. “T<strong>here</strong> is nothing wrong<br />

with competition – government however must make sure<br />

through appropriate legislation that t<strong>here</strong> is a level playing<br />

field <strong>for</strong> all competitors especially in this sensitive area. It<br />

must also be taken into consideration whe<strong>the</strong>r competition<br />

in <strong>the</strong> household packaging arena endangers <strong>the</strong> national<br />

ecological and economical achievements and benefits created<br />

over <strong>the</strong> years. It must also not decrease <strong>the</strong> flexibility<br />

and improvement potential of <strong>the</strong> collection system. Such<br />

effects that we see in Germany are not desirable ones,” says<br />

Stiglitz. v<br />

Green dot: one-third of payers break off<br />

licensing<br />

fees not paid<br />

licensing<br />

fees paid<br />

Germany Austria<br />

Source: DSD, ARA calculations, proce basis 2005<br />

licensing<br />

fees not paid<br />

licensing<br />

fees paid

Scrap Handling • Recycling • Paper Handling • Industry • Harbours • Timber Handling • Sand and Gravel<br />

Heavy duty<br />

boom system<br />

<strong>for</strong> tough continuous<br />

operation<br />

135 kW Output<br />

27,9 t Operating weight<br />

825 M Material Handling Machine:<br />

long living and stable values<br />

New king-sized com<strong>for</strong>t<br />

cabin with sliding door,<br />

hydraulically elevating<br />

Service-friendly<br />

daily service com<strong>for</strong>table<br />

and fast from <strong>the</strong> ground<br />

Material Handling Machines • Timber Handling Machines • Multihandler<br />

22-225t 23-38,5t 11,5t<br />

www.sennebogen.com 15<br />

SENNEBOGEN Maschinenfabrik GmbH • Hebbelstrasse 30 • 94315 Straubing / Germany • Tel.: +49 (0) 9421/540-146 • e-Mail: greenline@sennebogen.de

Analysis | Primary Materials<br />

Hedging against<br />

commodity price risks<br />

Three Examples of how to react on <strong>the</strong> market situation<br />

The strong movements in commodity prices over <strong>the</strong> past<br />

few years have had a major impact on many companies’<br />

core business and financial results. Within <strong>the</strong> metal<br />

industry, firms involved in processing, as well as produc-<br />

ers and recycling companies, are all feeling <strong>the</strong> repercus-<br />

sions. Mainly due to <strong>the</strong> very high volatility (fluctuation<br />

intensity), results are hard to predict.<br />

Particularly in <strong>the</strong> recycling industry, price movement risks<br />

principally occur between <strong>the</strong> time of purchase and <strong>the</strong> final<br />

sale of recycled commodities. If, <strong>for</strong> example, various scrap<br />

is bought, recycled over <strong>the</strong> next three months into sepa-<br />

rate components, such as copper, nickel, aluminium, molyb-<br />

denum or o<strong>the</strong>r metals, and <strong>the</strong>n sold, t<strong>here</strong> is <strong>the</strong> risk of a<br />

price decrease in <strong>the</strong> market <strong>for</strong> <strong>the</strong> individual components<br />

between <strong>the</strong> purchase date and <strong>the</strong> sale date. Due to <strong>the</strong><br />

high fluctuation intensity, this risk can assume significant<br />

proportions.<br />

The term ‘hedging’ is often mentioned when referring to price<br />

fluctuation risks. But what does hedging actually involve,<br />

particularly in connection with <strong>the</strong> metal processing and<br />

recycling industries?<br />

In this context, hedging against commodity prices is generally<br />

used, and it can be carried out via several strategies.<br />

Some are offered in <strong>the</strong> financial sp<strong>here</strong>, <strong>for</strong> example by<br />

banks. In this case, hedging instruments are involved that<br />

should be seen as generally completely divorced from <strong>the</strong><br />

physical supply of <strong>the</strong> raw material. Similar to strategies <strong>for</strong><br />

interest or currencies, t<strong>here</strong> are many different possibilities<br />

that can be adapted to <strong>the</strong> market opinion and/or <strong>the</strong> individual<br />

situation in a company.<br />

But <strong>the</strong> first step be<strong>for</strong>e <strong>the</strong> various hedging instruments or<br />

possibilities should even be considered is to ascertain <strong>the</strong><br />

16<br />

actual risk position <strong>for</strong> <strong>the</strong> individual commodities used by<br />

<strong>the</strong> company – i.e. <strong>for</strong> what proportion of <strong>the</strong> core business<br />

can risks and/or losses arise in <strong>the</strong> event of negative price<br />

trends, do prices that have dropped during <strong>the</strong> recycling<br />

process have to be passed on to <strong>the</strong> purchaser.<br />

Once <strong>the</strong> way in which <strong>the</strong> company is exposed to a price<br />

fluctuation risk has been established, various hedging<br />

options may be appropriate.<br />

Financial institutions usually offer pure hedging instruments<br />

(derivatives) that do not encompass a physical supply of <strong>the</strong><br />

raw material. When financial derivatives are used to hedge<br />

against price risks, a distinction is made between procure-<br />

ment management and price management.<br />

Advantages: by separating <strong>the</strong> price from <strong>the</strong> procurement<br />

decision, a recycling company’s entire raw material procure-<br />

ment – and later sale – can, <strong>for</strong> example, be made with dif-<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

1 year volatility of various<br />

base values<br />

DAX<br />

DJ Ind. Avrg<br />

British Petroleum<br />

EUR/USD<br />

USD/JPY<br />

IPE Brent<br />

1.0% Fuel Oil<br />

0.2% Gas Oil<br />

Aluminium<br />

Copper<br />

Nickel<br />

Source: Deutsche Bank AG, Global Markets Research

Editorial<br />

Procurement Management Price Management<br />

Delivery date<br />

Delivery quantity<br />

Most favourable contractual conditions<br />

Best daily price<br />

ferent suppliers on a variable price basis and with different<br />

purchasers, and it can be covered by a single hedge with<br />

one calculation price.<br />

Disadvantages: Hedging by means of a ‘financial derivative’<br />

does not guarantee physical supply. T<strong>here</strong><strong>for</strong>e, if <strong>the</strong> core<br />

business – <strong>the</strong> physical supply – is not effected (<strong>for</strong> example,<br />

because <strong>the</strong> supplier cannot provide <strong>the</strong> specified quantity),<br />

but <strong>the</strong> hedge is still in place, it can result in payments –<br />

depending on hedging strategy – even though <strong>the</strong> core business<br />

is not being per<strong>for</strong>med.<br />

As opposed to physical fixed price supply, a negative market<br />

development can lead to a negative financial rating when<br />

using ‘financial’ hedging instruments (financial derivatives),<br />

depending on hedging strategy.<br />

Market conditions<br />

The basis <strong>for</strong> every ‘financial’ hedge is <strong>the</strong> respective <strong>for</strong>ward<br />

rate curve. This tells a commodities buyer what price a hedge<br />

<strong>for</strong> a future date or period of time can be fixed at. This curve<br />

can take different <strong>for</strong>ms. For example, if <strong>the</strong> <strong>for</strong>ward prices<br />

are higher than <strong>the</strong> prices <strong>for</strong> a short-term delivery, e.g. <strong>the</strong><br />

cash price (delivery in two business days), this is known as<br />

a contango. However, if <strong>the</strong> <strong>for</strong>ward prices are lower than <strong>the</strong><br />

spot price, this is referred to as backwardation.<br />

To calculate <strong>the</strong> <strong>for</strong>ward rate curve, several factors are drawn<br />

on, <strong>for</strong> example <strong>the</strong> short-term price (spot price), storage<br />

costs, interest charges, production costs and <strong>the</strong> influence<br />

of <strong>the</strong> wea<strong>the</strong>r.<br />

T<strong>here</strong> are several options to hedge against a price decline:<br />

in this context, it is certainly useful to be familiar with finan-<br />

Fixed price<br />

Price ceiling or price floor<br />

Commodity purchase<br />

Source: Deutsche Bank AG, Global Markets Research<br />

cial price hedging options and to put <strong>the</strong>m into practice, if<br />

required. To this end, t<strong>here</strong> are numerous different strategies<br />

that can be tailored to a company’s individual requirements<br />

or situation. This article intends to examine <strong>the</strong> following<br />

options in more detail.<br />

1. Securing a fixed price via financial futures trading (swap)<br />

2. Securing a ‘minimum price’ by buying a put option with<br />

full participation in rising market prices<br />

3. Securing a fixed price via a floating-floating swap<br />

Example: swap – securing a fixed price<br />

A company wants to secure a fixed price today <strong>for</strong> a later time<br />

period, e.g. <strong>the</strong> second half of 2008, <strong>for</strong> its nickel sales. A contract<br />

based, <strong>for</strong> example, on <strong>the</strong> monthly average rates of <strong>the</strong><br />

London Metal Exchange (LME) nickel cash price quotations<br />

is negotiated with <strong>the</strong> purchaser. Additionally, a swap hedge<br />

is completed with a bank <strong>for</strong> 2009, through which <strong>the</strong> company<br />

receives a fixed price, while in return paying <strong>the</strong> bank <strong>the</strong><br />

monthly average of <strong>the</strong> daily LME nickel cash price quotations.<br />

Overall, <strong>the</strong> variable payment flows cancel each o<strong>the</strong>r out,<br />

leaving just <strong>the</strong> payment flow <strong>for</strong> <strong>the</strong> fixed price and <strong>the</strong><br />

commodity supply.<br />

This means that <strong>the</strong> secured fixed price is completely independent<br />

of <strong>the</strong> material procurement/sale.<br />

Advantage: with a fixed price swap strategy, <strong>the</strong> company is<br />

hedged against falling prices. It does not have to pay a premium.<br />

Disadvantage: <strong>the</strong> company cannot participate in rising<br />

prices; physical supply is not covered by completing a swap.<br />

Objective: securing a fixed calculation basis.<br />

17

Analysis | Primary Materials<br />

In figures, e.g. <strong>for</strong> nickel: cash price US-Dollar 28,000/metric<br />

tonne, <strong>for</strong>ward price <strong>for</strong> <strong>the</strong> second half of 2008 with monthly<br />

settlement is e.g. US-Dollar 28,300/metric tonne and t<strong>here</strong>-<br />

<strong>for</strong>e US-Dollar 300/metric tonne above <strong>the</strong> cash price.<br />

Example: put option<br />

A company has to pass price decreases on to its purchasers,<br />

but can also usually put through rising prices. Hedging<br />

through buying a put option is an alternative <strong>here</strong>. In this<br />

way, <strong>the</strong> company can participate in rising prices in <strong>the</strong> core<br />

business (if this is set up on a variable price basis) and is<br />

still hedged against falling prices.<br />

A put option works in a similar way to a sort of ‘insurance’. A<br />

minimum price, or strike price, is secured. For prices below<br />

<strong>the</strong> strike price, a compensatory payment <strong>for</strong> <strong>the</strong> benefit of<br />

<strong>the</strong> option buyer is made. For prices above <strong>the</strong> strike price,<br />

<strong>the</strong> put option buyer can fully participate in <strong>the</strong> higher prices<br />

in <strong>the</strong> core business. To do this, however, a premium has<br />

to be paid upon purchase of <strong>the</strong> option.<br />

The size of <strong>the</strong> option premium depends in particular on <strong>the</strong><br />

following factors:<br />

- strike price<br />

- duration<br />

- volatility (fluctuation intensity) of <strong>the</strong> commodity<br />

Advantage: hedge against falling prices; full participation in<br />

rising prices.<br />

Disadvantage: high premium costs; physical supply is not<br />

guaranteed by completing a put option.<br />

Objective: securing a fixed calculation basis, participation<br />

in rising prices.<br />

18<br />

variable price<br />

Purchaser Company<br />

commodity fixed price<br />

variable price<br />

Purchaser Company<br />

variable price<br />

poss. compensatory paymt<br />

raw material premium payment<br />

<strong>for</strong> ‘safe chance’<br />

In figures, <strong>for</strong> nickel: cash price per metric tonne = US-Dollar<br />

28,000, Strike price <strong>for</strong> <strong>the</strong> option e.g. US-Dollar 28,000/<br />

metric tonne, premium: US-Dollar 3,200/metric tonne<br />

As many companies cannot easily take <strong>the</strong> hedging costs –<br />

which are very high due to <strong>the</strong> high volatility in commodities,<br />

<strong>for</strong> example – into account in <strong>the</strong>ir calculation, strategies are<br />

often preferred which are defined as ‘somew<strong>here</strong> between’<br />

futures trading and an option. These can be, <strong>for</strong> example,<br />

fluctuation margin strategies or o<strong>the</strong>r structured hedging<br />

strategies.<br />

Example: securing a fixed price<br />

via a floating-floating swap<br />

In one quarter, a recycling company purchases scrap that<br />

has a nickel content of around ten per cent. As <strong>the</strong> nickel<br />

price has a high fluctuation intensity, it is very much a pricesetting<br />

factor <strong>for</strong> <strong>the</strong> purchased scrap. In this example,<br />

<strong>the</strong> process of recycling <strong>the</strong> scrap into almost pure nickel<br />

takes around three months, meaning its sale begins in<br />

<strong>the</strong> subsequent quarter. If <strong>the</strong> nickel price drops in this<br />

subsequent quarter, <strong>the</strong> price decline would have a negative<br />

impact in terms of <strong>the</strong> selling price <strong>for</strong> <strong>the</strong> recycling company.<br />

To avoid this, <strong>the</strong> following transaction can be completed.<br />

A floating-floating swap works in a very similar way to<br />

securing a fixed price as described above. Here, <strong>the</strong> recycling<br />

company hedges itself <strong>for</strong> one quarter against a falling<br />

nickel price. The average price of <strong>the</strong> previous-quarter prices<br />

established on <strong>the</strong> LME is taken as a basis <strong>for</strong> securing <strong>the</strong><br />

price. In this way, securing <strong>the</strong> price <strong>for</strong> <strong>the</strong> sales prices is<br />

more closely linked to <strong>the</strong> purchase prices.<br />

Securing <strong>the</strong> price is completely independent of <strong>the</strong> material<br />

procurement/sale.

Editorial<br />

Advantage: through <strong>the</strong> strategy of securing a fixed price<br />

(swap), <strong>the</strong> company is hedged against failing prices. T<strong>here</strong><br />

are no ‘premium costs’. The hedging price <strong>for</strong> <strong>the</strong> ‘sale’ is<br />

based on <strong>the</strong> prices <strong>for</strong> <strong>the</strong> ‘purchase period’. Due to <strong>the</strong><br />

set-up of <strong>the</strong> <strong>for</strong>ward rate curve (spread), <strong>the</strong> sales price is<br />

higher than <strong>the</strong> purchase price.<br />

Disadvantage: <strong>the</strong> company cannot participate in rising<br />

prices. Physical supply is not covered by securing a fixed<br />

price (swap).<br />

Objective: securing a fixed calculation basis.<br />

In figures, e.g. <strong>for</strong> nickel: spread: US-Dollar 200/metric tonne.<br />

If <strong>the</strong> price is fixed at US-Dollar 28,000/metric tonne in <strong>the</strong><br />

‘purchase quarter’, <strong>the</strong> recycling company is hedged with a<br />

price of US-Dollar 28,200 <strong>for</strong> <strong>the</strong> ‘sales quarter’. The hedging<br />

instruments described <strong>here</strong> are only a small selection of <strong>the</strong><br />

available options. T<strong>here</strong> are both numerous strategies and<br />

numerous commodities that can be considered <strong>for</strong> financial<br />

hedging strategies.<br />

Steffen Rapp<br />

Regarding commodities <strong>for</strong> which t<strong>here</strong> is no direct price<br />

securing option, it is often worthwhile to compare <strong>the</strong><br />

price trends <strong>for</strong> o<strong>the</strong>r commodities that are ‘financially<br />

tradable’with <strong>the</strong> price trend <strong>for</strong> <strong>the</strong> commodity used in <strong>the</strong>ir<br />

own company, and to hedge <strong>the</strong> risks that could arise using<br />

a financial hedging strategy <strong>for</strong> <strong>the</strong> ‘tradable commodity’, if<br />

necessary. v Steffen Rapp, Deutsche Bank<br />

19

Opinion | Graham Davy<br />

Come toge<strong>the</strong>r...<br />

The European Market: one directive, but 27 <strong>version</strong>s of WEEE<br />

Following up on his recent speech given at <strong>the</strong> January<br />

IERC (International Electronic Recycler’s Congress)<br />

conference in Austria, Graham Davy, Global Chief<br />

Executive of Sims Recycling Solutions, takes a look at<br />

global responses to <strong>the</strong> challenge of e-waste. As one of<br />

<strong>the</strong> very few organisations that are capable of viewing ewaste<br />

from a global perspective, Davy is ideally placed to<br />

give his opinion on improving his response to <strong>the</strong> issue.<br />

The European Union (EU) was created to promote <strong>the</strong> free<br />

movement of goods, labour and services but this is not<br />

what is happening with regard to ei<strong>the</strong>r product recycling or<br />

product reuse. Indeed, <strong>the</strong> EU is anything but one market<br />

- while t<strong>here</strong> is one EU directive, t<strong>here</strong> seems to be 27 different<br />

<strong>version</strong>s of Waste Electrical and Electronic Equipment<br />

(WEEE) implementation, as well as <strong>the</strong> same number of<br />

interpretations of <strong>the</strong> ‘permitting’ regulations. Each country<br />

is able to put its own blocks on <strong>the</strong> free movement of WEEE<br />

across country boundaries, which results in difficulties <strong>for</strong><br />

<strong>the</strong> industry and society in achieving sustainable economies<br />

of scale. In addition, transfrontier shipment regulations are<br />

a barrier to <strong>the</strong> trade of WEEE product and add cost into <strong>the</strong><br />

The Austrian translation of WEEE<br />

is different to those on <strong>the</strong><br />

o<strong>the</strong>r side of <strong>the</strong> alps.<br />

20<br />

supply chain. But should t<strong>here</strong> be <strong>the</strong>se barriers between<br />

<strong>the</strong> generally well-developed economies of Europe?<br />

Following implementation of <strong>the</strong> Restriction of use of certain<br />

Hazardous Substances (ROHS) Directive, affected electronics<br />

manufacturers were able to produce one product <strong>for</strong> all 27<br />

countries. However, post-WEEE requires recyclers and <strong>the</strong>ir<br />

customers to have 27 different solutions <strong>for</strong> recovery and<br />

recycling. The result is that European recyclers working on<br />

<strong>the</strong> international stage are placed at a disadvantage.<br />

Complex pictures all over <strong>the</strong> world<br />

Looking at <strong>the</strong> United States t<strong>here</strong> is very little in <strong>the</strong> way of<br />

a unified federal response to e-waste – more like a patchwork<br />

of 50 individual states, w<strong>here</strong> some have e-waste<br />

legislation and o<strong>the</strong>rs don’t. Export controls may be federal<br />

but in practice are often confused with state arrangements<br />

<strong>for</strong> e-waste legislation, while penalties vary hugely. The U.S.<br />