Supporting the First Stryker Brigade in Iraq - Army Logistics ...

Supporting the First Stryker Brigade in Iraq - Army Logistics ...

Supporting the First Stryker Brigade in Iraq - Army Logistics ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SBCT Up-Armor EvolutionBY CAPTAIN<br />

Before we deployed from Fort<br />

Lewis, Wash<strong>in</strong>gton, to Operation<br />

<strong>Iraq</strong>i Freedom <strong>in</strong> November<br />

2003, <strong>the</strong> 296th <strong>Brigade</strong> Support<br />

Battalion (BSB) of <strong>the</strong> 3d <strong>Brigade</strong>,<br />

2d Infantry Division—<strong>the</strong> first<br />

<strong>Stryker</strong> <strong>Brigade</strong> Combat Team<br />

(SBCT)—learned about improvised<br />

explosive devices (IEDs) and some<br />

of <strong>the</strong> hostile forces tactics, techniques,<br />

and procedures (TTP) that<br />

we might encounter. We started<br />

look<strong>in</strong>g for ways to protect our BSB<br />

soldiers from IEDs on <strong>the</strong> roads of<br />

<strong>Iraq</strong>, concentrat<strong>in</strong>g on harden<strong>in</strong>g<br />

vehicles with sandbags after we<br />

arrived <strong>in</strong> Kuwait.<br />

Mad Attakai<br />

At Forward Operat<strong>in</strong>g Base (FOB)<br />

Pacesetter near Samarra, <strong>Iraq</strong>, we<br />

learned from o<strong>the</strong>r units <strong>the</strong> basic requirements for IED<br />

protection and began experiment<strong>in</strong>g with different uparmor<br />

configurations. The brigade S–4 procured about<br />

1,000 sheets of steel for configur<strong>in</strong>g armor for two- and<br />

four-door high-mobility, multipurpose, wheeled vehicles<br />

(HMMWVs) to protect <strong>the</strong> soldiers from drive-by<br />

shoot<strong>in</strong>gs and IEDs. With <strong>the</strong> sandbags that we<br />

<strong>in</strong>stalled before depart<strong>in</strong>g Camp Udairi, Kuwait, we felt<br />

<strong>the</strong> HMMWVs had sufficient protection.<br />

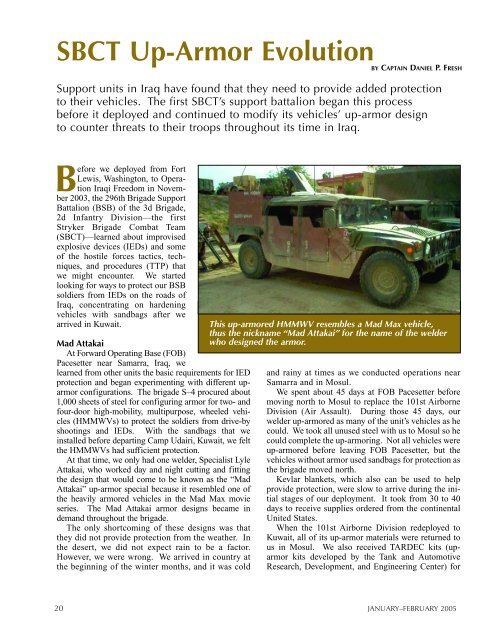

At that time, we only had one welder, Specialist Lyle<br />

Attakai, who worked day and night cutt<strong>in</strong>g and fitt<strong>in</strong>g<br />

<strong>the</strong> design that would come to be known as <strong>the</strong> “Mad<br />

Attakai” up-armor special because it resembled one of<br />

<strong>the</strong> heavily armored vehicles <strong>in</strong> <strong>the</strong> Mad Max movie<br />

series. The Mad Attakai armor designs became <strong>in</strong><br />

demand throughout <strong>the</strong> brigade.<br />

The only shortcom<strong>in</strong>g of <strong>the</strong>se designs was that<br />

<strong>the</strong>y did not provide protection from <strong>the</strong> wea<strong>the</strong>r. In<br />

<strong>the</strong> desert, we did not expect ra<strong>in</strong> to be a factor.<br />

However, we were wrong. We arrived <strong>in</strong> country at<br />

<strong>the</strong> beg<strong>in</strong>n<strong>in</strong>g of <strong>the</strong> w<strong>in</strong>ter months, and it was cold<br />

20<br />

DANIEL P. FRESH<br />

Support units <strong>in</strong> <strong>Iraq</strong> have found that <strong>the</strong>y need to provide added protection<br />

to <strong>the</strong>ir vehicles. The first SBCT’s support battalion began this process<br />

before it deployed and cont<strong>in</strong>ued to modify its vehicles’ up-armor design<br />

to counter threats to <strong>the</strong>ir troops throughout its time <strong>in</strong> <strong>Iraq</strong>.<br />

This up-armored HMMWV resembles a Mad Max vehicle,<br />

thus <strong>the</strong> nickname “Mad Attakai” for <strong>the</strong> name of <strong>the</strong> welder<br />

who designed <strong>the</strong> armor.<br />

and ra<strong>in</strong>y at times as we conducted operations near<br />

Samarra and <strong>in</strong> Mosul.<br />

We spent about 45 days at FOB Pacesetter before<br />

mov<strong>in</strong>g north to Mosul to replace <strong>the</strong> 101st Airborne<br />

Division (Air Assault). Dur<strong>in</strong>g those 45 days, our<br />

welder up-armored as many of <strong>the</strong> unit’s vehicles as he<br />

could. We took all unused steel with us to Mosul so he<br />

could complete <strong>the</strong> up-armor<strong>in</strong>g. Not all vehicles were<br />

up-armored before leav<strong>in</strong>g FOB Pacesetter, but <strong>the</strong><br />

vehicles without armor used sandbags for protection as<br />

<strong>the</strong> brigade moved north.<br />

Kevlar blankets, which also can be used to help<br />

provide protection, were slow to arrive dur<strong>in</strong>g <strong>the</strong> <strong>in</strong>itial<br />

stages of our deployment. It took from 30 to 40<br />

days to receive supplies ordered from <strong>the</strong> cont<strong>in</strong>ental<br />

United States.<br />

When <strong>the</strong> 101st Airborne Division redeployed to<br />

Kuwait, all of its up-armor materials were returned to<br />

us <strong>in</strong> Mosul. We also received TARDEC kits (uparmor<br />

kits developed by <strong>the</strong> Tank and Automotive<br />

Research, Development, and Eng<strong>in</strong>eer<strong>in</strong>g Center) for<br />

JANUARY–FEBRUARY 2005