elektronika electronics - Electronics Journal - Elektrotehnicki fakultet

elektronika electronics - Electronics Journal - Elektrotehnicki fakultet

elektronika electronics - Electronics Journal - Elektrotehnicki fakultet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

26<br />

ELECTRONICS, VOL. 8, NO.1, MAY 2004.<br />

Self-Heating Effects in Virtual Substrate SiGe HBTs<br />

Abstract - In this paper we investigated the self-heating<br />

effects in SiGe heterojunction bipolar transistors (HBTs)<br />

fabricated on SiGe alloy virtual substrate. Using a twodimensional<br />

process and device numerical simulation, we have<br />

found that self-heating effects and local temperature increase<br />

due to the internal power dissipation are substantially more<br />

pronounced in virtual substrate HBTs in comparison with<br />

identical HBT devices on silicon substrate.<br />

Keywords - HBT, virtual, substrate, self-heating<br />

I INTRODUCTION<br />

Modern Silicon Heterojunction Bipolar Transistors (Si<br />

HBTs) with strained-SiGe base are very promising devices<br />

for high-frequency circuit applications [1]. The ECL<br />

microwave circuits in SiGe HBT/CMOS technology has already<br />

achieved fmax>180-GHz [2]. Recently, a new type of so-called<br />

“virtual substrate” technology [3] is emerging that allows a<br />

fabrication of both the high-performance heterojunction MOS<br />

FETs (HFETs) and SiGe HBTs on the same chip. The virtual<br />

substrate (VS) consists of thick (1um) fully relaxed SiGe<br />

buffer layer epitaxially grown on silicon substrate. The ability<br />

to synthesize on-chip HFETs, inductors and microstrip<br />

structures together with HBTs on VS makes SiGe HBTs ideal<br />

for microwave and RF applications [4]. There is no<br />

fundamental difference in the operation between Si HBTs<br />

and virtual substrate HBTs (VS HBTs) [5]. However, the<br />

thermal conductivity of the SiGe alloy forming the virtual<br />

substrate layer is much lower (approximately 15x lower at<br />

20% Ge composition( then that of silicon [6].<br />

Thus, during the DC operation of the device, VS HBT<br />

experiences considerably more self-heating than conventional<br />

Si HBT. Lattice self-heating results from the high dissipated<br />

power density in the device. Even in low-power-applications,<br />

the scaled sub-micron VS HBTs operating at high collector<br />

current densities for maximum speed experience a nonnegligible<br />

self-heating effects. A local increase of device<br />

temperature degrades VS HBT performance by reducing its<br />

cutoff frequencies ft and fmax and increasing internal leakage<br />

currents . Self-heating of HBTs can also significantly affects<br />

the behaviour of precision analog circuits, such as current<br />

sources and current mirrors, by changing their output<br />

admittances and introducing errors due to the increased<br />

device mismatching [7,8].<br />

1 Micro<strong>electronics</strong> Department, Faculty of Electronic<br />

Engineering Nis, Universityof Nis, Beogradska 14, 18000 Nis,<br />

Serbia and Montenegro. E-mail:janko@elfak.ni.ac.yu<br />

2 School of Electrical, Electronic and Computer Engineering,<br />

Merz Court, University of Newcastle, NE1 7RU, United Kingdom,<br />

E-mail: A.B.Horsfall @newcastle.ac.uk<br />

Nebojsa D. Jankovic 1 , Aulton B. Horsfall 2<br />

In this paper, we will evaluate the self-heating effects in<br />

VS HBTs by using a commercial numerical technology and<br />

device simulation software (TCAD) from SILVACO [9]. For<br />

accurate prediction of the self-heating in sub-micron devices,<br />

it is necessary to employ a full energy balance and thermionic<br />

emission models thath are connected with appropriate<br />

thermal models in simulations. It is achieved using<br />

SILVACO (GIGA) software package [9], which solves selfconsistently<br />

the electro-thermal coupled transport equations.<br />

A comparison between self-heating effects occurring in Si<br />

HBT and VS HBT at the similar DC power dissipation will<br />

be performed with respect to the VS HBT’s output<br />

impedance, and current gain.<br />

II 2D DEVICE STRUCTURE AND NUMERICAL<br />

MODELLING<br />

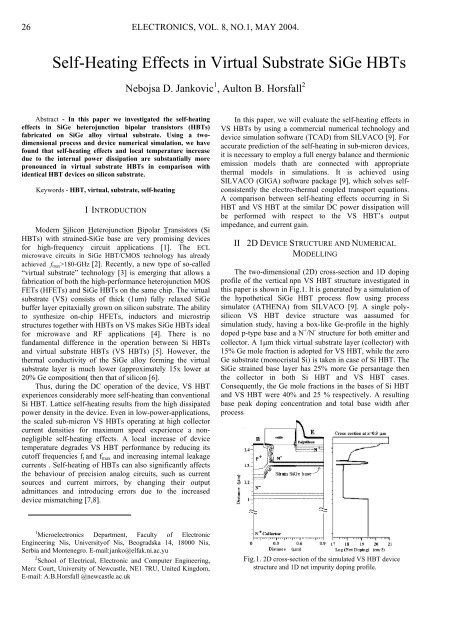

The two-dimensional (2D) cross-section and 1D doping<br />

profile of the vertical npn VS HBT structure investigated in<br />

this paper is shown in Fig.1. It is generated by a simulation of<br />

the hypothetical SiGe HBT process flow using process<br />

simulator (ATHENA) from SILVACO [9]. A single polysilicon<br />

VS HBT device structure was aassumed for<br />

simulation study, having a box-like Ge-profile in the highly<br />

doped p-type base and a N + /N - structure for both emitter and<br />

collector. A 1µm thick virtual substrate layer (collector) with<br />

15% Ge mole fraction is adopted for VS HBT, while the zero<br />

Ge substrate (monocristal Si) is taken in case of Si HBT. The<br />

SiGe strained base layer has 25% more Ge persantage then<br />

the collector in both Si HBT and VS HBT cases.<br />

Consequently, the Ge mole fractions in the bases of Si HBT<br />

and VS HBT were 40% and 25 % respectively. A resulting<br />

base peak doping concentration and total base width after<br />

process<br />

Fig.1. 2D cross-section of the simulated VS HBT device<br />

structure and 1D net impurity doping profile.