New drive – Curtain up for the technology of the future - DEUTZ Home

New drive – Curtain up for the technology of the future - DEUTZ Home

New drive – Curtain up for the technology of the future - DEUTZ Home

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>DEUTZ</strong>LIVE<br />

The magazine <strong>of</strong> <strong>DEUTZ</strong> AG Edition 1/2010<br />

Technology<br />

<strong>New</strong> names <strong>for</strong> new<br />

<strong>technology</strong><br />

Expertise<br />

How <strong>DEUTZ</strong> found a way<br />

out <strong>of</strong> <strong>the</strong> crisis<br />

<strong>New</strong> <strong>drive</strong> <strong>–</strong><br />

<strong>Curtain</strong> <strong>up</strong> <strong>for</strong> <strong>the</strong><br />

<strong>technology</strong> <strong>of</strong> <strong>the</strong> <strong>future</strong><br />

®

Photo: <strong>DEUTZ</strong> AG<br />

Dr Helmut Leube<br />

<strong>New</strong> <strong>drive</strong><br />

The 2009 financial year has been one <strong>of</strong> <strong>the</strong><br />

most difficult in <strong>DEUTZ</strong> AG‘s long history.<br />

For <strong>the</strong> first six months <strong>of</strong> 2008, impressive<br />

results were still being reported. Then two years<br />

ago this summer an un<strong>for</strong>eseeable crisis began<br />

to set in that went beyond <strong>the</strong> financial sector<br />

and soon entered <strong>the</strong> real economy. For <strong>DEUTZ</strong><br />

this meant having to cope with severe setbacks.<br />

What began as a consequence <strong>of</strong> poor speculation<br />

by bankers, soon entered <strong>the</strong> real economies<br />

<strong>of</strong> North America and Europe and resulted<br />

in a dramatic drop in demand, primarily <strong>for</strong> mobile<br />

machinery, our largest segment. Engine unit<br />

sales more than halved going from 252,359 units<br />

down to 117,961 units with <strong>the</strong> drop in revenue<br />

being slightly less at 42.2 % and amounting to<br />

g863.4 million. Operating pr<strong>of</strong>it be<strong>for</strong>e one-<strong>of</strong>f<br />

items crashed to g<strong>–</strong>46.3 million. But in this difficult<br />

year we quickly took appropriate measures.<br />

Since its start, <strong>the</strong> MOVE package <strong>of</strong> measures to<br />

reduce costs and raise efficiency, has achieved<br />

savings <strong>of</strong> around g136 million from material and<br />

Editorial<br />

overhead costs. However, personnel measures,<br />

such as short-time working, temporary staff cutbacks,<br />

early retirement and even en<strong>for</strong>ced redundancies,<br />

were still necessary to achieve long-term<br />

reductions in fixed costs and to ensure our competitiveness.<br />

In addition, over <strong>the</strong> past 12 months<br />

we have sharply focussed on our working capital<br />

and cash flow situations. Internal financing has<br />

meant a positive operative cash flow situation despite<br />

<strong>the</strong> severe collapse in sales. By <strong>the</strong> end <strong>of</strong><br />

2009, we had managed to survive <strong>the</strong> crisis practically<br />

debt-free.<br />

For <strong>the</strong> first time since <strong>the</strong> onset <strong>of</strong> <strong>the</strong> crisis, we<br />

were able to report a clear rise in demand at <strong>the</strong><br />

year end. The fourth quarter confirmed <strong>the</strong> trend<br />

with an approximate positive operating result.<br />

<strong>DEUTZ</strong> has passed <strong>the</strong> low point <strong>of</strong> <strong>the</strong> crisis.<br />

Looking to this year, we can affirm a clear continuation<br />

<strong>of</strong> this positive development. Turnover<br />

and sales <strong>for</strong> <strong>the</strong> first quarter <strong>of</strong> 2010 are above<br />

expectations. A significantly improved order book<br />

means we can expect 2010 to be much better<br />

than 2009.<br />

Find out on p.18 how <strong>DEUTZ</strong> set a new course<br />

<strong>for</strong> <strong>the</strong> <strong>future</strong> while being in <strong>the</strong> midst <strong>of</strong> <strong>the</strong> biggest<br />

crisis <strong>of</strong> current times. In spite <strong>of</strong> <strong>the</strong> severe<br />

economic situation we kept looking ahead and<br />

developed <strong>the</strong> two new TCD 2.9 L4 and TCD 3.6<br />

L4 engines. They are also <strong>the</strong> central point <strong>of</strong> this<br />

year‘s bauma stand (p.8). And it isn‘t just <strong>the</strong>se<br />

two that are new at <strong>DEUTZ</strong>. To highlight <strong>the</strong> technological<br />

advance represented by <strong>the</strong> development<br />

<strong>of</strong> our engines <strong>for</strong> Tier 4 interim emissions,<br />

all <strong>DEUTZ</strong> engines from this emission stage will<br />

receive new product designations. Find out on<br />

p.10 how <strong>the</strong>se will look.<br />

Dear <strong>DEUTZ</strong> LIVE readers, we have shown that<br />

even in times <strong>of</strong> crisis we do not lose sight <strong>of</strong><br />

what‘s important. Technological expertise and<br />

<strong>the</strong> ability to demonstrate strength under extreme<br />

conditions is what marks us out. Looking to <strong>the</strong><br />

<strong>future</strong> <strong>–</strong> that is <strong>DEUTZ</strong>. Let us look ahead toge<strong>the</strong>r<br />

and go into <strong>the</strong> <strong>future</strong> with new energy from our<br />

new engines.<br />

Yours,<br />

Dr Helmut Leube<br />

3

Contents<br />

4 <strong>DEUTZ</strong>LIVE 01/2010<br />

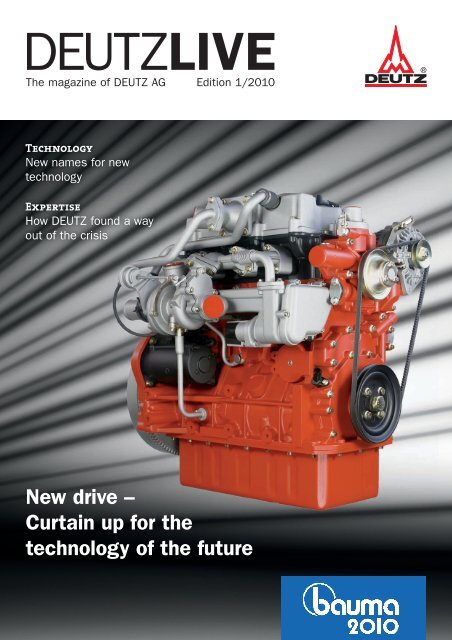

Title photo<br />

<strong>DEUTZ</strong> presents<br />

<strong>the</strong> new 4-cylinder<br />

TCD 2.9 L4 engine<br />

10 With <strong>the</strong> introduction <strong>of</strong><br />

engines <strong>for</strong> <strong>the</strong> stricter EU<br />

emissions stage IIIB/US EPA<br />

Tier 4 interim, <strong>DEUTZ</strong> is<br />

changing its range <strong>of</strong> model<br />

designations<br />

Title<br />

8 <strong>New</strong> <strong>drive</strong> - <strong>Curtain</strong> <strong>up</strong> <strong>for</strong> <strong>the</strong><br />

<strong>technology</strong> <strong>of</strong> <strong>the</strong> <strong>future</strong><br />

In <strong>the</strong> midst <strong>of</strong> <strong>the</strong> crisis <strong>DEUTZ</strong> sets a <strong>future</strong><br />

course and develops two new engines

Photos: <strong>DEUTZ</strong> AG, Pixelio, Fotolia, Bomag, Flughafen Leipzig<br />

Contents<br />

10 <strong>New</strong> names <strong>for</strong> new <strong>technology</strong><br />

<strong>New</strong> product designations provide <strong>DEUTZ</strong><br />

customers with important product in<strong>for</strong>mation<br />

13 Top <strong>the</strong>me: Exhaust gas aftertreatment<br />

<strong>DEUTZ</strong> symposium on exhaust gas aftertreatment<br />

at bauma 2010<br />

14 Restrained power<br />

The power <strong>of</strong> a <strong>DEUTZ</strong> engine in <strong>the</strong> Bomag<br />

“hybrid roller”<br />

16 S<strong>up</strong>er with <strong>DEUTZ</strong><br />

The new fl agship from Joseph Vögele AG:<br />

The S<strong>up</strong>er 3000-2 - powered by <strong>DEUTZ</strong><br />

18 How <strong>DEUTZ</strong> found a way out <strong>of</strong> <strong>the</strong> crisis<br />

Following record results <strong>for</strong> 2007, <strong>the</strong> crisis <strong>the</strong>n hit<br />

<strong>DEUTZ</strong>. But <strong>the</strong> long-established company managed to<br />

reverse <strong>the</strong> trend<br />

20 Weightless with <strong>DEUTZ</strong><br />

<strong>DEUTZ</strong> provides transport at <strong>the</strong><br />

Leipzig/Halle Airport<br />

22 <strong>DEUTZ</strong> at <strong>the</strong> top <strong>of</strong> world<br />

In <strong>the</strong> world’s highest country <strong>DEUTZ</strong><br />

provides dependable energy s<strong>up</strong>plies<br />

Topics<br />

3 Editorial<br />

6 <strong>New</strong>s<br />

23 Press news<br />

23 Reader activity<br />

14 Powered by <strong>DEUTZ</strong> - <strong>the</strong> Bomag “hybrid roller”<br />

20 Weightless with <strong>DEUTZ</strong> - <strong>DEUTZ</strong> in action at <strong>the</strong><br />

Leipzig/Halle Airport<br />

22 Extreme conditions: Since 2009 <strong>DEUTZ</strong> has<br />

had a presence in <strong>the</strong> Nepalese market<br />

IMPRINT | <strong>DEUTZ</strong> LIVE Edition 1/2010 | PUBLISHED BY <strong>DEUTZ</strong> AG, Ottostraße 1, 51149 Köln (Porz-Eil) | RESPONSIBLE Janina Decker, Company Communication |<br />

OBJECT MANAGEMENT Janina Decker, Phone: +49 (0)221 822 24 93, Fax: +49 (0)221 822 15 24 93, Email: decker.j@deutz.com | EDITORS Janina Decker | DESIGN department Agentur für<br />

Kommunikation, Köln | CREATIVE DIRECTOR Yusuf Öztürk | LAYOUT Michael Göken, Nina Kanani | PHOTOS/ILLUSTRATIONS Janina Decker, <strong>DEUTZ</strong> AG, Shutterstock, Fotolia, Pixelio, Leipziger<br />

Flughafen, Bomag, Vögele | PRINTED BY Druckpartner, Essen<br />

5

<strong>New</strong>s<br />

Las Vegas<br />

Strong showing<br />

<strong>DEUTZ</strong> AG demonstrates <strong>for</strong>ward-looking<br />

at <strong>the</strong> World <strong>of</strong> Concrete in Las Vegas.<br />

From 2 - 5 February 2010, <strong>DEUTZ</strong> was at<br />

one <strong>of</strong> <strong>the</strong> USA’s most prestigious construction<br />

trade fairs presenting its machinery<br />

engines that meet <strong>the</strong> stricter US EPA<br />

Tier 3/ Tier 4 interim emission standards.<br />

A wide range <strong>of</strong> exhaust gas aftertreatment<br />

components from <strong>the</strong> DVERT ® system also<br />

awaited trade fair visitors. <strong>DEUTZ</strong> presented<br />

DVERT ® components, filters and SCR<br />

<strong>technology</strong> as display models as well as<br />

exhibiting <strong>the</strong> TCD 2010, TCD 2011, TCD<br />

2012 engine series. A special highlight<br />

<strong>for</strong> visitors was a computer-aided simulation<br />

<strong>of</strong> <strong>the</strong> brand new engine with <strong>the</strong><br />

preliminary project designation TCD 20XX.<br />

Cologne<br />

JIS centre opens<br />

6 <strong>DEUTZ</strong>LIVE 01/2010<br />

<strong>DEUTZ</strong> at <strong>the</strong> WOC 2010<br />

<strong>DEUTZ</strong> again demonstrates it is in <strong>the</strong> <strong>for</strong>efront <strong>of</strong> engine manufacture<br />

optimisation by investing €2.5 million in a new just-in-sequence (JIS)<br />

assembly centre at its Porz location in Cologne. Within a 12,000 m²<br />

building, <strong>DEUTZ</strong> is optimising its assembly processes and material<br />

management to deal with <strong>the</strong> increasing product diversity resulting<br />

from new emissions legislation. The wide variety <strong>of</strong> individual components<br />

are picked just-in-time in <strong>the</strong> required sequence. In many cases<br />

<strong>the</strong>y are <strong>the</strong>n pre-assembled be<strong>for</strong>e being delivered to <strong>the</strong> assembly<br />

lines. S<strong>up</strong>pliers send components to <strong>the</strong> JIS centre on just <strong>the</strong> day<br />

required enabling a permanent reduction in on-site stock levels. To<br />

manage <strong>the</strong> material, <strong>the</strong> components are made available in <strong>the</strong> <strong>for</strong>m<br />

<strong>of</strong> sequence boxes at more than 30 workstations.<br />

The switch to delivery via <strong>the</strong> JIS centre already began in mid-2009.<br />

Production management systems were switched to full sequencing<br />

with different orders being lined <strong>up</strong> at assembly like a string <strong>of</strong> pearls.<br />

With <strong>the</strong> required lead times, <strong>the</strong> JIS centre and s<strong>up</strong>pliers can <strong>the</strong>n<br />

deliver just <strong>the</strong> right level <strong>of</strong> materials at just <strong>the</strong> right time. With <strong>the</strong><br />

implementation <strong>of</strong> JIT (Just in Time) / JIS (Just in Sequence) logistics,<br />

<strong>DEUTZ</strong> is optimising its workflows within engine production. In <strong>future</strong>,<br />

only those basic components used on all engine variants will be held<br />

at <strong>the</strong> assembly line workstations with sequencing doing away with <strong>the</strong><br />

need <strong>for</strong> walkways.<br />

Around 50 staff, who <strong>for</strong>merly worked within assembly, are to be employed<br />

in <strong>the</strong> JIS centre on a two-shift basis. In <strong>the</strong>ir new roles <strong>the</strong>y will<br />

sequence s<strong>up</strong>ply <strong>up</strong> to 50 separate engine assembly workstations.<br />

Ulm<br />

500,000 <strong>DEUTZ</strong> engines from Ulm<br />

A milestone has been reached at <strong>the</strong> <strong>DEUTZ</strong> plant in Ulm. At <strong>the</strong> turn <strong>of</strong><br />

<strong>the</strong> year, <strong>the</strong> 500,000st <strong>DEUTZ</strong> engine rolled <strong>of</strong>f <strong>the</strong> production line at<br />

<strong>the</strong> Ulm-Donautal site. The Ulm site went into production in 1967. The<br />

team <strong>the</strong>re is <strong>the</strong>n able to draw on decades <strong>of</strong> experience in <strong>the</strong> design<br />

and assembly <strong>of</strong> air-cooled and water-cooled engines. It all began with<br />

production <strong>of</strong> <strong>the</strong> air-cooled FL312 V-engine, with <strong>the</strong> FL413 engine<br />

series being added just one year later, a series that is still enjoying<br />

success today as part <strong>of</strong> <strong>the</strong> product range.<br />

In 1993 production commenced in Ulm <strong>of</strong> <strong>the</strong> 1015 water-cooled engine<br />

series To date over 35,000 units <strong>of</strong> this engine type have left <strong>the</strong><br />

site in a multitude <strong>of</strong> variants. It became popular through its use in <strong>the</strong><br />

Dakar Rally, <strong>the</strong> world‘s toughest <strong>of</strong>f-road motor race, with its proven<br />

reliability and robustness helping many race teams to success. The Vengines<br />

<strong>of</strong> <strong>the</strong> 413/513 and 1015/2015 production series deliver impressive<br />

per<strong>for</strong>mance and efficiency whe<strong>the</strong>r on road in heavy goods<br />

vehicles, on construction sites, in mines or on rails. They have made<br />

Ulm <strong>the</strong> centre <strong>for</strong> air and water cooled engines with a displacement<br />

over 8 litres. Ulm is also <strong>the</strong> centre <strong>for</strong> all <strong>DEUTZ</strong>‘s marine activity.<br />

The relocation <strong>of</strong> production <strong>of</strong> <strong>the</strong> 912/913/914 air-cooled engine<br />

series from Cologne to Ulm in late 2006/early 2007 marked <strong>the</strong> most<br />

important turning point in <strong>the</strong> plant‘s recent history. The Ulm plant today<br />

produces air-cooled and water-cooled engines with a power output<br />

<strong>of</strong> <strong>up</strong> to 500kW <strong>for</strong> use in stationary equipment, construction equipment,<br />

commercial vehicles and rail vehicles.<br />

The 500,000st <strong>DEUTZ</strong> engine from Ulm

Photos: <strong>DEUTZ</strong> AG<br />

Cologne<br />

Volvo and <strong>DEUTZ</strong> sign new s<strong>up</strong>ply agreement<br />

The Volvo Gro<strong>up</strong> has been working closely<br />

<strong>for</strong> many years with <strong>the</strong> <strong>DEUTZ</strong> engine<br />

manufacturer. In 1998 both companies<br />

signed an agreement <strong>for</strong> <strong>the</strong> development<br />

and s<strong>up</strong>ply <strong>of</strong> diesel engines with displacements<br />

from 4-7 litres. The agreement was<br />

made <strong>for</strong> a 15 year period and comes to<br />

an end in 2013.<br />

The new s<strong>up</strong>ply agreement will come into<br />

effect from 1 January 2014. It covers <strong>the</strong><br />

fur<strong>the</strong>r development <strong>of</strong> medium-sized<br />

<strong>DEUTZ</strong> industrial engines <strong>for</strong> <strong>the</strong> European<br />

COM IV and US Tier 4 final emission<br />

standards. The agreement means <strong>DEUTZ</strong><br />

remains <strong>the</strong> sole s<strong>up</strong>plier <strong>of</strong> 4-8 litre engines<br />

<strong>for</strong> Volvo’s construction machinery.<br />

Cologne<br />

Friends Association established <strong>for</strong> <strong>DEUTZ</strong> AG<br />

engine collection<br />

In cooperation with <strong>the</strong> Cologne City<br />

Museum, <strong>DEUTZ</strong> AG has established a<br />

Friends Association <strong>for</strong> <strong>the</strong> preservation<br />

and <strong>up</strong>keep <strong>of</strong> its historical engine collection.<br />

The aim <strong>of</strong> <strong>the</strong> „Friends <strong>of</strong> <strong>DEUTZ</strong>‘s<br />

Engine Collection“ is to safeguard and<br />

maintain <strong>DEUTZ</strong>‘s unique engine collection,<br />

a collection that is also protected<br />

through its registration as a German<br />

national cultural asset. This unique and<br />

historical collection goes back to <strong>the</strong> year<br />

1875. Already in 1925, exhibits could<br />

Cologne<br />

Bosch, <strong>DEUTZ</strong> and Eberspächer set <strong>up</strong> joint<br />

venture <strong>for</strong> diesel exhaust aftertreatment<br />

On 9 December 2009, Robert Bosch<br />

GmbH, <strong>DEUTZ</strong> AG and Eberspächer GmbH<br />

& Co. KG signed an agreement to set <strong>up</strong><br />

a joint venture in diesel aftertreatment.<br />

On 7 April 2010, <strong>the</strong> “Bosch Emission<br />

Systems” joint venture was approved by<br />

<strong>the</strong> EU Commission and may now begin<br />

operations.<br />

Bosch Emission Systems, based in Stuttgart,<br />

is to utilize <strong>the</strong> core competencies<br />

in exhaust gas aftertreatment from <strong>the</strong><br />

three participating companies, and to<br />

<strong>of</strong>fer complete modularised system solutions<br />

<strong>for</strong> construction and agricultural<br />

machinery as well as <strong>for</strong> commercial vehicles.<br />

This includes electronic controlling<br />

and, if required, burner <strong>technology</strong><br />

<strong>for</strong> <strong>the</strong> regeneration <strong>of</strong> diesel particulate<br />

<strong>DEUTZ</strong> will also continue to s<strong>up</strong>ply engines<br />

complying with <strong>the</strong> Euro 3, 4 and 5 emissions<br />

standards <strong>for</strong> existing use in Volvo<br />

commercial vehicles. “We pride ourselves<br />

on <strong>the</strong> success <strong>of</strong> <strong>the</strong> collaboration and<br />

look <strong>for</strong>ward to it continuing over <strong>the</strong> long<br />

term.” says Dr. Helmut Leube, CEO <strong>of</strong><br />

<strong>DEUTZ</strong> AG.<br />

be viewed by <strong>the</strong> public in a company<br />

museum. The association encourages<br />

broad public access to <strong>the</strong> collection, e.g.<br />

through visitor schemes as well as <strong>the</strong><br />

financing <strong>of</strong> new exhibits and restoration<br />

projects.<br />

Helmut Müller, who heads <strong>the</strong> history activities<br />

<strong>for</strong> <strong>DEUTZ</strong>, holds <strong>the</strong> chairmanship<br />

<strong>of</strong> <strong>the</strong> Friends Association. Its deputy is<br />

Dr. Michael Euler-Schmidt, acting Director<br />

<strong>of</strong> <strong>the</strong> Cologne City Museum.<br />

filters. The products on <strong>of</strong>fer are tailored<br />

to mobile machinery such as excavators,<br />

wheel loaders, tractors and combine harvesters,<br />

as well as to stationary systems.<br />

O<strong>the</strong>r areas <strong>of</strong> usage are commercial vehicles<br />

such as heavy goods vehicles and<br />

buses.<br />

The concept is based on a modularised<br />

system. A large pool <strong>of</strong> standard components<br />

enables custom-built exhaust gas<br />

aftertreatment systems to be assembled<br />

<strong>for</strong> any vehicle or any machine. “We have<br />

made a name <strong>for</strong> ourselves as an engine<br />

manufacturer who can provide individual<br />

solutions <strong>for</strong> our customers. We are now<br />

bringing this important know-how to <strong>the</strong><br />

joint venture and by doing so we are not<br />

only investing in our own products, but<br />

NOTICES | In brief<br />

Management team<br />

<strong>for</strong> <strong>DEUTZ</strong> Dalian now<br />

complete<br />

<strong>New</strong>s<br />

Since August 2007 <strong>DEUTZ</strong> AG and FAW Jiefang<br />

Automotive Co. Ltd. (FAW), a wholly<br />

owned subsidiary <strong>of</strong> China First Automobile<br />

Works Gro<strong>up</strong> Corp. (FAW Gro<strong>up</strong>) in Dalian,<br />

China, have been s<strong>up</strong>porting <strong>the</strong> joint<br />

venture <strong>DEUTZ</strong> (Dalian) Engine Co., Ltd.<br />

(DDE). The Cologne engine manufacturer is<br />

responsible <strong>for</strong> <strong>the</strong> joint venture’s industrial<br />

management and last year introduced new<br />

personnel to pivotal managerial positions in<br />

order to hasten <strong>the</strong> young venture towards<br />

pr<strong>of</strong>it-making.<br />

The 41 year old Bernd H<strong>of</strong>fmann has become<br />

<strong>the</strong> Chinese company’s new CEO. The<br />

mechanical engineer had previously spent<br />

five years as head <strong>of</strong> <strong>the</strong> CLAAS Hungaria<br />

Kft. in Hungary. He has also headed production<br />

systems at CLAAS KGaA in Harsewinkel<br />

in Germany.<br />

With Stella Teng as <strong>the</strong> new CFO, <strong>the</strong> <strong>DEUTZ</strong><br />

Dalian Diesel Engine Ltd. management team<br />

is now complete. The 53-year-old has worked<br />

<strong>for</strong>, among o<strong>the</strong>rs, <strong>the</strong> Pfizer company in<br />

China. Teng, who has an MBA from <strong>the</strong> University<br />

<strong>of</strong> Michigan, last held <strong>the</strong> CFO position<br />

at DHL-Sinotrans in China.<br />

With <strong>the</strong> joint venture located in <strong>the</strong> north<br />

Chinese city <strong>of</strong> Dalian, <strong>DEUTZ</strong> is significantly<br />

expanding its presence across <strong>the</strong> Chinese<br />

market. <strong>DEUTZ</strong> Dalian manufactures and<br />

sells diesel engines <strong>for</strong> commercial vehicle<br />

as well as industrial applications. For <strong>the</strong><br />

2009 financial year, <strong>the</strong> joint venture manufactured<br />

approximately 99,500 engines <strong>of</strong><br />

which around 6,700 were 4 to 8 litre engines<br />

built on <strong>the</strong> basis <strong>of</strong> licensed <strong>DEUTZ</strong> <strong>technology</strong>.<br />

also in <strong>the</strong> fast-growing market <strong>for</strong> exhaust gas aftertreatment<br />

systems”, stated Gino Mario Biondi,<br />

<strong>the</strong> Management Board Member <strong>for</strong> <strong>technology</strong> at<br />

<strong>DEUTZ</strong> AG. By using practically only standardized<br />

components means significant competitive advantages<br />

in respect <strong>of</strong> cost, development time and validation<br />

time. Modular systems also give flexibility.<br />

Individually designed tubing solutions enable optimal<br />

utilization <strong>of</strong> <strong>the</strong> restricted installation space<br />

on mobile machinery.<br />

Series production <strong>of</strong> <strong>the</strong> aftertreatment units <strong>for</strong><br />

diesel engines is planned to begin in <strong>the</strong> third quarter<br />

<strong>of</strong> <strong>the</strong> current year. Around 100 staff from <strong>the</strong><br />

participating companies will be employed by Bosch<br />

Emission Systems with 20 <strong>of</strong> <strong>the</strong>se coming from<br />

<strong>DEUTZ</strong> AG.<br />

7

Title<br />

<strong>New</strong> <strong>drive</strong> <strong>–</strong> <strong>Curtain</strong> <strong>up</strong> <strong>for</strong> <strong>the</strong><br />

<strong>technology</strong> <strong>of</strong> <strong>the</strong> <strong>future</strong><br />

<strong>DEUTZ</strong> demonstrates that it is <strong>for</strong>ward-looking by<br />

presenting at bauma 2010 two new engines,<br />

<strong>the</strong> TCD 2.9 L4 and TCD 3.6 L4.<br />

Their distinguishing features are a compact design, high per<strong>for</strong>mance<br />

and proven reliability. The TCD 2.9 L4 is <strong>the</strong> new engine from <strong>DEUTZ</strong>.<br />

<strong>DEUTZ</strong> is presenting <strong>the</strong> new engine <strong>for</strong> <strong>the</strong> fi rst time at bauma 2010.<br />

It had been announced with <strong>the</strong> preliminary project designation<br />

TCD 20XX.<br />

Available in both naturally aspirated and turbocharged versions (with<br />

or without a charge air intercooler) and equipped with cooled external<br />

exhaust gas recirculation and 1,600 bar common rail high-pressure<br />

8 <strong>DEUTZ</strong>LIVE 01/2010<br />

TCD 2.9 L4<br />

injection, <strong>the</strong> ultracompact 4-cylinder 2.9 litre-series in-line engine<br />

covers a per<strong>for</strong>mance range from 25 to 56 kW. The compact engine,<br />

specially developed <strong>for</strong> extremely short and space-restricted installations,<br />

<strong>of</strong>fers high per<strong>for</strong>mance and torque with very smooth running.<br />

The engine achieves a maximum 300 Nm <strong>of</strong> torque at 1,600 rpm.<br />

A modular exhaust gas aftertreatment system has been designed to<br />

meet <strong>the</strong> industrial machinery need <strong>for</strong> compactness and cost effi ciency.<br />

A maintenance-free and cost-effective diesel oxidation catalytic<br />

converter (DOC), along with a particle oxidation catalytic converter<br />

(DOC + POC), can cater <strong>for</strong> most applications. A closed DPF option<br />

(diesel particle fi lter) is also available.<br />

For <strong>the</strong> TCD 2.9 L4 <strong>the</strong>re is also a complete range <strong>of</strong> customer options<br />

including effi cient lateral auxiliary <strong>drive</strong>s and mass compensation<br />

shafts. Oil change intervals at 500 h and a maintenance-free valve<br />

train increase productivity and lower operating costs. Low noise levels

Photos: <strong>DEUTZ</strong> AG<br />

give fur<strong>the</strong>r cost savings by reducing insulation requirements.<br />

The TCD 2.9 L4 gets its fi rst <strong>of</strong>fi cial public showing at <strong>the</strong> <strong>DEUTZ</strong> AG<br />

stand at bauma. The new engine had an initial showing at <strong>the</strong> Agritechnica<br />

in Hanover in November 2009, albeit as a virtual presentation. A<br />

computer assisted animation enabled trade fair visitors to get a preliminary<br />

glimpse <strong>of</strong> <strong>the</strong> <strong>DEUTZ</strong> <strong>technology</strong> <strong>of</strong> tomorrow.<br />

The TCD 2.9 L4 is however not <strong>the</strong> only new engine from <strong>DEUTZ</strong>. Whilst<br />

in <strong>the</strong> middle <strong>of</strong> <strong>the</strong> most extreme economic situation <strong>of</strong> recent decades,<br />

<strong>DEUTZ</strong> consciously invested in <strong>the</strong> <strong>future</strong> by developing <strong>the</strong> new<br />

TCD 3.6 L4 engine.<br />

The water cooled TCD 3.6 L4 has a power range <strong>of</strong> 50 to 85 kW and<br />

achieves a maximum <strong>of</strong> 400 Nm <strong>of</strong> torque at 1,400 - 1,600 rpm. The<br />

turbocharged 4-cylinder engine, available with or without a charge air<br />

intercooler and cooled external exhaust gas recirculation, is equipped<br />

TCD 3.6 L4<br />

Title<br />

with a 1,600 bar common rail system and impresses through its low<br />

power to weight ratio and high power density. Long service intervals<br />

also help to keep maintenance costs down. The TCD 3.6 L4, like all<br />

<strong>DEUTZ</strong> engines, has extremely good cold-start properties and is <strong>the</strong>re<strong>for</strong>e<br />

suited <strong>for</strong> use in extreme climatic conditions. A particle oxidation<br />

catalytic converter (DOC + POC) is available <strong>for</strong> exhaust gas after-treatment,<br />

as well as having a DPF (diesel particle fi ltered) option.<br />

With <strong>the</strong> introduction <strong>of</strong> new emission standards, <strong>the</strong> two newly developed<br />

TCD 2.9 L4 and TCD 3.6 L4 engines tie in with <strong>the</strong> legendary<br />

<strong>DEUTZ</strong> 2011-series, which remains in production <strong>for</strong> current emission<br />

standards. “<strong>DEUTZ</strong> stands <strong>for</strong> innovations and best-in-class <strong>technology</strong>.<br />

Our new engines combine maximum customer benefi t with<br />

minimum operating costs. This will extend and fur<strong>the</strong>r streng<strong>the</strong>n<br />

our technological leadership,” emphasized Gino Mario Biondi, <strong>DEUTZ</strong><br />

Managing Director <strong>of</strong> Development and Production. $<br />

9

Innovation<br />

<strong>New</strong> names <strong>for</strong><br />

new <strong>technology</strong><br />

There are o<strong>the</strong>r signs <strong>of</strong> change at <strong>DEUTZ</strong> as well as <strong>the</strong> new TCD 2.9 L4 engine<br />

being presented at bauma 2010.<br />

Previous<br />

engine designation<br />

TCD 20XX L04<br />

TCD 2010 L04<br />

TCD 2012 L04<br />

TCD 2012 L06<br />

TCD 2013 L06<br />

TCD 2015 V06<br />

TCD 2015 V08<br />

10 <strong>DEUTZ</strong>LIVE 01/2010<br />

<strong>New</strong><br />

engine designation<br />

TCD 2.9 L4<br />

TCD 3.6 L4<br />

TCD 4.1 L4<br />

TCD 6.1 L6<br />

TCD 7.8 L6<br />

TCD 12.0 V6<br />

TCD 16.0 V8<br />

Number <strong>of</strong><br />

cylinders<br />

L: In-line engine<br />

V: V-engine<br />

Displacement in litres<br />

(rounded)<br />

Diesel engine<br />

Intercooled<br />

Turbocharged engine<br />

<strong>DEUTZ</strong> is at <strong>the</strong> world’s largest<br />

trade fair <strong>for</strong> construction and mining<br />

machinery as a leading technological<br />

provider <strong>of</strong> low-emission<br />

diesel engines with a broad per<strong>for</strong>mance<br />

range <strong>of</strong> 25-520 kW. With<br />

<strong>the</strong> introduction <strong>of</strong> engines <strong>for</strong> <strong>the</strong><br />

stricter EU emissions stage IIIB/US<br />

EPA Tier 4 interim, <strong>DEUTZ</strong> is altering<br />

its entire range <strong>of</strong> model designations<br />

to highlight this technological<br />

advance.<br />

Self-explanatory and succinct engine<br />

designation codes will provide<br />

customers with all <strong>the</strong> required<br />

product in<strong>for</strong>mation. The first three<br />

letters give specifics such as turbocharger,<br />

intercooling and fuel type.<br />

This is followed by engine displacement<br />

in litres as well as cylinder set<br />

<strong>up</strong> and number. Engines still being<br />

produced according to current and<br />

earlier emissions standards are to<br />

retain <strong>the</strong>ir existing designations.<br />

At just a glance, <strong>the</strong> new designation<br />

codes <strong>the</strong>re<strong>for</strong>e provide a<br />

unique aid to <strong>DEUTZ</strong> customers.<br />

In <strong>the</strong> mid-range per<strong>for</strong>mance segment,<br />

<strong>DEUTZ</strong> has extensively developed<br />

its tried and tested 2012-series<br />

in-line engines <strong>for</strong> <strong>the</strong> next<br />

emissions stage. In <strong>the</strong> 70 to 115<br />

kW per<strong>for</strong>mance range, <strong>DEUTZ</strong> can<br />

<strong>of</strong>fer customers <strong>the</strong> water-cooled<br />

TCD 4.1 L4 engine, which delivers<br />

a maximum torque <strong>of</strong> 610 Nm<br />

at 1,400 to 1,600 rpm. The turbocharged,<br />

intercooled 4-cylinder<br />

in-line engine is equipped with a<br />

1,600 bar <strong>DEUTZ</strong> common rail system<br />

(DCR ® ) and cooled external ex-

Photos: <strong>DEUTZ</strong> AG<br />

haust gas recirculation. The robust<br />

engine design impresses through<br />

its high power density, outstanding<br />

reliability and long service intervals.<br />

A range <strong>of</strong> customised options are<br />

available <strong>for</strong> <strong>the</strong> 4-cylinder engines<br />

including effi cient lateral auxiliary<br />

<strong>drive</strong>s and mass compensation<br />

shafts. The modular exhaust gas<br />

aftertreatment system provides a<br />

closed diesel particle fi lter (DPF)<br />

whose regeneration is aided by a<br />

controlled aircore choke.<br />

In <strong>the</strong> 120 to 180 kW per<strong>for</strong>mance<br />

range, <strong>DEUTZ</strong> <strong>of</strong>fers <strong>the</strong> watercooled<br />

TCD 6.1 L6 with a maximum<br />

torque <strong>of</strong> 1,000 Nm at 1,400 to<br />

1,600 rpm. The robust 6-cylinder<br />

in-line engine is equipped with a turbocharger<br />

and intercooler, cooled<br />

external exhaust gas recirculation<br />

and an electronically controlled<br />

<strong>DEUTZ</strong> 1,600 bar common rail<br />

system (DCR ® ) with high-pressure<br />

injection <strong>for</strong> power ranges <strong>up</strong> to<br />

160 kW and 2,000 bar <strong>for</strong> top-<strong>of</strong><strong>the</strong>-range<br />

per<strong>for</strong>mance. The engine<br />

impresses through its outstanding<br />

cost effectiveness, long engine service<br />

life and long service intervals.<br />

A closed diesel particle fi lter (DPF)<br />

with aircore choke regeneration <strong>for</strong><br />

INFO | Displacement<br />

power ranges less than 130 kW,<br />

and diesel burner regeneration <strong>for</strong><br />

power ranges greater than 130 kW,<br />

enables <strong>the</strong> TCD 6.1 L6 to fulfi l <strong>the</strong><br />

requirements <strong>of</strong> <strong>the</strong> new emission<br />

levels.<br />

The water-cooled 6-cylinder TCD<br />

7.8 L6 engine, with per<strong>for</strong>mance<br />

ranges <strong>of</strong> 160 to 250 kW, is <strong>the</strong><br />

most powerful engine in <strong>the</strong> midrange<br />

power class. It achieves a<br />

maximum torque <strong>of</strong> 1,400 Nm at<br />

1,400 to 1,600 rpm. The engine<br />

has a turbocharger with a charge air<br />

intercooler, cooled external exhaust<br />

gas recirculation, wet cylinder liners<br />

and a <strong>DEUTZ</strong> 2,000 bar common rail<br />

(DCR ® ) high-pressure injection system,<br />

and is designed <strong>for</strong> heavy-duty<br />

operation. The high-per<strong>for</strong>mance<br />

engine has excellent power density<br />

and outstanding reliability with<br />

long service intervals. The TCD 7.8<br />

uses an exhaust gas aftertreatment<br />

system to meet <strong>the</strong> heavy-duty requirements<br />

<strong>of</strong> industrial machinery.<br />

A closed diesel particle fi lter (DPF)<br />

with active diesel burner regeneration<br />

ensures maximum machine<br />

availability under any conditions.<br />

The TCD 12.0 V6 covers <strong>the</strong> 240 to<br />

Displacement is one clear indicator <strong>of</strong> an engine’s classifi cation. It is<br />

<strong>the</strong> sum <strong>of</strong> all <strong>the</strong> cylinders’ combustion chambers. For each cylinder,<br />

<strong>the</strong> combustion chamber is calculated from <strong>the</strong> amount <strong>of</strong> travel available<br />

to <strong>the</strong> piston (stroke) and <strong>the</strong> cylinder diameter (bore), using <strong>the</strong><br />

<strong>for</strong>mula bore (cm 3 ) x stroke (cm).<br />

Power = torque x rpm<br />

Innovation<br />

11

12 <strong>DEUTZ</strong>LIVE 01/2010<br />

390 kW per<strong>for</strong>mance range. The V-confi guration water-cooled<br />

engine is turbocharged and intercooled, and is equipped with<br />

wet cylinder liners and common rail high-pressure injection with<br />

an injection pressure <strong>of</strong> 2,000 bar. The compact V-design enables<br />

it to be used within extremely small installation dimensions.<br />

Designed <strong>for</strong> heavy-duty use, <strong>the</strong> TCD 12.0 impresses<br />

through its robustness and long maintenance intervals. With its<br />

proven high-per<strong>for</strong>mance SCR <strong>technology</strong>, <strong>the</strong> TCD 12.0 is designed<br />

<strong>for</strong> <strong>the</strong> needs <strong>of</strong> large, heavy-duty industrial machinery<br />

<strong>for</strong> which fuel consumption is a major priority.<br />

The high-end engine is <strong>the</strong> powerful TCD 16.0 V8. The watercooled<br />

350 to 520 kW 8-cylinder engine rounds <strong>of</strong>f <strong>the</strong> <strong>DEUTZ</strong><br />

range <strong>of</strong> products <strong>for</strong> <strong>the</strong> IIIB / Tier 4 interim emissions standards.<br />

Equipped with a turbocharger, charge air intercooler and<br />

wet cylinder liners, <strong>the</strong> TCD 16.0 generates a maximum torque<br />

<strong>of</strong> 2,890 Nm at 1,400 rpm, and impresses through optimal per<strong>for</strong>mance<br />

characteristics. A modern 2,000 bar electronic common<br />

rail injection system combined with an SCR exhaust gas<br />

after-treatment system achieves reductions in environmentally<br />

harmful emissions. The compact V-engine design requires signifi<br />

cantly less space and <strong>the</strong>re<strong>for</strong>e reduces installation costs<br />

<strong>for</strong> customers. $<br />

TCD 2.9 L4 TCD 3.6 L4 TCD 4.1 L4 TCD 6.1 L6<br />

TCD 7.8 L6<br />

TCD 12.0 V6 TCD 16.0 V8

Photos: <strong>DEUTZ</strong> AG<br />

Top <strong>the</strong>me:<br />

Exhaust gas aftertreatment<br />

<strong>DEUTZ</strong> symposium on exhaust gas aftertreatment<br />

at bauma 2010<br />

Because this year’s bauma focuses<br />

on <strong>the</strong> range <strong>of</strong> applications<br />

<strong>for</strong> construction machinery<br />

and vehicles, <strong>the</strong>n exhaust gas<br />

aftertreatment will also take<br />

on a central role. From January<br />

2011 and commencing with per<strong>for</strong>mance<br />

classes from 130kW<br />

to under 560kW, diesel engines<br />

<strong>for</strong> mobile machinery must comply<br />

with EU exhaust gas stage<br />

IIIB and US EPA Tier 4 interim.<br />

These require a clear reduction<br />

in particle and NOx emissions<br />

For <strong>DEUTZ</strong> this means not only<br />

complying with <strong>the</strong> differing<br />

global emissions legislation but<br />

also meeting customer requirements<br />

as effectively and as economically<br />

as possible as well as<br />

providing <strong>the</strong>m individually with<br />

<strong>the</strong>ir power-<strong>drive</strong> needs. <strong>DEUTZ</strong><br />

is well prepared <strong>for</strong> emissions<br />

reductions and demonstrates<br />

its expertise again at this year’s<br />

bauma. The challenges and innovative<br />

technologies arising from<br />

<strong>the</strong> new emissions legislation<br />

are to be presented by <strong>DEUTZ</strong> on<br />

21 April 2010 at a “<strong>DEUTZ</strong> modular<br />

technologies <strong>for</strong> new emission<br />

standards” symposium.<br />

Numerous experts will be available<br />

to answer questions on ex-<br />

haust gas aftertreatment and to<br />

provide in<strong>for</strong>mation on <strong>the</strong> new<br />

exhaust levels, <strong>the</strong> DVERT® system<br />

(<strong>DEUTZ</strong> Variable Emission<br />

Reductions Technology) as well<br />

as <strong>the</strong> newly designed TCD 2.9<br />

L4 engine. $<br />

Technology<br />

13

Expertise<br />

Restrained<br />

power<br />

14 <strong>DEUTZ</strong>LIVE 01/2010<br />

The Bomag “hybrid roller”:<br />

power from <strong>DEUTZ</strong>

Photos: Bomag<br />

Customers from <strong>the</strong> construction machinery<br />

branch require above all that <strong>the</strong> power units<br />

<strong>of</strong> <strong>the</strong>ir equipment can cope with <strong>the</strong> highest<br />

<strong>of</strong> demands and can demonstrate above average<br />

capability and reliability. In addition, <strong>the</strong><br />

power units must be energy-efficient, low on<br />

fuel consumption and environmentally friendly<br />

by complying with <strong>the</strong> stricter emissions regulations.<br />

Too much to ask? Not <strong>for</strong> <strong>DEUTZ</strong>. At<br />

bauma 2010, Bomag presents a roller prototype<br />

whose <strong>DEUTZ</strong> hybrid <strong>drive</strong> meets every<br />

one <strong>of</strong> <strong>the</strong>se requirements.<br />

Global demands <strong>for</strong> CO 2 reductions<br />

are leading to an increasingly<br />

growing discussion on alternative<br />

power <strong>drive</strong> designs.<br />

Hybrids in <strong>the</strong> passenger vehicle<br />

segment have been around <strong>for</strong><br />

years but remain <strong>the</strong> exception<br />

<strong>for</strong> mobile machinery. Already<br />

in 2007 <strong>DEUTZ</strong> was pioneering<br />

<strong>the</strong> development <strong>of</strong> a hybrid<br />

<strong>drive</strong> <strong>for</strong> a wheel loader <strong>for</strong> <strong>the</strong><br />

Atlas Weyhausen company. This<br />

was a sensation <strong>for</strong> non-road<br />

applications. The AR 60 wheel<br />

loader has meanwhile found a<br />

successor that is on <strong>the</strong> way to<br />

being series-produced with <strong>the</strong><br />

<strong>DEUTZ</strong> hybrid <strong>drive</strong> (<strong>DEUTZ</strong> LIVE<br />

reports).<br />

The <strong>DEUTZ</strong> hybrid <strong>drive</strong> is also<br />

highly suited to o<strong>the</strong>r construction<br />

machinery. The compacting<br />

<strong>of</strong> asphalt is ideal <strong>for</strong> utilizing<br />

hybrid <strong>technology</strong>. Compacting<br />

is characterised by a roller’s<br />

nonstop reversing manoeuvres:<br />

braking, direction change and<br />

<strong>the</strong>n a short burst <strong>of</strong> acceleration.<br />

On top <strong>of</strong> this, <strong>the</strong> compacting<br />

process requires an on<br />

and <strong>of</strong>f activation <strong>of</strong> a generator<br />

system, which requires still more<br />

power.<br />

<strong>DEUTZ</strong> again takes a pioneering<br />

role in collaboration with its partners.<br />

At bauma 2010, Bomag,<br />

<strong>the</strong> global leader in compacting<br />

<strong>technology</strong> as well as a manufacturer<br />

<strong>for</strong> earth, asphalt and<br />

waste compacting equipment,<br />

presents its original field tested<br />

“hybrid roller” based on BW 174<br />

AP AM, <strong>the</strong> most successful<br />

Bomag roller with a market share<br />

<strong>of</strong> more than 50 percent.<br />

This “hybrid roller” uses a 47<br />

kW TD2009 <strong>DEUTZ</strong> combustion<br />

engine and a <strong>DEUTZ</strong> hybrid system<br />

made <strong>up</strong> <strong>of</strong> an e-machine, a<br />

high-per<strong>for</strong>mance battery, along<br />

with powerful electronics and a<br />

maximum usable 22kW <strong>of</strong> electric<br />

power. The hybrid system’s<br />

e-machine is integrated into <strong>the</strong><br />

combustion engine’s flywheel<br />

housing <strong>the</strong>reby saving space.<br />

Expertise<br />

The electronics and battery are<br />

easily accessible by being located<br />

in <strong>the</strong> roller’s door.<br />

The operating principles <strong>of</strong> <strong>the</strong><br />

<strong>DEUTZ</strong> hybrid system are both<br />

simple and efficient. The electric<br />

motor takes energy from <strong>the</strong><br />

battery and assists <strong>the</strong> main<br />

power unit as required, e.g.<br />

when switching to vibration or<br />

during acceleration. This <strong>the</strong>n<br />

covers <strong>the</strong> peaks <strong>of</strong> when per<strong>for</strong>mance<br />

is needed. The concept<br />

enables a significantly reduced<br />

nominal per<strong>for</strong>mance level from<br />

<strong>the</strong> diesel engine, i.e. downsizing,<br />

meaning no need <strong>for</strong> complex<br />

exhaust gas aftertreatment<br />

systems. During low engine-load<br />

phases, e.g. during braking or<br />

vibration system deactivation,<br />

<strong>the</strong> e-machine functions as a<br />

generator and recharges <strong>the</strong> battery.<br />

Mechanical kinetic energy<br />

can <strong>the</strong>n be rec<strong>up</strong>erated. During<br />

optimal work phases <strong>the</strong> diesel<br />

engine always operates at its<br />

most efficient. A fur<strong>the</strong>r feature<br />

<strong>of</strong> <strong>the</strong> system is its automatic<br />

start/stop function. When running<br />

idle, and when consumers<br />

are shut down, <strong>the</strong> diesel engine<br />

automatically switches <strong>of</strong>f.<br />

Movement <strong>of</strong> <strong>the</strong> <strong>drive</strong> lever, or<br />

<strong>the</strong> activation <strong>of</strong> a consumer,<br />

switches on <strong>the</strong> diesel engine<br />

via <strong>the</strong> e-machine. This takes<br />

place without any delay so that<br />

<strong>the</strong> operator can begin work immediately.<br />

This significantly reduces overall<br />

fuel consumption and <strong>the</strong> associated<br />

emissions <strong>of</strong> CO2. Initial<br />

tests have been very promising<br />

with diesel savings <strong>of</strong> <strong>up</strong> to thirty<br />

percent.<br />

The tested prototype can be<br />

seen at bauma 2010. Advanced<br />

compacting engineering co<strong>up</strong>led<br />

with frontline engine <strong>technology</strong> -<br />

making <strong>the</strong> BW174 AP hybrid into<br />

a 21st century roller. $<br />

15

Expertise<br />

16 <strong>DEUTZ</strong>LIVE 01/2010<br />

The new construction or resurfacing <strong>of</strong> motorways,<br />

major or minor roads and airports cannot happen<br />

without pavers.<br />

Vögele <strong>of</strong>fers crawler equipped road-pavers in<br />

power classes <strong>for</strong> any use. What <strong>the</strong>y all have in<br />

common is economy combined with reliability. The<br />

newly developed SUPER 3000-2 is <strong>the</strong> new leader<br />

in large pavers in per<strong>for</strong>mance capacity, technological<br />

leadership and ergonomic com<strong>for</strong>t. With a<br />

lay down rate <strong>of</strong> <strong>up</strong> to 1,600 t/h and a pave width<br />

<strong>of</strong> <strong>up</strong> to 16 m, <strong>the</strong> paver can quickly lay down seamless<br />

and very wide asphalt surfaces as well as<br />

completing major construction projects. The main<br />

requirements from a paver are reliability and <strong>the</strong>

Photo: Vögele<br />

S<strong>up</strong>er with <strong>DEUTZ</strong><br />

ability to cope with heavy-duty stresses. Vögele<br />

<strong>the</strong>re<strong>for</strong>e relies on <strong>the</strong> powerful <strong>drive</strong> <strong>technology</strong><br />

from <strong>DEUTZ</strong>. The paver is equipped with <strong>the</strong><br />

highly modern <strong>DEUTZ</strong> 6-cylinder TCD 2015 V06 4V<br />

diesel engine. This compact and powerful engine<br />

achieves a maximum power <strong>of</strong> 300 kW at 1,800<br />

rpm. The TCD 2015 is equipped with an electronic,<br />

magnetic valve injection system that provides low<br />

fuel consumption and high economy. Compared to<br />

o<strong>the</strong>r large pavers <strong>of</strong> this class, consumption is<br />

low at around 217 g/kWh. The 6-cylinder engine<br />

naturally complies with <strong>the</strong> current EU-COM 3a and<br />

US EPA Tier 3 emission regulations.<br />

Expertise<br />

bauma is <strong>the</strong> trade fair <strong>for</strong> new products and innovations <strong>for</strong> <strong>the</strong> construction<br />

machinery sector. It <strong>the</strong>n goes without saying that <strong>the</strong> <strong>DEUTZ</strong> name is constantly<br />

referred to <strong>the</strong>re. Just in time <strong>for</strong> bauma 2010, Joseph Vögele AG presents its<br />

new flagship, <strong>the</strong> S<strong>up</strong>er 3000-2 road-paver that leads <strong>the</strong> world’s largest paver<br />

fleet. And what <strong>drive</strong>s it? <strong>DEUTZ</strong>, <strong>of</strong> course.<br />

The SUPER 3000-2 can also be operated in an<br />

“ECO-Mode” <strong>of</strong> 292 kW at 1,500 rpm <strong>the</strong>reby<br />

fur<strong>the</strong>r reducing <strong>the</strong> paver’s already low fuel consumption<br />

and noise levels.<br />

The 2015 engine’s compact dimensions reduce <strong>the</strong><br />

amount <strong>of</strong> installation space required and <strong>the</strong>re<strong>for</strong>e<br />

also installation costs. $<br />

17

Expertise<br />

How <strong>DEUTZ</strong> found<br />

a way out <strong>of</strong> <strong>the</strong> crisis<br />

Just short <strong>of</strong> 286,000 engine sales was <strong>the</strong> record result <strong>for</strong> <strong>DEUTZ</strong> in <strong>the</strong> 2007 fi nancial year. The <strong>for</strong>ecast<br />

<strong>for</strong> 2008 was promising <strong>–</strong> engine sales were to reach <strong>the</strong> 300,000 level. Metaphorically speaking, <strong>the</strong> engines<br />

were revving at levels never experienced be<strong>for</strong>e. The <strong>DEUTZ</strong> Board <strong>of</strong> Management and staff looked promisingly<br />

to 2008 and expected ano<strong>the</strong>r successful year.<br />

The fi rst six months <strong>of</strong> 2008 seemed to fulfi l all expectations <strong>for</strong><br />

<strong>DEUTZ</strong>, and <strong>the</strong> previous year’s success look as if it was to continue.<br />

But <strong>the</strong>n in September 2008, a report from <strong>the</strong> USA hit <strong>the</strong><br />

headlines: <strong>the</strong> US Investment Bank Lehman Bro<strong>the</strong>rs appeared to be<br />

bankr<strong>up</strong>t. The reason was <strong>the</strong> bursting <strong>of</strong> a property bubble. Since<br />

<strong>the</strong> end <strong>of</strong> <strong>the</strong> 1990s, increasing numbers <strong>of</strong> Americans had got<br />

into debt in order to fulfi l <strong>the</strong>ir dreams <strong>of</strong> house ownership. The US<br />

property market boomed and houses purchased on credit continually<br />

rose in price enabling lending banks to give out even more credit.<br />

To fi nance <strong>the</strong> increasing levels <strong>of</strong> credit, banks began to trade <strong>the</strong><br />

outstanding loans and <strong>of</strong>fered <strong>the</strong>m to <strong>the</strong> stock markets as securities<br />

with guarantees <strong>of</strong> high returns. The US economy began to falter,<br />

<strong>the</strong> Federal Reserve Bank raised base rates and this led to lending<br />

banks <strong>the</strong>n raising <strong>the</strong>ir interest rates on loans. This had <strong>the</strong> consequence<br />

<strong>of</strong> many house owners being unable to repay loans and <strong>the</strong>n<br />

losing <strong>the</strong>ir homes.<br />

The securities, which were based on <strong>the</strong> property bubble, dramatically<br />

lost value with many banks having to resort to fi nancing <strong>the</strong><br />

18 <strong>DEUTZ</strong>LIVE 01/2010<br />

losses through short-term and low interest loans to o<strong>the</strong>r banks.<br />

An increasing lack <strong>of</strong> confi dence <strong>the</strong>n led to banks refusing to give<br />

each o<strong>the</strong>r credit. On 15 September, stock markets around <strong>the</strong> world<br />

collapsed with <strong>the</strong> German share index dropping to its lowest level<br />

since October 2006.<br />

The crisis <strong>the</strong>n extended beyond <strong>the</strong> fi nancial sector to <strong>the</strong> real<br />

economy with a <strong>for</strong>ce that nobody had predicted. What began as a<br />

property crisis <strong>the</strong>n slowly hit <strong>DEUTZ</strong>. For <strong>the</strong> third quarter <strong>of</strong> 2008,<br />

<strong>DEUTZ</strong> reported a weakening in levels <strong>of</strong> incoming orders and sales,<br />

particularly <strong>for</strong> engines <strong>of</strong> less than four litres. It was soon clear that<br />

this was not a short term fi nancial crisis but a fundamental and long<br />

term shift in <strong>the</strong> global economy. The outlook <strong>for</strong> 2008 had to be<br />

adjusted to <strong>the</strong> new economic situation and <strong>the</strong> fi rst measures had<br />

to be implemented.<br />

<strong>DEUTZ</strong> took a decision in October 2008 to commence <strong>the</strong> “MOVE”<br />

package <strong>of</strong> measures. The package contained short term measures

Photos: <strong>DEUTZ</strong> AG, Shutterstock, Fotolia<br />

intended to secure short term<br />

earnings as well as structural<br />

measures <strong>for</strong> long term improvements<br />

in per<strong>for</strong>mance. The package’s<br />

cornerstones included a<br />

new pricing policy, increased<br />

productivity and efficiency targets<br />

<strong>for</strong> manufacturing, R&D and<br />

quality control as well as a lowering<br />

<strong>of</strong> material and overhead<br />

costs.<br />

Staff levels also required adjusting<br />

to <strong>the</strong> drop in demand. In<br />

<strong>the</strong> second half <strong>of</strong> 2008, <strong>DEUTZ</strong><br />

was compelled to implement an<br />

initial course <strong>of</strong> staff restructuring<br />

that continued into 2009 and<br />

eventually led to a reduction <strong>of</strong><br />

more than 700 personnel. The<br />

Board <strong>of</strong> Management and employee<br />

representative boards<br />

also agreed on short time working,<br />

first <strong>for</strong> production and <strong>the</strong>n<br />

<strong>for</strong> all company departments<br />

excluding R&D. These measures<br />

were also to continue through to<br />

<strong>the</strong> spring <strong>of</strong> 2010.<br />

For <strong>the</strong> first half <strong>of</strong> 2009, <strong>DEUTZ</strong><br />

had to report drastic downturns<br />

on incoming orders, sales and<br />

turnover. With <strong>the</strong> background<br />

<strong>of</strong> an ongoing global recession,<br />

overall sales and turnover had<br />

halved compared to 2008. The<br />

collapse <strong>of</strong> sales in <strong>the</strong> US<br />

meant <strong>up</strong> to 60 % losses in <strong>the</strong><br />

under 4 litre engine segment.<br />

These heavy downturns pushed<br />

<strong>DEUTZ</strong> ever deeper into a trough<br />

whose way out was unknown.<br />

Despite all <strong>the</strong> uncertainties in<br />

making any prognoses, <strong>DEUTZ</strong><br />

focused on maintaining and expanding<br />

its technological lead<br />

and continued to heavily invest<br />

in research and development in<br />

order to create a solid basis <strong>for</strong><br />

<strong>future</strong> growth.<br />

Staying power and<br />

technological expertise<br />

While more than 85 % <strong>of</strong> staff in<br />

Germany went on to short-time<br />

working, in <strong>the</strong> development<br />

departments work continued at<br />

full speed on <strong>the</strong> new emission<br />

standards EU Stage IIIB/ US<br />

EPA Tier 4 interim and EU Stage<br />

IV /US EPA Tier 4, which are to<br />

come into <strong>for</strong>ce from 2011 to<br />

2015 in western Europe and<br />

North America. At <strong>the</strong> Paris In-<br />

termat trade fair in <strong>the</strong> spring<br />

<strong>of</strong> 2009, <strong>DEUTZ</strong> was able to<br />

present at one <strong>of</strong> <strong>the</strong> world’s<br />

most prestigious construction<br />

machinery trade fairs, its entire<br />

range <strong>of</strong> four litre products<br />

that comply with <strong>the</strong> new emission<br />

standards. The engines<br />

received an excellent response<br />

and acceptance from <strong>the</strong> <strong>DEUTZ</strong><br />

customers.<br />

A fur<strong>the</strong>r step included organisational<br />

restructuring <strong>of</strong><br />

<strong>the</strong> company. After <strong>the</strong> Board<br />

<strong>of</strong> Management was reduced<br />

from four to three members in<br />

March 2009, <strong>the</strong>re was <strong>the</strong>n a<br />

significant slimming down by 35<br />

percent <strong>of</strong> staff below management<br />

board level. Operational<br />

functions at <strong>the</strong> Cologne and<br />

Ulm locations were amalgamated<br />

to achieve greater structural<br />

efficiency with faster decisionmaking<br />

procedures and a flatter<br />

hierarchy.<br />

In <strong>the</strong> midst <strong>of</strong> <strong>the</strong> crisis <strong>DEUTZ</strong><br />

<strong>the</strong>n took ano<strong>the</strong>r step towards<br />

<strong>the</strong> <strong>future</strong>. Toge<strong>the</strong>r with Robert<br />

Bosch GmbH and J. Eberspächer<br />

GmbH & Co. KG, <strong>DEUTZ</strong> signed<br />

a “Memorandum <strong>of</strong> Understanding”<br />

on collaborating on <strong>the</strong><br />

development, manufacture and<br />

marketing <strong>of</strong> diesel exhaust gas<br />

aftertreatment systems <strong>for</strong> <strong>the</strong><br />

non-road sector.<br />

At <strong>the</strong> time <strong>of</strong> signing in <strong>the</strong> autumn<br />

<strong>of</strong> 2009, <strong>the</strong>re appeared<br />

to be a slight stabilisation taking<br />

place <strong>for</strong> <strong>the</strong> first time <strong>for</strong><br />

over a year. Although this stabilisation<br />

was still at a low level,<br />

<strong>the</strong> trend, having already been<br />

evident in <strong>the</strong> second quarter,<br />

was confirmed by <strong>the</strong>re being<br />

demand <strong>for</strong> <strong>DEUTZ</strong> engines and<br />

services in <strong>the</strong> third quarter <strong>of</strong><br />

2009 despite <strong>the</strong> ongoing difficult<br />

economic situation. In<br />

September 2009, <strong>DEUTZ</strong> was<br />

able to achieve a satisfactory<br />

<strong>DEUTZ</strong> at <strong>the</strong> Intermat 2009 - sets <strong>future</strong> course during <strong>the</strong> crisis<br />

per<strong>for</strong>mance <strong>for</strong> <strong>the</strong> first time<br />

in months, mainly through<br />

<strong>the</strong> progress made from <strong>the</strong><br />

“MOVE” package <strong>of</strong> measures.<br />

<strong>DEUTZ</strong> reaches a trend<br />

reversal<br />

Despite all its cost-saving measures,<br />

<strong>DEUTZ</strong> kept investing<br />

heavily in research and development.<br />

This enabled <strong>the</strong> new TCD<br />

2.9 L4 and TCD 3.6 L4 engines<br />

to be virtually presented to <strong>the</strong><br />

public at <strong>the</strong> Agritechnica 2009.<br />

They are examples <strong>of</strong> <strong>DEUTZ</strong>’s<br />

technological lead that it wants<br />

to expand on into <strong>the</strong> <strong>future</strong>.<br />

The <strong>future</strong> began in <strong>the</strong> spring<br />

<strong>of</strong> 2010. In March <strong>of</strong> this year<br />

Expertise<br />

<strong>DEUTZ</strong> could report that it had<br />

survived <strong>the</strong> crisis practically<br />

debt-free. This was made possible<br />

not only from <strong>the</strong> €136m<br />

savings from “MOVE” but also<br />

a systematic management <strong>of</strong><br />

working capital. The financial<br />

crisis has still hit <strong>DEUTZ</strong> hard.<br />

Turnover dropped by more than<br />

42 % to around €863m and engine<br />

unit sales <strong>of</strong> 118,000 were<br />

not even half <strong>the</strong> level <strong>of</strong> <strong>the</strong> previous<br />

year. But <strong>the</strong> worst seems<br />

to be over. The hard hit engine<br />

segment <strong>for</strong> construction machinery<br />

has clearly recovered<br />

with orders currently exceeding<br />

expectations. Short-time working<br />

could also be lifted across<br />

<strong>the</strong> entire company. The outlook<br />

<strong>for</strong> 2010 is <strong>for</strong> a significant rise<br />

in sales and turnover.<br />

In hindsight all <strong>the</strong>se factors<br />

make one thing clear: A crisis is<br />

always a challenge. It demands<br />

being able to think differently,<br />

to be resilient and to know your<br />

strengths. Above all to be active<br />

and not reactive. Over <strong>the</strong> past<br />

year <strong>DEUTZ</strong> did not just react<br />

but acted by investing in <strong>future</strong><br />

<strong>technology</strong> despite being in <strong>the</strong><br />

midst <strong>of</strong> a recession. During <strong>the</strong><br />

crisis, <strong>DEUTZ</strong> set a course <strong>for</strong><br />

pr<strong>of</strong>itable growth and now goes<br />

strongly into <strong>the</strong> <strong>future</strong> reenergized<br />

by its new engines. $<br />

19

Technology<br />

Weightless<br />

with <strong>DEUTZ</strong><br />

The Leipzig/Halle Airport is, at<br />

eighty years <strong>of</strong> operation, not<br />

only one <strong>of</strong> Germany’s most<br />

established airports but since<br />

1990 has gradually expanded<br />

to become one <strong>of</strong> Europe’s most<br />

modern. It has a well-functioning<br />

and modern infrastructure and is<br />

an ideal travel hub, being located<br />

in <strong>the</strong> centre <strong>of</strong> Europe. Passenger<br />

aircraft are dispatched<br />

on <strong>the</strong> two 3,600 m runways and<br />

air freight comes and goes on a<br />

24-hour basis. What appears to<br />

be practically weightless generally<br />

isn’t, with <strong>the</strong> devil being in<br />

<strong>the</strong> detail.<br />

At a height <strong>of</strong> tens <strong>of</strong> thousands<br />

<strong>of</strong> metres, aircraft seem to move<br />

ef<strong>for</strong>tlessly through <strong>the</strong> clouds.<br />

But on <strong>the</strong> ground <strong>the</strong>y need<br />

<strong>the</strong> sturdy help <strong>of</strong> aircraft tugs<br />

to move safely between take-<strong>of</strong>f<br />

and park positions. The Goldh<strong>of</strong>er<br />

AST 2R 210 is one such<br />

aircraft tug. Five <strong>of</strong> this type are<br />

being used at <strong>the</strong> Leipzig/Halle<br />

Airport, and <strong>the</strong>re are a total <strong>of</strong><br />

nine from Goldh<strong>of</strong>er that use<br />

<strong>DEUTZ</strong> engines. The AST 2R210<br />

20 <strong>DEUTZ</strong>LIVE 01/2010<br />

is multi-talented among towbarless<br />

aircraft tugs. For <strong>the</strong> fast,<br />

reliable and safe ground transport<br />

<strong>of</strong> 100-300 ton aircraft,<br />

<strong>the</strong>se tugs set real benchmarks<br />

thanks to <strong>the</strong>ir powerful engines.<br />

They enable Airbuses and Jumbo<br />

Jets to be ef<strong>for</strong>tlessly coordinated<br />

between park, take-<strong>of</strong>f and<br />

landing positions. The powerful<br />

and compact tug’s gripper arm<br />

attaches to <strong>the</strong> aircraft’s nose<br />

wheel, a hydraulic plat<strong>for</strong>m lifts<br />

it, and <strong>the</strong> tug tows <strong>the</strong> aircraft<br />

to <strong>the</strong> required position.<br />

A tug with a powerful<br />

diesel heart<br />

A piggy-back weighing tons, <strong>the</strong><br />

aircraft trailing way behind <strong>the</strong><br />

tug with only a “Follow Me” vehicle<br />

to show <strong>the</strong> way <strong>–</strong> this requires<br />

a powerful engine! With<br />

<strong>the</strong> <strong>DEUTZ</strong> TCD 2012 L06, <strong>the</strong><br />

tugs are equipped with a powerful<br />

diesel heart. Available in<br />

robust 4 and 6 in-line cylinder<br />

versions, <strong>the</strong> water-cooled 2012<br />

engine is characterized by a high<br />

power density <strong>of</strong> 67 <strong>–</strong> 155 kW<br />

at 2,400 rpm and complies with<br />

emission standards <strong>for</strong> mobile<br />

machinery according to EU-Nonroad<br />

2004/26/EU Stage IIIA and<br />

US EPA Tier 3. The slender engine<br />

design also provides maximum<br />

flexibility. The TCD 2012<br />

is also economic through <strong>the</strong><br />

<strong>DEUTZ</strong> high pressure injection<br />

common rail system (DCR®).<br />

Pushback vehicles with <strong>DEUTZ</strong><br />

TCD 2012 engines<br />

The so-called pushbacks can<br />

also be per<strong>for</strong>med by aircraft<br />

tugs. A pushback manoeuvre is

Photos: Flughafen Leipzig/Halle<br />

Technology<br />

For most people airport atmospheres trigger feelings <strong>of</strong> wonderment. Within <strong>the</strong> large halls and long walkways<br />

you soon get that familiar holiday feeling, and a glance towards <strong>the</strong> planes landing and departing makes you long<br />

to get away. But <strong>for</strong> arrivals and departures to function smoothly, a lot <strong>of</strong> behind <strong>the</strong> scenes s<strong>up</strong>port is required.<br />

<strong>DEUTZ</strong> LIVE took a look at <strong>the</strong> Leipzig/Halle Airport and discovered that this airport also relies on tried and<br />

tested <strong>DEUTZ</strong> expertise.<br />

required <strong>for</strong> aircraft which are<br />

nosed at <strong>the</strong> boarding gates.<br />

The majority <strong>of</strong> jet aircraft are<br />

unable, or are not permitted, to<br />

reverse under <strong>the</strong>ir own power.<br />

Aircraft are also <strong>of</strong>ten positioned<br />

where <strong>the</strong>y are unable to<br />

turn by <strong>the</strong>mselves, especially<br />

at major airports. JBT-Aerotech<br />

also use <strong>the</strong> <strong>DEUTZ</strong> TCD 2012<br />

to power <strong>the</strong> two pushback vehicles<br />

in service at <strong>the</strong> Leipzig/<br />

Halle Airport. There are two<br />

pushback methods. Ei<strong>the</strong>r a<br />

push bar, similar to a tow bar, is<br />

used or a nose tug is employed<br />

which, similar to a normal tug,<br />

attaches to <strong>the</strong> nose wheel. This<br />

enables much faster moving <strong>of</strong><br />

<strong>the</strong> aircraft. The aircraft is <strong>the</strong>n<br />

pushed onto a taxiway where it<br />

can <strong>the</strong>n proceed to take-<strong>of</strong>f under<br />

its own power. This is a demanding<br />

task <strong>for</strong> <strong>the</strong> tug engines<br />

because <strong>the</strong> aircraft’s turbines<br />

start-<strong>up</strong> during pushback and<br />

as soon as <strong>the</strong>re is enough distance<br />

from <strong>the</strong> departure building.<br />

This is necessary so that<br />

<strong>the</strong> aircraft can <strong>the</strong>n quickly exit<br />

<strong>the</strong> taxiway.<br />

Leipzig/Halle Airport<br />

as a European hub <strong>for</strong> DHL<br />

The Leipzig/Halle Airport is not<br />

just important <strong>for</strong> passenger<br />

aircraft. In 2008 <strong>the</strong> Deutsche<br />

Post World Net, decided to use<br />

Leipzig/Halle as <strong>the</strong>ir European<br />

DHL hub. The central German<br />

airport <strong>the</strong>n became one <strong>of</strong> <strong>the</strong><br />

most important freight hubs in<br />

Europe. Around 50 DHL cargo<br />

aircraft use <strong>the</strong> Leipzig/Halle Airport<br />

daily, and nothing functions<br />

without <strong>DEUTZ</strong>. DHL recently ordered<br />

a fur<strong>the</strong>r 98 Mulag tugs<br />

to add to <strong>the</strong> existing fleet <strong>of</strong><br />

150. These aircraft tugs, which<br />

ensure <strong>the</strong> <strong>for</strong>warding <strong>of</strong> several<br />

hundreds <strong>of</strong> postal containers<br />

every day, are also equipped<br />

with <strong>the</strong> <strong>DEUTZ</strong> TCD 2012. $<br />

21

Rubrik Life<br />

<strong>DEUTZ</strong> at <strong>the</strong> top <strong>of</strong> world<br />

Between <strong>the</strong> world’s most highly populated states, <strong>the</strong> autonomous region <strong>of</strong> Tibet’s People’s Republic <strong>of</strong> China<br />

in <strong>the</strong> north, and India in <strong>the</strong> south, west and east, is <strong>the</strong> state <strong>of</strong> Nepal, on average <strong>the</strong> world’s highest<br />

country. To <strong>the</strong> north and east lie a major section <strong>of</strong> <strong>the</strong> Himalaya range including Mount Everest, whose summit<br />

at 8,848 m above sea level is <strong>the</strong> highest point on earth, as well as seven o<strong>the</strong>r <strong>of</strong> <strong>the</strong> world’s highest peaks. In<br />

this country, whose climate poses many challenges, <strong>DEUTZ</strong> has a presence with its air-cooled engines<br />

that provide reliable local energy s<strong>up</strong>plies as diesel gensets..<br />

For <strong>the</strong> inland state <strong>of</strong> nearly 30<br />

million inhabitants, with many<br />

living in <strong>the</strong> Himalayan region,<br />

each day poses fresh challen-<br />

ges. There are more than 16<br />

hours <strong>of</strong> power cuts daily, and<br />

this in a country where more<br />

than <strong>for</strong>ty percent live above<br />

22 <strong>DEUTZ</strong>LIVE 01/2010<br />

3,000m. The majority <strong>of</strong> Nepalese,<br />

around 85%, live on <strong>the</strong><br />

land with 15% being urban dwellers.<br />

The most populated centre<br />

remains <strong>the</strong> Kathmandu valley,<br />

where nothing functions without<br />

energy s<strong>up</strong>plies. It is not<br />

just <strong>the</strong> banks and <strong>of</strong>fices that<br />

require a guaranteed s<strong>up</strong>ply <strong>of</strong><br />

energy, but also <strong>the</strong> hotel sector<br />

- Nepal is a magnet <strong>for</strong> tourists.<br />

Around 300,000 people travel<br />

to Nepal each year with tourism<br />

bringing in €50m, around 30%<br />

<strong>of</strong> total income. Temperature<br />

and air pressure represent daily<br />

challenges to humans and machines<br />

alike in a country where<br />

some regions even today remain<br />

undeveloped. The air cooled<br />

<strong>DEUTZ</strong> 914 series engines are<br />

<strong>the</strong> insider tip <strong>for</strong> this mountai-<br />

nous region. They are easy to<br />

use and extremely economical.<br />

Fur<strong>the</strong>rmore, <strong>the</strong> robust <strong>DEUTZ</strong><br />

engines can always be depen-<br />