scope of work - Vizag Steel

scope of work - Vizag Steel

scope of work - Vizag Steel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Work Desc :<br />

5<br />

6<br />

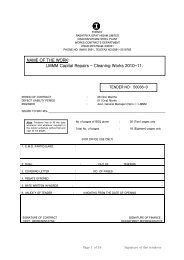

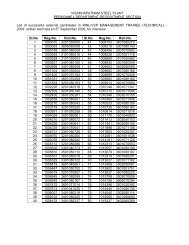

SCOPE OF WORK TENDER NO :<br />

TENDER No : 72211-0<br />

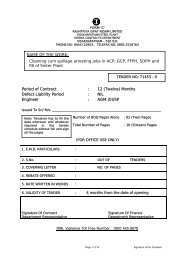

Common shutdown jobs, Capital repair jobs and Maintenance <strong>of</strong> Heat<br />

Exchangers in Utilities Department <strong>of</strong> VISAKHAPATNAM <strong>Steel</strong> Plant<br />

Removal <strong>of</strong> the existing valve and keeping at designated location<br />

Fixing the serviced valve in position & testing for leak tightness<br />

1.4 Scope <strong>of</strong> <strong>work</strong> for erection <strong>of</strong> new copper pipes at PRS-I (Item no.6<br />

<strong>of</strong> BOQ)<br />

a) Preparatory arrangements to be done before starting <strong>of</strong> the job as per<br />

the directions <strong>of</strong> VSP Engineer<br />

b) Obtain <strong>work</strong> permit / shut down & drop the quick shut <strong>of</strong>f valve,<br />

Pressure control valve, vent lines etc and the existing copper pipe<br />

carefully & place them at the location shown by VSP Engineer.<br />

c) The down stream & upstream flanges are to be isolated from the<br />

process as well as electrically by fixing the 350 NB cl-600 dummies, if<br />

required.<br />

d) The pipes are to be cut by grinding wheel/plasma cutting machine<br />

at the location shown by VSP Engineer. Plasma cutting machine may be<br />

supplied by VSP free <strong>of</strong> cost, de-pending upon availability.<br />

e) The pipe edges are to be prepared for high pressure pipe welding<br />

<strong>of</strong> radiography quality.<br />

f) The new pipe pieces along with flanges are to be tack welded by TIG<br />

welding.<br />

g) After matching <strong>of</strong> the flange holes with new pipe flanges, full<br />

welding <strong>of</strong> the joints to be carried out by TIG welding.<br />

h) The pipes are to be cleaned for oxygen service.<br />

i) The valves, pipes, quick shut <strong>of</strong>f valve, pressure control valve are to<br />

be degreased & fixed.<br />

j) The downstream & upstream valve flanges are to be tightened.<br />

k) The vent lines are to be fixed back.<br />

l) Then leak checking and rectification, radiography are to be carried<br />

out.<br />

m) Other than DC welding machine, equipment, consumables, DP test kit<br />

required for TIG welding is in VSP's <strong>scope</strong>.<br />

n) TIG welding & radiography is to be measured separately.<br />

1.5 Scope <strong>of</strong> <strong>work</strong> for oxygen service cleaning & degreasing <strong>of</strong> seamless<br />

piping size: 250 NB (item no.7 <strong>of</strong> BOQ)<br />

a) Each pipe length / pipe fitting is transported to cleaning site. To be<br />

cleaned thoroughly by brush/cloth and blown with ompressed air.<br />

b) The pipe length / fitting is to be taken to steam tapping point and<br />

to be cleaned it's internal & external surfaces thoroughly with steam.<br />

c) After steam cleaning, it shall be dried with nitrogen for atleast<br />

30minutes and <strong>of</strong>fered for inspection.<br />

d) Degreasing <strong>of</strong> pipe internal shall be done by CTC using polyester<br />

cloth only & then blown with nitrogen for atleast 30 minutes.<br />

14 <strong>of</strong> 39 Signature <strong>of</strong> the Tenderer