FREE ENTRY - Global Media Publishing Ltd. - UK.COM

FREE ENTRY - Global Media Publishing Ltd. - UK.COM

FREE ENTRY - Global Media Publishing Ltd. - UK.COM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

w w w . g m p . u k . c o m / p o w e r<br />

<strong>FREE</strong> <strong>ENTRY</strong><br />

to the <strong>UK</strong> & Europe’s No. 1 Independent<br />

Power, Energy & Electricity / Electrex<br />

Exhibition 2012<br />

The essential comprehensive showcase for the<br />

Standby Power, Electrical and Energy Sectors.<br />

Wednesday 18th April 2012, 09.30 – 17.00<br />

Thursday 19th April 2012, 09.30 – 16.00<br />

Hall 2 NEC Birmingham <strong>UK</strong><br />

PRE-REGISTER TODAY<br />

for <strong>FREE</strong> fast-track entry and a complimentary<br />

copy of the Official Show Catalogue<br />

18-19 April - NEC - Birmingham - <strong>UK</strong><br />

IPEE2012<br />

Independent Power Energy & Electricity<br />

P R O M O T I N G O N - S I T E P O W E R A N D C O G E N E R A T I O N<br />

��������<br />

To Register for free please visit:<br />

www.ipee.co.uk<br />

www.electrex.ltd.uk<br />

w O R l d w i d E i N d E p E N d E N t p O w E R<br />

NOVEMBER 2011<br />

�<br />

IPEE 2012<br />

&<br />

ELECTREX<br />

EXHIBITIONS

NEW LSA 42.3<br />

A L T E R N A T O R<br />

GENERATING PURE ENERGY<br />

Leroy-Somer’s EPG (Electric Power Generation) division, the world leader in Low and Medium<br />

Voltage alternators, has the most extensive range on the market, suitable for a wide variety<br />

of applications. Leroy-Somer EPG expertise is recognized throughout the Power Generation<br />

business, as is its proven ability to meet customers’ needs worldwide. Leroy-Somer EPG<br />

in alternator design.<br />

Visit us in booth 5248<br />

For more information on LSA 42.3 or the EPG Alternator range: www.lsa423.com

Managing Editor:<br />

Aidan Turnbull<br />

powereditorial@gmp.uk.com<br />

Sales Director:<br />

Neb Saric<br />

nsaric@gmp.uk.com<br />

Publisher:<br />

Richard Teasdale<br />

rteasdale@gmp.uk.com<br />

Journal Assistant:<br />

Sally Jones<br />

sjones@gmp.uk.com<br />

Accounts Division:<br />

Gretta Hay<br />

accounts@gmp.uk.com<br />

Far East Sales:<br />

Christine Guan<br />

Tel: 0086-10-65059168<br />

cguan@public3.bta.net.cn<br />

MSN: cguan019@hotmail.com<br />

Mobile: 0086-13701009982<br />

German/Danish/Swedish Sales:<br />

Mario Dobresko<br />

mdobresko@gmp.uk.com<br />

Russia Sales:<br />

Sergey Stanovkin<br />

stanovkin@dars.ru<br />

US Sales & Subscriptions:<br />

Alex Carter<br />

acarter@gmp.uk.com<br />

Asia-Pacific Correspondent:<br />

John Goss<br />

john.goss@ceejay.com.hk<br />

Contributors<br />

ComAp, Kohler, Lombardini, Frost &<br />

Sullivan, Cummins Power Generation,<br />

Wartsila, Greenvironment, Dalkia,<br />

MWM, Edina, Metso, MAN Diesel &<br />

Turbo, Alfagy, Fleetsolve, Capstone,<br />

Tecogen, EANDIS, Tenesol.<br />

Published by:<br />

<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong><br />

<strong>Global</strong> House, 13 Market Square,<br />

Horsham, West Sussex, RH12 1EU,<br />

<strong>UK</strong>. Tel: +44 (0)1403 220750<br />

Fax: +44 (0)1403 220751<br />

Website: www.gmp.uk.com<br />

© Worldwide Independent Power<br />

(ISSN 1468-7100).<br />

Subscription price £120 (<strong>UK</strong>),<br />

£180 (overseas) per year.<br />

Please send address changes to<br />

Worldwide Independent Power,<br />

<strong>Global</strong> House, 13 Market Square,<br />

Horsham, RH12 1EU, <strong>UK</strong>.<br />

Printed by Manor Creative, <strong>UK</strong><br />

NEXT ISSUE/December 2011<br />

Gas turbines<br />

Gas engines<br />

Cogeneration<br />

Noise & vibration<br />

Gen-sets<br />

Alternators<br />

HRSG<br />

Boilers<br />

Steam turbines & Rental Issues<br />

GMP<br />

<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong><br />

N O V E M B E R 2 0 1 1<br />

C O N T E N T S<br />

Gen-sets 16<br />

Kohler is releasing a new line of KDI diesel engines.<br />

Monitoring 18<br />

The ComAp WebSupervisor iPhone app is what you really need.<br />

Diesel engines 20<br />

Six MAN Diesel & Turbo generators were bought by NG-Energo.<br />

Renewables 22<br />

Alfagy’s Greenhill Dairy Farm Biogas plant is innovatory.<br />

UPS 24<br />

Eels are being protected thanks to a direct methanol fuel cell.<br />

Emissions 26<br />

FGD equipment at the 2,000MW Fiddler’s Ferry powerplant.<br />

CHP & Powerplants 28<br />

Fleetsolve has just installed 2 liquid biomass CHP systems.<br />

Hire & Rental 30<br />

We look at Capstone’s C1000 1MW power packages.<br />

Controls 32<br />

Natural gas engine-driven cogeneration from Tecogen.<br />

Microturbines 34<br />

Brandenburg’s 600kW microturbine Barsikow CHP plant.<br />

Smart Grids 36<br />

EANDIS is deploying GE’s PowerOnFusion system in Europe.<br />

Frost & Sullivan 38<br />

The European Wind Energy market is recovering from a slump.<br />

PV & Batteries 40 & 42<br />

Tenesol is bringing PV energy to Morocco & Mexico, while we<br />

report on the SOLON Corporation using Saft Li-ion units.<br />

R E G U L A R S<br />

News/Sharewatch 6,8,10,11,12<br />

Contracts/Products 44, 46,<br />

��������������������<br />

<strong>FREE</strong> <strong>ENTRY</strong><br />

to the <strong>UK</strong> & Europe’s No. 1 Independent<br />

Power, Energy & Electricity / Electrex<br />

Exhibition 2012<br />

The essential comprehensive showcase for the<br />

Standby Power, Electrical and Energy Sectors.<br />

Wednesday 18th April 2012, 09.30 – 17.00<br />

Thursday 19th April 2012, 09.30 – 16.00<br />

Hall 2 NEC Birmingham <strong>UK</strong><br />

PRE-REGISTER TODAY<br />

for <strong>FREE</strong> fast-track entry and a complimentary<br />

copy of the Official Show Catalogue<br />

18-19 April - NEC - Birmingham - <strong>UK</strong><br />

IPEE2012<br />

Independent Power Energy & Electricity<br />

����������������������������������������<br />

��������<br />

To Register for free please visit:<br />

www.ipee.co.uk<br />

www.electrex.ltd.uk<br />

���������������������������<br />

�������������<br />

�<br />

IPEE 2012<br />

&<br />

ELECTREX<br />

EXHIBITIONS<br />

New engines from Kohler. p.16.<br />

Our power portfolio includes:<br />

W O R L D W I D E I N D E P E N D E N T P O W E R<br />

Don’t miss<br />

the IPEE &<br />

Electrex 2012<br />

Show being<br />

held on April<br />

18th & 19th,<br />

2012, at the<br />

NEC<br />

IPEE 2012 is being held on April 18th<br />

& 19th in Hall 2 of the NEC,<br />

Birmingham. It features more<br />

visitors, more exhibitors, more<br />

business - more of everything.<br />

In 2010 IPEE/Electrex was bigger and<br />

better than previous years and<br />

reflects the stable <strong>UK</strong> Independent<br />

Standby and Electrical market.<br />

Capstone’s C1000. See p.30.<br />

2012<br />

M I D D L E E A S T P O W E R<br />

AMPS<br />

Members

THE RIGHT AMOUNT OF<br />

POWER AT THE RIGHT TIME.<br />

THE NEW STANDARD FOR<br />

FLEXIBLE POWER GENERATION.<br />

Environmental rules tighten, short-term energy demand fluctuates and<br />

long-term demand grows. Fuel prices and availability, weather conditions<br />

and technology – the only constant is change. How can energy be<br />

produced in a way that’s both environmentally and economically sound?<br />

Our answer: add flexibility to the energy mix. Our fast, responsive and<br />

efficient power plants ensure that supply meets demand at all times,<br />

setting a new standard for flexible power generation. Read more at<br />

wartsila.com.<br />

WÄRTSILÄ® is a registered trademark.

WEL<strong>COM</strong>E<br />

A warm welcome to this month’s<br />

issue of Worldwide Independent<br />

Power - as always bringing you<br />

closer to the stories and issues<br />

affecting on-site power and<br />

cogeneration around the world.<br />

For editorial comments, please do<br />

not hesitate to contact the editor.<br />

BIENVENUE<br />

Soyez le bienvenu à cette issue de<br />

Worldwide Independent Power.<br />

Comme d'habitude, nous vous<br />

apportons toujours plus près des<br />

sujets qui affectent l'énergie et la<br />

co-generation sur place autour du<br />

monde.<br />

N'hésitez pas contacter le<br />

rédacteur pour des commentaires<br />

éditoriaux.<br />

WILLKOMMEN<br />

Herzlich Willkommen zur Ausgabe<br />

dieses Monates von Worldwide<br />

Independent Power. Wie immer<br />

bringen wir Sie näher heran an die<br />

Ereignisse und Geschichten der<br />

Stromerzeugungsindustrie rund um<br />

die Welt.<br />

Für redaktionelle Kommentare und<br />

Anregungen wenden Sie sich bitte<br />

an den Autor.<br />

BIENVENIDO<br />

Bienvenido a esta edición de<br />

Worldwide Independent Power.<br />

Como siempre, acercándolo a los<br />

temas que afectan a la energía y a<br />

la cogeneración in-situ. No dude<br />

en contactar con nuestro editor<br />

para cualquier cuestión editorial.<br />

BENVENUTI<br />

Benvenuti a questa nuova edizione<br />

di Worldwide Independent Power.<br />

Come sempre cercheremo di<br />

offrirvi storie e questioni<br />

riguardanti on-site power e<br />

cogeneration a livello globale. Per<br />

commenti editoriali, si prega di<br />

contattare l'editore.<br />

Aidan Turnbull<br />

- Editor<br />

The rise & rise of renewables<br />

W ORLDWIDE I NDEPENDENT P OWER • NOVEMBER 2011<br />

EDITOR’S LETTER<br />

Looking back a whole year is always interesting. If you are into such<br />

things, there’s been some pretty impressive data coming out of the<br />

<strong>Global</strong> Trends in Renewable Energy Investment 2011 report prepared for<br />

the UN by Bloomberg New Energy Finance. Last year, for example, global investment in renewable<br />

energy sources grew by 32% to reach a record level of US$211bn (£132bn), a UN study has reported.<br />

Two of the biggest elements contributing to this included wind farms in China - and rooftop solar<br />

panels in Europe, it said.<br />

Economic researchers also discovered that in 2010 developing nations invested more in green power<br />

than rich nations for the first time since such records began.<br />

Achim Steiner, executive director of the UN Environment Programme, told WIP: “The continuing<br />

growth in this core segment of the green economy is not happening by chance. The combination of<br />

government target-setting, policy support and stimulus funding is underpinning the renewable industry's<br />

rise and bringing the much needed transformation of our global energy system within reach."<br />

In 2010, developing economies spent more on "financial new investment", pumping US$72bn into<br />

renewable projects compared with the US $70bn outlay by developed economies. The figures show that<br />

China topped the table of investors again, spending US$48.9bn - up 28% from 2009. There were also<br />

sizeable increases in investment from other developing or emerging economies:<br />

* Africa and the Middle East: up 104% to US$5bn<br />

* India: up 25% to US$3.8bn<br />

* South and Central America: up 39% (from 2009 levels) to US$13.1bn<br />

As a corollary, researchers did notice a 22% decline in the investment in large-scale projects - such as<br />

windfarms - within Europe, where the funding fell to US$35bn.<br />

The figures were also influenced by a rise in small-scale projects, such as photovoltaic (PV) solar<br />

panels, especially within Germany, where investment in a "micro-solar boom" had increased by 132% to<br />

US$34bn compared with 2009 figures. As the renewable technologies continued to mature, the report<br />

added, the cost per megawatt (MW) continued to fall. It said that the cost of PV modules had fallen on<br />

a per-MW basis by 60% since 2008.<br />

The reports suggests that there will be - "Further<br />

improvements in the cost of energy for solar, wind<br />

and other technologies lie ahead, posing a bigger<br />

and bigger threat to the dominance of fossil-fuel<br />

generation sources in the next few years."<br />

Achim Steiner considers that a number of key<br />

events will help to maintain the momentum<br />

towards renewables. "The UN climate convention<br />

meeting in Durban, South Africa, held between<br />

November 28th until the 9th of December will be<br />

followed by the Rio+20 summit in Brazil in 2012.<br />

Events like these offer key opportunities to<br />

accelerate and scale-up this positive transition to a<br />

low-carbon, resource-efficient green economy."<br />

According to a global study published by the US<br />

Pew Environment Group, China remains the world's<br />

leading investor in low-carbon energy technology.<br />

The table, published by showed that the Chinese<br />

invested US$54.4bn (£34.1bn) in 2010, up from<br />

$39.1bn in 2009.<br />

EUROPE ASIA-PACIFIC MIDDLE EAST<br />

AFRICA AMERICAS<br />

5

KPMG wins award<br />

The US Environmental<br />

Protection Agency (EPA)<br />

has presented professional<br />

services firm KPMG with<br />

an award for using<br />

cogeneration to provide<br />

50% of the energy used by<br />

its data centre in<br />

Montvale, New Jersey.<br />

KPMG deployed more than<br />

12 natural-gas-powered<br />

Capstone microturbines at<br />

its headquarters in<br />

Montvale as part of its<br />

CHP system. The system<br />

generates 720 kW of<br />

power, or nearly 50% of<br />

the load required by the<br />

company's data centre at<br />

the campus, according to<br />

the EPA. <br />

MEC &<br />

Greevironment in<br />

joint deal<br />

CCHP specialist<br />

Greenvironment will<br />

install microturbines for a<br />

113 MWt district heating<br />

scheme in Poland’s<br />

Kolobrzeg region for local<br />

utility MEC Kolobrzeg.<br />

Greenvironment, which<br />

specialises in the use of<br />

microturbine technology<br />

in electricity generation<br />

from biogas and natural<br />

gas, is planning to put to<br />

put a 200 kWel C200<br />

microturbine into<br />

operation as a pilot plant<br />

in spring 2012.<br />

Microturbines benefit<br />

from high availability, low<br />

maintenance requirements,<br />

low emissions,<br />

favourable EEG and KWKG<br />

bonus compensation and<br />

flexible heat use, says the<br />

company.<br />

6<br />

In brief...<br />

NEWS<br />

Saft wins Boeing Li-ion batteries contract<br />

Boeing Space & Intelligence Systems will be<br />

supplied with lithium-ion (Li-ion) satellite batteries<br />

by Saft for MEXSAT-1 and MEXSAT-2.<br />

The satellites are part of the new MEXSAT comms<br />

system, which will provide government and civilian<br />

broadband communications to Mexico, supporting<br />

humanitarian needs and enhanced coverage for<br />

domestic communications.<br />

The MEXSAT communications system will consist of<br />

two 702 HP Geomobile satellites, MEXSAT-1 and 2,<br />

and one Fixed Satellite Service (FSS), MEXSAT-3.<br />

The new order marks the third contract issued<br />

under Saft’s long-term agreement signed with<br />

Boeing in 2009 for Li-ion GEO satellite batteries.<br />

Saft will provide high-energy batteries consisting of<br />

its qualified VES140S cells. With a 15-year life span,<br />

N OVEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

the battery packs will power the satellites with 14<br />

kW of onboard power during eclipse seasons (two<br />

45-day periods per year in GEO orbit).<br />

Dieselec Thistle found on Gatwick runways<br />

Dieselec Thistle, one of the <strong>UK</strong>’s<br />

largest independent generator<br />

specialists, has supplied a standby<br />

diesel generator to help ensure<br />

Gatwick’s aprons & runways<br />

remain safe for aircraft during<br />

taxiing, take-off and landing.<br />

The 350KVA generator will provide<br />

back-up power for the surface<br />

water pumps which are used to<br />

ensure that any excess water is<br />

drained off the runway into<br />

on-site ponds around the airport.<br />

Designed to start immediately in<br />

the event of a mains power<br />

FG Wilson supporting Derry-Londonderry<br />

FG Wilson is sponsoring the Derry-<br />

Londonderry yacht in the world’s<br />

longest yacht race, Clipper Round<br />

the World Race, 2011. Altogether<br />

10 identical 68ft (20m) ocean<br />

racing yachts are participating .<br />

The race started in Southampton,<br />

England on the 31st July and it is<br />

estimated that the circumnavigation<br />

of the route will take 11<br />

months to complete. With 15<br />

races spread over eight legs, the<br />

10 teams have ample opportunity<br />

to build up their points in their<br />

bid to win the championship<br />

position. Ciaran McCarney, FG<br />

failure, the generator will ensure<br />

that business critical operation of<br />

the pump systems continue without<br />

interruption to avoid any<br />

potential disruption to airport<br />

services This new contract builds<br />

on Dieselec Thistle’s aviation<br />

Wilson’s Business Development<br />

and Dealer Support Manager,<br />

commented: “The race is a great<br />

opportunity for FG Wilson as it<br />

provides 10 months of coverage<br />

and promotion of the FG Wilson<br />

brand around the world. The race<br />

reaches a potential global<br />

audience of 524 million in 194<br />

countries and visits 16 cities. It is<br />

also an exciting project for FG<br />

Wilson to be involved with and we<br />

will be following the race, rooting<br />

for our yacht to win!”<br />

A world leader in the supply of<br />

diesel and gas powered generator<br />

expertise, which also includes<br />

recent contracts to supply standby<br />

diesel generators for the air<br />

traffic control radar facilities at<br />

Stansted Airport and Bovingdon<br />

radar mast. Paul Moore, MD of<br />

Dieselec Thistle comments:<br />

“Business continuity is as<br />

important in the aviation sector<br />

as any business safety of passengers<br />

and air crew. The apron &<br />

runway surface water pump<br />

system is just one element of<br />

airport infrastructure that needs<br />

reliable backup power supply.”<br />

sets, FG Wilson’s global<br />

production facilities are in Brazil,<br />

China, India, USA and company<br />

headquarters in Northern Ireland.<br />

Manufacturing operations cover a<br />

combined area of over 185,000m²<br />

- from which more than 80,000<br />

generator sets are produced each<br />

year.

essential.<br />

www.marellimotori.com

8<br />

In brief...<br />

Solarzentrum wins<br />

certification<br />

A new PV-Therm module<br />

made by Solarzentrum<br />

Allgäu of Germany has<br />

earned 4 TÜV PTL<br />

certificates, confirming<br />

that the product complies<br />

globally with the safety and<br />

quality codes required of<br />

thermal solar collectors and<br />

PV modules. Now ready for<br />

market, the WIOSUN PVT<br />

180 module combines both<br />

a thermal solar collector<br />

and PV module, providing<br />

simultaneous heating,<br />

cooling and electricity to a<br />

facility all at the same<br />

time.<br />

Toleram targets<br />

Estonian markets<br />

The Tolaram Group of<br />

Singapore is poised to<br />

launch a €30m CHP<br />

production project in Kehr,<br />

Estonia, based on biomass<br />

fuels. A joint venture with<br />

Estonian energy company<br />

Eesti Energia, Tolaram says<br />

annual production from this<br />

project will involve 108<br />

GWh of heat and 63 GWh of<br />

electricity per year.<br />

Facilities are projected to<br />

begin producing energy by<br />

2014.<br />

The key thinking behind<br />

behind this new CHP<br />

technology focuses on<br />

reducing Estonia’s dependency<br />

on Russian gas<br />

imports. The biomass fuels<br />

will help Estonia meet its<br />

international climate treaty<br />

agreements and improve<br />

the overall energy<br />

efficiency across the<br />

country.<br />

NEWS<br />

<strong>UK</strong> Govt offers £1bn to back CCS plans<br />

Two large energy firms have<br />

agreed to work together to<br />

develop carbon-capture and<br />

storage (CCS) in Aberdeenshire -<br />

if they can get the funding.<br />

The <strong>UK</strong> government said it would<br />

hand over £1bn to develop CCS,<br />

which captures emissions from<br />

power stations and buries them<br />

under the seabed.<br />

A pilot project at Longannet in<br />

Fife was cancelled last month due<br />

to cost. Now Shell and Scottish<br />

and Southern Energy want to<br />

develop the pioneering t<br />

echnology at Peterhead power<br />

station. CCS is seen as vital to the<br />

future of producing energy from<br />

sources such as coal and gas, as it<br />

would cut the carbon-dioxide<br />

emissions which are released.<br />

The aim is to capture and liquify<br />

CO2 emissions, which would then<br />

be transferred via a pipeline to<br />

depleted oil and gas fields under<br />

the sea bed.<br />

Longannet, a coal-fired power<br />

station, had been the only<br />

N OVEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

contender in a long-running<br />

competition by the government<br />

for a power plant that could<br />

become the test ground for<br />

carbon capture and storage.<br />

Scottish Power, which operates<br />

Longannet, put the cost at<br />

£1.5bn.<br />

The <strong>UK</strong> government decided it did<br />

not want to spend more than<br />

£1bn on supporting the trial and<br />

pulled away from the project.<br />

A statement from Shell and<br />

Scottish and Southern Energy<br />

(SSE) said their new agreement at<br />

the gas-fired Peterhead plant<br />

would ‘accelerate’ a programme<br />

of design studies.<br />

They said they would be able to<br />

begin a full design study in the<br />

second half of 2012, if they won<br />

money from the <strong>UK</strong> government<br />

or the EU's NER300 fund.<br />

The Peterhead project aims to<br />

design and develop a CCS system<br />

for capturing emissions after<br />

combustion at one of its existing<br />

three 385MW combined gas cycle<br />

turbines. The CO2 would then be<br />

transported to the Shell-operated<br />

Goldeneye gas field.<br />

DeltaStream is now under construction<br />

This DeltaStream unit - currently being built [below] - is designed to sit on the seabed and generates<br />

electricity from three separate horizontal axis turbines mounted on a common frame. Wales’ first full<br />

scale tidal stream energy generator will be deployed in 2012, having secured £6.4m support from the<br />

European Regional Development Fund through the Welsh Government.<br />

Earlier this year, First Minister Carwyn Jones announced the funding for Tidal Energy <strong>Ltd</strong>’s 1.2MW<br />

DeltaStream device on a visit to Pembrokeshire’s Ramsey Sound, the site chosen for the demonstration<br />

project by the Welsh Government and the Department of Energy and Climate Change.<br />

In total, Tidal Energy <strong>Ltd</strong> has secured £11m to manufacture and deploy the DeltaStream device, the<br />

balance being provided by majority shareholder Eco2 <strong>Ltd</strong>. Cranfield University, which for the past three<br />

years has provided specialist design support to the project, will continue its research and development<br />

work and will also play a role in the deployment of the prototype, overseeing condition monitoring and<br />

the performance of the device.<br />

Invented by Pembrokeshire engineer Richard Ayre, DeltaStream sits on the seabed without the need for a<br />

positive anchoring system. It generates electricity from three separate horizontal axis turbines mounted<br />

on a common frame. The device, which will provide a sustainable source of electricity to homes in the<br />

city of St Davids during its 12 month demonstration period, has<br />

been designed to be easily installed and maintained, with minimal<br />

impact on the environment.<br />

In its 2010 Low Carbon Energy Policy Statement, the Welsh<br />

Government suggested that the deployment of tidal and wave<br />

devices off the nation’s 1,200km coastline could provide as<br />

much as 4GW of clean, predictable electricity: it hopes this<br />

could become a reality by 2025.<br />

The First Minister told WIP: “Investing in renewable energy<br />

technologies is vital to build a low carbon economy and help<br />

drive forward Wales’ ambitions to become a more sustainable<br />

nation. We are committed to promoting the generation of clean<br />

electricity while protecting our natural environment.”

Petro-Canada is a Suncor Energy business<br />

TM Trademark of Suncor Energy Inc. Used under licence.<br />

LUB2659<br />

Sentron LD 5000<br />

Field Tested. Field Proven.<br />

MWM Approved.<br />

Better perform performance, mance, less do downtime, wntim me, better profitability<br />

y – ever everyone yone approves approvees<br />

of that.<br />

Call Caall<br />

1-866-335-3369 or visit sentron.ca to tto<br />

begin your trial.

In brief...<br />

Gazprom buys Envacom<br />

Gazprom - the Russian state<br />

gas corporation - has<br />

bought German electricity<br />

utility Envacom. Jonathan<br />

Feingold, director of<br />

Gazprom Energy says the<br />

company wants to be a<br />

major player in the German<br />

power market. Envacom's<br />

retail market business will<br />

be changed to Gazprom<br />

Energy to demonstrate the<br />

change of ownership.<br />

10<br />

NEWS<br />

N OVEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

GE Jenbacher engines<br />

bought for pyrogasification<br />

plant in Turin, Italy<br />

Two Jenbacher J316 engines from GE have<br />

been bought by the Villanova Mondovi pyrogasification<br />

plant near Turin, Italy. GE<br />

reports that the technology deployed for<br />

the Villanova Mondovi plant, which turns<br />

waste wood into energy, evolved from a<br />

similar gasifier project in Grossenkneten,<br />

Germany.<br />

The German plant was co-financed by the<br />

region of Lower Saxony, which produces the<br />

highest net electrical efficiency ever<br />

reached by a syngas cogeneration plant in<br />

this output range - between 27% and 29%,<br />

depending on the quality of the wood and<br />

the air used in the process, reports GE.<br />

The Villanova Mondovi project - with an<br />

output estimated at 995 kW - qualifies for<br />

the government’s incentive tariff, which<br />

encourages the development of smaller,<br />

geographically-distributed power plants.<br />

Owned and operated by Italian energy<br />

company Energia & Calora, the plant was<br />

commissioned at the beginning of 2011 and<br />

is supplying thermal energy for a district<br />

heating network that covers an industrial<br />

area along with private and public buildings,<br />

including the local school.<br />

“The strong teamwork between Pyrox<br />

GmbH, its subsidiary Pyrox Italia Srl. and GE<br />

has been a key to the remarkable success of<br />

this innovative project, which uses<br />

advanced technology to reach unprecedented<br />

levels of efficiency and output for a<br />

plant of this type,” Andreas Marocco, head<br />

of management of Pyrox Italia told WIP.<br />

“We are very proud that our project<br />

supports the country’s efforts to increase its<br />

energy output while reducing the<br />

environmental impact by taking advantage<br />

of abundant fuel sources, such as wood<br />

biomass.”<br />

The National Action Plan of Italy calls for<br />

45% of the country’s cleaner energy to be<br />

produced from biomass, with 60% of that<br />

total coming from solid biomass, such as<br />

wood. There is a strong trend in that<br />

direction; the use of wood biomass for<br />

energy production in Italy has increased by<br />

7% over the last two years.<br />

“Italy is an attractive market for wood<br />

biomass power projects, which have the<br />

strong support of the Italian government as<br />

the country strives to expand and diversify<br />

its alternative energy capacity,” comments<br />

Rafael Santana, president and CEO—Gas<br />

Engines for GE Energy. He concluded:<br />

“With its proven high efficiency and low<br />

emissions, our advanced gas engine technology<br />

is an excellent match for smaller, local<br />

projects using local fuels while reducing the<br />

overall environmental impact.”

NEWS<br />

Wärtsilä inaugurates new distribution centre in<br />

Kampen, The Netherlands<br />

Wärtsilä, a global leader in complete life<br />

cycle power solutions for the marine and<br />

energy markets, inaugurated its new spare<br />

parts distribution centre in Kampen, the<br />

Netherlands, on November 7th, 2011. The<br />

Central Distribution Centre was officially<br />

opened by Wärtsilä's President & CEO Björn<br />

Rosengren together with Bort Koelewijn,<br />

the Mayor of Kampen.<br />

The Central Distribution Centre is the core<br />

of Wärtsilä <strong>Global</strong> Logistics Services, and<br />

integrates eight previously localized spare<br />

parts warehouses into one global supply<br />

chain operation. It covers the entire<br />

material flow from order confirmation until<br />

the point of delivery at the customer's<br />

doorstep. The new centre will shorten<br />

transportation distances, reduce spare parts<br />

traffic between warehouses, and improve<br />

management of the entire supply chain.<br />

Wärtsilä's global service network continues<br />

to serve the customers with a full range of<br />

services and repairs.<br />

"The new centre will deliver spare parts to<br />

customers and Wärtsilä's 160 service<br />

locations around the globe. By using one<br />

global logistics centre, and through the<br />

creation of a highly efficient logistics flow,<br />

Wärtsilä is better positioned to serve its<br />

customers and suppliers. Consolidating<br />

logistics and warehousing will result in<br />

faster and more efficient spare parts<br />

deliveries, 24 hours a day 7 days a week,"<br />

Christoph Vitzthum, Group Vice President,<br />

Wärtsilä Services, told WIP.<br />

The new distribution centre began<br />

operations in December 2010 and will be<br />

fully operational before the end of this<br />

year. The facilities cover an area of 37,000<br />

m2. Wärtsilä's total investment in the new<br />

distribution centre has been approximately<br />

€70 million. Once fully operational it will<br />

have a staff of 140 people.<br />

The Central Distribution Centre has been<br />

designed and implemented by Swisslog, a<br />

logistics solutions provider. CEVA Logistics, a<br />

supply chain management company, is<br />

responsible for the shipments and<br />

operational warehouse handling.<br />

Wärtsilä Services offers services to both<br />

the global marine and energy markets and<br />

operates the most extensive service<br />

network in the industry. The company's<br />

extensive portfolio of services includes<br />

spare parts and field services, as well as<br />

the servicing of engines, propulsion<br />

systems, electrical and automation systems,<br />

and boilers. It also covers environmental<br />

services and solutions, upgrades and conversions,<br />

long-term agreements for engine<br />

and propulsion systems, as well as training<br />

services.<br />

Wärtsilä's Services business is also in the<br />

forefront in developing new service<br />

concepts to meet customer needs for<br />

optimal operational efficiency. Wärtsilä<br />

Services operates some 70 fully-owned<br />

workshops and employs over 11,000<br />

service professionals.<br />

Wärtsilä has all its three business units Ship<br />

Power, Power Plants and Services as well as<br />

Research and Development represented in<br />

the Netherlands and has more than 1,000<br />

employees in seven locations.<br />

W ORLDWIDE I NDEPENDENT P OWER • NOVEMBER 2011<br />

In brief...<br />

drilling 100th platforms Siemens or SGT-300 FPSO (Floating, gas<br />

turbine is shipped, says company<br />

The<br />

Siemens<br />

power<br />

ecently<br />

generation<br />

shipped<br />

model<br />

its 100th<br />

is<br />

SGT-300<br />

a single-<br />

industrial gas turbine from its manufacturshafting<br />

plant 7.9 in MW Lincoln, gas turbine <strong>UK</strong>, and featuring will be used a Dry<br />

Low for cogeneration Emissions (DLE) applications system. in the oil &<br />

gas sector. The 100th turbine is part of an<br />

order of three from Petrochina Company<br />

mpen, Waalwijk and Zwolle.<br />

Limited for the end user China National<br />

Petroleum Corporation (CNPC) and is<br />

destined for Iraq. All three turbines will<br />

generate power and process heat for the<br />

oil & gas industry.<br />

Siemens says the success of the SGT-300 is<br />

partly due to its high resilience to<br />

hydrogen sulphide, allowing it to operate<br />

on sour gas, minimising gas processing<br />

costs. The power generation model under<br />

the spotlight is a single-shaft 7.9 MW gas<br />

turbine featuring a Dry Low Emissions (DLE)<br />

system.<br />

Nigeria operating a new 6.5MW<br />

CHP plant in<br />

Benin City<br />

The Nigerian<br />

Bottling Company<br />

(NBC), a subsidiary<br />

of Coca-Cola<br />

Hellenic, has<br />

celebrated six<br />

months of succesful<br />

operation for its<br />

latest 6.5 MW CHP<br />

plant. This has been established in a<br />

company factory in Benin City, Edo State,<br />

Nigeria.<br />

The new CHP plant is helping the company<br />

to significantly reduce its energy<br />

consumption, and achieve a 40% reduction<br />

in carbon emissions.<br />

The CHP plant, which is gas and dieselfired,<br />

was commissioned in May 2011.<br />

NBC says the plant meets 99% of its energy<br />

requirements and guarantees a constant<br />

power supply in an area where grid power<br />

is often problematic.<br />

The facility is being managed by<br />

Contour<strong>Global</strong> over the next 15 years on a<br />

Built, Operate and Transfer (BOT) basis,<br />

after which it will be transferred to NBC.<br />

i<br />

11

12<br />

DUNEA, the Dutch drinking water company, currently provides 1.2<br />

million people of South-West Holland with drinking water. The water<br />

is caught in the sand dunes and purified in three pumping stations.<br />

The renovation of Dunea’s energy supply installation in<br />

Scheveningen led to the project being awarded to Belgium’s<br />

leading supplier of power solutions, E. VAN WINGEN NV, (EVW).<br />

Existing power supply problems on the Scheveningen site were<br />

solved by erecting two new pump houses in which four diesel<br />

NEWS<br />

VAN WINGEN wins power contract from DUNEA<br />

N OVEEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

gensets had to be integrated. The project was gigantic and took<br />

two years to implement. From the two pump houses fresh water is<br />

distributed to consumers.<br />

To guarantee supply an emergency power provision was required.<br />

After stringent screening of the tenders EVW was selected to carry<br />

out the engineering, construction and installation of the<br />

emergency power supply, including providing a fuel supply<br />

pipework, as well as a power control system.<br />

In case of mains failure Dunea can remain operational with the back<br />

up of four emergency diesel generators installed in the two pump<br />

houses.<br />

EVW selected the Perkins 4012 diesel engine to be at the heart of<br />

each 1475 kVA genset. The four units supply enough power to enable<br />

Dunea to guarantee the catchment, purification and distribution of<br />

water into the supply network. Providing the power control system<br />

to safeguard power supply and data communications was of<br />

particular importance to Dunea.<br />

Unlike other traditional mains failure projects the emphasis was less<br />

on deliveries and installation than on engineering. EVW’s<br />

engineering department, with five experienced designers, has been<br />

running at full steam delivering a piece of highly professional and<br />

state-of-the-art project, reports the company.<br />

For EVW this was again an opportunity to confirm its position as a<br />

reliable high end supplier in the Netherlands after its first major<br />

breakthrough with the power backup systems supplied to the high<br />

speed train tunnels for Siemens.<br />

www.vanwingen.be

Our New Range of Generating Sets<br />

…Designed to Deliver More<br />

FG Wilson’s Wilson’<br />

s 26 – 200 kVA<br />

range<br />

of generating<br />

sets have<br />

been<br />

redesigned to provide<br />

enhanced performance,<br />

pe erformance,<br />

dur durability ability<br />

and<br />

serviceability se erviceability a as s standard.<br />

W We e understand<br />

tthe<br />

the needs<br />

of<br />

gener generating ating sset<br />

set customers.<br />

FForty<br />

orty<br />

yyears<br />

ears expe experience, erience, combined<br />

with a<br />

focus<br />

on<br />

engineering<br />

ex excellence ce ellence and<br />

product<br />

inno innovation v vation<br />

has<br />

helped<br />

us cre create ate e a<br />

new rrange<br />

ange of<br />

gener generating at ting sets,<br />

capable<br />

of<br />

meeti meeting ing the<br />

challenges<br />

of<br />

ev even een<br />

the<br />

most<br />

div diverse erse applicatio applications. ons.<br />

This ex exciting citing redesign reddesign<br />

deserves<br />

a<br />

closer<br />

look...<br />

Go to www.FGWilson.com/WIP_new www.FFGWilson.com/<br />

WIP P_new or<br />

visit your<br />

local locaal<br />

Authorised Authorised<br />

FG Wils Wilson son Dealer

If hydrocarbons supplies run out, we’re<br />

in trouble. More importantly, if our<br />

existing supplies are in terminal<br />

decline, we’re in almost as much trouble<br />

anyway; and much sooner. If our ability to<br />

extract fossil fuels declines to uneconomic<br />

levels, it really doesn’t matter how much<br />

is actually down there.<br />

So how much is down there and how<br />

long will it last us? Estimates,<br />

unsurprisingly, vary a lot. Many<br />

governments consider estimates of their<br />

supplies as state secrets. Undaunted,<br />

many academics attempt to make<br />

predictions even with this incomplete<br />

information. For oil we’ve got maybe 30<br />

to 40 years left according to a 2011 study.<br />

But more importantly, as alluded to<br />

before, peak oil extraction is probably<br />

more important and may have already<br />

been and gone.<br />

It is highly likely that once this decade is<br />

out we will have reached it, if we haven’t<br />

already, and we will have already begun<br />

to see the negative effects of oil’s<br />

transition from a demand-led to supplyconstrained<br />

commodity. “The age of<br />

cheap liquid fuels is over,” claims the<br />

report.<br />

Estimating coal and natural gas supplies<br />

are more complicated. The industry Oil<br />

and Gas Journal estimates them at 417<br />

years and 167 years, respectively.<br />

Unfortunately, as with its 43 year<br />

estimate for oil these figures are likely<br />

overly optimistic.<br />

As the report highlights, exporting<br />

nations and industry have significant<br />

incentives to conceal and distort their<br />

figures. These estimates should be<br />

considered with some scepticism.<br />

Scientific blogger, Raphaël Van Laer, has<br />

calculated fossil fuel reserve depletion<br />

estimates based on 2009 reserve and<br />

production (R/P) ratios supplied by the US<br />

Energy Information Administration (EIA).<br />

His model estimates depletion by around<br />

2070 for oil, 2061 for natural gas and<br />

14<br />

SHAREWATCH<br />

Fossil fuels - nearly gone?<br />

Almost all of human civilization’s power needs are met by burning hydrocarbons, points out<br />

WIP’s economic analyst Chris Hopkins. But how much is left - and how long will it last?<br />

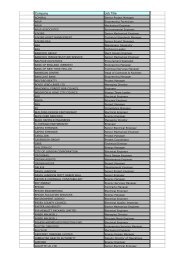

Company<br />

(Currency)<br />

Monthly<br />

share price<br />

52 week<br />

high/low<br />

ABB (CHF) 21.80 18.34/<br />

23.97<br />

Ansaldo (EUR) 9.66 8.85/<br />

11.94<br />

Atlas Copco (SEK) 148.90 98.10/<br />

161.20<br />

Caterpillar (USD) 105.82 58.06/<br />

116.55<br />

* CHLORIDE Taken over<br />

by EMERSON<br />

Cummins (USD) 103.32 63.04/<br />

121.49<br />

Doosan Heavy<br />

Industries (KRW)<br />

Foster Wheeler<br />

(USD)<br />

56500<br />

50800/<br />

96200<br />

30.49 20.33/<br />

39.75<br />

GE (USD) 18.85 13.75/<br />

21.65<br />

John Deere (EUR) 1400 990.00/<br />

1400<br />

Kirloskar (INR) 286.60 280.00/<br />

3406.65<br />

MAN (EUR) 91.96 47.90/<br />

97.85<br />

Mitsubishi (JPY) 2000 1784/<br />

2500<br />

MTU Detroit<br />

Diesel (EUR)<br />

555.08 34.91/<br />

56.60<br />

Rolls-Royce (GBX) 645.00 533.00/<br />

674.50<br />

Siemens (EUR) 94.70 70.02/<br />

99.39<br />

Volvo Penta (SEK) 110.50 80.85/<br />

122.00<br />

Wärtsilä (EUR) 23.11 18.17/<br />

29.50<br />

anywhere from 2079-2155 for coal, due to<br />

incomplete data. He, again, cautions that<br />

problems stemming from the economics of<br />

extracting these resources will hit us far<br />

before these dates, though. There are<br />

many who would survey this uncertainty<br />

Change over<br />

month<br />

N OVEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

Change<br />

over year<br />

Change since<br />

Jan. 2008<br />

-3.58% +14.92% -21.86%<br />

-2.08% -12.34% +11.81%<br />

+2.62% +43.31% +68.73%<br />

+1.17% +58.64% +120.11%<br />

-1.57% +134.46% +125.56%<br />

-2.75% -25.26%<br />

-10.03% +44.78% -57.53%<br />

-3.03% +30.72% -47.87%<br />

0.00% +2.94% +13.36%<br />

-1.60% -28.71%<br />

Monthly figures taken at the end of October 2011<br />

-5.11% +73.89% +3.32%<br />

+3.96% +4.48% -15.99%<br />

+1.62% +37.42% +53.07%<br />

+2.38% +14.67% +32.65%<br />

+4.77% +27.94% +5.94%<br />

+0.09% +26.50% +23.12%<br />

-6.68% +23.03% -46.60%<br />

and simply decry the foolishness of trying<br />

to inductively estimate our future<br />

resources. Whatever you believe, one<br />

thing is clear: our fossil fuel-based<br />

economies will almost certainly not<br />

survive the coming century. WIP

Ctra. Murcia - San Javier,Km. 23,6<br />

SAN JAVIER (Murcia) SPAIN<br />

Tel. +34 968 19 11 28 | Fax +34 968 19 04 20<br />

www.himoinsa.com | E-mail: info@himoinsa.com<br />

energy<br />

emergency<br />

Emergency gensets that perform a<br />

strong step load capability.<br />

HIMOINSA uses the latest<br />

technology in electronics to<br />

guarantee the best monitoring of the<br />

genset.<br />

The new generation of energy:<br />

serving the future.<br />

Generating Sets manufactured to work with<br />

maximum reliability that meets the expectations<br />

which are designed to, able to perform at your best<br />

with the highest quality assurance<br />

We are present in more than 100 countries through<br />

our subsidiaries and distributors network<br />

www.himoinsa.com

This completely new family of<br />

engines features highly-advanced<br />

technology for clean combustion<br />

and limited emissions without the use of<br />

after-treatment systems, while<br />

simultaneously enabling remarkable<br />

performance levels to be reached.<br />

The excellent power and torque in<br />

relation to the engines’ compact size and<br />

the absence of particulate abatement<br />

systems (such as DPFs) translate into clear<br />

advantages for all OEMs who can now<br />

replace their current engines with lowerdisplacement<br />

units and, at the same time,<br />

enjoy the benefits of reduced fuel<br />

consumption and longer maintenance<br />

intervals, since no filter regeneration is<br />

required.<br />

Fully optimised to meet market<br />

demands, the design was developed using<br />

the most advanced technology currently<br />

available, says Kohler.<br />

Clean combustion achieved with a highpressure<br />

(2000 bar) Common Rail system<br />

of the latest generation, combined with<br />

an electronically triggered EGR valve that<br />

makes circulate the right amount of<br />

16<br />

GEN-SETS<br />

New gen-sets developed by<br />

Kohler/Lombardini<br />

Kohler is releasing a new line of KDI (Kohler Direct Injection) diesel engines in preparation for<br />

new regulations on emissions which are soon to take effect (final TIER 4, above 19 kW in the<br />

KDI<br />

1903 TCR<br />

KDI<br />

TCR<br />

2504<br />

US; Stage IIIB, above 37 kW in the EU). WIP has the story.<br />

exhaust gases (which are<br />

liquid-cooled by a water/air<br />

heat exchanger), enables<br />

emission levels to comply with<br />

the new regulations while<br />

providing exceptional<br />

performance - and all without<br />

the use of after-treatment<br />

systems.<br />

Kohler/Lombardini have<br />

chosen the most advanced<br />

common rail system available<br />

on the market. It’s specifically<br />

designed for extreme<br />

durability and resistance to<br />

the highly severe conditions of<br />

operation that are typical of<br />

applications in the industrial<br />

and building construction<br />

sectors. The high pressure pump<br />

operates at 2000 bars. This feature,<br />

combined with G3S solenoid-type<br />

injectors, enables fuel optimistion during<br />

injection.<br />

The 4 valves per cylinder system used<br />

was designed to house the injector in a<br />

perfectly vertical position at the very<br />

center of the combustion<br />

chamber. This solution optimises<br />

fuel filling, atomisation and<br />

mixing with oxygen in the<br />

chamber.<br />

The intake manifold and the<br />

combustion chamber were<br />

developed with thorough fluiddynamic<br />

(CFD) analysis for<br />

maximum combustion efficiency.<br />

The waste-gated turbocharger<br />

has been specifically tuned to<br />

minimise the turbo-lag response<br />

and provide the precise volume<br />

of air for an excellent low end<br />

torque capability. Specific oil<br />

control devices also allows for<br />

N OVEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

the required lubrication of the turbine<br />

shaft for long term durability. The use of<br />

a charge air cooler is required to ensure<br />

the correct air inlet temperature for the<br />

optimal engine performance whilst<br />

achieving emissions compliance.<br />

The exhaust gas recirculation system,<br />

which is the product of a painstaking CFD<br />

analysis, consists of two cooling stages<br />

that optimise heat exchange without<br />

increasing overall size. Also, its position<br />

on the hot side effectively prevents the<br />

EGR valve from jamming, which ensures<br />

maximum reliability.<br />

The Common Rail injection system and<br />

the electronic control unit required for<br />

controlling it are both of the latest<br />

generation. They were specifically developed<br />

for heavy-duty applications in power<br />

and industry sectors.<br />

WIP<br />

Internet link<br />

www.lombardini.it<br />

KDI<br />

TCR 2504

HOTflow only from HOTSTART<br />

�<br />

��Thermal camera imagery shows yellow and<br />

white hotspots in an engine fitted with a<br />

standard engine heater. These hotspots<br />

deteriorate hoses, shorten coolant life and<br />

increase maintenance costs.<br />

www.hotstart.com<br />

509.536.8660<br />

STANDARD ENGINE<br />

HOTflow ENGINE<br />

��HOTSTART HOTflow heaters use an<br />

integrated pump to circulate coolant<br />

throughout the engine. Forced circulation<br />

eliminates hotspots while improving engine<br />

performance, reducing maintenance time<br />

and lowering energy costs.

18<br />

MONITORING<br />

Monitoring gen-sets using the<br />

WebSupervisor iPhone app<br />

One of the biggest problems in the standby power sector is getting information on condition status<br />

to people on the move. ComAp has, accordingly, introduced its new ComAp WebSupervisor<br />

iPhone app to allow registered gen-sets to be directly monitored by iPhone. WIP has the story.<br />

The operation and maintenance of<br />

power generation equipment is a<br />

costly business, monitoring of that<br />

equipment is often key to keeping such<br />

costs under control, reports ComAp.<br />

ComAp recognises that while some<br />

companies have the luxury or centralised<br />

monitoring and control suites, sometimes<br />

it is important to get information directly<br />

to people on the move.<br />

This is where the new ComAp<br />

WebSupervisor iPhone app comes in.<br />

‘Simply visit the Apple App store and<br />

download the app onto your iPhone,’ says<br />

the company. Within minutes you are<br />

able to monitor your registered gen-sets<br />

directly from your iPhone, it reports.<br />

Has that rental set you have on the<br />

building project in town flagged up<br />

that maintenance is due? - The<br />

WebSupervisor iPhone app will alert you!<br />

Is someone stealing fuel from your<br />

remote cell-tower standby generator up in<br />

hills? - The WebSupervisor iPhone app will<br />

alert you!<br />

What if the Low Oil pressure alarm<br />

comes up during automatic test on the<br />

standby set you maintain at the local<br />

shopping centre? - The WebSupervisor<br />

iPhone app will alert you!<br />

The WebSupervisor iPhone app utilises<br />

Apple’s ‘push notification’ technology to<br />

get you regular updates from your<br />

monitored sets direct to the application.<br />

This is designed to give the user<br />

reassurance that power generation assets<br />

are performing correctly right in your<br />

pocket.<br />

If you want more information or simply<br />

want to review the fleet at any time the<br />

WebSupervisor iPhone App gives you direct<br />

access to your WebSupervisor account and<br />

all registered sets from anywhere your<br />

iPhone has a signal.<br />

The WebSupervisor iPhone app is part of<br />

ComAp extensive range of communications<br />

products and options all aimed at<br />

getting you ‘simply connected’, so you<br />

can focus on the important things, such as<br />

controlling costs or quickly fixing the<br />

problems as they arise.<br />

The simple interface makes at a glance<br />

review of assets easy. Fleet managers,<br />

N OVEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

site engineers, infrastructure managers,<br />

equipment owners, investors, service<br />

managers or service engineers all benefit<br />

from this highly connected approach to<br />

management of equipment.<br />

Internet link<br />

www.comap.cz<br />

WIP

Fleet management.<br />

The answer’s in your hands.<br />

Visit the Apple app store and download<br />

your <strong>FREE</strong> WebSupervisor iPhone app.<br />

WebSupervisor<br />

Your entire fleet,<br />

safe in your pocket.<br />

The new WebSupervisor iPhone app is the latest development in<br />

ComAp’s extensive range of communications products that<br />

helps you stay connected in real time to your equipment.<br />

The unique and easy to use interface uses Apple’s<br />

‘push notification’ technology to deliver regular<br />

updates on your monitored gen-set, alerting<br />

you to operating problems, fuel status<br />

or unapproved use.<br />

Whenever you need information on<br />

power generation equipment the <strong>FREE</strong><br />

WebSupervisor iPhone App gives you direct<br />

access to your WebSupervisor account and any<br />

number of registered sets straight from your iPhone.<br />

Visit the ComAp website:<br />

www.comap.cz

Mining group NG-Energo has<br />

announced it has won the bidding<br />

to build a turnkey 24 MW power<br />

plant featuring MAN Diesel & Turbo<br />

generators for the ore and diamond<br />

mining company JSC Severalmaz in<br />

northern Russia.<br />

MAN Diesel & Turbo will provide the<br />

plant’s six MAN 18V28/32S Holebydesigned<br />

four-stroke gen-sets powered by<br />

diesel oil.<br />

NG-Energo’s turnkey contract with JSC<br />

Severalmaz covers construction, purchase<br />

and installation as well as logistics. The<br />

project will be executed within the course<br />

of a single year by NG-Energo and Order<br />

Project Management at MAN Diesel &<br />

Turbo in Holeby, Denmark.<br />

The project will be carried out in two<br />

phases, the first of which is planned to<br />

commence in May 2012. MAN Diesel &<br />

Turbo is contracted to deliver the gensets<br />

in two batches of three engines with the<br />

first scheduled for December 2011 and<br />

the second for October 2012.<br />

Three years ago MAN Diesel signed a<br />

similar contract with Empower <strong>Ltd</strong>. for<br />

the supply of 15 × 18V28/32S MAN Diesel<br />

four-stroke gen-sets.<br />

Empower was established to develop a<br />

20<br />

DIESEL ENGINES<br />

NG-Energo chooses 24MW<br />

powerplant for Russian mine<br />

MAN Diesel & Turbo generators have been bought by the mining group NG-Energo for a<br />

mine in northern Russian. By May 2012 six MAN 18V28/32S Holeby-designed four-stroke<br />

gen-sets powered by diesel oil will form the heart of the site’s power-generating capacity.<br />

MAN dry scrubber<br />

technology -<br />

schematic of the<br />

DryEGCs system.<br />

fleet of generating equipment for leasing<br />

to utility and industrial customers in<br />

emerging markets (initially Africa) on a<br />

short-term, flexible basis.<br />

Empower currently operates the units on<br />

behalf of its customers, who purchase<br />

power under a standardised PPA (Power<br />

Purchase Agreement).<br />

The company is wholly owned by Actis<br />

Infrastructure 2 LP, a fund established and<br />

managed by Actis, a leading privateequity<br />

investor in emerging markets.<br />

The 18V28/32S engine is a turbocharged,<br />

single-acting, four-stroke diesel engine of<br />

the trunk-piston type with a cylinder bore<br />

of 280 mm, a stroke of 320 mm, and a<br />

crankshaft speed of 720/750 rpm. Each<br />

gen-set has an output of 4,230 kW.<br />

The 15 gen-sets have been deployed at<br />

one or more locations in sub-Saharan<br />

Africa, most likely in batches of three.<br />

The gen-sets were packaged for Empower<br />

<strong>Ltd</strong>. by East African Industrial<br />

Development <strong>Ltd</strong>. (EAID), the MAN Diesel<br />

representative for East Africa. EAID was<br />

closely involved in the original design of<br />

the generation concept.<br />

V28/32S engines are well-known for<br />

their ability to run on HFO, their high<br />

reliability, the long time between over-<br />

N OVEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

MAN 18V28/32S<br />

Holeby-designed<br />

diesel four-stroke<br />

gen-set.<br />

hauls, and their lifetime of over 20 years<br />

if properly maintained. Units are used<br />

worldwide by power plants, and as a<br />

uxiliary engines aboard ships. Over 6,000<br />

such engines are currently in service.<br />

MAN Diesel & Turbo’s activities in the<br />

power generation and cogeneration<br />

sectors are based on a well established<br />

range of diesel engines and a rapidly<br />

growing gas engine offering.<br />

On the liquid fuel side, two- and fourstroke<br />

engines in a power range from 450<br />

kW to 80 MW. can utilise heavy and<br />

distillate fossil fuels as well as an<br />

increasing range of renewable liquid<br />

bio-fuels.<br />

Currently CO2 –neutral bio-fuel engines<br />

from MAN Diesel & Turbo are in daily<br />

operation on plant oils including palm and<br />

jatropha oils, used cooking oils and<br />

rendered animal fats. On the gaseous fuel<br />

side, single and dual-fuel gas engines from<br />

MAN Diesel & Turbo covering a power<br />

bracket of 2,3 to 17,55 MW are gaining an<br />

increasing share of the global market for<br />

power generation and cogeneration using<br />

both natural and non-natural gases.<br />

WIP<br />

Internet link<br />

www.mandieselturbo.com

MB<br />

17<br />

TB 17<br />

G<br />

Load<br />

Busbar<br />

AGC<br />

200<br />

The<br />

new AGC<br />

200<br />

is designed for a range rangee<br />

of<br />

applications from fromm<br />

single gen-sets in island mode<br />

to<br />

highly highly complex power<br />

stations with up to 16<br />

generators, generaators,<br />

8 bus tie breakers,<br />

and 1 mains/utility breaker.<br />

CANbus<br />

G<br />

AGC<br />

200<br />

AGC<br />

200<br />

G G<br />

AGC<br />

200<br />

Diesel<br />

generator generatoo<br />

r set<br />

1<br />

Diesel<br />

generator generatoo<br />

r sset<br />

et<br />

2<br />

Diesel<br />

generator generatoo<br />

r sset<br />

et<br />

3<br />

DDiesel<br />

iesel<br />

ggenerator<br />

enerato<br />

or<br />

sset<br />

et<br />

4<br />

More control conntrol<br />

– less fuel fue el<br />

– excellen excellent nt value<br />

Features:<br />

�� � ����� ��������������<br />

�������������� � � � � � � � � � � � � � � �������<br />

operating operating temperature<br />

�� � ����������������������<br />

�������������������������������������� � � � � � � � � � � � � � ��������<br />

in 110<br />

0 seconds<br />

�� �� ��������� �����������������������������<br />

�������������� ����������������������� � � � � � � � � � � � � � ���������<br />

of gen-sets for optimised<br />

fuel consumption<br />

�� �� ����� ��������������������<br />

�������������� ������<br />

� � � � � � � � � � � � � ��������<br />

communication<br />

Meet us at the PPower-Gen<br />

ower-<br />

Geen<br />

International exhibition in La Las as Ve Vegas, egas, 13-15<br />

December,<br />

, at st stand tand no. 4230<br />

TThe<br />

he DEIF<br />

Group: sales, training trainning<br />

and competence centres in Brazil, Chin China, na, Denmark, FFrance,<br />

rance, Germany, , India, Norway, Norw way, , <strong>UK</strong>,<br />

and USA,<br />

DEIF<br />

A/S · Frisenborgvej<br />

33 3 33<br />

· DK-7800<br />

Skive · Tel.: Te el.: +45 9614<br />

9614<br />

· Fax:<br />

+45 9614<br />

9615<br />

· info@deif.com<br />

m · www.deif.com<br />

www.deif.<br />

.com<br />

PERFORMANCE THAT MAKES IT’S MARK<br />

��������������������������<br />

������������������������������������<br />

����������������������������<br />

�����������������������<br />

��������������������������<br />

��������������������������<br />

ENGINES FOR POWER GENERATION APPLICATIONS

�������������<br />

��������<br />

����������<br />

�������������������<br />

��������������������<br />

����������������<br />

�����������������������������<br />

�����������������������������������<br />

���������������������������������<br />

���������������������������<br />

������������������<br />

Visit us at the USA’s<br />

POWER-GEN International<br />

December ����������<br />

13th-15th, 2011<br />

�������������<br />

Central Halls/ 2622<br />

Las Vegas Convention Center<br />

���������������-������<br />

�-���������������������������<br />

��������������������<br />

RENEWABLES<br />

Prime m-o-o-vers<br />

in their field<br />

Alfagy’s Greenhill Dairy Farm Biogas plant is the first such<br />

facility in Northern Ireland in 20 years to provide sustainable<br />

heat and power for homes and businesses, reports WIP.<br />

The Greenhill Dairy Farm Biogas<br />

plant is the first plant in Northern<br />

Ireland in 20 years to provide<br />

sustainable heat and power for homes and<br />

businesses.<br />

The power station mimics a cow’s<br />

stomach and cooks animal waste at 40°C<br />

(104°F) to produce methane gas. The gas<br />

is then piped into two engines that drive<br />

generators while hot water is also<br />

produced for drying plant waste, called<br />

digestate, and to pasteurise milk.<br />

This use of waste to produce valuable<br />

energy shows how rural areas and<br />

agriculture can function sustainably.<br />

Power derived from cow dung and grass<br />

silage cuts power prices for all consumers<br />

and decreases agricultures carbon<br />

footprint.<br />

Additionally, the unit will reduce<br />

Northern Irelands reliance on fossil fuels<br />

and prevent volatile energy prices whilst<br />

bringing new jobs to this rural area.<br />

The 700-acre Greenhill farm delivers<br />

grass and animal waste from some 600<br />

cows to fuel the plant. Looking like a<br />

giant muffin, the plant produces 430 Kw<br />

of electricity per hour - enough to supply<br />

some 430 homes with electricity. Alfagy<br />

was selected by the developer for the<br />

project as the Combined Heat and Power<br />

(CHP) and gas conditioning supplier after<br />

a competition against GE Energy, MWM<br />

and MAN. The project faced challenges in<br />

getting funding from a bank during the<br />

financial crisis that is still raging<br />

internationally. However, Alfagys’ high<br />

level of quality and service convinced the<br />

bank to grant a development loan. This is<br />

considered something of an<br />

accomplishment in the current climate<br />

according to Peter Kindt, Alfagy<br />

chairman.<br />

"Given the current credit crunch, this<br />

project is certainly an important<br />

demonstration of a sustainable energy<br />

future. The deciding factor for the<br />

finance of the project was our plant’s<br />

world beating efficiency that produced<br />

1.8 million more revenue than the<br />

competition. Our payback is simply the<br />

fastest in the market,” adds Peter Kindt.<br />

The Ardstraw power plant will be the<br />

52nd biogas power plant in the <strong>UK</strong> and<br />

only the second in Northern Ireland.<br />

More farmers in Northern Ireland are now<br />

considering similar projects, reports the<br />

company.<br />

WIP<br />

Internet link<br />

www.alfagy.com<br />

N OVEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

At the heart of the Alfagy<br />

biogas plant.<br />

Greenhill’s digester.

Moving ahead of the energy curve<br />

The world’s largest offshore wind energy conference and exhibition<br />

29 November - 1 December 2011 Amsterdam, The Netherlands<br />

Gain unrivalled insight into the offshore wind energy industry<br />

It is the world’s largest offshore wind energy event featuring a comprehensive conference<br />

and a compact and cross-sector exhibition with outstanding networking opportunities.<br />

� �����������������������������������������������������<br />

� �������������������������������������<br />

Join 7,000 international professionals in shaping the offshore landscape of tomorrow’s<br />

energy market.<br />

SUPPORTED BY:<br />

With sound enclosure<br />

www.tedom.eu<br />

www.ewea.org/offshore2011<br />

ORGANISED BY:<br />

Register now to benefi t<br />

from early bird rates<br />

CHP Units: Cento Series<br />

One design, many possibilities<br />

NEW<br />

In a container<br />

Units equipped with original TEDOM engines. Electrical output 80 - 200 kW.

UPS Systems has installed a direct<br />

methanol fuel cell (DMFC) at the<br />

<strong>UK</strong> Environment Agency’s Woolston<br />

Weir fishery to monitor the movement of<br />

eels.<br />

The aim is to help conservation work by<br />

providing power to telemetry and CCTV<br />

equipment at an ‘eel pass’ to monitor the<br />

endangered creatures’ journey upstream<br />

to fresh water.<br />

To gauge the success of the new eel<br />

pass, the Environment Agency has<br />

installed a monitoring and telemetry<br />

system at the Woolston site, which uses<br />

CCTV to record and monitor the eels’<br />

journeys providing data about its success.<br />

To provide power to the eel pass, UPS<br />

has installed an EFOY Pro 2200 DMFC<br />

alongside two load-carrying batteries<br />

hooked up in parallel. The DMFC acts as a<br />

charger to ensure the batteries are kept<br />

at optimum voltage at all times.<br />

The system provides continuous power<br />

to a water pump that oxygenates a<br />

holding tank where the eels are counted<br />

and checked. It also powers a webcam<br />

and the telemetry system.<br />

The EFOY Pro 2200 is said to offer 38%<br />

more power than the EFOY Pro 1600; it<br />

24<br />

UPS<br />

UPS, the Environment Agency &<br />

the ‘eel-good’ factor<br />

UPS Systems has installed a direct methanol fuel cell (DMFC) at the <strong>UK</strong> Environment<br />

Agency’s Woolston Weir fishery to monitor the movement of eels. Key to the system is an EFOY<br />

Pro 2200 DMFC alongside two load-carrying batteries hooked up in parallel, reports WIP.<br />

generates 90W of electricity and is said to<br />

be suitable for a range of prime and<br />

standby power applications.<br />

The EFOY Pro 2200 [see right] is<br />

regarded by its manufacturer as a ‘plugand-play’<br />

solution - customers do not<br />

need special expertise to install it. “EFOY<br />

has proved that, in some situations, its<br />

fuel cells can save users up to 90% in<br />

operating and maintenance costs, so the<br />

argument for investing in fuel cell<br />

technology continues to grow,” comments<br />

UPS Systems’ Managing Director Tom<br />

Sperrey.<br />

The EFOY Pro 2200 is described as robust<br />

and doesn’t require maintenance, so it<br />

can be left alone for long periods. For<br />

example, an EFOY Pro 2200 using a 28litre<br />

methanol cartridge can power a 50W<br />

traffic signal serial blinker for 26 days,<br />

while a traditional battery can only power<br />

it for one day.<br />

Like other fuel cells in the EFOY range,<br />

the EFOY Pro 2200 can be used in hybrid<br />

installations which take advantage of<br />

renewable energy sources such as solar or<br />

wind. Such configurations recharge the<br />

batteries that power electrical<br />

equipment. This makes the EFOY Pro 2200<br />

N OVEMBER 2011 • WORLDWIDE I NDEPENDENT P OWER<br />

suitable for standby power applications<br />

and for operation in remote areas where<br />

there isn’t easy access to the grid, says<br />

UPS Systems. The EFOY Pro 2200 can be<br />

located outside, and can operate in all<br />

weather conditions.<br />

The manufacturer of EFOY fuel cells,<br />

Smart Fuel Cell AG, has shipped more<br />

than 16,000 fully commercial products to<br />

industrial and private end users for more<br />

than six years. It has created a convenient<br />

supply infrastructure for its fuel<br />

cartridges, which deliver week-long<br />

autonomous energy and can be obtained<br />

from more than 1,400 sales points in<br />

Europe [www.sfc.com].<br />

SFC Energy AG is a market leader in fuel<br />

cell technologies for mobile and off-grid<br />

power applications serving the leisure,<br />

industrial and defence markets. As one of<br />

Germany’s technology pioneers, SFC has<br />

won numerous innovation awards. Unlike<br />

most other fuel cell manufacturers, who<br />

are in the research and development<br />

phase or run subsidised demonstration<br />

projects, SFC has shipped more than<br />

21,000+ fully commercial products to<br />

industrial and private end-users since<br />

2007.<br />

WIP<br />

Internet link<br />

www.upssystems.co.uk

E. VAN WINGEN NV<br />

Battery<br />

Monitoring<br />

Battery<br />

Testing<br />

Battery<br />

Maintenance Seminars<br />

www.batterymonitoring.com<br />

”Real Battery Monitoring & Management<br />

solutions - not promises!”<br />

CellCare Technologies Limited<br />

Unit J1, Valley Way<br />

Welland Business Park<br />

Market Harborough<br />

Leicestershire, LE16 7PS<br />

United kingdom<br />

T: +44 (0)1858 468438<br />

F: +44 (0)1858 468439<br />

E: info@cellcare.com<br />

W: www.cellcare.com<br />

WORLDWIDE DIESEL & GAS POWER<br />

DIESEL GEN-SETS<br />

MAINS FAILURE SOLUTIONS<br />

POWER STATIONS<br />

COGENERATION<br />

BIOMASS APPLICATIONS<br />

D.ups ROTARY NO-BREAK SYSTEMS<br />

ENGINEERING, MANUFACTURING,<br />

INSTALLATION, SERVICE & MAINTENANCE<br />

Industrieterrein Durmakker 27 - 9940 Evergem, Belgium<br />

T +32 (0)9 253 08 00 - F +32 (0)9 253 40 82<br />

info@vanwingen.be - www.vanwingen.be

SE Generation, a generation business<br />

of Scottish & Southern Energy, has<br />

invested £240m to install flue gas<br />

desulphurisation (FGD) equipment at its<br />

2,000MW Fiddler’s Ferry power station in<br />

Cheshire, <strong>UK</strong>. It has also done the same<br />

for half of the capacity at its 2,000MW<br />

Ferrybridge power station in South<br />

Yorkshire.<br />

The plant can now operate in line with<br />

the limits on sulphur-dioxide emissions<br />

contained in the Large Combustion Plan<br />

Directive (LCPD).<br />

The FGD equipment means the stations<br />

can use higher-sulphur coal mined in the<br />