Mining & Mined Caverns - Parsons Brinckerhoff

Mining & Mined Caverns - Parsons Brinckerhoff

Mining & Mined Caverns - Parsons Brinckerhoff

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Mined</strong> <strong>Caverns</strong><br />

APRIL 2012 http://www.pbworld.com/news/publications.aspx<br />

52<br />

Large hydro-electric projects often comprise mined<br />

caverns to house the turbines and generating equipment.<br />

The cavern becomes the powerhouse and must<br />

be linked to the surface by several tunnels, adits and<br />

shafts, depending upon the configuration.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> is currently involved in a<br />

number of hydro-electric projects and has experience in<br />

hydropower caverns from the civil engineering, geotechnical<br />

engineering and mechanical-electrical engineering<br />

perspectives. For the latter, <strong>Parsons</strong> <strong>Brinckerhoff</strong> is<br />

the owner’s engineer for the 1,332 MW capacity Ingula<br />

Pumped Storage project in South Africa, having undertaken<br />

tender stage designs for the mechanical-electrical<br />

components of the scheme, most of which are housed<br />

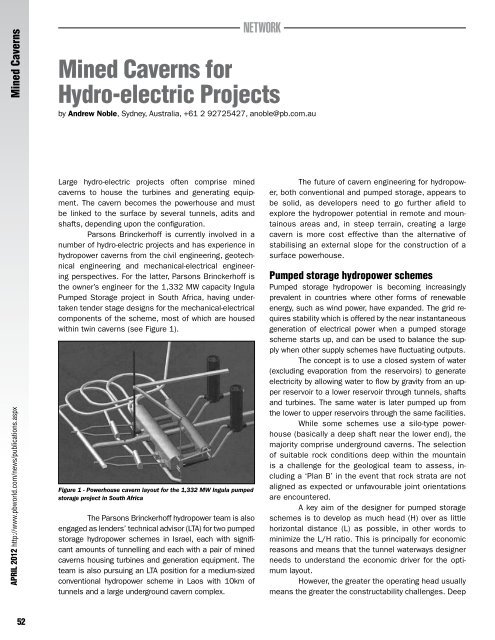

within twin caverns (see Figure 1).<br />

The <strong>Parsons</strong> <strong>Brinckerhoff</strong> hydropower team is also<br />

engaged as lenders’ technical advisor (LTA) for two pumped<br />

storage hydropower schemes in Israel, each with significant<br />

amounts of tunnelling and each with a pair of mined<br />

caverns housing turbines and generation equipment. The<br />

team is also pursuing an LTA position for a medium-sized<br />

conventional hydropower scheme in Laos with 10km of<br />

tunnels and a large underground cavern complex.<br />

Network<br />

<strong>Mined</strong> <strong>Caverns</strong> for<br />

Hydro-electric Projects<br />

by Andrew Noble, Sydney, Australia, +61 2 92725427, anoble@pb.com.au<br />

Figure 1 - Powerhouse cavern layout for the 1,332 MW Ingula pumped<br />

storage project in South Africa<br />

The future of cavern engineering for hydropower,<br />

both conventional and pumped storage, appears to<br />

be solid, as developers need to go further afield to<br />

explore the hydropower potential in remote and mountainous<br />

areas and, in steep terrain, creating a large<br />

cavern is more cost effective than the alternative of<br />

stabilising an external slope for the construction of a<br />

surface powerhouse.<br />

Pumped storage hydropower schemes<br />

Pumped storage hydropower is becoming increasingly<br />

prevalent in countries where other forms of renewable<br />

energy, such as wind power, have expanded. The grid requires<br />

stability which is offered by the near instantaneous<br />

generation of electrical power when a pumped storage<br />

scheme starts up, and can be used to balance the supply<br />

when other supply schemes have fluctuating outputs.<br />

The concept is to use a closed system of water<br />

(excluding evaporation from the reservoirs) to generate<br />

electricity by allowing water to flow by gravity from an upper<br />

reservoir to a lower reservoir through tunnels, shafts<br />

and turbines. The same water is later pumped up from<br />

the lower to upper reservoirs through the same facilities.<br />

While some schemes use a silo-type powerhouse<br />

(basically a deep shaft near the lower end), the<br />

majority comprise underground caverns. The selection<br />

of suitable rock conditions deep within the mountain<br />

is a challenge for the geological team to assess, including<br />

a ‘Plan B’ in the event that rock strata are not<br />

aligned as expected or unfavourable joint orientations<br />

are encountered.<br />

A key aim of the designer for pumped storage<br />

schemes is to develop as much head (H) over as little<br />

horizontal distance (L) as possible, in other words to<br />

minimize the L/H ratio. This is principally for economic<br />

reasons and means that the tunnel waterways designer<br />

needs to understand the economic driver for the optimum<br />

layout.<br />

However, the greater the operating head usually<br />

means the greater the constructability challenges. Deep