Weber Carburator Manual.pdf - Power by BMW E21

Weber Carburator Manual.pdf - Power by BMW E21

Weber Carburator Manual.pdf - Power by BMW E21

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10-14 Part 2 <strong>Weber</strong> carburetors Chapter 10<br />

79 Fit the retalnlrog ring (18 1and Insert 1M screws (171-<br />

80 Align the merb on tl'le thennost.1 1115Mmbly (19) and<br />

nou sing (2 7) fie centre mark). then ti ght en the reta ining screws<br />

(171-<br />

8 1 Press the li miter cap (6 5) onto the idle mixture screw 1661<br />

w ith the extension pointing away from the main body abut ment.<br />

8 CarblJrettor adjUltmenb<br />

W ith the carburettor com plet ely assemb led. the follow ing<br />

adjustments must be made prior to fitting It to the engine;<br />

, Fully open the throttle. hold the choke valves full y open and<br />

release the t hrottle. Turn the t hrottle idlin g adj ustment screw<br />

(62) unt il it Just tOtJches the idle stop lever (56 ). than continue<br />

to Sa'IW it in 1 complete tum.<br />

2 Tum the idling mixture screw (66) in until it is in light<br />

contact wi th its seat, the n back it off 1 co mple te tum.<br />

3 Tum the secoodary throttle adjustment stop (44) unt il a ga p<br />

of 0 .0 5 mm (O.D02 In) exists between the outer edge of m e<br />

seconda ry throttl e val.... end the secondary berr ei. Check the<br />

liiap w it h fee ler gauge s.<br />

Vacuum pull down<br />

4 Fit an elastic band to the choke lever (14) and over the<br />

cover (11 so t hat it hold s the choke valves (3 1 $hut. Open the<br />

throttl e to allow the choke valves to fu lly close .<br />

5 Using a small electric ian's screw driver, push the cc ntect<br />

ring on th e die phragm spin dle unt il the spindle is in firm contact<br />

with the adjustment screw (24 ). Using a drill o r metal dowel,<br />

check that the dis tance between the choke valve straight edges<br />

and the Intake walls 15 as given in the Adjustment data under<br />

maximum vacuum pull down.<br />

6 To check the minimum vacuum pull down, use long nose<br />

plier s to hold the diaphragm spindle in firm contact w ith the<br />

adj ustment screw 1241.but make sure that the modulato r spring<br />

Is compressed fully. Use a dri ll to make the check in the<br />

identical manner to that given in paragraph 5. Note that on<br />

some carburettor types the minim um vecuu m pull down can be<br />

checked <strong>by</strong> inserting a screwdriver t hrough a hole in the<br />

housing 12 7); on oth er models thilS hol e is blanked off.<br />

7 If any of the dimensions checked in paragraphs 5 and 6 are<br />

not correct, the adjustment screw (24) m ust be turned II<br />

nacessary. This w ill necessit ate removing the seal (25) and the<br />

owner must be satisfied thilt no legislation I, being contravened<br />

<strong>by</strong> thi s action .<br />

Choke phasing<br />

8 Open the th rottle then release it ll nd position the fast idle<br />

adju stin g screw (4 7) on the middle ste p of the fast idle cam.<br />

9 Close the choke valves as fer ll S possibl e <strong>by</strong> turning the<br />

choke lever 1141 antI-clock wi se. Usi ng 8 drill. check th at the<br />

distance between the chok e valve straight edges and the inteke<br />

w alls is as given in the Adjustment deta. If nat. carefu lly bend<br />

the short arm on the shaft 115 1 as neeeeserv li e the int ernal<br />

arm).<br />

Dechoke adjustment<br />

10 Open the throttl e and fully close the choke valves <strong>by</strong> turning<br />

the chOke lever (14) ant i-cloc)(wise. Wh ile holding the lever<br />

IT41. fully open the throttle. The distance between the choke<br />

valve str aight edges and t he intake w ellS should be as give n in<br />

the Adjustment dlta when checked with a suitable drill. If not,<br />

bend the choke lever (2 9) as necessary.<br />

F8st idle adjustment<br />

1 1 Open the throttl e and position the fast idle edjusti ng screw<br />

(4 7) on the highest section of the fast idle cern. Us ing II feeler<br />

gauge. check that the dist ance between the prima ry th rottle<br />

valve and the oute r barrel w all is as given In the Adju stment<br />

data. If not. loosen the locknut (48) end t um the adjusting S(:rew<br />

14 7) as necesmlry: tight en the locknut when the adjustment is<br />

complet ed (pho to).<br />

A<br />

_-_ _ 0<br />

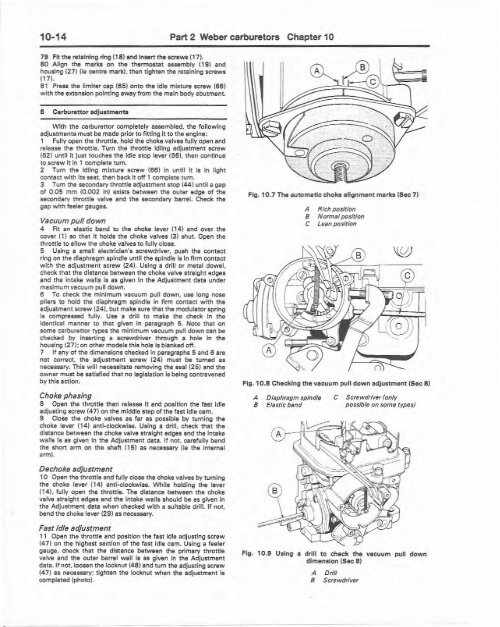

Fig. 10.711M autom.tic ch oke ali gn ment marks (Sec 7 1<br />

A Rich po sition<br />

B Normalposition<br />

C Leim position<br />

Fig, 10.8 Checldng the va cu um pull down adjustment (Sec 81<br />

A Diap hragm spindle<br />

B Elastic btm d<br />

C ScrewdrlvIr (only<br />

possible on some types)<br />

Fig . 10.9 Uaing a drill t o check t he vac uum pull down<br />

dimension (Sec 8 )<br />

A Drill<br />

B Screwdriver