Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

• Use only perfect saw discs. I.e. sharpened, without any cracks, fissures, deformations etc. Faulty discs have to be replaced<br />

immediately.<br />

• Be particular about the arrow on the disc pointing on the same direction as that on the unit. .<br />

• The unit protection devices may never be removed or removed from operation in any way.<br />

• Damaged or faulty protection devices must be replaced immediately.<br />

• If you are disturbed by anybody when working with the saw, always finish the work you are doing before taking a look elsewhere.<br />

• Your work should always be placed on the bench. Never use the unit when the piece to be cut is outside the bench.<br />

• Be particular about your hands safely laid in a way that if slipping down, they will never come in contact with the saw.<br />

• If working with a long piece, use additional supports or an underlay for the saw not to get stuck. .<br />

• The part of work to be cut off must be free from nails and other foreign object. Always stand aside to the saw disc.<br />

• Do not overload the unit, it will run slower and will overheat.<br />

• Never cut several pieces at a time.<br />

• Always use the sliding guide rod.<br />

• Do not attempt remove free chips, pieces of wood or a jammed work from the saw without switching it off and unplugging.<br />

• It is necessary to switch the unit off and unplug first, if work is to be taken out of defects eliminated.<br />

• Adjustment, measurement , cleaning etc. may be done with the motor switched off and the unit unplugged..<br />

• Never leave your workplace unattended without the motor switched off and the unit unplugged.<br />

• When the maintenance and repairs of the safety and protection devices is completed, they have to be replaced as appropriate.<br />

• It is unconditional to know all the safety regulations in effect in the place of use and all the other safety regulations of general<br />

recognition.<br />

• When the unit is used in closed rooms, the use is allowed in combination with a suitable exhaust system only.<br />

• This bench circular saw has to be connected to the mains of 230 V and 10 A as a minimum.<br />

• Use the supply cable of the unit for the assigned purpose only.<br />

• Keep a safe posture and good balance when working.<br />

• Before using the unit, it is essential to check on safety devices. Make sure that the parts apparently slightly damaged operate<br />

correctly.<br />

• Check on every moving part and it perfect operation. Especially, be particular about any damage and . sticking parts. All the<br />

parts have to be fitted as appropriate and to meet the conditions of their perfect operation.<br />

• Unless otherwise stated herein, the damaged parts and safety devices have to be replaced or repaired at an authorised servicing<br />

centre.<br />

• Have the damaged switches replaced at an authorised servicing centre. .<br />

• The unit meets all the safety regulations. Repairs may be done by a qualified electrician at an authorised servicing centre and<br />

only genuine spare parts must be used only. A risk of accidents arises of this is not observed.<br />

• Grooves, undercuts etc. should not be done with the unit, unless with a suitable protection above the bench (closed around) .<br />

• The saw should not be used for impact works (spliced slots etc.)<br />

Operation<br />

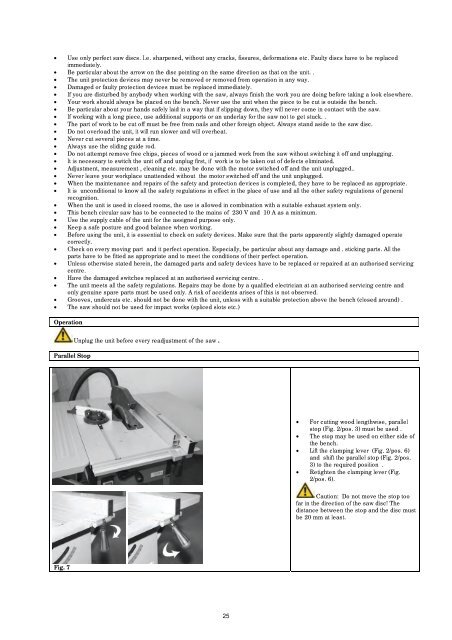

Parallel Stop<br />

Unplug the unit before every readjustment of the saw .<br />

• For cutting wood lengthwise, parallel<br />

stop (Fig. 2/pos. 3) must be used .<br />

• The stop may be used on either side of<br />

the bench.<br />

• Lift the clamping lever (Fig. 2/pos. 6)<br />

and shift the parallel stop (Fig. 2/pos.<br />

3) to the required position .<br />

• Retighten the clamping lever (Fig.<br />

2/pos. 6).<br />

Caution: Do not move the stop too<br />

far in the direction of the saw disc! The<br />

distance between the stop and the disc must<br />

be 20 mm at least.<br />

Fig. 7<br />

25