how to use this manual general information - 757.org

how to use this manual general information - 757.org

how to use this manual general information - 757.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IN–18 INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED<br />

SYSTEMS<br />

3. SYMPTOM SIMULATION<br />

The most difficult case in troubleshooting is when there are no problem symp<strong>to</strong>ms occurring. In such cases,<br />

a thorough cus<strong>to</strong>mer problem analysis must be carried out, then simulate the same or similar conditions and<br />

environment in which the problem occurred in the cus<strong>to</strong>mer’s vehicle. No matter <strong>how</strong> much experience a<br />

technician has, or <strong>how</strong> skilled he may be, if he proceeds <strong>to</strong> troubleshoot without confirming the problem<br />

symp<strong>to</strong>ms he will tend <strong>to</strong> overlook something important in the repair operation and make a wrong guess<br />

somewhere, which will only lead <strong>to</strong> a standstill. For example, for a problem which only occurs when the engine<br />

is cold, or for a problem which occurs due <strong>to</strong> vibration ca<strong>use</strong>d by the road during driving, etc., the problem<br />

can never be determined so long as the symp<strong>to</strong>ms are confirmed with the engine hot condition or the<br />

vehicle at a standstill. Since vibration, heat or water penetration (moisture) is likely ca<strong>use</strong> for problem which<br />

is difficult <strong>to</strong> reproduce, the symp<strong>to</strong>m simulation tests introduced here are effective measures in that the external<br />

ca<strong>use</strong>s are applied <strong>to</strong> the vehicle in a s<strong>to</strong>pped condition.<br />

Important Points in the Symp<strong>to</strong>m Simulation Test:<br />

In the symp<strong>to</strong>m simulation test, the problem symp<strong>to</strong>ms should of course be confirmed, but the problem area<br />

or parts must also be found out. To do <strong>this</strong>, narrow down the possible problem circuits according <strong>to</strong> the symp<strong>to</strong>ms<br />

before starting <strong>this</strong> test and connect a tester beforehand. After that, carry out the symp<strong>to</strong>m simulation<br />

test, judging whether the circuit being tested is defective or normal and also confirming the problem symp<strong>to</strong>ms<br />

at the same time. Refer <strong>to</strong> the matrix chart of problem symp<strong>to</strong>ms for each system <strong>to</strong> narrow down the<br />

possible ca<strong>use</strong>s of the symp<strong>to</strong>m.<br />

1<br />

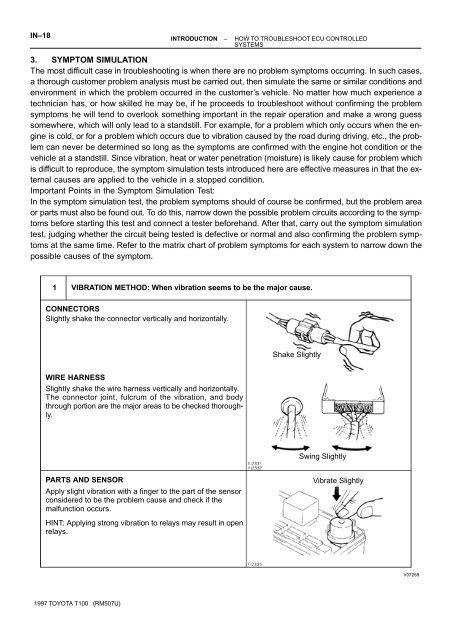

VIBRATION METHOD: When vibration seems <strong>to</strong> be the major ca<strong>use</strong>.<br />

CONNECTORS<br />

Slightly shake the connec<strong>to</strong>r vertically and horizontally.<br />

WIRE HARNESS<br />

Slightly shake the wire harness vertically and horizontally.<br />

The connec<strong>to</strong>r joint, fulcrum of the vibration, and body<br />

through portion are the major areas <strong>to</strong> be checked thoroughly.<br />

PARTS AND SENSOR<br />

Apply slight vibration with a finger <strong>to</strong> the part of the sensor<br />

considered <strong>to</strong> be the problem ca<strong>use</strong> and check if the<br />

malfunction occurs.<br />

HINT: Applying strong vibration <strong>to</strong> relays may result in open<br />

relays.<br />

1997 TOYOTA T100 (RM507U)<br />

Shake Slightly<br />

Swing Slightly<br />

Vibrate Slightly<br />

V07268