- Page 2:

Fundamentals of Biomechanics

- Page 6:

Duane Knudson Department of Kinesio

- Page 10:

VI FUNDAMENTALS OF BIOMECHANICS CHA

- Page 14:

VIII FUNDAMENTALS OF BIOMECHANICS R

- Page 18:

X FUNDAMENTALS OF BIOMECHANICS part

- Page 22:

Kinesiology is the scholarly study

- Page 26:

4 FUNDAMENTALS OF BIOMECHANICS beca

- Page 30:

6 FUNDAMENTALS OF BIOMECHANICS Figu

- Page 34:

8 FUNDAMENTALS OF BIOMECHANICS Figu

- Page 38:

10 FUNDAMENTALS OF BIOMECHANICS tat

- Page 42:

12 FUNDAMENTALS OF BIOMECHANICS App

- Page 46:

14 FUNDAMENTALS OF BIOMECHANICS The

- Page 50:

16 FUNDAMENTALS OF BIOMECHANICS sou

- Page 54:

18 FUNDAMENTALS OF BIOMECHANICS lic

- Page 58:

20 FUNDAMENTALS OF BIOMECHANICS Int

- Page 62:

22 FUNDAMENTALS OF BIOMECHANICS WEB

- Page 66:

24 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 70:

26 FUNDAMENTALS OF BIOMECHANICS mat

- Page 74:

28 FUNDAMENTALS OF BIOMECHANICS say

- Page 78:

30 FUNDAMENTALS OF BIOMECHANICS cat

- Page 82:

32 FUNDAMENTALS OF BIOMECHANICS say

- Page 86:

34 FUNDAMENTALS OF BIOMECHANICS mor

- Page 90:

36 FUNDAMENTALS OF BIOMECHANICS to

- Page 94:

PARTII BIOLOGICAL/STRUCTURAL BASES

- Page 98:

42 FUNDAMENTALS OF BIOMECHANICS Fig

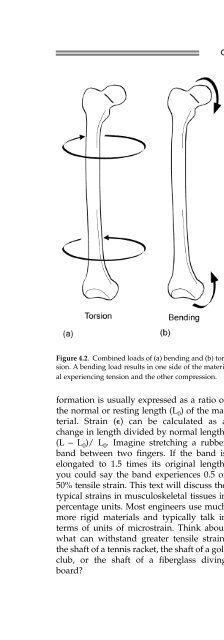

- Page 102: 44 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 106: 46 FUNDAMENTALS OF BIOMECHANICS jou

- Page 110: 48 FUNDAMENTALS OF BIOMECHANICS of

- Page 114: 50 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 118: 52 FUNDAMENTALS OF BIOMECHANICS Act

- Page 122: 54 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 126: 56 FUNDAMENTALS OF BIOMECHANICS rec

- Page 130: 58 FUNDAMENTALS OF BIOMECHANICS int

- Page 134: 60 FUNDAMENTALS OF BIOMECHANICS ed

- Page 138: 62 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 142: 64 FUNDAMENTALS OF BIOMECHANICS use

- Page 146: 66 FUNDAMENTALS OF BIOMECHANICS exa

- Page 150: Many professionals interested in hu

- Page 156: 72 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 160: 74 FUNDAMENTALS OF BIOMECHANICS Act

- Page 164: 76 FUNDAMENTALS OF BIOMECHANICS for

- Page 168: 78 FUNDAMENTALS OF BIOMECHANICS App

- Page 172: 80 FUNDAMENTALS OF BIOMECHANICS inc

- Page 176: 82 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 180: 84 FUNDAMENTALS OF BIOMECHANICS For

- Page 184: 86 FUNDAMENTALS OF BIOMECHANICS The

- Page 188: 88 FUNDAMENTALS OF BIOMECHANICS tur

- Page 192: 90 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 196: 92 FUNDAMENTALS OF BIOMECHANICS Ply

- Page 200: 94 FUNDAMENTALS OF BIOMECHANICS dev

- Page 204:

96 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 208:

98 FUNDAMENTALS OF BIOMECHANICS Fig

- Page 212:

100 FUNDAMENTALS OF BIOMECHANICS In

- Page 216:

102 FUNDAMENTALS OF BIOMECHANICS fo

- Page 220:

Mechanics is the branch of physics

- Page 224:

108 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 228:

110 FUNDAMENTALS OF BIOMECHANICS im

- Page 232:

112 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 236:

114 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 240:

116 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 244:

118 FUNDAMENTALS OF BIOMECHANICS ou

- Page 248:

120 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 252:

122 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 256:

124 FUNDAMENTALS OF BIOMECHANICS In

- Page 260:

126 FUNDAMENTALS OF BIOMECHANICS se

- Page 264:

128 FUNDAMENTALS OF BIOMECHANICS ne

- Page 268:

130 FUNDAMENTALS OF BIOMECHANICS we

- Page 272:

132 FUNDAMENTALS OF BIOMECHANICS WE

- Page 276:

134 FUNDAMENTALS OF BIOMECHANICS Hi

- Page 280:

136 FUNDAMENTALS OF BIOMECHANICS In

- Page 284:

138 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 288:

140 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 292:

142 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 296:

144 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 300:

146 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 304:

148 FUNDAMENTALS OF BIOMECHANICS us

- Page 308:

150 FUNDAMENTALS OF BIOMECHANICS ta

- Page 312:

152 FUNDAMENTALS OF BIOMECHANICS en

- Page 316:

154 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 320:

156 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 324:

158 FUNDAMENTALS OF BIOMECHANICS we

- Page 328:

160 FUNDAMENTALS OF BIOMECHANICS ve

- Page 332:

162 FUNDAMENTALS OF BIOMECHANICS th

- Page 336:

164 FUNDAMENTALS OF BIOMECHANICS Ap

- Page 340:

166 FUNDAMENTALS OF BIOMECHANICS (c

- Page 344:

Angular kinetics explains the cause

- Page 348:

Let's look at another example of ap

- Page 352:

Application: Muscle-Balance and Str

- Page 356:

The symbol for the moment of inerti

- Page 360:

Variations in the moment of inertia

- Page 364:

trates the net joint torques at the

- Page 368:

and 55% of the height for males and

- Page 372:

calculate the positions of the cent

- Page 376:

tal and vertical positions of the c

- Page 380:

fectively increases the base of sup

- Page 384:

Application: Inverse Dynamics of Wa

- Page 388:

SUGGESTED READING Brown, L. E. (Ed.

- Page 392:

194 FUNDAMENTALS OF BIOMECHANICS Gr

- Page 396:

196 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 400:

198 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 404:

200 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 408:

202 FUNDAMENTALS OF BIOMECHANICS cr

- Page 412:

204 FUNDAMENTALS OF BIOMECHANICS Re

- Page 416:

206 FUNDAMENTALS OF BIOMECHANICS Mu

- Page 420:

208 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 424:

210 FUNDAMENTALS OF BIOMECHANICS wh

- Page 428:

PARTIV APPLICATIONS OF BIOMECHANICS

- Page 432:

216 FUNDAMENTALS OF BIOMECHANICS sp

- Page 436:

218 FUNDAMENTALS OF BIOMECHANICS mo

- Page 440:

220 FUNDAMENTALS OF BIOMECHANICS va

- Page 444:

222 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 448:

224 FUNDAMENTALS OF BIOMECHANICS Di

- Page 452:

Coaching athletics also involves te

- Page 456:

This young player shows good balanc

- Page 460:

weaknesses in some athlete's exerci

- Page 464:

QUALITATIVE ANALYSIS OF CATCHING As

- Page 468:

Dyson, G. (1986). Mechanics of athl

- Page 472:

238 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 476:

240 FUNDAMENTALS OF BIOMECHANICS sw

- Page 480:

242 FUNDAMENTALS OF BIOMECHANICS on

- Page 484:

244 FUNDAMENTALS OF BIOMECHANICS ri

- Page 488:

246 FUNDAMENTALS OF BIOMECHANICS 5.

- Page 492:

248 FUNDAMENTALS OF BIOMECHANICS Fi

- Page 496:

250 FUNDAMENTALS OF BIOMECHANICS an

- Page 500:

252 FUNDAMENTALS OF BIOMECHANICS IN

- Page 504:

254 FUNDAMENTALS OF BIOMECHANICS pl

- Page 508:

Aagaard, P. (2003). Training-induce

- Page 512:

Basmajian, J. V., & Wolf, S. L. (Ed

- Page 516:

Chalmers, G. (2002). Do golgi tendo

- Page 520:

Dyson, G. (1986). Mechanics of athl

- Page 524:

ments. Journal of Applied Biomechan

- Page 528:

ing locomotor movements. Exercise a

- Page 532:

sessment. Australian Journal of Phy

- Page 536:

to strength and conditioning. Balti

- Page 540:

Journal of Science and Medicine in

- Page 544:

cur as a function of learning a tim

- Page 548:

Woo (Eds.), Multiple muscle systems

- Page 552:

Schneider, K., Zernicke, R. F., Sch

- Page 556:

cles in the acceleration phase of t

- Page 560:

absolute angle: an angle measured t

- Page 564:

compliance: the ratio of change in

- Page 568:

First Law of Thermodynamics: applic

- Page 572:

kinematic chain: a linkage of rigid

- Page 576:

parallel elastic component: a part

- Page 580:

series elastic component: a part of

- Page 584:

Wolff's Law: bones remodel accordin

- Page 588:

This appendix provides initial answ

- Page 592:

quadriceps groups to extend the kne

- Page 596:

flow of fluid, while lift acts at r

- Page 600:

Rating Principle Body part (inadequ

- Page 604:

310 FUNDAMENTALS OF BIOMECHANICS Ba

- Page 608:

312 FUNDAMENTALS OF BIOMECHANICS F

- Page 612:

314 FUNDAMENTALS OF BIOMECHANICS Ki

- Page 616:

316 FUNDAMENTALS OF BIOMECHANICS Oc

- Page 620:

318 FUNDAMENTALS OF BIOMECHANICS St

- Page 624:

This section of the book provides a

- Page 628:

LAB ACTIVITY 1 NAME _______________

- Page 632:

LAB ACTIVITY 2 NAME _______________

- Page 636:

LAB ACTIVITY 3 NAME _______________

- Page 640:

LAB ACTIVITY 4 NAME _______________

- Page 644:

LAB ACTIVITY 5A NAME ______________

- Page 648:

LAB ACTIVITY 5B NAME ______________

- Page 652:

LAB ACTIVITY 6A NAME ______________

- Page 656:

LAB ACTIVITY 6B NAME ______________

- Page 660:

LAB ACTIVITY 7A NAME ______________

- Page 664:

LAB ACTIVITY 7B NAME ______________

- Page 668:

LAB ACTIVITY 8 NAME _______________

- Page 672:

LAB ACTIVITY 9 NAME _______________

- Page 676:

LAB ACTIVITY 10 NAME ______________

- Page 680:

LAB ACTIVITY 11 NAME ______________

- Page 684:

LAB ACTIVITY 12 NAME ______________