Metalurgija: sadašnjost Metallurgy: Present Metalurgija ... - CARNet

Metalurgija: sadašnjost Metallurgy: Present Metalurgija ... - CARNet

Metalurgija: sadašnjost Metallurgy: Present Metalurgija ... - CARNet

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

K. LABER et al.: ANALYSIS OF THE TEMPERATURE CHANGE OVER THE CONTINUOUS INGOT LENGTH...<br />

of temperature distribution over the casting length before<br />

the fi rst rolling stand, the casting end temperature<br />

during heating the casting in the heating furnace was<br />

increased by 50 °C relative to the nominal casting temperature<br />

(1 150 °C).<br />

The rolling speed ranged from 0,10 m/s in the fi rst<br />

stand to 7,0 m/s in stand no. 17; the roll temperature<br />

was 60 °C, and ambient temperature 20 °C. The coeffi -<br />

cient of heat exchange between the rolls and the band<br />

was α = 3 000 W/m 2 K, and the coeffi cient of heat exchange<br />

between the band and the air was α air = 100 W/<br />

m 2 K. The friction coeffi cient and the friction factor were<br />

assumed to be variable, being dependent on the band<br />

temperature, and amounting to, respectively, µ =<br />

0,3÷0,42 and m = 0,6÷0,8. The test material was steel<br />

20MnB4 [4].<br />

The following object’s parameters were assumed for<br />

thermovision tests: emissivity, 0,82; distance from the<br />

object, 3 m; ambient temperature, 20 °C; refl ected temperature,<br />

20 °C; relative humidity, 50 % [5].<br />

RESULTS AND DISSCUSION<br />

Figure 1 shows example results of numerical computation<br />

of temperature distribution for the starting and<br />

end regions of the feedstock and for the end feedstock<br />

part heated up by 50 °C before the fi rst rolling stand.<br />

Unevenness of temperature occurring initially at the<br />

beginning and end of the feedstock decreased as the<br />

rolling process progressed in particular passes. The<br />

main cause of this phenomenon was the contact of the<br />

band with the rolls during the rolling process and the<br />

generation of heat due to plastic deformation. The temperature<br />

values computed numerically were compared<br />

with the actual values measured with a thermovision<br />

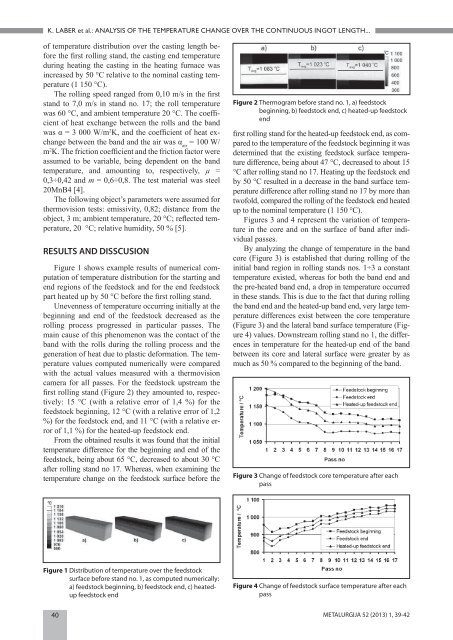

camera for all passes. For the feedstock upstream the<br />

fi rst rolling stand (Figure 2) they amounted to, respectively:<br />

15 °C (with a relative error of 1,4 %) for the<br />

feedstock beginning, 12 °C (with a relative error of 1,2<br />

%) for the feedstock end, and 11 °C (with a relative error<br />

of 1,1 %) for the heated-up feedstock end.<br />

From the obtained results it was found that the initial<br />

temperature difference for the beginning and end of the<br />

feedstock, being about 65 °C, decreased to about 30 °C<br />

after rolling stand no 17. Whereas, when examining the<br />

temperature change on the feedstock surface before the<br />

Figure 1 Distribution of temperature over the feedstock<br />

surface before stand no. 1, as computed numerically:<br />

a) feedstock beginning, b) feedstock end, c) heatedup<br />

feedstock end<br />

Figure 2 Thermogram before stand no. 1, a) feedstock<br />

beginning, b) feedstock end, c) heated-up feedstock<br />

end<br />

fi rst rolling stand for the heated-up feedstock end, as compared<br />

to the temperature of the feedstock beginning it was<br />

determined that the existing feedstock surface temperature<br />

difference, being about 47 °C, decreased to about 15<br />

°C after rolling stand no 17. Heating up the feed stock end<br />

by 50 °C resulted in a decrease in the band surface temperature<br />

difference after rolling stand no 17 by more than<br />

twofold, compared the rolling of the feedstock end heated<br />

up to the nominal temperature (1 150 °C).<br />

Figures 3 and 4 represent the variation of temperature<br />

in the core and on the surface of band after individual<br />

passes.<br />

By analyzing the change of temperature in the band<br />

core (Figure 3) is established that during rolling of the<br />

initial band region in rolling stands nos. 1÷3 a constant<br />

temperature existed, whereas for both the band end and<br />

the pre-heated band end, a drop in temperature occurred<br />

in these stands. This is due to the fact that during rolling<br />

the band end and the heated-up band end, very large temperature<br />

differences exist between the core temperature<br />

(Figure 3) and the lateral band surface temperature (Figure<br />

4) values. Downstream rolling stand no 1, the differences<br />

in temperature for the heated-up end of the band<br />

between its core and lateral surface were greater by as<br />

much as 50 % compared to the beginning of the band.<br />

Figure 3 Change of feedstock core temperature after each<br />

pass<br />

Figure 4 Change of feedstock surface temperature after each<br />

pass<br />

40 METALURGIJA 52 (2013) 1, 39-42