Lambda Sensors |

Lambda Sensors |

Lambda Sensors |

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Lambda</strong> <strong>Sensors</strong> Installation<br />

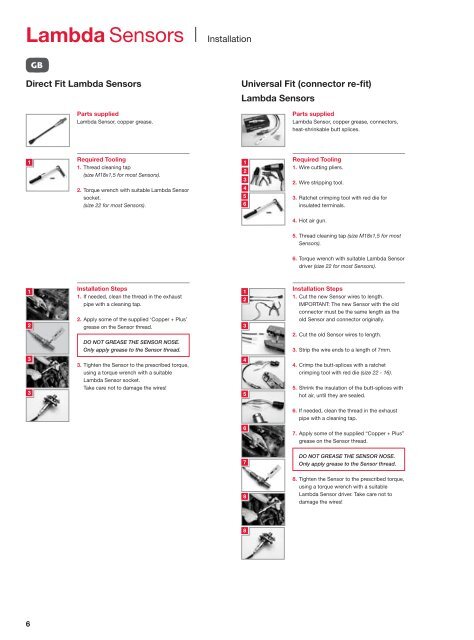

Direct Fit <strong>Lambda</strong> <strong>Sensors</strong><br />

Parts supplied<br />

<strong>Lambda</strong> Sensor, copper grease.<br />

1<br />

Required Tooling<br />

1<br />

1. Thread cleaning tap<br />

2<br />

(size M18x1,5 for most <strong>Sensors</strong>).<br />

1<br />

2<br />

2. Torque wrench with suitable <strong>Lambda</strong> Sensor<br />

socket.<br />

(size 22 for most <strong>Sensors</strong>).<br />

Installation Steps<br />

1. If needed, clean the thread in the exhaust<br />

pipe with a cleaning tap.<br />

2. Apply some of the supplied ‘Copper + Plus’<br />

grease on the Sensor thread.<br />

DO NOT GREASE THE SENSOR NOSE.<br />

Only apply grease to the Sensor thread.<br />

. Tighten the Sensor to the prescribed torque,<br />

using a torque wrench with a suitable<br />

<strong>Lambda</strong> Sensor socket.<br />

Take care not to damage the wires!<br />

Universal Fit (connector re-fit)<br />

<strong>Lambda</strong> <strong>Sensors</strong><br />

5<br />

1<br />

2<br />

5<br />

7<br />

8<br />

8<br />

Parts supplied<br />

<strong>Lambda</strong> Sensor, copper grease, connectors,<br />

heat-shrinkable butt splices.<br />

Required Tooling<br />

1. Wire cutting pliers.<br />

2. Wire stripping tool.<br />

. Ratchet crimping tool with red die for<br />

insulated terminals.<br />

. Hot air gun.<br />

5. Thread cleaning tap (size M18x1,5 for most<br />

<strong>Sensors</strong>).<br />

. Torque wrench with suitable <strong>Lambda</strong> Sensor<br />

driver (size 22 for most <strong>Sensors</strong>).<br />

Installation Steps<br />

1. Cut the new Sensor wires to length.<br />

IMPORTANT: The new Sensor with the old<br />

connector must be the same length as the<br />

old Sensor and connector originally.<br />

2. Cut the old Sensor wires to length.<br />

. Strip the wire ends to a length of 7mm.<br />

. Crimp the butt-splices with a ratchet<br />

crimping tool with red die (size 22 - 16).<br />

5. Shrink the insulation of the butt-splices with<br />

hot air, until they are sealed.<br />

. If needed, clean the thread in the exhaust<br />

pipe with a cleaning tap.<br />

7. Apply some of the supplied “Copper + Plus”<br />

grease on the Sensor thread.<br />

DO NOT GREASE THE SENSOR NOSE.<br />

Only apply grease to the Sensor thread.<br />

8. Tighten the Sensor to the prescribed torque,<br />

using a torque wrench with a suitable<br />

<strong>Lambda</strong> Sensor driver. Take care not to<br />

damage the wires!