Creating Shared Value Report - Nestlé Philippines, Inc.

Creating Shared Value Report - Nestlé Philippines, Inc.

Creating Shared Value Report - Nestlé Philippines, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

21<br />

Conserving<br />

Water<br />

Change , %<br />

60.00%<br />

50.00%<br />

40.00%<br />

30.00%<br />

20.00%<br />

10.00%<br />

0.00%<br />

-10.00%<br />

-20.00%<br />

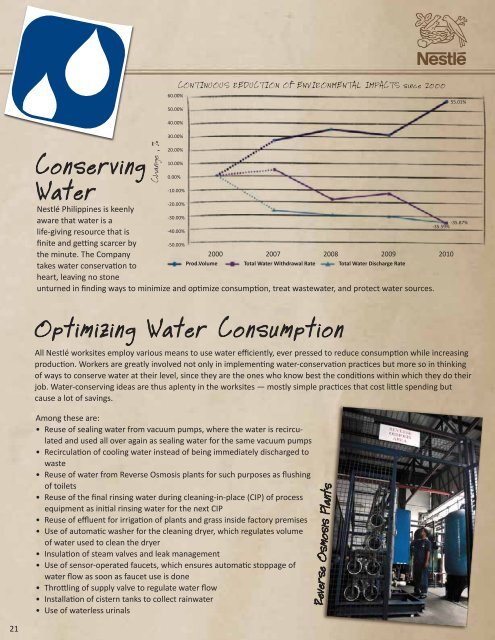

CONTINUOUS REDUCTION OF ENVIRONMENTAL IMPACTS since 2000<br />

<strong>Nestlé</strong> <strong>Philippines</strong> is keenly<br />

aware that water is a<br />

-30.00%<br />

life-giving resource that is<br />

-40.00%<br />

-35.59%<br />

finite and getting scarcer by<br />

-50.00%<br />

the minute. The Company<br />

2000 2007 2008 2009 2010<br />

takes water conservation to<br />

heart, leaving no stone<br />

Prod.Volume Total Water Withdrawal Rate Total Water Discharge Rate<br />

unturned in finding ways to minimize and optimize consumption, treat wastewater, and protect water sources.<br />

Optimizing Water Consumption<br />

All <strong>Nestlé</strong> worksites employ various means to use water efficiently, ever pressed to reduce consumption while increasing<br />

production. Workers are greatly involved not only in implementing water-conservation practices but more so in thinking<br />

of ways to conserve water at their level, since they are the ones who know best the conditions within which they do their<br />

job. Water-conserving ideas are thus aplenty in the worksites — mostly simple practices that cost little spending but<br />

cause a lot of savings.<br />

Among these are:<br />

• Reuse of sealing water from vacuum pumps, where the water is recirculated<br />

and used all over again as sealing water for the same vacuum pumps<br />

• Recirculation of cooling water instead of being immediately discharged to<br />

waste<br />

• Reuse of water from Reverse Osmosis plants for such purposes as flushing<br />

of toilets<br />

• Reuse of the final rinsing water during cleaning-in-place (CIP) of process<br />

equipment as initial rinsing water for the next CIP<br />

• Reuse of effluent for irrigation of plants and grass inside factory premises<br />

• Use of automatic washer for the cleaning dryer, which regulates volume<br />

of water used to clean the dryer<br />

• Insulation of steam valves and leak management<br />

• Use of sensor-operated faucets, which ensures automatic stoppage of<br />

water flow as soon as faucet use is done<br />

• Throttling of supply valve to regulate water flow<br />

• Installation of cistern tanks to collect rainwater<br />

• Use of waterless urinals<br />

Reverse Osmosis Plants<br />

55.01%<br />

-35.87%