scope of work - Vizag Steel

scope of work - Vizag Steel

scope of work - Vizag Steel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Work Desc :<br />

29<br />

30<br />

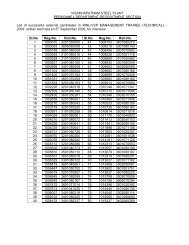

SCOPE OF WORK TENDER NO :<br />

TENDER No : 72211-0<br />

Common shutdown jobs, Capital repair jobs and Maintenance <strong>of</strong> Heat<br />

Exchangers in Utilities Department <strong>of</strong> VISAKHAPATNAM <strong>Steel</strong> Plant<br />

9.20.0 Assisting in repair <strong>of</strong> end covers partition walls before starting<br />

chemical cleaning, if required.<br />

9.21.0 End covers gaskets are to be replaced before starting chemical<br />

cleaning / after chemical cleaning depending on condition.<br />

9.22.0 Special protective paints if any are to be applied before / after<br />

chemical cleaning as per direction <strong>of</strong> VSP engineer, necessary surface<br />

cleaning / power buffing is to be done. Application <strong>of</strong> special protective<br />

paints is to be arranged by VSP.<br />

9.23.0 End covers, connecting piping is also to be cleaned thoroughly<br />

before boxing up.<br />

9.24.0 Quantities <strong>of</strong> descalent (sulphamic acid), Sodium hydroxide, trisodium<br />

phosphate to be added are to be decided by the VSP engineer each<br />

time based on the holdup volume <strong>of</strong> system which includes the following<br />

a) Circulation tank capacity and level to which the tank will be filled.<br />

b) Volume <strong>of</strong> suction and discharge connections between pump, circulation<br />

tank and exchanger to be cleaned.<br />

c) Volume <strong>of</strong> exchanger tubes, dished end etc..<br />

9.25.0 System is to be inspected for every 1/2 hour for leakages <strong>of</strong> water<br />

and chemical solutions and inspected leakages are to be attended<br />

immediately.<br />

9.26.0 During fresh water circulation deaeration <strong>of</strong> exchanger is to be<br />

ensured. After deaeration only, chemicals to the circulation tank shall be<br />

added.<br />

9.27.0 Cleaning procedure and quantity <strong>of</strong> chemicals etc,. may be ammended<br />

based on the technical requirement at the discretion <strong>of</strong> the Engineer -in -<br />

charge.<br />

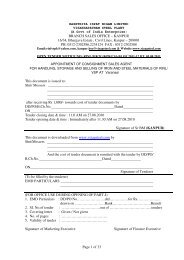

10.0 For item no.56 : Technological assistance for manual cleaning <strong>of</strong> heat<br />

exchangers<br />

Centrifugal turbo-compressors <strong>of</strong> different makes/capacities are installed<br />

in utilities department handling various fluids like air, nitrogen, oxygen.<br />

Each compressor is equipped with shell and tube type heat exchangers for<br />

inter stage cooling and oil coolers for cooling lubricating oil.<br />

The compressor motors are provided with motor cooler (shell and tube type<br />

exchanger).<br />

Chillers <strong>of</strong> Voltas/Sulzer/York/Carrier make are installed in Chilled Water<br />

Plants / ASP and these are equipped with condensers/evaporators.<br />

The <strong>scope</strong> <strong>of</strong> <strong>work</strong> for this item covers all the heat exchangers mentioned<br />

26 <strong>of</strong> 39 Signature <strong>of</strong> the Tenderer