deutz live 1/2009

deutz live 1/2009

deutz live 1/2009

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Innovation<br />

Rail construction machinery<br />

Low-emissions<br />

workhorses<br />

on rails<br />

Track construction equipment needs to satisfy<br />

high requirements. In Munich and Nuremberg,<br />

DEUTZ engines are the driving force behind<br />

several multi-functional vehicles.<br />

INFO | Technical Regulations for Hazardous<br />

The Technical Regulations for Hazardous Substances 554 (diesel engine exhausts) prescribe<br />

special protective measures for work areas in which diesel engine emissions (DME) can occur.<br />

The Technical Regulations for Hazardous Substances are published in the German Ministry for<br />

Labour and Social Affairs's joint ministerial official gazette.<br />

16 DEUTZLIVE 1/<strong>2009</strong><br />

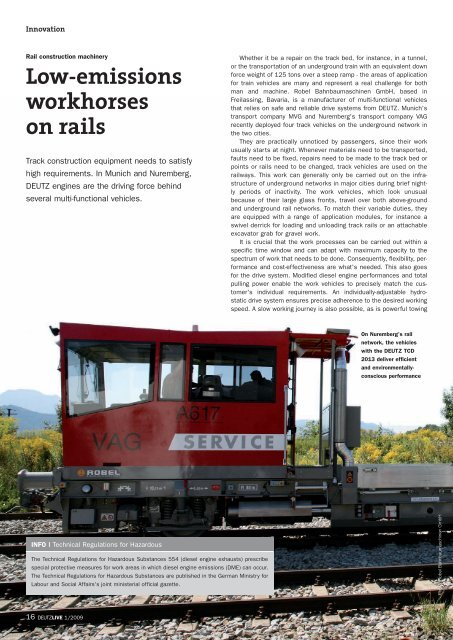

Whether it be a repair on the track bed, for instance, in a tunnel,<br />

or the transportation of an underground train with an equivalent down<br />

force weight of 125 tons over a steep ramp - the areas of application<br />

for train vehicles are many and represent a real challenge for both<br />

man and machine. Robel Bahnbaumaschinen GmbH, based in<br />

Freilassing, Bavaria, is a manufacturer of multi-functional vehicles<br />

that relies on safe and reliable drive systems from DEUTZ. Munich's<br />

transport company MVG and Nuremberg's transport company VAG<br />

recently deployed four track vehicles on the underground network in<br />

the two cities.<br />

They are practically unnoticed by passengers, since their work<br />

usually starts at night. Whenever materials need to be transported,<br />

faults need to be fixed, repairs need to be made to the track bed or<br />

points or rails need to be changed, track vehicles are used on the<br />

railways. This work can generally only be carried out on the infrastructure<br />

of underground networks in major cities during brief nightly<br />

periods of inactivity. The work vehicles, which look unusual<br />

because of their large glass fronts, travel over both above-ground<br />

and underground rail networks. To match their variable duties, they<br />

are equipped with a range of application modules, for instance a<br />

swivel derrick for loading and unloading track rails or an attachable<br />

excavator grab for gravel work.<br />

It is crucial that the work processes can be carried out within a<br />

specific time window and can adapt with maximum capacity to the<br />

spectrum of work that needs to be done. Consequently, flexibility, performance<br />

and cost-effectiveness are what's needed. This also goes<br />

for the drive system. Modified diesel engine performances and total<br />

pulling power enable the work vehicles to precisely match the customer's<br />

individual requirements. An individually-adjustable hydrostatic<br />

drive system ensures precise adherence to the desired working<br />

speed. A slow working journey is also possible, as is powerful towing<br />

On Nuremberg's rail<br />

network, the vehicles<br />

with the DEUTZ TCD<br />

2013 de<strong>live</strong>r efficient<br />

and environmentallyconscious<br />

performance<br />

Photo: Robel Bahnbaumaschinen GmbH