Solid Height - Spring Manufacturers Institute

Solid Height - Spring Manufacturers Institute

Solid Height - Spring Manufacturers Institute

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ment, that’s a huge market, and government buyers<br />

are invoking the Buy American clause more often<br />

than they did in the past, so you can do well,” he<br />

says. The Buy American initiative has been around<br />

for a long time, but it was not enforced heavily. “It<br />

is being enforced now,” says Pepka, emphatically.<br />

“There are Buy American regulations for export and<br />

import controls, especially related to components that<br />

go into weapons.” These include the Defense Federal<br />

Acquisition Regulation Supplement (DFARS).<br />

“I think there will continue to be a spring industry<br />

in the U.S. China will have to deal with inflationary<br />

costs that are substantial, and everything will<br />

even out in 10-15 years,” he predicts. “Nevertheless,<br />

offshoring will continue. It’s a marketplace where<br />

buyers will often go to the lowest cost producer,<br />

regardless of where in the world they are.”<br />

Pepka posits, on the macro scale, that is it time<br />

for the owner of a spring company to decide which<br />

markets he wants to be in. “Here is how I would put<br />

it,” says Pepka, “Do you want to run an $8 million<br />

company that has a good profit level or a $10 million<br />

company that breaks even? You can’t always make<br />

up profit in volume. Sometimes, you have to ask<br />

yourself if it’s time to fire a few customers.”<br />

16 SPRINGS July 2006<br />

Pepka says springmakers must determine where<br />

they want to position themselves. “For example,” he<br />

says, “if you are in the oil patch business, you have to<br />

maintain high quality and timeliness, and still have to<br />

be agile. If you are in the aviation parts business, you<br />

have to maintain certifications and keep improving<br />

the shop floor. How successful you can be has a lot<br />

to do with what market niche you choose.”<br />

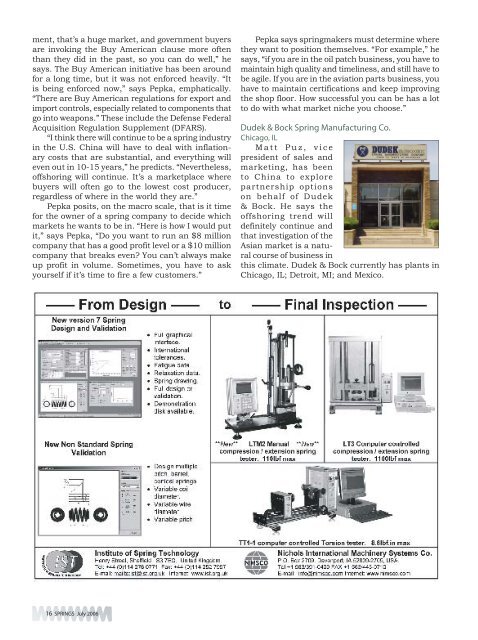

Dudek & Bock <strong>Spring</strong> Manufacturing Co.<br />

Chicago, IL<br />

Matt Puz, vice<br />

president of sales and<br />

marketing, has been<br />

to China to explore<br />

partnership options<br />

on behalf of Dudek<br />

& Bock. He says the<br />

offshoring trend will<br />

definitely continue and<br />

that investigation of the<br />

Asian market is a natural<br />

course of business in<br />

this climate. Dudek & Bock currently has plants in<br />

Chicago, IL; Detroit, MI; and Mexico.