Italy Dominates in Crushning Buckets New Core Drills ... - PDWorld

Italy Dominates in Crushning Buckets New Core Drills ... - PDWorld

Italy Dominates in Crushning Buckets New Core Drills ... - PDWorld

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Italy</strong> dom<strong>in</strong>ates <strong>in</strong><br />

Crush<strong>in</strong>g <strong>Buckets</strong><br />

Crush<strong>in</strong>g, sort<strong>in</strong>g and<br />

screen<strong>in</strong>g buckets are<br />

considered the latest<br />

<strong>in</strong>novation <strong>in</strong> hydraulic<br />

attachments related<br />

to the demolition and<br />

recycl<strong>in</strong>g <strong>in</strong>dustries.<br />

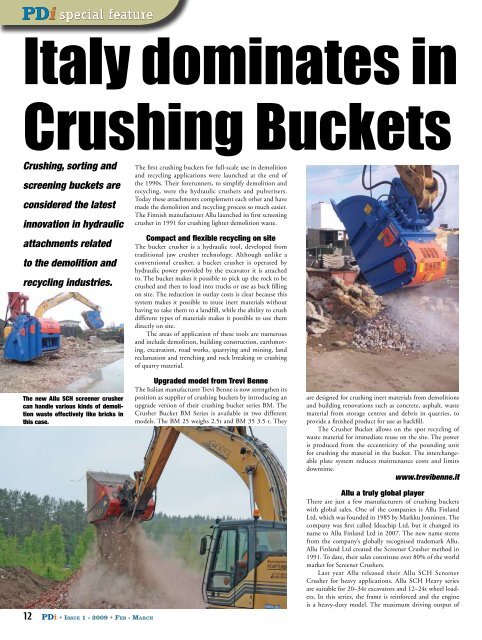

The new Allu SCH screener crusher<br />

can handle various k<strong>in</strong>ds of demolition<br />

waste effectively like bricks <strong>in</strong><br />

this case.<br />

12 PDi • Is s u e 1 - 2009 • Fe b - Ma r c h<br />

The first crush<strong>in</strong>g buckets for full-scale use <strong>in</strong> demolition<br />

and recycl<strong>in</strong>g applications were launched at the end of<br />

the 1990s. Their forerunners, to simplify demolition and<br />

recycl<strong>in</strong>g, were the hydraulic crushers and pulverisers.<br />

Today these attachments complement each other and have<br />

made the demolition and recycl<strong>in</strong>g process so much easier.<br />

The F<strong>in</strong>nish manufacturer Allu launched its first screen<strong>in</strong>g<br />

crusher <strong>in</strong> 1991 for crush<strong>in</strong>g lighter demolition waste.<br />

Compact and flexible recycl<strong>in</strong>g on site<br />

The bucket crusher is a hydraulic tool, developed from<br />

traditional jaw crusher technology. Although unlike a<br />

conventional crusher, a bucket crusher is operated by<br />

hydraulic power provided by the excavator it is attached<br />

to. The bucket makes it possible to pick up the rock to be<br />

crushed and then to load <strong>in</strong>to trucks or use as back fill<strong>in</strong>g<br />

on site. The reduction <strong>in</strong> outlay costs is clear because this<br />

system makes it possible to reuse <strong>in</strong>ert materials without<br />

hav<strong>in</strong>g to take them to a landfill, while the ability to crush<br />

different types of materials makes it possible to use them<br />

directly on site.<br />

The areas of application of these tools are numerous<br />

and <strong>in</strong>clude demolition, build<strong>in</strong>g construction, earthmov<strong>in</strong>g,<br />

excavation, road works, quarry<strong>in</strong>g and m<strong>in</strong><strong>in</strong>g, land<br />

reclamation and trench<strong>in</strong>g and rock break<strong>in</strong>g or crush<strong>in</strong>g<br />

of quarry material.<br />

Upgraded model from Trevi Benne<br />

The Italian manufacturer Trevi Benne is now strengthen its<br />

position as supplier of crush<strong>in</strong>g buckets by <strong>in</strong>troduc<strong>in</strong>g an<br />

upgrade version of their crush<strong>in</strong>g bucket series BM. The<br />

Crusher Bucket BM Series is available <strong>in</strong> two different<br />

models. The BM 25 weighs 2.5t and BM 35 3.5 t. They<br />

are designed for crush<strong>in</strong>g <strong>in</strong>ert materials from demolitions<br />

and build<strong>in</strong>g renovations such as concrete, asphalt, waste<br />

material from storage centres and debris <strong>in</strong> quarries, to<br />

provide a f<strong>in</strong>ished product for use as backfill.<br />

The Crusher Bucket allows on the spot recycl<strong>in</strong>g of<br />

waste material for immediate reuse on the site. The power<br />

is produced from the eccentricity of the pound<strong>in</strong>g unit<br />

for crush<strong>in</strong>g the material <strong>in</strong> the bucket. The <strong>in</strong>terchangeable<br />

plate system reduces ma<strong>in</strong>tenance costs and limits<br />

downtime.<br />

www.trevibenne.it<br />

Allu a truly global player<br />

There are just a few manufacturers of crush<strong>in</strong>g buckets<br />

with global sales. One of the companies is Allu F<strong>in</strong>land<br />

Ltd, which was founded <strong>in</strong> 1985 by Markku Jonn<strong>in</strong>en. The<br />

company was first called Ideachip Ltd, but it changed its<br />

name to Allu F<strong>in</strong>land Ltd <strong>in</strong> 2007. The new name stems<br />

from the company’s globally recognised trademark Allu.<br />

Allu F<strong>in</strong>land Ltd created the Screener Crusher method <strong>in</strong><br />

1991. To date, their sales constitute over 80% of the world<br />

market for Screener Crushers.<br />

Last year Allu released their Allu SCH Screener<br />

Crusher for heavy applications. Allu SCH Heavy series<br />

are suitable for 20–34t excavators and 12–24t wheel loaders.<br />

In this series, the frame is re<strong>in</strong>forced and the eng<strong>in</strong>e<br />

is a heavy-duty model. The maximum driv<strong>in</strong>g output of