Our automation system for a continuous tandem mill coupled with ...

Our automation system for a continuous tandem mill coupled with ...

Our automation system for a continuous tandem mill coupled with ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

20<br />

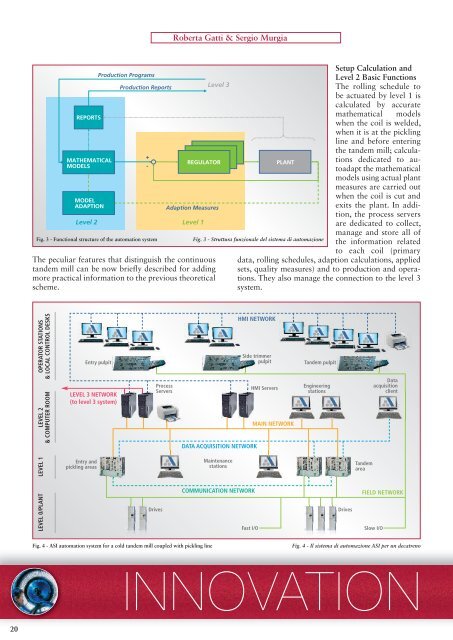

REPORTS<br />

MATHEMATICAL<br />

MODELS<br />

Level 2<br />

Production Programs<br />

Production Reports<br />

The peculiar features that distinguish the <strong>continuous</strong><br />

<strong>tandem</strong> <strong>mill</strong> can be now briefly described <strong>for</strong> adding<br />

more practical in<strong>for</strong>mation to the previous theoretical<br />

scheme.<br />

+<br />

-<br />

Roberta Gatti & Sergio Murgia<br />

Level 1<br />

Level 3<br />

R<br />

R<br />

REGULATOR<br />

MODEL<br />

ADAPTION Adaption Measures<br />

Fig. 3 - Functional structure of the <strong>automation</strong> <strong>system</strong> Fig. 3 - Struttura funzionale del sistema di automazione<br />

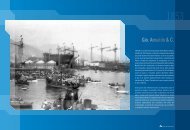

OPERATOR STATIONS<br />

& LOCAL CONTROL DESKS<br />

LEVEL 2<br />

& COMPUTER ROOM<br />

LEVEL 1<br />

LEVEL 0/PLANT<br />

Entry pulpit<br />

LEVEL 3 NETWORK<br />

(to level 3 <strong>system</strong>)<br />

Entry and<br />

pickling areas<br />

Process<br />

Servers<br />

Setup Calculation and<br />

Level 2 Basic Functions<br />

The rolling schedule to<br />

be actuated by level 1 is<br />

calculated by accurate<br />

mathematical models<br />

when the coil is welded,<br />

when it is at the pickling<br />

line and be<strong>for</strong>e entering<br />

the <strong>tandem</strong> <strong>mill</strong>; calcula-<br />

PLANT<br />

tions dedicated to autoadapt<br />

the mathematical<br />

models using actual plant<br />

measures are carried out<br />

when the coil is cut and<br />

exits the plant. In addition,<br />

the process servers<br />

are dedicated to collect,<br />

manage and store all of<br />

the in<strong>for</strong>mation related<br />

to each coil (primary<br />

data, rolling schedules, adaption calculations, applied<br />

sets, quality measures) and to production and operations.<br />

They also manage the connection to the level 3<br />

<strong>system</strong>.<br />

HMI NETWORK<br />

DATA ACQUISITION NETWORK<br />

Maintenance<br />

stations<br />

Side trimmer<br />

pulpit Tandem pulpit<br />

HMI Servers<br />

MAIN NETWORK<br />

Engineering<br />

stations<br />

Drives Drives<br />

Data<br />

acquisition<br />

client<br />

Fig. 4 - ASI <strong>automation</strong> <strong>system</strong> <strong>for</strong> a cold <strong>tandem</strong> <strong>mill</strong> <strong>coupled</strong> <strong>with</strong> pickling line Fig. 4 - Il sistema di automazione ASI per un decatreno<br />

Fast I/O<br />

Tandem<br />

area<br />

COMMUNICATION NETWORK FIELD NETWORK<br />

Slow I/O<br />

INNOVATION