warning - Scag Power Equipment

warning - Scag Power Equipment

warning - Scag Power Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

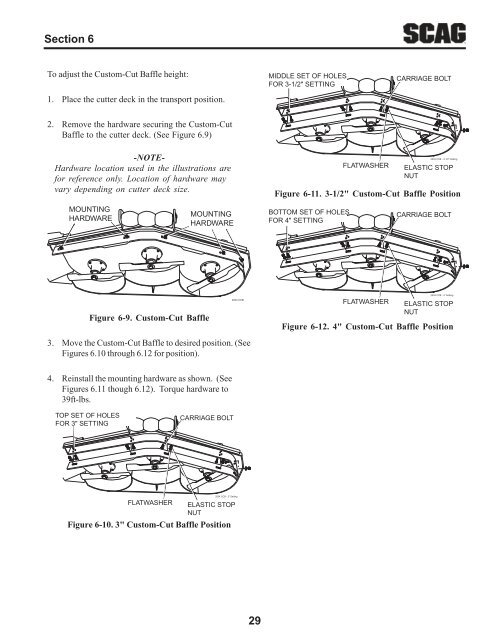

Section 6To adjust the Custom-Cut Baffle height:1. Place the cutter deck in the transport position.MIDDLE SET OF HOLESFOR 3-1/2" SETTINGCARRIAGE BOLT2. Remove the hardware securing the Custom-CutBaffle to the cutter deck. (See Figure 6.9)-NOTE-Hardware location used in the illustrations arefor reference only. Location of hardware mayvary depending on cutter deck size.FLATWASHER2004 CCB - 3-1/2" SettingELASTIC STOPNUTFigure 6-11. 3-1/2" Custom-Cut Baffle PositionMOUNTINGHARDWAREMOUNTINGHARDWAREBOTTOM SET OF HOLESFOR 4" SETTINGCARRIAGE BOLTFigure 6-9. Custom-Cut Baffle2004 CCBFLATWASHER2004 CCB - 4" SettingELASTIC STOPNUTFigure 6-12. 4" Custom-Cut Baffle Position3. Move the Custom-Cut Baffle to desired position. (SeeFigures 6.10 through 6.12 for position).4. Reinstall the mounting hardware as shown. (SeeFigures 6.11 though 6.12). Torque hardware to39ft-lbs.TOP SET OF HOLESFOR 3" SETTINGCARRIAGE BOLTFLATWASHER2004 CCB - 3" SettingELASTIC STOPNUTFigure 6-10. 3" Custom-Cut Baffle Position29