English - Komatsu Forest

English - Komatsu Forest

English - Komatsu Forest

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INTERNATIONAL MAGAZINE<br />

18<br />

READ MORE<br />

4<br />

No 4 • 2007<br />

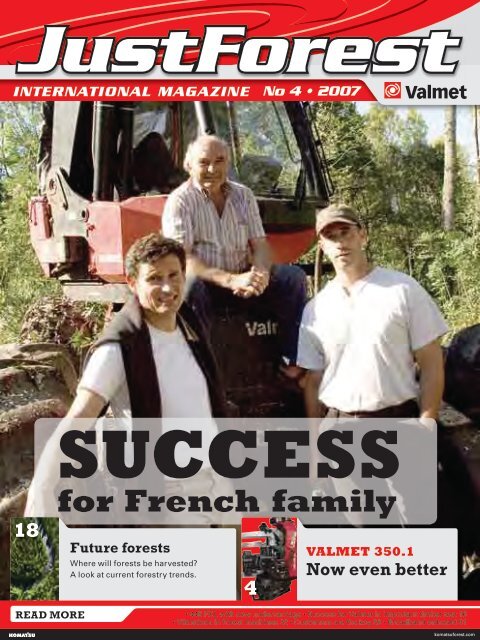

SUCCESS<br />

for French family<br />

Future forests<br />

Where will forests be harvested?<br />

A look at current forestry trends.<br />

VALMET 350.1<br />

Now even better<br />

• 445 FXL with new undercarriage • Success for Valmet in important timber test 16<br />

• Vibrations in forest machines 22 • Customers are the key 29 • Broadband onboard 31<br />

komatsuforest.com

QUALITY LEAVES A LASTING IMPRESSION<br />

We know the forest.<br />

We also know the challenges facing<br />

modern-day wood harvesting.<br />

We know that quality machinery<br />

demands tyres that live up to the task.<br />

We have developed and manufactured<br />

forestry tyres for several decades.<br />

We strongly believe that investing<br />

in quality is the sensible choice.<br />

Nordic Tyres (UK) Ltd<br />

Unit 2<br />

Sydney Place<br />

Lockerbie, Dumfries & Galloway<br />

DG 11 2JA<br />

tel +44 (0)1576 203 020<br />

fax +44 (0)1576 203 029<br />

Nokian Tyres Inc.<br />

339 Mason Rd. La Vergne<br />

TN 37086 Nashville USA<br />

Tel. 1 615 287 0600<br />

Fax 1 615 287 0610<br />

www.nokiantires.com<br />

Nokian <strong>Forest</strong> King F Nokian <strong>Forest</strong> Rider Nokian <strong>Forest</strong> King TRS L-2<br />

Tyres 4 U<br />

165 -171 Milton St.<br />

PO BOX 233<br />

N.S.W. 2131 Ashfield<br />

Tel: 61 (02) 9799 9133<br />

Fax: 61 (02) 9799 3211<br />

Nokian Heavy Tyres Ltd<br />

P.O.Box 20, FI-37101 Nokia<br />

Tel. +358 10 401 7000, fax +358 10 401 7318<br />

www.tyres4u.com.au www.nokiantyres.com/heavytyres

A Great Year<br />

The year 2007 has been positive<br />

in many ways, for me<br />

as the new CEO of <strong>Komatsu</strong><br />

<strong>Forest</strong> and for the company.We’re<br />

experiencing an economic boom<br />

in all markets except North America.The<br />

challenge for us, as well as for our colleagues<br />

in the industry, has not been to<br />

sell enough machines, but rather to meet<br />

the enormous demand.We’ve used every<br />

means available to meet customers’ needs<br />

for new machines and we’re well on the<br />

way to increasing production capacity.<br />

Greater production capacity is a prerequisite<br />

for long-term growth, as all analyses<br />

indicate that demand for raw materials<br />

in the forest industry will remain<br />

high.From our position as one of the leading<br />

forest machine manufacturers, we<br />

can look forward to at least another four<br />

or five good years.Other industries reliant<br />

on raw materials will enjoy an economic<br />

boom until 2015, although there may be<br />

small downturns.<br />

Consequently, <strong>Komatsu</strong> <strong>Forest</strong> will<br />

continue its intensive product development<br />

efforts.In terms of volume, Europe<br />

and North America are currently important<br />

markets for our business, though<br />

Russia, South America, Asia and China<br />

will make strong headway over the coming<br />

years. Our ambition is to meet the<br />

needs of each market.<br />

Throughout 2008, we’ll implement a<br />

number of targeted initiatives.These will<br />

INTERNATIONAL MAGAZINE<br />

Publisher: Roland Lundqvist<br />

roland.lundqvist@komatsuforest.com<br />

Editor: Anders Pauser<br />

anders.p@nordreportern.se<br />

Address: Just <strong>Forest</strong>, <strong>Komatsu</strong> <strong>Forest</strong> AB,<br />

Box 7124, SE-907 04 Umeå, Sweden<br />

Contact: Telephone +46 90 70 93 00,<br />

fax +46 90 12 04 60<br />

include the continuation of our quality<br />

assurance work, further improvements to<br />

product support services, and as already<br />

mentioned, increased production capacity.<br />

We’ll also continue our environmental<br />

program to produce fuel-efficient<br />

machines with reduced environmental<br />

impact.The environment is one of <strong>Komatsu</strong><br />

<strong>Forest</strong>’s core values, and we hope that<br />

by refining harvesting methods we can<br />

contribute to more environmentally aware<br />

logging.<br />

With the resources we’re now investing,<br />

I’m convinced that 2008 has the right<br />

criteria to be as successful as 2007 – if not<br />

more so. r<br />

Toshio Miyake<br />

Chief Executive Officer,<br />

<strong>Komatsu</strong> <strong>Forest</strong><br />

Internet: www.komatsuforest.com<br />

Production: AB Nordreportern<br />

Writers: Gunnar Andersson, Anders Pauser, Erik<br />

Säfvenberg Photographers: Anders Pauser , Erik<br />

Säfvenberg, Gunnar Andersson<br />

Layout and original: Fredrik Lundell<br />

CONTENTS<br />

Even better 350.1 4<br />

France – Europe’s third<br />

largest timber producer 6<br />

New proactive organization 7<br />

Control at every stage<br />

The Dubuis Family<br />

8<br />

chooses Valmet<br />

445FXL features new<br />

10<br />

undercarriage 12<br />

Market news 14<br />

Five forestry trends 18<br />

Increased logging in the future 20<br />

New MaxiL<br />

ProSelect – new saw bars and saw<br />

21<br />

chains to choose from 25<br />

Thinning a hot topic 26<br />

Customers are the key 29<br />

Optimized transport saves<br />

money and the environment 30<br />

<strong>Forest</strong> machines need broadband 31<br />

Popular website 32<br />

Printed by: Ågrens Tryckeri, Örnsköldsvik, Sweden<br />

Paper: Gotic Silk 130 gram<br />

Circulation: 47,000<br />

Languages: Swedish, Finnish, <strong>English</strong>, German,<br />

French, Portuguese, Spanish, and Russian<br />

The content may be quoted if the source is cited.<br />

komatsuforest.com<br />

JUST FOREST NO 4 • 2007 3

VALMET 350.1<br />

Even better 350.1<br />

The best-selling Valmet 350.1 has been upgraded yet again, with<br />

new features that include refined length measurement, a new feed<br />

roller type, and an improved delimbing knife design.<br />

Continual improvements<br />

are an<br />

important part<br />

of quality assurance<br />

at <strong>Komatsu</strong> <strong>Forest</strong>. The pursuit<br />

of further refinements and<br />

improvements to the company’s<br />

products is central to customer<br />

satisfaction. In the case<br />

of the Valmet 350.1 harvesting<br />

head, this has meant a series of<br />

upgrades. The most recent were<br />

implemented at the beginning<br />

of 2007, and now it’s time again.<br />

Extensive improvements make<br />

Valmet’s 350.1, used on the Valmet<br />

901 and 911 harvesters,<br />

even stronger, more reliable, and<br />

more effective<br />

“The new features and<br />

improvements are the natural<br />

outcome of the continual, systematic<br />

quality assurance and<br />

product development work,”<br />

says Gunnar Nilsson, product<br />

manager for harvesting heads at<br />

New rotator design<br />

4 JUST FOREST NO 4 • 2007<br />

<strong>Komatsu</strong> <strong>Forest</strong>.<br />

All Valmet harvesting heads<br />

are based on a proven basic<br />

design, which has been repeatedly<br />

refined over the years. The Valmet<br />

350.1 is well established and<br />

popular in many markets, but<br />

is most popular in Scandinavia,<br />

where it’s mainly used for thinning<br />

and lighter final logging.<br />

This harvesting head’s compact<br />

short frame makes it nimble yet<br />

provides the optimum strengthto-weight<br />

ratio.<br />

The upgraded Valmet 350.1<br />

has an improved rotator, a new<br />

tilt link design, relocated tilt cylinders,<br />

a redesigned valve block<br />

mount, and improved hose routing.<br />

The delimbing knives have<br />

a modified shape and the head is<br />

available with a new, extra delimbing<br />

knife mounted in the frame.<br />

What’s more, the saw motor<br />

hood and saw box are altered for<br />

improved performance. r<br />

VALMET 350.1<br />

New feature overview:<br />

New rotator design<br />

Newly developed tilt link<br />

New measuring wheel type<br />

Improved roller motor hose routing<br />

New saw unit<br />

Extras strong valve block mount<br />

Modified saw motor hood seal<br />

New feed roller option<br />

New knife design<br />

Extra frame-mounted delimbing knife option<br />

Repositioned tilt cylinders<br />

Altered saw box design, more space for trunk<br />

New tilt link New measuring wheel type

New feed roller hose routing<br />

New, stronger saw unit (360.2) New delimbing<br />

knife design<br />

JUST FOREST NO 4 • 2007 5

France<br />

Europe’s third largest <strong>Forest</strong><br />

In total, France has 37 million<br />

acres (15 million<br />

hectares) of forest. Of this<br />

land, 25 million acres (10<br />

million hectares) are owned by<br />

about ten million people while<br />

the remainder is state-owned forest.<br />

France has three major forest<br />

regions, in the northeast, the<br />

central highlands, and the southwest.<br />

Deciduous forest accounts<br />

for 60 percent and coniferous<br />

6 JUST FOREST NO 4 • 2007<br />

forest for the other 40 percent. Of<br />

all harvesting, 70 percent is thinning<br />

and the other 30 percent<br />

final logging, with the work conducted<br />

by the 1,400 forwarders,<br />

600 harvesters, and 1,450 skidders<br />

currently operating in the<br />

French forests.<br />

FOREST MACHINE sales volumes<br />

have remained relatively constant<br />

in recent years, with about 100<br />

With an annual timber harvest<br />

of some 45 million cubic meters<br />

France has the third largest<br />

forest industry in Europe. The<br />

past decade has seen widespread<br />

mechanization.<br />

harvesters, 150 forwarders, and<br />

60 skidders sold each year. <strong>Komatsu</strong><br />

<strong>Forest</strong> is currently the one of<br />

the largest forest machine supplier<br />

in the French market.<br />

FRANCE IS A relatively mature<br />

forest machine market, even if<br />

mechanization is not yet on a par<br />

with Scandinavia. Mechanization<br />

is currently at about 55 percent.<br />

The highest degree of mechaniza-<br />

tion, at 80 percent, is seen in the<br />

coniferous forests of southwest<br />

France. Due to the large amount<br />

of deciduous forest, mechanization<br />

will never reach as high a<br />

level as in Scandinavia and there<br />

are still almost 10,000 handcutters<br />

at work in France. There is,<br />

however, potential for increased<br />

mechanization, primarily in the<br />

coniferous forests of central and<br />

northeastern France. r

New proactive organization<br />

On July 1, <strong>Komatsu</strong><br />

<strong>Forest</strong> introduced a new<br />

forest machine sales<br />

organization in the<br />

French market. With<br />

the help of two dealers,<br />

sales are expected to<br />

increase.<br />

<strong>Komatsu</strong> <strong>Forest</strong>’s<br />

marketing manager in<br />

France, Régis Jutier, is<br />

chairman of ASCODIF,<br />

the French trade association<br />

for forest machine<br />

Manufacturers and<br />

distributors. In this role,<br />

he is involved in many<br />

issues important to the<br />

industry and acts as an<br />

intermediary to state<br />

agencies.<br />

ASCODIF currently has<br />

27 members, including<br />

the major forest machine<br />

manufacturers and distributors<br />

active in the French market. Juti-<br />

French sales fall under<br />

<strong>Komatsu</strong> <strong>Forest</strong>’s European<br />

distribution center<br />

and the French sales organization<br />

is headed by Marketing<br />

Manager Régis Jutier. All in all,<br />

four people work at <strong>Komatsu</strong> <strong>Forest</strong>’s<br />

office in France, located in<br />

Aubergenville just outside Paris.<br />

Aside from the marketing manager,<br />

the organization also has a<br />

service and spare parts manager<br />

Primo Fasolo.<br />

Sales in the field, along with<br />

service and spare parts supply,<br />

are managed by two dealerships,<br />

Matfor Service in northern<br />

France and Cema in the southern<br />

part of the country.<br />

Matfor Service is owned by<br />

major dealer Payen and is headquartered<br />

in Molsheim, near<br />

Strasbourg. The company serves<br />

its Valmet customers with three<br />

service workshops and three traveling<br />

sales staff.<br />

IN THE SOUTH, Cema has five<br />

workshops and, if we include<br />

owner Jean-Pierre Carrère, three<br />

sales staff. Cema is headquartered<br />

in Egleton, some 60 miles<br />

(100 km) southwest of Clermont-<br />

Ferrand. Cema has previous<br />

extensive experience of Valmet<br />

machines. r<br />

Valmet man in powerful position<br />

er was elected president of the<br />

association in 2005 with a threeyear<br />

mandate period.<br />

“We act as a link between the<br />

members and the two ministries<br />

responsible for our industry,”<br />

says Jutier. “We lobby for<br />

improvements in forestry education<br />

and even work with labor<br />

market issues and legislation.”<br />

AN IMPORTANT AREA with<br />

which ASCODIF works is the<br />

pricing of used machines, mainly<br />

by trying to create universal<br />

pricelists. Next year the association<br />

intends to review the education<br />

system, as there are many<br />

forestry schools with programs<br />

Jean-Pierre Carrère, the ownes of Cema.<br />

of too low quality.<br />

ASCODIF is also involved<br />

in discussions on subsidies<br />

for machine purchases fund-<br />

ed by the EU, an issue that Jutier<br />

believes very important.<br />

Finally, ASCODIF arranges<br />

forest machine trade shows. r<br />

JUST FOREST NO 4 • 2007 7

Ent. Chadelat is the largest forestry contractor in France.Owner Gilles Chadelat’s<br />

successful business model is based on retaining control over every stage of the<br />

harvesting process. And 15 Valmet forest machines are the most important part of<br />

this process.<br />

Control over every stage<br />

Gilles’ career in the<br />

forest machine<br />

industry has gone<br />

well ever since he<br />

first sat behind the controls of a<br />

skidder more than 30 years ago.<br />

Today he heads the largest forest<br />

machine company in France,<br />

with 65 employees and five fields<br />

of operation. The largest division<br />

is forest machine contracting,<br />

which represents 70 percent<br />

of operations and has 15 Valmet<br />

machines (including a Timbco<br />

425) and three skidders in its<br />

lineup. The company harvests<br />

150,000 cubic meters a year.<br />

In addition to this, Gilles’<br />

company has 14 trucks, a workshop,<br />

a sawmill, and road construction<br />

machines for the 15-<br />

16 miles (about 25 km) of road it<br />

lays each year. He even buys forestland<br />

to harvest.<br />

“Retaining control over every<br />

stage of the harvesting process<br />

makes customer negotiations<br />

much easier. Put simply, size is<br />

an advantage and makes it easier<br />

to keep prices up,” says Gilles.<br />

WE MET Gilles in a clearing<br />

in the densely forested central<br />

mountain area of France<br />

near Claviéres. The company<br />

has bought a large plot of state-<br />

Gilles Chadelat, one of France’s<br />

most successful forest machine<br />

contractors.<br />

8 JUST FOREST NO 4 • 2007<br />

owned forest here that is currently<br />

being thinned by one of<br />

the company’s two new Valmet<br />

911.3s. This is the initial thinning<br />

of 17 year-old forest with<br />

tree diameters of 8-10 inches (20-<br />

25 cm), with the timber going<br />

straight to the sawmill. In total,<br />

operator Jerome Amouroux harvests<br />

about 1,750-1,800 trees, or<br />

100 cubic meters of timber, each<br />

day in single shifts, which is the<br />

only shift system used in France.<br />

“I’ve been operating the<br />

machine for three months and<br />

the Valmet 911.3 is a pleasure to<br />

use with good comfort. I like the<br />

auto-leveling, especially onhilly<br />

ground where inclines often<br />

exceed 20 degrees,” he says.“<br />

Considering the steep terrain,<br />

fuel consumption is good at 2-<br />

2/3 US gallons (ten liters) an<br />

hour. And I like the Maxi system,<br />

which increases efficiency.”<br />

Owner Gilles appreciates the<br />

30-35 percent increase in produc-

tivity that the new Valmet 911.3<br />

delivers compared to the older<br />

Valmet 911.1 in the company’s<br />

lineup. He now has another Valmet<br />

911.3 on order for delivery<br />

this fall.<br />

ENT. CHADELAT’S strategy is<br />

to replace a couple of machines<br />

a year, and in the future Gilles<br />

Chadelat believes he’ll be able to<br />

do the same work with fewer har-<br />

vesters as productivity increases<br />

continually.<br />

His company, which has<br />

grown gradually, has had Valmet<br />

machines since he bought<br />

his first Valmet 901 in 1990. His<br />

decision to continue to invest in<br />

Valmet machines is based on the<br />

strong relations he’s established<br />

with the dealers and the well<br />

functioning service. Moreover,<br />

Chadelat and the operators like<br />

the good visibility and productivity<br />

offered by Valmet machines.<br />

“Everyone here is aware of the<br />

strengths of each machine,” says<br />

Gilles. “It’s important to know<br />

your machines and our technicians<br />

and our operators really<br />

like Valmet.”<br />

Gilles himself enjoys his<br />

work, even if the French market<br />

is a tough environment and<br />

the industry offers small margins.<br />

He’s evidently pleased that<br />

Jerome Amouroux has been operating his new Valmet 911.3 for<br />

three months and is very pleased with the comfort, the visibility, and<br />

the Maxi system.<br />

his business concept has worked<br />

so well,and he’s particularly satisfied<br />

with his effective organization<br />

for transporting machines<br />

in the relatively limited region in<br />

which the company works. Having<br />

reliable machines that can<br />

always be moved to where the<br />

work is encourages Gilles to face<br />

the future with confidence. r<br />

FACTS Chadelat’s lineup<br />

Among the harvesters are three Valmet 911.1s, three Valmet 921s,<br />

and two Valmet 911.3s. The forwarders include a Valmet 890.1, a Valmet<br />

860.1, a Valmet 840, and two Valmet 860s. A new Valmet 911.3<br />

and a new Valmet 860.3 are on order.<br />

JUST FOREST NO 4 • 2007 9

From the 1960s to the present day. The forest machine of yesteryear was a ’fardier’, today it’s a Valmet 941. Jean Pierre Dubuis, who founded<br />

the company, is seen here together with his son Didier, who runs operations today.<br />

The Dubuis family<br />

choose Valmet<br />

An investment in the market’s most powerful harvester, the Valmet 941,<br />

has given Didier Dubuis’ company Dubuis new possibilities in thick<br />

deciduous stands. The company is one of France’s oldest forest machine<br />

companies and has been partially mechanized since the 1960s.<br />

10 JUST FOREST NO 4 • 2007

We met Didier<br />

Dubuis in the<br />

middle of a poplar<br />

plantation<br />

west of Brives where the company’s<br />

Valmet is effectively harvesting<br />

the huge trees. At the edge of<br />

the stand, just by chance, is an<br />

old ’fardier’, a type of winched<br />

lifting truck. Such devices were<br />

coupled to farm tractors and<br />

used to load and transport logs.<br />

Didier’s father Jean Pierre had<br />

such a machine when he founded<br />

the company in 1962. Today<br />

his father is retired, but still<br />

helps out on occasion and turned<br />

up when Just <strong>Forest</strong> visited.<br />

“I started working for the<br />

company in 1987,” Didier told<br />

us. “We bought out first Valmet<br />

machine in 1998, a Valmet 860,<br />

and since then we’ve stuck with<br />

Valmet.”<br />

Today the company harvests<br />

60,000 cubic meters and forwards<br />

75,000 cubic meters of<br />

timber a year, some of this on<br />

assignment for other contrac-<br />

A Valmet 941 is a very effective machine on poplar plantations.<br />

tors. In total, Didier has nine<br />

employees operating three Valmet<br />

harvesters - a 911, a 921.1,<br />

and a 941. Dubuis also has four<br />

Valmet forwarders, two 840.2s,<br />

an 860.1, and an 860.3.A very<br />

pleased Didier has another Valmet<br />

860.3 on order.<br />

When we discussed the lineup,<br />

Didier couldn’t help but mention<br />

the advantages of the Valmet<br />

941, a powerhouse than can harvest<br />

effectively even in steep terrain.<br />

The machine is used to harvest<br />

hardwood too, even if such<br />

harvesting pays less and places<br />

great demands on the machine.<br />

In the poplar stand being harvested<br />

when we visited, the trees<br />

had diameters of 16-18 inches<br />

(40-45 cm), though this posed no<br />

problems.<br />

“In a poplar stand like this,<br />

the thick branches are always<br />

tough, but the machine does a<br />

good job,” commented operator<br />

Laurent Plaisse. “It’s a truly powerful<br />

machine that copes with<br />

all types of tree. I like to use the<br />

machine on slopes and the way<br />

the rotating cab always keeps the<br />

head in front is a real advantage.”<br />

Didier is a strong supporter of<br />

the Valmet machines with which<br />

his personnel are so happy. He<br />

said that service has been excellent<br />

since the company invested<br />

in the first Valmet 860 machine.<br />

“I bought it because it read so<br />

good on paper,” Didier explained.<br />

“And the Valmet 941 proved to<br />

be just in good in reality, and so<br />

it’s continued. The Valmet 941<br />

is a good example of a machine<br />

that really lives up to its specifications.”<br />

r<br />

Laurent Plaisse appreciates the Valmet 941 for its power and efficiency<br />

even in steep terrain.<br />

JUST FOREST NO 4 • 2007 11

445 FXL with<br />

new chassis<br />

The new Valmet 445 FXL offers <strong>Komatsu</strong> <strong>Forest</strong>’s customers a machine well<br />

equipped for demanding forest conditions. The 445 FXL has a <strong>Komatsu</strong><br />

designed and built forestry track system and final drives, with longer tracks<br />

and a redesigned car body.<br />

The new Valmet<br />

445FXL is fitted with<br />

brand new track units<br />

from <strong>Komatsu</strong>.<br />

12 JUST FOREST NO 4 • 2007

The new tracks are designed and developed<br />

solely for the forest, with very sturdy<br />

and thoroughly tested components.<br />

The Valmet 445 FXL is<br />

the second feller-buncher<br />

model supplied with<br />

a <strong>Komatsu</strong> designed and built<br />

forestry track system. Previously,<br />

the larger Valmet 475 FXL<br />

received a thorough upgrade,<br />

including a new track system.<br />

The new Valmet 445 FXL<br />

features a number of improvements<br />

to increase productivity<br />

and reliability. Most important is<br />

the specially designed track system<br />

and increased track chain<br />

pitch, increased to 9 inches (228<br />

mm). Machine mobility and stability<br />

have been improved by fitting<br />

sturdier tracks and track<br />

shoes. Further, the 445 FXL<br />

incorporates <strong>Komatsu</strong> designed<br />

and built forestry final drives.<br />

Each track has its own independent<br />

closed loop track drive, separate<br />

from the boom circuit,<br />

allowing for simultaneous operation<br />

of the tracks and boom<br />

functions. The closed loop track<br />

drives also provide hydrostatic<br />

braking on slopes and allow for<br />

energy recovery when stopping.<br />

This system is standard on most<br />

Valmet tracked machines and<br />

ensures maximum productivity.<br />

“The track unit has been<br />

designed and developed solely<br />

for the forest, with very sturdy<br />

and well tested components,”<br />

explains product manager Yasu<br />

Tanaka. “Among other things,<br />

we’ve seen increased reliability<br />

with the new <strong>Komatsu</strong> forestry<br />

final drive.”<br />

THE 445 FXL car body has been<br />

redesigned to improve reliability<br />

with today’s heavy felling<br />

demands. Four-way cab leveling<br />

is achieved using two cylinders,<br />

with a maximum forward<br />

tilt of 27 degrees increasing the<br />

machine’s stability on steep slopes<br />

while reducing operator fatigue.<br />

The 445 FXL booms have<br />

also been upgraded to meet the<br />

demands of today’s harvesting<br />

attachments.<br />

The Valmet 445 FXL is a very<br />

fuel efficient machine and is<br />

equipped with a Cummins Tier<br />

3-compliant 8.3-liter QSC engine<br />

that produces 300 horsepower.<br />

The engine control system<br />

and calibration provide rapid yet<br />

smooth response.<br />

THE COOLING system has<br />

been improved with larger fin<br />

spacing, which reduces debris<br />

buildup and simplifies cleaning.<br />

Together with the reversing fan,<br />

this keeps the machine running<br />

cool day after day.<br />

The 445 FXL has a new<br />

optional pump gear box oil cooler<br />

available. This new option cools<br />

the pump gear box oil increasing<br />

seal life for both the gear box and<br />

the hydraulic pumps.<br />

The Valmet 445 FXL is service<br />

friendly with centralized grease<br />

points and easily accessible daily<br />

service points. A roomy, quiet<br />

and comfortable cab with excellent<br />

visibility and ergonomically<br />

positioned controls maximizes<br />

operator efficiency. “With the<br />

new Valmet 445 FXL, we can<br />

offer the market a highly productive<br />

machine with the market’s<br />

best undercarriage,” comments<br />

Yasu. “This is a machine that will<br />

provide the reliability and performance<br />

our customers have come<br />

to expect from <strong>Komatsu</strong>.” r<br />

INFO Valmet 445 FXL<br />

WEIGHT WITHOUT HEAD: 67,000 lb (30,390 kg)<br />

ENGINE: Cummins QSC Tier 3, 8.3 liters<br />

POWER: 300 HP at 2,000 rpm<br />

TORQUE: 1,000 lb-ft (1,356 Nm) @ 1,500 RPM<br />

FUEL TANK CAPACITY: 185 gallons (700 liters)<br />

MACHINE WIDTH: 10’ 4” (3,140 mm), 600 mm single grouser shoes<br />

MAX. SPEED: 3.3 mph (5.3 km/h)<br />

TRACTIVE EFFORT: 74,315 lb (33,710 kg)<br />

TRACK length 15’8” ft (4,871 mm), 600 mm or 700 mm track shoes<br />

GROUND PRESSURE: 8.74 psi with 600 mm, 7.62 psi with 700 mm<br />

MAX. REACH: 21’ 5” (6,530 mm), 4-Bar Power Link Stick Boom<br />

CAB LEVELING: Front 27°, back 5°, side ±20°<br />

JUST FOREST NO 4 • 2007 13

The 32,000 square feet (3,000 square meters) of the<br />

forest machine center in Finland are now in full use.<br />

<strong>Forest</strong> machine center inauguration<br />

THE 32,000 SQUARE feet (3,000 square<br />

meters) of the forest machine center in Pirkkala<br />

outside Tampere, Finland are now in<br />

full use. More than 650 guests from Finland,<br />

Timo Ylänen, new CEO of<br />

<strong>Komatsu</strong> <strong>Forest</strong> Oy.<br />

THE ANNUAL meeting of the<br />

European distributors of Valmet<br />

machines was held in the Latvian<br />

capital Riga. Representatives<br />

from 19 dealers gathered in Riga<br />

to discuss market issues, strategies,<br />

and activities in the European<br />

market. The meeting also saw<br />

Berndt Rauser bestow an award<br />

on the European dealer of the<br />

14 JUST FOREST NO 4 • 2007<br />

the rest of Scandinavia, the Baltic States, and<br />

Russia attended the inauguration, listening<br />

to speakers that included Toshio Miyake,<br />

CEO of <strong>Komatsu</strong> <strong>Forest</strong>, and Timo Ylänen,<br />

year. This year’s Golden Bogie<br />

went to Cesar Sanchez of Spanish<br />

importer HITRAF. r<br />

CEO of <strong>Komatsu</strong> <strong>Forest</strong> Oy, as well as music<br />

from Finnish pop singer Laura Voutilainen.<br />

The forest machine center is an operations<br />

hub for <strong>Komatsu</strong> <strong>Forest</strong> in Finland. r<br />

New CEO in Finland<br />

Distributors meeting in Riga<br />

The European distributors meeting<br />

in Riga attracted no fewer<br />

than 19 distributors from around<br />

Europe.<br />

No less than 650 people from various countries<br />

attended the Grand Opening Ceremony of the new<br />

forest machine center.<br />

TIMO YLÄNEN is the new CEO of <strong>Komatsu</strong> <strong>Forest</strong> Oy from October<br />

1. He is 44 years old, has broad international experience of the forest<br />

machine industry, and joins <strong>Komatsu</strong> <strong>Forest</strong> from John Deere, where<br />

he headed the company’s forest machine sales to European dealers.<br />

“The opportunity to work with Valmet and its high quality, high<br />

potential forest machines is an exciting challenge,” says Timo. r

Key customers<br />

choose Valmet<br />

THIRTY FOREST machines have now been<br />

delivered under the three major contracts<br />

<strong>Komatsu</strong> <strong>Forest</strong>’s German sales company<br />

<strong>Komatsu</strong> <strong>Forest</strong> GmbH won in Germany<br />

and Austria. A customer buying almost<br />

a dozen machines is not an everyday occurrence<br />

in the German market, and in these<br />

cases <strong>Komatsu</strong> <strong>Forest</strong> GmbH’s high-quality<br />

service helped tip the balance in Komat-<br />

Valmet in focus at Spanish forestry<br />

convention<br />

The Valmet 941 with a 370E head proved its productivity to curious<br />

onlookers at Asturforesta in Spain.<br />

su’s favor when the deals were made. The<br />

three customers are the Austrian forestry<br />

company ÖBf AG, which is partly stateowed,<br />

the Bavarian state forestry company<br />

BaySF, and a large sawmill in eastern Germany.<br />

ÖBf AG, for example, bought seven<br />

forwarders and four harvesters while<br />

the sawmill in eastern Germany bought a<br />

number of Valmet 941 harvesters. r<br />

FOR THE SEVENTH time, the<br />

Spanish Asturforesta forestry<br />

convention was held near the<br />

town of Tineo in northern Spain,<br />

near the border with France and<br />

Portugal. Valmet was in focus<br />

at the convention, which is held<br />

every second year, with its well<br />

attended demos held under realistic<br />

conditions. The demos<br />

“I’m convinced key customers<br />

see the advantages of<br />

our all-inclusive concept,<br />

which combines productive<br />

machines and quality service,”<br />

says Jürgen Munz, CEO<br />

of <strong>Komatsu</strong> <strong>Forest</strong> Gmbh.<br />

“So we’ll most probably see<br />

similarly large deals in the<br />

future.”<br />

attracted large crowds wanting<br />

to see, among other machines,<br />

the Valmet 840.3, the Valmet 941,<br />

and the Valmet 911.3 X3M. Many<br />

visitors were also drawn to the<br />

exhibition tent, where attractions<br />

included the Valmet Oryx simulator.<br />

The convention had 15,000<br />

professional visitors and more<br />

than 120 exhibitors. r<br />

JUST FOREST NO 4 • 2007 15

Valmet to the fore<br />

Figur Best 1. Resultat length measurement av längdmätning. and Ljusgrön best crosscutting. stapel anger andel Valmet stockar left inom ± 2 cm. Mörkgrön<br />

the del competition är den nivå maskinen behind in skulle an important ha nått vid timber perfekt kalibrering value test.<br />

(teoretisk maxnivå). Röd<br />

linje anger medelnivå 2006 för de fem produktionsmaskinerna, grön linje skogsbrukets mål.<br />

Machine system 1<br />

Machine system 2<br />

Machine system 3<br />

Machine system 4<br />

Valmet 941/370.2<br />

Every five years, the<br />

Swedish forestry<br />

research foundation<br />

Skogforsk conducts<br />

an extensive timber value<br />

test. This time, seven different<br />

machine systems were compared<br />

in areas such as length and diameter<br />

measurement, value crosscutting,<br />

and fixed length crosscutting.<br />

This is the third test conducted<br />

and Skogforsk concludes<br />

that harvesters in general show<br />

continual improvements in cap-<br />

16 JUST FOREST NO 4 • 2007<br />

0<br />

10<br />

20<br />

30<br />

Length measurement results. The bars represent the percentage of logs within ±0.78 inch (2 cm). The red<br />

line shows the average level of the five machine systems in 2006. The green line is the Swedish forestry<br />

industry’s goal.<br />

40<br />

turing timber value.<br />

Good length and diameter<br />

measurements are a prerequisite<br />

for getting the most value out<br />

of the timber. If machines measure<br />

correctly, crosscutting efficiency<br />

is higher. <strong>Komatsu</strong> <strong>Forest</strong><br />

was represented by a Valmet<br />

941 equipped with a Valmet<br />

370.2 harvesting head and a<br />

Valmet Maxi harvester computer.<br />

This proved to be a winning<br />

combination in both measuring<br />

and crosscutting. The Valmet<br />

50<br />

60<br />

70<br />

80<br />

90<br />

machine system was the best in<br />

its class at length measurement.<br />

In the second test round, 93 percent<br />

of all logs fell within the correct<br />

length interval.<br />

“Once we’d adjusted the inching<br />

speed, we performed much<br />

better than our main competitors<br />

in length measurement accuracy,”<br />

says Per Annemalm, Product<br />

Manager at <strong>Komatsu</strong> <strong>Forest</strong>.<br />

The researchers at Skogforsk<br />

concluded with current measuring<br />

system designs. More exact<br />

100<br />

measurement will require new<br />

techniques that use remote or<br />

“touch-less” sensing.<br />

According to the test, Valmet’s<br />

current diameter measuring<br />

is reliable and has been<br />

refined and improved since the<br />

previous test. The improvement<br />

is due to factors that include better<br />

control, improved technology<br />

components, the new “regression<br />

analysis” calibration, and<br />

stronger machines. Crosscutting<br />

efficiency indicates how

much value the harvester manages<br />

to generate from each tree<br />

in relation to the optimal value<br />

if you knew the tree length and<br />

diameter in advance. The tests<br />

show that crosscutting efficiency<br />

is generally good, and Valmet<br />

was among the best machine<br />

systems. The researchers also<br />

reported that Valmet provided<br />

very high crosscutting efficiency,<br />

99.1 percent, and was once again<br />

best of the bunch.<br />

“It’s difficult to progress<br />

much further with value crosscutting<br />

and it’s perhaps not even<br />

profitable for forest owners as<br />

the computer is forced to calculate<br />

even more alternatives,<br />

which can limit machine productivity<br />

and thereby increase<br />

harvesting costs,” Per explains.<br />

What’s more, extracting<br />

maximum value is not the only<br />

aim. Delivering what sawmills<br />

and industry need is important<br />

too. With fixed length crosscutting,<br />

the harvester meets saw-<br />

mill needs and the level of efficiency<br />

here indicates how well<br />

the crosscut timber matches the<br />

desired lengths. Each machine<br />

system was tested with 800 logs<br />

and the Valmet machine system<br />

crosscut more than 90 percent of<br />

the logs in the optimal manner,<br />

as per the crosscutting instructions.<br />

“We quickly achieved the<br />

desired fixed length crosscutting<br />

and remained at that level<br />

throughout the test,” says Per. r<br />

NEWS<br />

New major plywood<br />

factory in Siberia<br />

The largest plywood<br />

factory in Siberia and<br />

the Far East is being<br />

built in Krasnoyarsk in 2007.<br />

The goal is to produce enough<br />

plywood to consume 250,000<br />

cubic meters from conifers<br />

and 100,000 cubic meters from<br />

birch annually. About 800 people<br />

will work at the production<br />

plant.<br />

Only large tree harvesting<br />

permitted<br />

Mozambique’s government<br />

has passed legislation<br />

that only permits<br />

certain tree species to be<br />

logged and then only those<br />

above a certain trunk diameter.<br />

Prime Minister Luisa Diogo<br />

told Agencia de Informacao de<br />

Mocambique that the law guarantees<br />

new growth and sustainability<br />

while securing the<br />

industry’s needs.<br />

<strong>Forest</strong> protection<br />

new source<br />

of income<br />

<strong>Forest</strong> owners in Finland<br />

are being offered<br />

new opportunities<br />

to earn from their forests.<br />

METSO, the program for biodiversity<br />

in the forests of southern<br />

Finland, has succeeded in<br />

getting many forest owners to<br />

consider alternatives to traditional<br />

timber production. Voluntary<br />

forest protection yields<br />

economic benefits equally as<br />

large as forestry while preserving<br />

the landscape in an undisturbed<br />

state for future generations.<br />

It takes about fifty years<br />

before thinning provides any<br />

real economic returns, and for<br />

many forest owners leaving<br />

things as they are is an alternative<br />

that provides a good conscience.<br />

JUST FOREST NO 4 • 2007 17

FIVE FORESTR<br />

FIVE<br />

Where will forests be harvested in the future? International<br />

forestry consultant Jonas Jacobsson lists five trends determining<br />

where the industry will source its raw materials in the future.<br />

About a third of the earth’s<br />

surface is forestland and the<br />

northern evergreen belt has<br />

made the USA, Canada, and Scandinavia<br />

important raw material producers<br />

for the forest industry. But change<br />

could be in the cards. Jacobsson is<br />

of the opinion that changes in forest<br />

ownership will influence where<br />

in the world forests are harvested. He<br />

lists five clear trends that influence<br />

development in various ways.<br />

According to Jacobsson, about<br />

85 percent of the world’s forests are<br />

state-owned. The most important and<br />

influential trend today is increased<br />

privatization of forest ownership.<br />

This mostly entails sovereign states<br />

selling off forestland, but also confiscated<br />

forest being returned to private<br />

owners.<br />

Jacobsson believes that the accelerated<br />

privatization trend will influence<br />

where forests are harvested in<br />

the future.<br />

“In the long term, an altered ownership<br />

structure will make new harvestable<br />

areas much more attractive<br />

prospects. When Russia and China<br />

open their borders more, they’ll<br />

become major forestry countries,”<br />

says Jacobsson.<br />

Russia’s enormous forest resources<br />

are extremely important to the<br />

future, and even if Russia’s timber<br />

stock is low in terms of volume per<br />

acre, there are a great many acres of<br />

Russian forestland.<br />

“If the legal position is cleared up<br />

and new rules of the game are established,<br />

players may be willing to start<br />

making the necessary investments<br />

in infrastructure to gain access to<br />

the sizeable timber resources,” says<br />

Jacobsson. r<br />

18 JUST FOREST NO 4 • 2007<br />

Conservationists<br />

buying forests<br />

While still quite uncommon,<br />

some conservation organizations<br />

buy forests to protect them from<br />

harvesting. In the USA, for example,<br />

Nature Conservancy buys<br />

land both at home and abroad.<br />

Sale of corporate forests<br />

It is increasingly common for major private forest<br />

companies to sell off forests to institutional investors.<br />

The trend began in the USA about ten years<br />

ago, mostly because forest is considered a safe<br />

investment with a value that often swings contrary<br />

to stock market fluctuations.<br />

This trend has even spread to Canada and<br />

Scandinavia and, according to Jacobsson, will<br />

most probably become increasingly common<br />

throughout the world.

Y TRENDS<br />

Y<br />

Return of confiscated forests<br />

Another privatization trend now seen in several former<br />

Eastern Bloc countries is the return of confiscated forest<br />

properties to their former owners.<br />

Privatization of state-owned forests<br />

One of the trends is for states to sell off forests to private interests. These may be plantations, such<br />

as in Australia, or forest holdings, such as in Sweden. More important though, according to Jacobsson,<br />

are the privatization trends in Russia and China.<br />

Russia is drawing up new contractual forms for long-term collaboration between the state and<br />

private enterprise, which in the long run could lead to private ownership. Long-term contracts with<br />

private enterprise are also up for discussion in Canada, and the authorities in China are assessing different<br />

privatization models.<br />

Planting of new forests<br />

China already has large areas of newly planted forests,<br />

though these can be protected as well as harvestable<br />

forests. South America has large plantations and the<br />

right conditions to plant even more new forests. There<br />

is sufficient precipitation and plenty of areas that were<br />

deforested long ago.<br />

However, there are factors that can check such development.<br />

Competition for land is increasing, which<br />

will cause prices to rise. This has already been seen in<br />

Chile while in Brazil, for example, interest in sugar cane<br />

plantations for ethanol production may lead to rising<br />

land prices. In several parts of the world, it may be increasingly<br />

difficult to plant larger new forests. The east<br />

coast of southern Africa is home to an area with sufficient<br />

rainfall, but there is no land left available, and in<br />

Australia large parts of the continent are too dry.<br />

JUST FOREST NO 4 • 2007 19

Increased future logging<br />

Logging volumes will<br />

increase in the future,<br />

mostly in Russia, Latin<br />

America, and China.<br />

<strong>Forest</strong> growth currently<br />

exceeds increases in<br />

logging in all non-tropical<br />

regions. This is the<br />

conclusion of a report<br />

from Finnish analysts<br />

Pöyry.<br />

The report on trends<br />

in the forest industry<br />

begins in 2004 and provides<br />

a clear picture of global forest<br />

resources and trends. Global<br />

harvests total 3.45 billion cubic<br />

meters and of this 51 percent is<br />

used for combustion and heating<br />

while 49 percent goes to industry.<br />

Of the timber used by industry,<br />

995 million cubic meters go to<br />

sawmills and 545 million cubic<br />

meters to the paper industry.<br />

Despite high logging volumes,<br />

absolute forest growth is<br />

positive in all non-tropical areas.<br />

This is especially true in Russia<br />

where the potential harvest<br />

increase is very large. The worst<br />

situation is seen in Oceania and<br />

Africa, where very large timber<br />

harvests for fuel needs cause a<br />

collective drop in forest resources.<br />

An interesting observation is<br />

that logging volumes in Canada<br />

are on a par with growth, while in<br />

the USA growth exceeds harvest.<br />

The report from Pöyry concludes<br />

that timber needs in all<br />

areas for industrial refinement<br />

will increase until 2015. The<br />

larger part of this increase is for<br />

paper pulp and paneling. The<br />

increase is estimated at 300 mil-<br />

20 JUST FOREST NO 4 • 2007<br />

lion cubic meters, counting from<br />

2000.<br />

Global logging volumes too<br />

are expected to keep increasing<br />

until 2020. Logging will mostly<br />

increase in Latin America and<br />

Russia. In order to meet this<br />

demand, the total area of fastgrowing<br />

plantations must almost<br />

600000<br />

500000<br />

400000<br />

300000<br />

200000<br />

100000<br />

Increased mechanization<br />

600000<br />

• As logging volumes increase so does mechanization.<br />

• The degree of mechanization is increasing most in Latin America, Eastern Europe, and Southeast Asia.<br />

500000•<br />

The degree of mechanization depends on local traditions, trees species, and terrain conditions.<br />

• The degree of mechanization is already very high in Scandinavia and can only be increased if the authorities<br />

take initiatives to increase logging volumes.<br />

400000•<br />

Variations in mechanization between countries are great. For example, in Spain, Portugal, and Italy forest<br />

machines are only used on plantations while private forest owners use handcutters.<br />

• Many markets exhibit a great need for simple, low-priced forest machines. Operator training is an impor-<br />

300000 tant issue.<br />

200000<br />

100000<br />

0<br />

Scandinavian<br />

countries<br />

Western<br />

Europe<br />

Nordic countries<br />

Russia<br />

Western Europe excl. Nordic<br />

double between 2005 and 2020.<br />

Plantation forests are expected<br />

to represent about 60 percent<br />

of the increase in logging volume.<br />

In Latin America, almost<br />

all increases in logging stem<br />

from plantations. As logging volumes<br />

increase so does forestry<br />

mechanization. Mechaniza-<br />

Russia Eastern<br />

Europe<br />

North<br />

America<br />

tion has most momentum in Latin<br />

America, Eastern Europe, and<br />

Southeast Asia. The degree of<br />

mechanization will also be affected<br />

by local traditions, trees species,<br />

and terrain conditions.<br />

The report was compiled by Dr.<br />

Hubert Röder of Pöyry <strong>Forest</strong><br />

Industry Consulting. r<br />

South<br />

America<br />

Increase until 2020<br />

Logging volume 2004<br />

North America Latin America<br />

Eastern Europe excl. Russia Oceania<br />

Oceania China<br />

China

New forwarder control<br />

system integrates complete<br />

supply chain<br />

Production reporting for<br />

the wood fiber supply<br />

chain is now complete.<br />

MaxiL is a new forwarder<br />

software application<br />

that even shows where<br />

log piles are located.<br />

The forest industry’s supply<br />

chain of harvesters,<br />

forwarders, timber<br />

trucks, and sawmills needs<br />

a detailed and uninterrupted<br />

chain of production reports from<br />

felling to sawing. Until recently,<br />

there was a gap in the production<br />

report chain, as forwarders<br />

have only been able to register<br />

and report the volume of each<br />

assortment. That gap has now<br />

been closed.<br />

A NEW standard has pushed the<br />

development of forwarder production<br />

reports. With the new<br />

Valmet MaxiL application, forwarded<br />

volumes and assortments<br />

can be associated with a particular<br />

landing, a selected destination<br />

MaxiL is a stand-alone application. All information about forwarded<br />

timber is entered by the user. This includes details of landing coordinates<br />

together with forwarded volume, species, and assortment.<br />

mill, or a geographic position.<br />

“The user describes and registers<br />

the forwarded timber<br />

according to species, assortment,<br />

and location,” explains Per<br />

Annemalm, Product Manager at<br />

<strong>Komatsu</strong> <strong>Forest</strong>.<br />

With MaxiL, the forward-<br />

er can use its .prl files to report<br />

exact positions using the coordinates<br />

of each roadside landing.<br />

This means more efficient handling<br />

every step of the way. Valmet<br />

MaxiL is an option that is<br />

currently only available for the<br />

Swedish market. r<br />

MAY WE ASK…<br />

…TIMO KORHONEN,<br />

Head of Sales, <strong>Komatsu</strong><br />

<strong>Forest</strong> Oy, Finland.<br />

How are sales<br />

in Finland?<br />

We’ve strengthened our market<br />

position in Finland the<br />

past few years and expect<br />

to continue to do so this<br />

year and next year. In absolute<br />

terms, the Finnish market<br />

has grown the past two<br />

and a half years, and due to<br />

altered market conditions<br />

we expect to see continued<br />

growth next year as well.<br />

How has the market<br />

changed?<br />

Finland will import less Russian<br />

timber due to new import<br />

duties. This means a<br />

need to increase logging in<br />

Finland, which means an increased<br />

need for new machines.<br />

However, the additional<br />

harvest in Finland will<br />

not only comprise final logging<br />

but even a great deal of<br />

thinning. As a result, we’re<br />

expecting further increases<br />

in demand for smaller machines<br />

such as the Valmet<br />

830.3, the Valmet 840.3, the<br />

Valmet 911.3, and the Valmet<br />

901.3.<br />

You’re also<br />

reorganizing?<br />

We’ve opened a new <strong>Forest</strong><br />

Machine Center that will be<br />

an important hub for our operations<br />

in Finland. This will<br />

even enable us to concentrate<br />

all our efforts on the<br />

Finnish market, which is a<br />

plus for all our Finnish customers.<br />

And they’ll notice<br />

the difference!<br />

JUST FOREST NO 4 • 2007 21

DRIVING TECHNIQUE<br />

AND MACHINE<br />

are important for low vibrations<br />

Being tossed around in the seat is one of the most important work environment issues<br />

for many forest machine operators. Moreover, an operator can play a decisive role in<br />

minimizing the effects on the body by maintaining good working posture. We explain<br />

what vibrations are and show how a machine with low full body vibrations makes operators<br />

more effective.<br />

The operator’s driving technique<br />

greatly influences the<br />

size of jarring movements.<br />

This is why it’s important to<br />

drive sensibly.<br />

22 JUST FOREST NO 4 • 2007

If a forest machine operator<br />

is to work effectively<br />

without tiring during<br />

a shift, the work environment<br />

must enable good posture<br />

and counter vibrations.<br />

Good working posture has been<br />

shown to be of great importance<br />

to how vibrations affect an<br />

operator. Consequently, a well<br />

designed cab that can be adjusted<br />

to ensure good working posture<br />

is important.<br />

OPERATOR MOST<br />

INFLUENTIAL<br />

One of the single most influential<br />

factors in determining the<br />

size of the vibrations generated<br />

by a machine is the operator. A<br />

smooth driving technique, cor-<br />

C<br />

A<br />

rectly adjusted driver’s seat, and<br />

good general health keep vibrations<br />

and their effects to a minimum.<br />

A fit and healthy operator<br />

can cope with vibrations better<br />

than an unfit individual, and a<br />

person weighing 265 lbs (120 kg)<br />

is more susceptible to vibrations<br />

than an operator weighing 155<br />

lbs (70 kg).<br />

Minimizing full body vibrations<br />

and shaking improves the<br />

work environment. Very little<br />

engine vibrations are transferred<br />

to the cab – shaking caused by<br />

driving and loading has most<br />

impact. Vertical vibrations have<br />

little effect on the operator. Sideto-side<br />

and forward-back shakes<br />

have the greatest impact and the<br />

most important jars to avoid are<br />

B<br />

those under 10 Hz. Hz is a unit<br />

for measuring vibrations per second.<br />

Very slow vibrations of frequencies<br />

less than 1 Hz can<br />

cause motion sickness, which is<br />

just like sea sickness or car sickness.<br />

STABLE MACHINES<br />

VIBRATE LESS<br />

A generally stable machine helps<br />

reduce vibrations. In the previous<br />

issue of Just <strong>Forest</strong>, we<br />

looked at the principles behind<br />

stability, and Valmet’s machines<br />

are renowned for their stability.<br />

Valmet harvesters are fitted<br />

with a stabilizer, which means<br />

the entire machine, including the<br />

rear carriage and its weight, work<br />

to maintain stability. Shakes and<br />

Vibrations can be described as movement from a resting position<br />

(A) across a certain distance to an endpoint (B), followed by movement<br />

in the opposite direction, passing the original resting position.<br />

The movement continues to a second endpoint (C), where it stops<br />

and reverses toward the resting position. The period of time (T)<br />

is the time it takes for the swinging action to complete this entire<br />

movement while the amplitude is the distance from A to C.<br />

a<br />

C<br />

A<br />

T<br />

jars are generally smaller on a<br />

harvester as the machine is often<br />

stationary while working, though<br />

harvester systems also ensure<br />

stability when driving shorter<br />

distances. Forwarders are built to<br />

be driven with large loads and so<br />

driving speed and driving technique<br />

greatly affect the size, or<br />

amplitude, of vibrations. The<br />

articulated design of Valmet’s<br />

forwarders, with a hydraulically<br />

dampened steering swivel joint,<br />

makes them stable and reduces<br />

full body shakes by producing<br />

smaller amplitudes. When a<br />

harvester is processing logs and<br />

when a forwarder is loading, the<br />

machines are kept stable. Stable<br />

machines are one of the key factors<br />

in keeping full body vibra-<br />

B<br />

JUST FOREST NO 4 • 2007 23<br />

t

An ergonomically designed cab with a correctly adjusted seat reduces<br />

the effects of vibrations.<br />

tions low, and stable support for<br />

the driver’s seat also helps reduce<br />

vibrations. A seat with unstable<br />

support can reinforce full body<br />

vibrations.<br />

ABOUT VIBRATIONS<br />

Vibrations are usually divided<br />

into two main types, full body<br />

vibrations (shakes and jars) and<br />

local vibrations, though here<br />

we’ll focus on the full body type,<br />

the main type of forest machine<br />

vibration. Full body vibrations<br />

occur when the structure on<br />

which we sit or stand moves or<br />

swings back and forward like a<br />

pendulum, and this motion can<br />

be described using physical measures.<br />

The first measure is ampli-<br />

INFO<br />

24 JUST FOREST NO 4 • 2007<br />

tude, the size of the vibration.<br />

Amplitude is expressed in millimeters,<br />

though in a forest<br />

machine the amplitude can be up<br />

to one meter (almost 40 inches).<br />

The other measure is frequency,<br />

which describes how often the<br />

vibration occurs in a unit of time.<br />

Frequency is expressed in Hz,<br />

or vibrations per second. Other<br />

characteristics contributing to<br />

the effect are the total time the<br />

vibrations continue, the direction<br />

of the vibrations, and the type of<br />

vibration. Vibration types are<br />

divided into different groups. On<br />

the one hand we have predictable<br />

vibrations, and on the other<br />

we have random vibrations,<br />

which are most common in forest<br />

machines. r<br />

The effects of full body vibrations<br />

Reducing vibrations<br />

Drive sensibly<br />

• Match your driving speed to the terrain.<br />

• Drive carefully on sloping terrain as your driving<br />

body posture can be adversely affected. Driving<br />

on flat ground has less impact on body position.<br />

• Drive smoothly and evenly. This also reduces fuel<br />

consumption and machine wear.<br />

• Work with smooth and fluid boom/crane movements.<br />

Personal health and work environment<br />

• Vary your working posture to avoid straining<br />

joints and muscles.<br />

• Adjust the seat and controls to match your height<br />

and weight.<br />

• Keep in good shape. This enables you to better<br />

reduce the effects on your body.<br />

• Take regular breaks.<br />

Help from the machine<br />

• Lower RPMs mean less vibration.<br />

• Replace the seat if it’s old. A worn driver’s seat<br />

and weak support actually reinforce vibrations<br />

and make it difficult to correctly adjust the seat.<br />

• Larger machines generally shake the body less<br />

than small machines.<br />

When someone is subjected to full body vibrations, muscles contract. This affects everything from heart rate to<br />

blood pressure and balance. It’s impossible to predict who will be more seriously affected by vibrations. Everyone<br />

reacts differently to them.

ProSelect – new saw bars and<br />

saw chains to choose from<br />

Valmet’s ProSelect<br />

product range is ever<br />

widening. Several<br />

different saw bars and<br />

chains suitable for a<br />

large variety of harvesting<br />

heads now join the<br />

lineup.<br />

Valmet’s ProSelect brand<br />

now offers an even wider<br />

range of high-performance<br />

saw bars and saw chains.<br />

The items specially designed<br />

for Valmet machines have been<br />

joined by new offerings. With its<br />

solid experience as a head manufacturer,<br />

Valmet has a good<br />

understanding of designing saw<br />

bars and saw chains that perform<br />

well and safely.<br />

Valmet ProSelect saw bars<br />

have a number of features to<br />

ensure long, safe use and performance.<br />

The bars are optimized<br />

for maximum stability, while a<br />

special steel alloy ensures great<br />

flexibility. A unique heat treatment<br />

makes the saw bar rigid<br />

and robust and the mount has<br />

holes instead of slots for a more<br />

stable fitting and longer service<br />

life. The optimized chain grooves<br />

increase oil flow and ensure that<br />

What you need, when you need it.<br />

the chain runs steadily through<br />

the grooves. Hardened metal<br />

shims on the nose sprocket protect<br />

bearings and provide longer<br />

service life than regular nose<br />

sprockets. The saw bar is available<br />

with three mount sizes, 10<br />

mm, 15 mm, and 3/4 inches.<br />

ProSelect saw chains are made<br />

to match the saw bar to provide<br />

optimal saw performance. The<br />

saw chains are durable and easy<br />

to maintain, designed to pro-<br />

Expertise and experience. These are the most important building blocks of ProSelect, our unique<br />

assortment of accessories and consumables for forestry machines. The chief purpose of ProSelect<br />

is to provide you with the prerequisites for increased profi tability. We do this through high quality,<br />

availability and a complete assortment of products and services. Concrete benefi ts for our customers<br />

range from minimized downtime to optimized performance and service life for your forestry machines.<br />

vide long service life with long<br />

intervals between sharpening,<br />

achieved in part by sharpening<br />

after fitting. The chains are made<br />

from a special nickel-steel alloy<br />

with hard chromium plating to<br />

provide additional durability and<br />

improved saw characteristics.<br />

What’s more, the factory-fitted<br />

and pre-lubricated rivets further<br />

extend service life. The chains<br />

are available in 1.6 and 2 gauge<br />

and for 3/4 inch saw bars. r

<strong>Forest</strong>s in the USA and Canada run a high risk of wildfire. To reduce the risk of wildfire, some 190 million acres (77 million hectares)<br />

of forest have been identified as in need of thinning or clearing.<br />

THINNING<br />

– a hot topic<br />

Interest in thinning and biomass fuels is increasing in North America and Europe, but<br />

for somewhat different reasons. In the USA, wildfire risk reduction is high on the agenda,<br />

while in Canada the aim is to stop the spread of the mountain pine beetle. In Europe,<br />

as well as in North America, demand for biomass fuel has increased the interest in<br />

clearing and harvesting small diameter trees.<br />

26 JUST FOREST NO 4 • 2007

Interest in thinning is<br />

increasing in much of<br />

the world, but for different<br />

reasons. In Europe,<br />

market demand for biomass fuel<br />

is driving development while in<br />

North America widespread forest<br />

fires and the spread of the mountain<br />

pine beetle were early drivers<br />

of the trend.<br />

In order to reduce the risk of<br />

major wildfires, mostly in western<br />

USA, biomass harvesting is<br />

to increase. The Healthy <strong>Forest</strong>s<br />

Initiative, signed by President<br />

Thinning is usually conducted as a silvicultural measure, as well as to increase forest product harvests (primarily<br />

pulpwood).<br />

Bush in 2004, emphasizes the<br />

need to reduce the proportion of<br />

combustible material in the forest.<br />

President Bush has said, for<br />

instance, that “By thinning out<br />

our forests, we reduce the risk of<br />

catastrophic fire” and “We need<br />

to thin our forests in America”. A<br />

full 190 million acres (77 million<br />

hectares) of forestland have been<br />

identified as at risk from wildfire<br />

due to insufficient thinning.<br />

ONE TECHNIQUE used to quickly<br />

reduce risk is to make shaded<br />

fuel breaks. These are areas where<br />

smaller trees, deadwood, undergrowth,<br />

and brushwood are cleared<br />

while mature, healthy trees<br />

that take longer to catch fire are<br />

left standing. These areas give<br />

firefighters more time to combat a<br />

fire by slowing its progress. Much<br />

thinning is currently conducted<br />

by handcutters with chainsaws.<br />

On the West Coast, west of the<br />

Cascade Mountain Range, forestlands<br />

contain copious amounts<br />

of combustible material, some<br />

50 tons of biomass per acre (120<br />

tons per hectare) and east of the<br />

range, where the climate is drier,<br />

about 30 tons of biomass per acre<br />

(70 tons per hectare). Most of the<br />

material from areas thinned and<br />

cleared of undergrowth is currently<br />

piled high and burned during<br />

winter, when there’s less risk<br />

of wildfire. Controlled fires are<br />

also used to reduce the amount<br />

of combustible material.<br />

WHILE WILDFIRES ARE a main<br />

reason for increased interest in<br />

thinning in the USA, mountain<br />

JUST FOREST NO 4 • 2007 27

There’s a great deal of combustible material in the forests of<br />

America, with as much as 50 tons of biomass per acre (120 tons<br />

per hectare).<br />

pine beetle infestation is the reason<br />

in Canada. Thinning damaged<br />

trees and rapidly removing<br />

infested timber is important<br />

in the fight to stop the beetle’s<br />

spread.<br />

THINNING IS EVEN increasing<br />

in Europe, though mostly due to<br />

increased demand for biomass<br />

fuel and new harvesting methods<br />

are on the horizon. Antti<br />

Asikainen, a professor at Finnish<br />

forestry research institute Metla,<br />

believes interest in small diameter<br />

timber harvested using multi-tree<br />

accumulators, as well as<br />

the clearing of older stands, will<br />

increase. Asikainen has a theory<br />

as to why the demand for biomass<br />

fuel has not been the driving<br />

force in North America.<br />

“North America, and even<br />

Russia, have much forest and get<br />

as much bioenergy as they need<br />

from sawmills without the need<br />

to specifically harvest the forest<br />

for biomass fuel,” he explains.<br />

Don Gosnell at the Ministry<br />

of <strong>Forest</strong> and Range in British<br />

Columbia, Canada confirms<br />

this idea and explains that most<br />

sawmills use the waste from<br />

sawing, such as sawdust, wood<br />

28 JUST FOREST NO 4 • 2007<br />

chips, and even bark, to produce<br />

heat and electricity as the material<br />

needs to be dealt with in some<br />

way or other. However, according<br />

to Gosnell, electricity is so<br />

cheap (about 3.5 cents per kilowatt<br />

hour) that it’s unprofitable<br />

to produce electricity from waste<br />

if it has to be transported to the<br />

generating facility.<br />

Asikainen, on the other<br />

hand, sees development gathering<br />

momentum in Europe, with<br />

more and more countries in Central<br />

Europe, including Italy and<br />

Austria, and even Poland, harvesting<br />

round timber and forest<br />

residues simultaneously. Wood<br />

chips are generally produced at<br />

landings, before transportation.<br />

Asikainen also sees greater interest<br />

in Europe for stumps, which<br />

have greater energy value than<br />

other forest residues.<br />

ROLF BJÖRHEDEN heads a biomass<br />

fuel project at Swedish<br />

research institute Skogforsk and<br />

believes development must be<br />

toward increased optimization<br />

and increased integration of biomass<br />

fuel management with<br />

other forestry. Björheden believes<br />

biomass harvesting will be<br />

Canada produces enormous amounts of sawmill waste. So much<br />

that it’s currently unprofitable to harvest biomass from the forests.<br />

New assortments will be handled by existing machines parallel to<br />

conventional harvesting.<br />

integrated with other harvesting<br />

using existing machines, a<br />

matter on which Asikainen also<br />

agrees, adding that conventional<br />

forest machines, with necessary<br />

adaptations for handling biomass,<br />

are the route to take for the<br />

foreseeable future. r

Customers are the key<br />

She has worked for the<br />

company for 30 years<br />

and knows operations<br />

inside out. Christin<br />

Davidsson is head of<br />

quality assurance at<br />

the factory in Umeå,<br />

Sweden.<br />

“Working with quality<br />

issues with <strong>Komatsu</strong> as<br />

our owner is very inspiring,”<br />

she says.<br />

Christin Davidsson<br />

has been head of<br />

quality assurance<br />

at the Umeå factory<br />

for about a year. She joined the<br />

company 30 years ago and has<br />

worked in many departments.<br />

“It’s very exciting to work with<br />

quality as <strong>Komatsu</strong> has extensive<br />

experience and a proud tradition<br />

of systematic quality assurance<br />

stretching back to the 1960s,”<br />

says Christin.<br />

One of the driving forces in<br />

About Christin<br />

Davidsson<br />

POSITION: Head of Quality Assurance<br />

EMPLOYED SINCE: 1977<br />

AGE: 47 years<br />

LIVES: Umeå, Sweden<br />

FAMILY: Two teenage daughters<br />

BEST PART OF THE JOB: Teamwork in a global<br />

company with experiences and focus that<br />

allow me to continually develop in my role.<br />

LEISURE INTERESTS: Reading, traveling, walking,<br />

and different forms of exercise.<br />

Christin’s work is to make customers<br />

proud to own a Valmet<br />

product. She has 27 department<br />

colleagues to help achieve this.<br />

“Our quality assurance work<br />

gets support and commitment<br />

from top management, and that<br />

lends great importance to our<br />

work.”<br />

Christin’s position plays an<br />

active role, very much in the here<br />

and now.<br />

“It’s important to create commitment<br />

and increase quality<br />

awareness throughout the organization,”<br />

explains Christin. “I<br />

want <strong>Komatsu</strong> <strong>Forest</strong> to be a worthy<br />

member of the <strong>Komatsu</strong> family<br />

in terms of quality assurance.”<br />

Quality assurance demands<br />

patience and perseverance. Christin<br />

possesses both qualities.<br />

“It takes time to see the<br />

results of our work, and in order<br />

to succeed we must work at it<br />

every day and never forget that<br />

the customer’s product experience<br />

is our guide.” r<br />

Christin Davidsson<br />

Three quick questions<br />

1. What does the forest represent for you?<br />

For me the forest is both a long-term work project and leisure<br />

time, something we must nurture for the future.<br />

2. What does <strong>Komatsu</strong> represent for you?<br />

A long-term perspective and quality with the customer in<br />

mind.<br />

3. Which is your favorite machine?<br />

I’d probably have to say the Valmet 901, because it’s a<br />

product that’s been around for a long time but that’s still<br />

developing along with customer expectations.<br />

JUST FOREST NO 4 • 2007 29

Optimized transport saves<br />

money and the environment<br />

A logistics management<br />

system for forest product<br />

transport developed<br />

in Sweden can save up to<br />

a fifth on transport costs.<br />

This saving is achieved<br />