Transportation Management Report 2011 - Capgemini

Transportation Management Report 2011 - Capgemini

Transportation Management Report 2011 - Capgemini

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

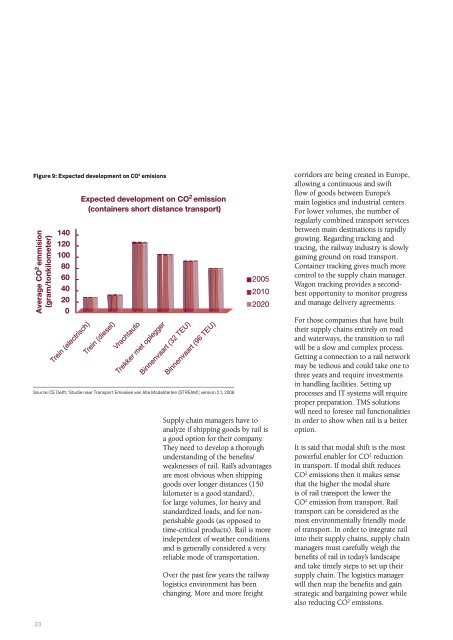

Figure 9: Expected development on CO 2 emisions<br />

Average CO2 emmision<br />

(gram/tonkilometer)<br />

23<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Expected development on CO 2 emission<br />

(containers short distance transport)<br />

Source: CE Delft, ‘Studie naar Transport Emissies van Alle Modaliteiten (STREAM)’, version 2.1, 2008<br />

2005<br />

2010<br />

2020<br />

Supply chain managers have to<br />

analyze if shipping goods by rail is<br />

a good option for their company.<br />

They need to develop a thorough<br />

understanding of the benefits/<br />

weaknesses of rail. Rail’s advantages<br />

are most obvious when shipping<br />

goods over longer distances (150<br />

kilometer is a good standard),<br />

for large volumes, for heavy and<br />

standardized loads, and for nonperishable<br />

goods (as opposed to<br />

time-critical products). Rail is more<br />

independent of weather conditions<br />

and is generally considered a very<br />

reliable mode of transportation.<br />

Over the past few years the railway<br />

logistics environment has been<br />

changing. More and more freight<br />

corridors are being created in Europe,<br />

allowing a continuous and swift<br />

flow of goods between Europe’s<br />

main logistics and industrial centers.<br />

For lower volumes, the number of<br />

regularly combined transport services<br />

between main destinations is rapidly<br />

growing. Regarding tracking and<br />

tracing, the railway industry is slowly<br />

gaining ground on road transport.<br />

Container tracking gives much more<br />

control to the supply chain manager.<br />

Wagon tracking provides a secondbest<br />

opportunity to monitor progress<br />

and manage delivery agreements.<br />

For those companies that have built<br />

their supply chains entirely on road<br />

and waterways, the transition to rail<br />

will be a slow and complex process.<br />

Getting a connection to a rail network<br />

may be tedious and could take one to<br />

three years and require investments<br />

in handling facilities. Setting up<br />

processes and IT systems will require<br />

proper preparation. TMS solutions<br />

will need to foresee rail functionalities<br />

in order to show when rail is a better<br />

option.<br />

It is said that modal shift is the most<br />

powerful enabler for CO 2 reduction<br />

in transport. If modal shift reduces<br />

CO 2 emissions then it makes sense<br />

that the higher the modal share<br />

is of rail transport the lower the<br />

CO 2 emission from transport. Rail<br />

transport can be considered as the<br />

most environmentally friendly mode<br />

of transport. In order to integrate rail<br />

into their supply chains, supply chain<br />

managers must carefully weigh the<br />

benefits of rail in today’s landscape<br />

and take timely steps to set up their<br />

supply chain. The logistics manager<br />

will then reap the benefits and gain<br />

strategic and bargaining power while<br />

also reducing CO 2 emissions.