HYDRAULIKPRESSE 1/2013 – PDF einseitig - Hansa Flex

HYDRAULIKPRESSE 1/2013 – PDF einseitig - Hansa Flex

HYDRAULIKPRESSE 1/2013 – PDF einseitig - Hansa Flex

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

hanSa-FleX worldwIde HaNsa-FleX welTweiT<br />

It looks like fossilised sunlight and was highly prized by the most ancient<br />

civilisations. Gold was even considered the metal of the gods by the egyptians.<br />

in fact, gold is still being mined today in one of the oldest mining<br />

sites in the world, the alsukari gold mine in southeastern egypt - almost<br />

1700 years after the last pharaoh’s reign came to an end. but where in times<br />

past the muscle power of thousands of workers was needed, today a huge<br />

fleet of modern machines is at work. since January <strong>2013</strong>, this site has been<br />

supplied with replacement hydraulic parts via a hydraulic service container<br />

(HsC) from HaNsa-FleX.<br />

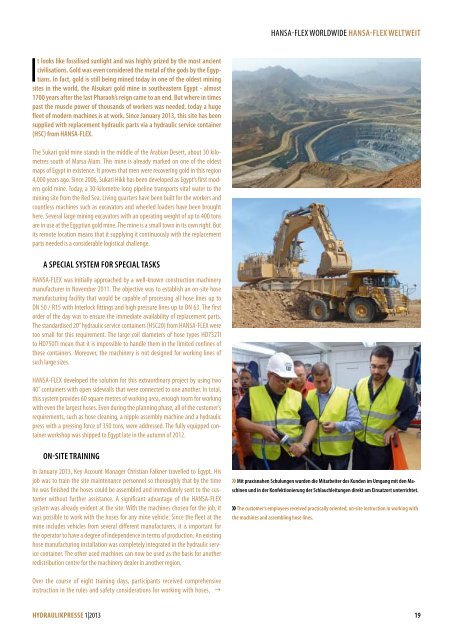

the Sukari gold mine stands in the middle of the arabian desert, about 30 kilometres<br />

south of marsa alam. this mine is already marked on one of the oldest<br />

maps of egypt in existence. It proves that men were recovering gold in this region<br />

4,000 years ago. Since 2006, Sukari hikk has been developed as egypt’s first modern<br />

gold mine. today, a 30-kilometre long pipeline transports vital water to the<br />

mining site from the red Sea. living quarters have been built for the workers and<br />

countless machines such as excavators and wheeled loaders have been brought<br />

here. Several large mining excavators with an operating weight of up to 400 tons<br />

are in use at the egyptian gold mine. the mine is a small town in its own right. but<br />

its remote location means that it supplying it continuously with the replacement<br />

parts needed is a considerable logistical challenge.<br />

a speCial sysTeM FOr speCial Tasks<br />

hanSa-FleX was initially approached by a well-known construction machinery<br />

manufacturer in november 2011. the objective was to establish an on-site hose<br />

manufacturing facility that would be capable of processing all hose lines up to<br />

dn 50 / r15 with Interlock fittings and high pressure lines up to dn 63. the first<br />

order of the day was to ensure the immediate availability of replacement parts.<br />

the standardised 20’’ hydraulic service containers (hSC20) from hanSa-FleX were<br />

too small for this requirement. the large coil diameters of hose types hd732tI<br />

to hd750tI mean that it is impossible to handle them in the limited confines of<br />

these containers. moreover, the machinery is not designed for working lines of<br />

such large sizes.<br />

hanSa-FleX developed the solution for this extraordinary project by using two<br />

40’’ containers with open sidewalls that were connected to one another. In total,<br />

this system provides 60 square metres of working area, enough room for working<br />

with even the largest hoses. even during the planning phase, all of the customer’s<br />

requirements, such as hose cleaning, a nipple assembly machine and a hydraulic<br />

press with a pressing force of 350 tons, were addressed. the fully equipped container<br />

workshop was shipped to egypt late in the autumn of 2012.<br />

ON-siTe TraiNiNG<br />

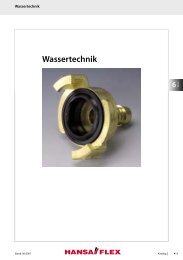

In January <strong>2013</strong>, key account manager Christian Falkner travelled to egypt. his<br />

job was to train the site maintenance personnel so thoroughly that by the time<br />

he was finished the hoses could be assembled and immediately sent to the customer<br />

without further assistance. a significant advantage of the hanSa-FleX<br />

system was already evident at the site: with the machines chosen for the job, it<br />

was possible to work with the hoses for any mine vehicle. Since the fleet at the<br />

mine includes vehicles from several different manufacturers, it is important for<br />

the operator to have a degree of independence in terms of production. an existing<br />

hose manufacturing installation was completely integrated in the hydraulic service<br />

container. the other used machines can now be used as the basis for another<br />

redistribution centre for the machinery dealer in another region.<br />

Mit praxisnahen schulungen wurden die Mitarbeiter des kunden im umgang mit den Maschinen<br />

und in der konfektionierung der schlauchleitungen direkt am einsatzort unterrichtet.<br />

The customer’s employees received practically oriented, on-site instruction in working with<br />

the machines and assembling hose lines.<br />

over the course of eight training days, participants received comprehensive<br />

instruction in the rules and safety considerations for working with hoses, g<br />

<strong>HYDRAULIKPRESSE</strong> 1|<strong>2013</strong><br />

19