GEA E-Tec/P freezers - GEA Food Solutions

GEA E-Tec/P freezers - GEA Food Solutions

GEA E-Tec/P freezers - GEA Food Solutions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

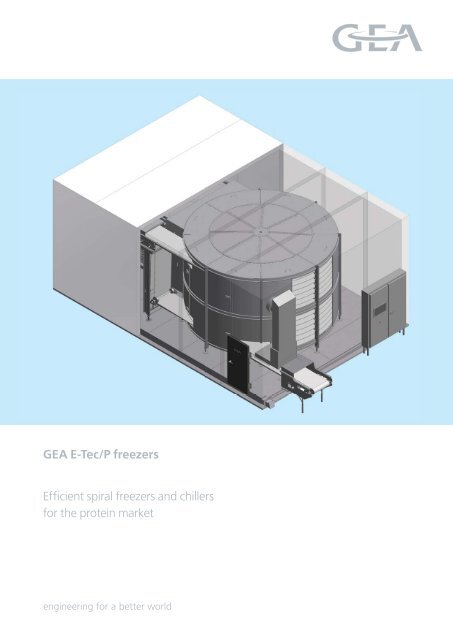

<strong>GEA</strong> E-<strong>Tec</strong>/P <strong>freezers</strong><br />

Effi cient spiral <strong>freezers</strong> and chillers<br />

for the protein market<br />

engineering for a better world

In a market where customer preferences, economic trends and global competition infl uence how<br />

you operate, it is necessary to turn challenges into opportunities. <strong>GEA</strong> performance-focused solu-<br />

tions off er versatility, increased yield and maximum product safety to cost-eff ectively produce ap-<br />

petizing, aff ordable and safe food. <strong>GEA</strong> E-<strong>Tec</strong>/P spiral <strong>freezers</strong> and chillers are fully customized to<br />

your application and designed for high-effi ciency and reliability.<br />

In touch with ...<br />

A freezer to turn challenges into opportunities<br />

Protect and preserve the quality of your products<br />

Once your product is formed, coated and heat-treated, its quality, freshness, appearance<br />

and weight all need to be protected and preserved. Short freezing time, compact footprints,<br />

a choice of confi gurations and a range of handling capacities are what make the <strong>GEA</strong> E-<br />

<strong>Tec</strong>/P range of spiral <strong>freezers</strong> perfect for protein applications. Your products are surrounded<br />

by a horizontal air stream at a consistent temperature. This effi cient freezing process<br />

reduces freezing time as well as energy consumption, contributing to a lower price per kilo.<br />

And it provides most versatility for chilling or freezing products whatever the size, confi g-<br />

uration or loading pattern of your products.<br />

Sized for the future<br />

Ensuring that a freezer meets all these criteria was the most important driver for the de-<br />

velopment team who recently launched <strong>GEA</strong> E-<strong>Tec</strong>/P freezer for protein applications. This<br />

all-new spiral freezer with horizontal air fl ow was jointly developed by <strong>GEA</strong> Refrigeration<br />

<strong>Tec</strong>hnologies and <strong>GEA</strong> <strong>Food</strong> <strong>Solutions</strong> (previously CFS). Both parties have considerable<br />

experience in the <strong>freezers</strong> for a wide range of applications, and since 2010, the two<br />

have been collaborating on the <strong>GEA</strong> E-<strong>Tec</strong>. The result is a new generation spiral freezer<br />

that meets growth and competitive challenges which you face in the coming years.<br />

<strong>GEA</strong> E-<strong>Tec</strong>/P spiral <strong>freezers</strong> and chillers stand for:<br />

• Effi cient freezing by horizontal airfl ow<br />

• Eff ective for every protein application<br />

• Excellent hygiene concept<br />

• Easy to operate and maintain<br />

• Energy savings through effi cient design

Designed for flexibility and performance<br />

Full height horizontal airfl ow<br />

Airfl ow baffl ing and air return<br />

Temperature distribution<br />

The optimal configuration for protein<br />

applications<br />

Horizontal airfl ow for effi cient freezing<br />

Horizontal airfl ow protects and preserves quality, freshness, appearance and weight<br />

of a wide range of protein applications such as chicken fi let, whole chicken, fresh and<br />

processed beef burger, pork products, veggie burgers, salmon, fi sh fi ngers and chilled<br />

pasteurized ready meals. The freezer can be specifi ed with capacities from 200 kilograms<br />

per hour up to 6 tons per hour.<br />

Consistent temperature across all tiers<br />

The <strong>GEA</strong> E-<strong>Tec</strong>/P operates on the Individually Quick Frozen principle (IQF). Each individual<br />

product is evenly surrounded by a horizontal air fl ow at a consistent, controlled<br />

temperature. The temperature diff erential across a tier is only 6°C, and this applies<br />

for all tiers. So the coolest air reaches the warmest products (as they enter the<br />

freezer), and the moisture is more rapidly sealed in. Consequently, horizontal air fl ow<br />

is the best confi guration for protein products, decreasing the freezing times and optimizing<br />

yield. Also opposite to vertical air fl ow technique which force air through the<br />

belt, the maximum belt loading is not restricting the air fl ow, therefore independent<br />

and consistently maintaining freezing eff ectiveness even with high tier no’s of 30 tiers<br />

or higher.<br />

Temperature curve<br />

02 |<br />

03

Designed for flexibility and performance<br />

Features and benefi ts<br />

Designed to meet your process requirements<br />

• Effi cient airfl ow: Full-height, horizontal airfl ow (1) minimizes product yield loss and energy consumption.<br />

Optimal heat transfer through stainless steel tubes and high-effi ciency evaporator with aluminium fi ns (2).<br />

• Optimal hygiene: Stainless steel fl oor and structure (3), airtight drum (4). Insulated enclosure panels clad with<br />

stainless steel or white food safe galvanized sheet (5). CIP options adapted to customer needs.<br />

• Easy to operate: Smart operator interface (6) with in-house operating philosophy to ensure easy operating, learning,<br />

information transfer and data exchange.<br />

• Ease of maintenance: Access to all components through the doors (7), hinged air guiding plates (8) and mezzanine<br />

platform. Direct bottom drive for minimum maintenance.<br />

3<br />

• Energy saving: Effi cient design (9) delivers 5 to 10% energy savings compared to vertical airfl ow solutions.<br />

Products don’t block airfl ow, so lower fan capacity and heat losses. It requires a smaller compressor installation.<br />

Automatic air balance system (10) avoids ice build-up and energy losses to the production room.<br />

The <strong>GEA</strong> E-<strong>Tec</strong>/P freezer off ers the versatility you need for chilling<br />

or freezing of protein products, whatever the size, confi guration<br />

or loading pattern of your products. To meet a wide range<br />

of application and run time between cleaning cycles requirements,<br />

the <strong>GEA</strong> E-<strong>Tec</strong>/P is available in a variety of confi gurations.<br />

The standard in-house evaporator design has a standard fi n spacing<br />

that ensures 16 to 24 hours production time.<br />

2<br />

In-house evaporator design Evaporator with large fi n spacing High belt loading<br />

9<br />

8<br />

7<br />

4<br />

10<br />

1<br />

5<br />

6<br />

Extending the run-time between cleaning<br />

As an option, extended fi n spacing evaporators can be specifi ed<br />

to increase the production time between cleaning cycles to up<br />

to 40 hours. Ultimately, a unique sequential defrost system ensures<br />

continuous production at a high capacity for up to 6 consecutive<br />

days.

In touch with hygiene<br />

Mini-CIP<br />

Product zone-CIP<br />

Full freezer-CIP<br />

Wall mounted stainless steel cabinet<br />

Excellence in hygiene<br />

A choice of Clean-in-Place (CIP) solutions<br />

The <strong>GEA</strong> E-<strong>Tec</strong>/P freezer combines effi ciency with hygiene. The standard freezer is<br />

provided with a fully welded hygienic stainless steel fl oor, stainless steel<br />

construction, a completely closed drum design and many welded constructions. The<br />

available options for Clean-in-Place (CIP) depending on requirements are:<br />

Mini-CIP:<br />

primarily for smaller machines where the cleaning of the interior is largely manual.<br />

Basic 2-zone cleaning system, by means of belt rinse spray bar above and below the<br />

belt on the infeed section combined with a ring of 4 rotary nozzles above the belt stack<br />

to apply foam and provide rinse top – down.<br />

Wall mounted stainless steel cabinet comprising the booster pump, valves and controls<br />

and room for 1 x 20 ltr drum of detergents.<br />

Product zone-CIP:<br />

for larger machines, this option ensures easy cleaning of the product zone.<br />

Semi-automatic 4-zone cleaning system for the product zone only, by means of:<br />

1. Belt rinse spray bar above and below the belt on the infeed section<br />

2. Ring of 4 x rotary nozzles above the belt stack to apply foam and provide<br />

rinse top - down<br />

3. Internal spray bar (rotates with the drum) spraying from inside to out<br />

4. Volumetric spray nozzles in the vertical columns<br />

Wall mounted stainless steel cabinet comprising the booster pump, valves and controls<br />

and room for 2 x 20 ltr drum of detergents / disinfectants. The cleaning sequence can<br />

be adjusted depending on the requirement.<br />

Full freezer-CIP:<br />

for specifi c applications and when automatic assisted cleaning of the entire freezer is<br />

needed. Semi-automatic 6-zone cleaning system for the complete freezer interior,<br />

comprising:<br />

1. Belt rinse spray bar above and below the belt on the infeed section<br />

2. Ring of 4 x rotary nozzles above the belt stack to apply foam and provide<br />

rinse top - down<br />

3. Internal spray bar (rotates with the drum) spraying from inside to out<br />

4. Volumetric spray nozzles in the vertical columns<br />

5. Rotating spray nozzles in the top and bottom walk way area between the<br />

structure and the cabinet enclosure<br />

6. Static spray system in the internal evaporator plenum<br />

Wall mounted stainless steel cabinet comprising the booster pump, valves and controls<br />

and room for 2 x 20 ltr drum of detergents / disinfectants. The cleaning sequence can<br />

be adjusted depending on the requirement.<br />

04 |<br />

05

<strong>GEA</strong> E-<strong>Tec</strong>/P spiral freezer. Typical application data.<br />

<strong>GEA</strong> E-<strong>Tec</strong>/P spiral freezer. <strong>Tec</strong>hnical data. Belt configurations.<br />

Sited built Spiral Freezer<br />

Sited built Spiral Freezer<br />

Straight-through 90° turn 180° turn 270° turn<br />

Package<br />

Freezer<br />

Dimensions Weight E-<strong>Tec</strong>/P E-<strong>Tec</strong>/P E-<strong>Tec</strong>/P E-<strong>Tec</strong>/P<br />

[mm] [g] 400 600 1000 Compact<br />

Poultry<br />

L x W x H<br />

Capacity*<br />

[kg/h]<br />

Capacity*<br />

[kg/h]<br />

Capacity*<br />

[kg/h]<br />

Capacity*<br />

[kg/h]<br />

Nuggets, battered and breaded, par-fried, frozen 60 x 40 x15 21 460-770 800-3,000 2,700-6,500 250-330<br />

Tenders, battered and breaded, par-fried, frozen 102 x 25 x 13 29 480-800 900-3,100 2,800-6,500 250-350<br />

Filets, battered and breaded, par-fried, frozen 140 x 90 x 19 115 410-700 750-2,700 2,400-6,500 230-300<br />

Chicken patties, battered and breaded, par-fried, frozen 100 (Dia.) x 10 (H) 115 450-750 800-3,000 2,600-6,500 240-320<br />

Nuggets, battered and breaded, fully cooked, frozen 60 x 40 x15 21 380-640 700-2,500 2,200-6,500 200-275<br />

Tenders, battered and breaded, fully cooked, frozen 102 x 25 x 13 29 410-690 750-2,700 2,400-6,500 225-300<br />

Filets, battered and breaded, fully cooked, frozen 140 x 90 x 19 115 360-610 650-2,400 2,100-6,300 200-260<br />

Chicken patties, battered & breaded, fully cooked, frozen 100 (Dia.) x 10 (H) 115 380-640 700-2,500 2,200-6,500 200-275<br />

Meat<br />

Beef patties, raw, aw frozen<br />

100 (Dia.) x 10 (H) 80 380-640 700-2,500 2,200-6,500 200-275<br />

Beef patties, fully cooked, frozen 100 (Dia.) x 10 (H) 70 320-530 600-2,100 1,900-5,600 175-230<br />

Meat ball, raw, frozen Sphere 25.4 8 380-639 700-2,500 2,200-6,500 200-275<br />

Meat ball, fully cooked, frozen Sphere 25.4 8 330-550 600-2,100 1,900-5,700 180-240<br />

Fish L x P x H<br />

Filets, raw, frozen zen<br />

200 x 90 x 13 115 350-600 650-2,300 2,000-6,100 190-250<br />

Fingers, battered and breaded, par-fried, frozen 100 x 32 x 15 29 600-1,000 1.150-4,100 3,600-6,500 340-450<br />

Filets, battered and breaded, par-fried, frozen 130 x 102 x 18 180 650-1,050 1,150-4.200 3.700-6.500 350-450<br />

Ready Meals L x P x H<br />

Lasagne, 400 gram, post pasteurized, chilled 149 x 122 x 45 (tray) 400 1,000-3,700 3,200-6,500<br />

* capacity figures are indications for basic estimation purpose<br />

<strong>GEA</strong> E-<strong>Tec</strong>/P spiral freezer. <strong>Tec</strong>hnical data.<br />

Package<br />

Freezer<br />

Nett belt width 400mm 600mm 1,000mm 400mm<br />

Vertical clearance between tiers, mm 50-75-100 50-75-100 75-100 50-75<br />

Product clearance between tiers, mm 35-50-75 35-50-75 50-75 35-50<br />

No. of tiers (min - max) 12-20 10-36 12-36 13 or 17

In touch with our customers<br />

Test before you invest<br />

Optimizing performance<br />

Worldwide service support<br />

The <strong>GEA</strong> E-<strong>Tec</strong>/P spiral <strong>freezers</strong> -<br />

a range designed for protein products<br />

With its high belt loading capacity, high uptime and fast initial freezing (sealing), the<br />

<strong>GEA</strong> E-<strong>Tec</strong>/P is optimized for applications in the protein business. The cooperation between<br />

<strong>GEA</strong> Refrigeration <strong>Tec</strong>hnologies and <strong>GEA</strong> <strong>Food</strong> <strong>Solutions</strong> led to some powerful<br />

synergy. As a co-development from provider of complete lines and solutions, who look<br />

at the design from a ‘system’ perspective, and a segment that has 100 years’ experience<br />

in freezing technology, <strong>GEA</strong> E-<strong>Tec</strong>/P spiral freezer meets all the needs of the protein<br />

processing industry. Ensure that you too, are ready for the future.<br />

Secured performance – test before you invest<br />

If you want to try creative ideas or new recipes either before or after you invest in a<br />

freezer, we can help you explore the options at one of our <strong>Tec</strong>hnology Centers.<br />

Together with our application specialists, you can test recipes and techniques for forming,<br />

coating, cooking and freezing, and then fi ne-tune the processes for an optimum<br />

balance of cost and quality. Test before you invest in our fully equipped <strong>Tec</strong>hnology<br />

Centers.<br />

With you all the way<br />

To extend the operational life and optimize the effi ciency of your preparation, marination<br />

and processing solutions, we can provide training, maintenance programs, equipment<br />

and software upgrades, performance benchmarking, diagnostics, applications<br />

expertise and factory integration services.<br />

Lowering your operational cost<br />

We are dedicated to optimizing your investment in equipment for processing meat,<br />

poultry, fi sh or vegetables by focusing on the factors that aff ect your business, now<br />

and in the future. These are the foundations of lifecycle performance. We can help en-<br />

sure that your products are varied, appetizing, aff ordable and safe – and produced at<br />

a loower<br />

cost per portion or per kilogram. And your processing lines will be fl exible,<br />

cosst-eff<br />

ective and lean.<br />

06 | 07

Excellence Passion Integrity Responsibility <strong>GEA</strong>-versity<br />

<strong>GEA</strong> Group is a global engineering company with multi-billion euro sales and operations in more<br />

than 50 countries. Founded in 1881, the company is one of the largest providers of innovative<br />

equipment and process technology. <strong>GEA</strong> Group is listed in the STOXX Europe 600 Index.<br />

www.gearefrigeration.com<br />

© <strong>GEA</strong>. All rights reserved. 03/2012 – RT-002-0806-US-EU – Subject to modification