Output control at up to 400 ft without a cord! - The Canadian Welding ...

Output control at up to 400 ft without a cord! - The Canadian Welding ...

Output control at up to 400 ft without a cord! - The Canadian Welding ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

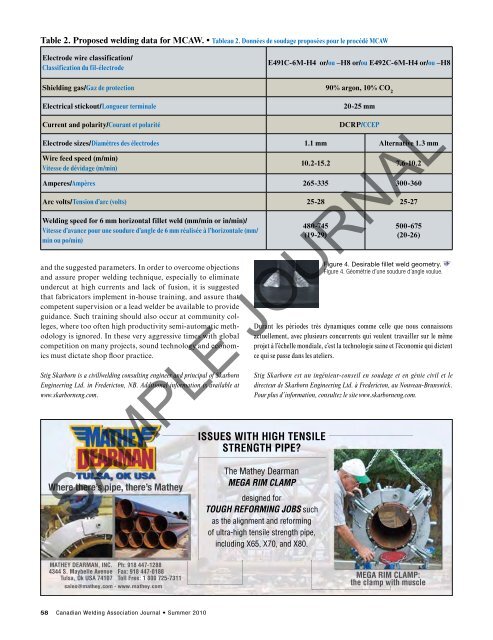

Table 2. Proposed welding d<strong>at</strong>a for MCAW. • Tableau 2. Données de soudage proposées pour le procédé MCAW<br />

Electrode wire classific<strong>at</strong>ion/<br />

Classific<strong>at</strong>ion du fil-électrode<br />

and the suggested parameters. In order <strong>to</strong> overcome objections<br />

and assure proper welding technique, especially <strong>to</strong> elimin<strong>at</strong>e<br />

undercut <strong>at</strong> high currents and lack of fusion, it is suggested<br />

th<strong>at</strong> fabric<strong>at</strong>ors implement in-house training, and assure th<strong>at</strong><br />

competent s<strong>up</strong>ervision or a lead welder be available <strong>to</strong> provide<br />

guidance. Such training should also occur <strong>at</strong> community colleges,<br />

where <strong>to</strong>o o<strong>ft</strong>en high productivity semi-au<strong>to</strong>m<strong>at</strong>ic methodology<br />

is ignored. In these very aggressive times with global<br />

competition on many projects, sound technology and economics<br />

must dict<strong>at</strong>e shop floor practice.<br />

Stig Skarborn is a civil/welding consulting engineer and principal of Skarborn<br />

Engineering Ltd. in Frederic<strong>to</strong>n, NB. Additional inform<strong>at</strong>ion is available <strong>at</strong><br />

www.skarborneng.com.<br />

E491C-6M-H4 or/ou –H8 or/ou E492C-6M-H4 or/ou –H8<br />

Shielding gas/Gaz de protection 90% argon, 10% CO 2<br />

Electrical stickout/Longueur terminale 20-25 mm<br />

Current and polarity/Courant et polarité DCRP/CCEP<br />

Electrode sizes/Diamètres des électrodes 1.1 mm Altern<strong>at</strong>ive 1.3 mm<br />

Wire feed speed (m/min)<br />

Vitesse de dévidage (m/min)<br />

10.2-15.2 7.6-10.2<br />

Amperes/Ampères 265-335 300-360<br />

Arc volts/Tension d’arc (volts) 25-28 25-27<br />

<strong>Welding</strong> speed for 6 mm horizontal fillet weld (mm/min or in/min)/<br />

Vitesse d’avance pour une soudure d’angle de 6 mm réalisée à l’horizontale (mm/<br />

min ou po/min)<br />

Where there’s pipe, there’s M<strong>at</strong>hey<br />

MATHEY DEARMAN, INC.<br />

4344 S. Maybelle Avenue<br />

Tulsa, Ok USA 74107<br />

Ph: 918 447-1288<br />

Fax: 918 447-0188<br />

Toll Free: 1 800 725-7311<br />

sales@m<strong>at</strong>hey.com - www.m<strong>at</strong>hey.com<br />

480-745<br />

(19-29)<br />

500-675<br />

(20-26)<br />

Figure 4. Desirable fillet weld geometry.<br />

Figure 4. Géométrie d’une soudure d’angle voulue.<br />

Durant les périodes très dynamiques comme celle que nous connaissons<br />

actuellement, avec plusieurs concurrents qui veulent travailler sur le même<br />

projet à l’échelle mondiale, c’est la technologie saine et l’économie qui dictent<br />

ce qui se passe dans les <strong>at</strong>eliers.<br />

Stig Skarborn est un ingénieur-conseil en soudage et en génie civil et le<br />

directeur de Skarborn Engineering Ltd. à Frederic<strong>to</strong>n, au Nouveau-Brunswick.<br />

Pour plus d’inform<strong>at</strong>ion, consultez le site www.skarborneng.com.<br />

ISSUES WITH HIGH TENSILE<br />

STRENGTH PIPE?<br />

<strong>The</strong> M<strong>at</strong>hey Dearman<br />

MEGA RIM CLAMP<br />

SAMPLE JOURNAL<br />

designed for<br />

TOUGH REFORMING JOBS such<br />

as the alignment and reforming<br />

of ultra-high tensile strength pipe,<br />

including X65, X70, and X80.<br />

MEGA RIM CLAMP:<br />

the clamp with muscle<br />

58 <strong>Canadian</strong> <strong>Welding</strong> Associ<strong>at</strong>ion Journal • Summer 2010<br />

483291_M<strong>at</strong>hey.indd 1 6/30/10 4:51:22 PM