Metalurgija: sadašnjost Metallurgy: Present Metalurgija ... - CARNet

Metalurgija: sadašnjost Metallurgy: Present Metalurgija ... - CARNet

Metalurgija: sadašnjost Metallurgy: Present Metalurgija ... - CARNet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

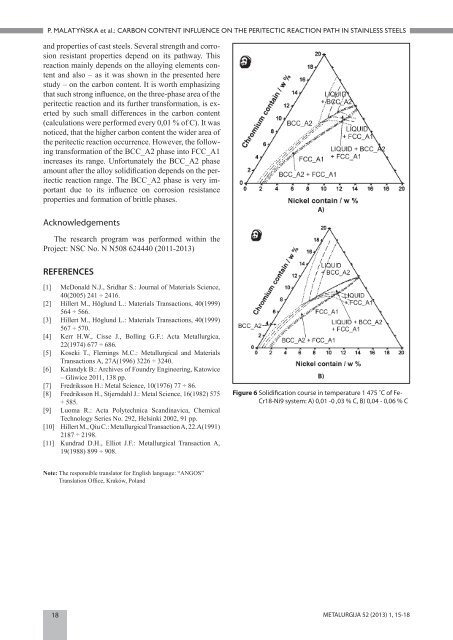

P. MALATYŃSKA et al.: CARBON CONTENT INFLUENCE ON THE PERITECTIC REACTION PATH IN STAINLESS STEELS<br />

and properties of cast steels. Several strength and corrosion<br />

resistant properties depend on its pathway. This<br />

reaction mainly depends on the alloying elements content<br />

and also – as it was shown in the presented here<br />

study – on the carbon content. It is worth emphasizing<br />

that such strong infl uence, on the three-phase area of the<br />

peritectic reaction and its further transformation, is exerted<br />

by such small differences in the carbon content<br />

(calculations were performed every 0,01 % of C). It was<br />

noticed, that the higher carbon content the wider area of<br />

the peritectic reaction occurrence. However, the following<br />

transformation of the BCC_A2 phase into FCC_A1<br />

increases its range. Unfortunately the BCC_A2 phase<br />

amount after the alloy solidifi cation depends on the peritectic<br />

reaction range. The BCC_A2 phase is very important<br />

due to its infl uence on corrosion resistance<br />

properties and formation of brittle phases.<br />

Acknowledgements<br />

The research program was performed within the<br />

Project: NSC No. N N508 624440 (2011-2013)<br />

REFERENCES<br />

[1] McDonald N.J., Sridhar S.: Journal of Materials Science,<br />

40(2005) 241 ÷ 2416.<br />

[2] Hillert M., Höglund L.: Materials Transactions, 40(1999)<br />

564 ÷ 566.<br />

[3] Hillert M., Höglund L.: Materials Transactions, 40(1999)<br />

567 ÷ 570.<br />

[4] Kerr H.W., Cisse J., Bolling G.F.: Acta Metallurgica,<br />

22(1974) 677 ÷ 686.<br />

[5] Koseki T., Flemings M.C.: Metallurgical and Materials<br />

Transactions A, 27A(1996) 3226 ÷ 3240.<br />

[6] Kalandyk B.: Archives of Foundry Engineering, Katowice<br />

– Gliwice 2011, 138 pp.<br />

[7] Fredriksson H.: Metal Science, 10(1976) 77 ÷ 86.<br />

[8] Fredriksson H., Stjerndahl J.: Metal Science, 16(1982) 575<br />

÷ 585.<br />

[9] Luoma R.: Acta Polytechnica Scandinavica, Chemical<br />

Technology Series No. 292, Helsinki 2002, 91 pp.<br />

[10] Hillert M., Qiu C.: Metallurgical Transaction A, 22.A(1991)<br />

2187 ÷ 2198.<br />

[11] Kundrad D.H., Elliot J.F.: Metallurgical Transaction A,<br />

19(1988) 899 ÷ 908.<br />

Note: The responsible translator for English language: “ANGOS”<br />

Translation Offi ce, Kraków, Poland<br />

18 METALURGIJA 52 (2013) 1, 15-18<br />

A)<br />

B)<br />

Figure 6 Solidifi cation course in temperature 1 475 ˚C of Fe-<br />

Cr18-Ni9 system: A) 0,01 -0 ,03 % C, B) 0,04 - 0,06 % C