Our automation system for a continuous tandem mill coupled with ...

Our automation system for a continuous tandem mill coupled with ...

Our automation system for a continuous tandem mill coupled with ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

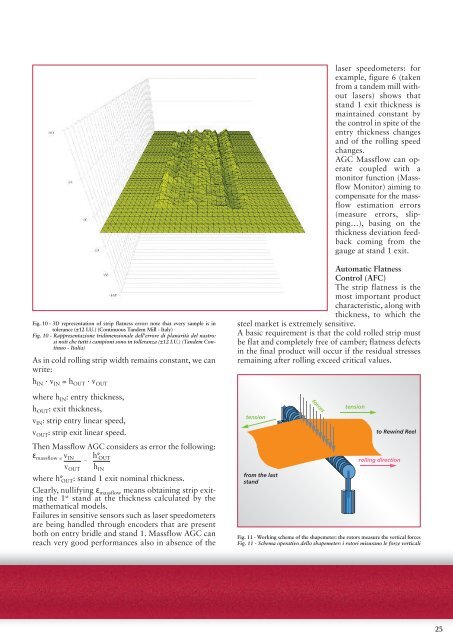

Fig. 10 - 3D representation of strip flatness error: note that every sample is in<br />

tolerance (±12 I.U.) (Continuous Tandem Mill - Italy)<br />

Fig. 10 - Rappresentazione tridimensionale dell’errore di planarità del nastro:<br />

si noti che tutti i campioni sono in tolleranza (±12 I.U.) (Tandem Continuo<br />

- Italia)<br />

As in cold rolling strip width remains constant, we can<br />

write:<br />

hIN · vIN = hOUT · vOUT where hIN: entry thickness,<br />

hOUT: exit thickness,<br />

vIN: strip entry linear speed,<br />

vOUT: strip exit linear speed.<br />

Then Massflow AGC considers as error the following:<br />

εmassflow = vIN _ h* OUT<br />

vOUT hIN where h* OUT: stand 1 exit nominal thickness.<br />

Clearly, nullifying εmassflow means obtaining strip exiting<br />

the 1st stand at the thickness calculated by the<br />

mathematical models.<br />

Failures in sensitive sensors such as laser speedometers<br />

are being handled through encoders that are present<br />

both on entry bridle and stand 1. Massflow AGC can<br />

reach very good per<strong>for</strong>mances also in absence of the<br />

laser speedometers: <strong>for</strong><br />

example, figure 6 (taken<br />

from a <strong>tandem</strong> <strong>mill</strong> <strong>with</strong>out<br />

lasers) shows that<br />

stand 1 exit thickness is<br />

maintained constant by<br />

the control in spite of the<br />

entry thickness changes<br />

and of the rolling speed<br />

changes.<br />

AGC Massflow can operate<br />

<strong>coupled</strong> <strong>with</strong> a<br />

monitor function (Massflow<br />

Monitor) aiming to<br />

compensate <strong>for</strong> the massflow<br />

estimation errors<br />

(measure errors, slipping…),<br />

basing on the<br />

thickness deviation feedback<br />

coming from the<br />

gauge at stand 1 exit.<br />

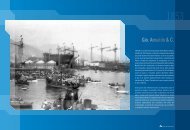

Automatic Flatness<br />

Control (AFC)<br />

The strip flatness is the<br />

most important product<br />

characteristic, along <strong>with</strong><br />

thickness, to which the<br />

steel market is extremely sensitive.<br />

A basic requirement is that the cold rolled strip must<br />

be flat and completely free of camber; flatness defects<br />

in the final product will occur if the residual stresses<br />

remaining after rolling exceed critical values.<br />

tension<br />

from the last<br />

stand<br />

<strong>for</strong>ces<br />

tension<br />

to Rewind Reel<br />

rolling direction<br />

Fig. 11 - Working scheme of the shapemeter: the rotors measure the vertical <strong>for</strong>ces<br />

Fig. 11 - Schema operativo dello shapemeter: i rotori misurano le <strong>for</strong>ze verticali<br />

25