pdf (3.6 MB) - ThyssenKrupp Bautechnik

pdf (3.6 MB) - ThyssenKrupp Bautechnik

pdf (3.6 MB) - ThyssenKrupp Bautechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2.3. DRIVING SHEET PILE WALLS 15<br />

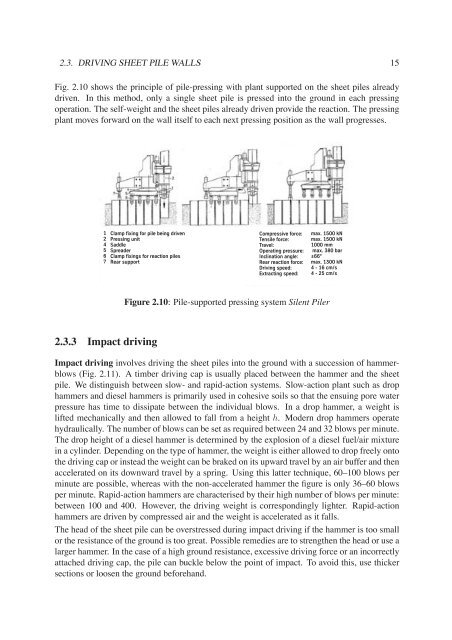

Fig. 2.10 shows the principle of pile-pressing with plant supported on the sheet piles already<br />

driven. In this method, only a single sheet pile is pressed into the ground in each pressing<br />

operation. The self-weight and the sheet piles already driven provide the reaction. The pressing<br />

plant moves forward on the wall itself to each next pressing position as the wall progresses.<br />

2.3.3 Impact driving<br />

Figure 2.10: Pile-supported pressing system Silent Piler<br />

Impact driving involves driving the sheet piles into the ground with a succession of hammerblows<br />

(Fig. 2.11). A timber driving cap is usually placed between the hammer and the sheet<br />

pile. We distinguish between slow- and rapid-action systems. Slow-action plant such as drop<br />

hammers and diesel hammers is primarily used in cohesive soils so that the ensuing pore water<br />

pressure has time to dissipate between the individual blows. In a drop hammer, a weight is<br />

lifted mechanically and then allowed to fall from a height h. Modern drop hammers operate<br />

hydraulically. The number of blows can be set as required between 24 and 32 blows per minute.<br />

The drop height of a diesel hammer is determined by the explosion of a diesel fuel/air mixture<br />

in a cylinder. Depending on the type of hammer, the weight is either allowed to drop freely onto<br />

the driving cap or instead the weight can be braked on its upward travel by an air buffer and then<br />

accelerated on its downward travel by a spring. Using this latter technique, 60–100 blows per<br />

minute are possible, whereas with the non-accelerated hammer the figure is only 36–60 blows<br />

per minute. Rapid-action hammers are characterised by their high number of blows per minute:<br />

between 100 and 400. However, the driving weight is correspondingly lighter. Rapid-action<br />

hammers are driven by compressed air and the weight is accelerated as it falls.<br />

The head of the sheet pile can be overstressed during impact driving if the hammer is too small<br />

or the resistance of the ground is too great. Possible remedies are to strengthen the head or use a<br />

larger hammer. In the case of a high ground resistance, excessive driving force or an incorrectly<br />

attached driving cap, the pile can buckle below the point of impact. To avoid this, use thicker<br />

sections or loosen the ground beforehand.