Primal SF-016 ER.pdf - Mielco

Primal SF-016 ER.pdf - Mielco

Primal SF-016 ER.pdf - Mielco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

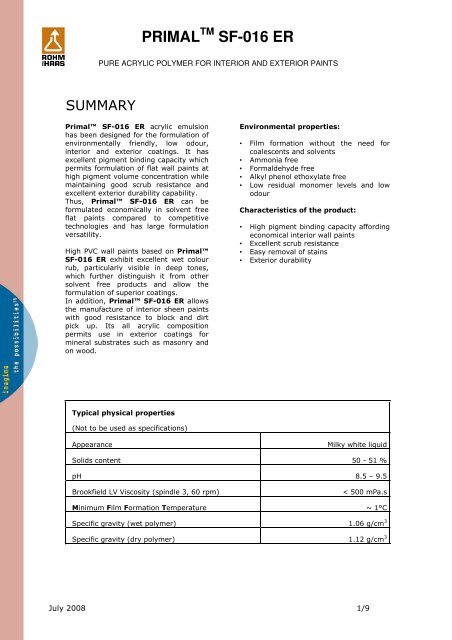

PRIMAL TM <strong>SF</strong>-<strong>016</strong> <strong>ER</strong><br />

PURE ACRYLIC POLYM<strong>ER</strong> FOR INT<strong>ER</strong>IOR AND EXT<strong>ER</strong>IOR PAINTS<br />

SUMMARY<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> acrylic emulsion<br />

has been designed for the formulation of<br />

environmentally friendly, low odour,<br />

interior and exterior coatings. It has<br />

excellent pigment binding capacity which<br />

permits formulation of flat wall paints at<br />

high pigment volume concentration while<br />

maintaining good scrub resistance and<br />

excellent exterior durability capability.<br />

Thus, <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> can be<br />

formulated economically in solvent free<br />

flat paints compared to competitive<br />

technologies and has large formulation<br />

versatility.<br />

High PVC wall paints based on <strong>Primal</strong><br />

<strong>SF</strong>-<strong>016</strong> <strong>ER</strong> exhibit excellent wet colour<br />

rub, particularly visible in deep tones,<br />

which further distinguish it from other<br />

solvent free products and allow the<br />

formulation of superior coatings.<br />

In addition, <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> allows<br />

the manufacture of interior sheen paints<br />

with good resistance to block and dirt<br />

pick up. Its all acrylic composition<br />

permits use in exterior coatings for<br />

mineral substrates such as masonry and<br />

on wood.<br />

Typical physical properties<br />

(Not to be used as specifications)<br />

Environmental properties:<br />

• Film formation without the need for<br />

coalescents and solvents<br />

• Ammonia free<br />

• Formaldehyde free<br />

• Alkyl phenol ethoxylate free<br />

• Low residual monomer levels and low<br />

odour<br />

Characteristics of the product:<br />

• High pigment binding capacity affording<br />

economical interior wall paints<br />

• Excellent scrub resistance<br />

• Easy removal of stains<br />

• Exterior durability<br />

Appearance Milky white liquid<br />

Solids content 50 - 51 %<br />

pH 8.5 – 9.5<br />

Brookfield LV Viscosity (spindle 3, 60 rpm) < 500 mPa.s<br />

Minimum Film Formation Temperature ~ 1°C<br />

Specific gravity (wet polymer) 1.06 g/cm 3<br />

Specific gravity (dry polymer) 1.12 g/cm 3<br />

July 2008 1/9

ROHM AND HAAS PAINT AND COATINGS MAT<strong>ER</strong>IALS<br />

FORMULATIONS GUIDELINES<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> allows specific<br />

solvent free formulation development<br />

and demonstrates wide formulation<br />

latitude from satin to flat paints including<br />

woodstains, which are suitable for both<br />

interior and exterior applications.<br />

It is a versatile binder for paint<br />

companies wishing to stock in bulk a<br />

minimum number of raw materials.<br />

Below are some guidelines to<br />

help formulators:<br />

Dispersants<br />

In our studies, good pigment dispersion<br />

and stability results were obtained with<br />

Orotan 731-A <strong>ER</strong> or Orotan N-4045<br />

at 0.8% to 1% active ingredient level<br />

based on pigment and extenders.<br />

Defoamers<br />

Standard defoamers can be used with<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong>. For example,<br />

Tego ® Foamex 1495 or Byk ® -024 gives<br />

good results.<br />

Rheology Modifiers & Thickeners<br />

Rohm and Haas Acrysol RM-12W,<br />

Acrysol DR-73 <strong>ER</strong>, Acrysol DR-72 and<br />

HEUR rheology modifiers (Acrysol RM-<br />

8W, Acrysol RM-5000) have all been<br />

used successfully in formulating semigloss<br />

to matt paints based on <strong>Primal</strong><br />

<strong>SF</strong>-<strong>016</strong> <strong>ER</strong>.<br />

Coalescents and co-solvents<br />

No coalescing agent is required with<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> to achieve good<br />

film formation down to 0°C.<br />

However, an addition of Texanol at 2-3<br />

% on polymer solids improves early<br />

water resistance in exterior masonry<br />

formulations.<br />

Extenders and opaque polymer<br />

Standard extenders can be used in<br />

paints formulated with <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong><br />

<strong>ER</strong>.<br />

Rohm and Haas organic opacifier<br />

Ropaque Ultra E has shown excellent<br />

results when used in satin to matt<br />

formulations based on <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong><br />

<strong>ER</strong>. Additionally, the use of Ropaque<br />

Ultra E in exterior coatings is<br />

recommended to further improve dirt<br />

pick up, algae and mould resistance.<br />

Adjustment of pH<br />

The pH of paints based on <strong>Primal</strong> <strong>SF</strong>-<br />

<strong>016</strong> <strong>ER</strong> need to be adjusted between<br />

8.5 and 9.5 to ensure good mechanical<br />

shear stability and avoid flocculation.<br />

Any base can be used for pH<br />

adjustment, the final choice will depend<br />

on the paint type (typically ammonia for<br />

exterior coatings and low odour hard<br />

bases for interior).<br />

Biocides<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> is preserved with a<br />

combination of BIT (1,2-<br />

Benzisothiazolin-3-one) and DTBMA<br />

(dithio-2, 2'-bis(N-methylbenzamide)).<br />

Although standard in can preservatives<br />

could be used by the formulators, it is<br />

always recommended to test<br />

compatibility and efficacy in small scale<br />

quantities.<br />

Rocima 564 is recommended as in-can<br />

preservative.<br />

If <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> is used in wet<br />

rooms or in exterior coatings it is<br />

recommended to use a film preservative<br />

like Rocima 350.<br />

July 2008 2/9

ROHM AND HAAS PAINT AND COATINGS MAT<strong>ER</strong>IALS<br />

Material Name Kilograms Liters<br />

Grind<br />

Water 150.0 150.0<br />

Orotan N-4045 (45%) 6.0 4.6<br />

Tego® Foamex 1495 1<br />

2.0 2.0<br />

Tioxide TR92 2<br />

Durcal 5 3<br />

Talc AT-1 4<br />

170.0 42.5<br />

50.0 18.2<br />

50.0 17.2<br />

Acrysol DR-72 (30%) 4.0 3.8<br />

Potassium Hydroxide (10% in water) 3.0 3.3<br />

Grind Sub-total 435.0 241.6<br />

Let Down<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (50.5%) 360.0 340.9<br />

Ropaque Ultra E (30%) 80.0 78.0<br />

Biocide* 2.0 2.0<br />

Potassium Hydroxide (10% in water) 9.0 9.9<br />

Acrysol DR-73 <strong>ER</strong> (30%) 16.4 15.4<br />

Water 97.6 97.6<br />

Totals 1000.0 785.4<br />

(*) : Kathon LXE (1.5%) was used in this formulation<br />

Paint Properties Film Properties<br />

Volume Solids : 37% Gloss (100 µm, on glass) :<br />

Weight Solids : 49% Gloss 20° : 2-3<br />

Density : 1.270 Gloss 60° : 13-14<br />

pH : ~ 9.3 Sheen 85° : 27-28<br />

Dispersant (active based on total powders) : 1.0%<br />

Coalescent (based on polymer solids) : 0.0% Contrast ratio :<br />

Calculated VOC* content (g/L of wet paint) : < 0.1 CR at 150 µm wet: 97.1%<br />

Viscosities<br />

Krebs Stormer (KU) : 118 - 128<br />

ICI (Poise) : 1.4 - 1.8<br />

Brookfield (spindle 4 / 60 rpm) (mPa.s) : 6200 - 7400<br />

Brookfield (spindle 4 / 6 rpm) (mPa.s) : 16000 - 20000<br />

Suppliers<br />

1<br />

Tego Chemie Service GmbH, Essen, Germany<br />

2<br />

Hunstman Tioxide, London, UK<br />

3<br />

Omya UK Ltd, Dorking, UK<br />

4<br />

Talc de Luzenac, Toulouse, France<br />

Interior Solvent Free Satin Formulation<br />

based on <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (PVC 42%)<br />

S-<strong>016</strong>-42-01<br />

(*) VOC: Amount in g/L of organic compounds having an initial boiling point<br />

less than or equal to 250°C measured at a standard pressure of 101.3 kPa.<br />

KATHON, MAINCOTE, MULTILOBE, OROTAN, PARALOID, PRIMAL, ELASTENE, AVANSE, ROPAQUE, ROVACE,<br />

SKANE, ACRYSOL, RHOPLEX and TAMOL (in certain countries) are trademarks of Rohm and Haas Company, or of its<br />

subsidiaries or affiliates. The same goods may be marketed in other countries under other Company trademark designations.<br />

These suggestions and data are based on information we believe to be reliable. They are offered in good faith, but without<br />

guarantee as conditions and methods of use of our products are beyond our control. We recommend that the prospective<br />

user determine the suitability of our materials and suggestions before adopting them on a commercial scale.<br />

Suggestions for uses of our products or the inclusion of descriptive material from patents and the citation of specific patents in<br />

this publication should not be understood as recommending the use of our products in violation of any patent or as permission<br />

or license to use any patents of the Rohm and Haas Company.<br />

July 2008 3/9<br />

PVC<br />

15.2%<br />

6.5%<br />

6.2%<br />

14.5%<br />

42.4%

ROHM AND HAAS PAINT AND COATINGS MAT<strong>ER</strong>IALS<br />

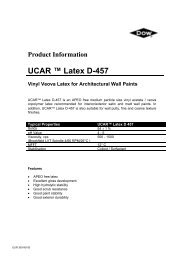

Material Name Kilograms Liters<br />

Grind<br />

Water 124.5 124.5<br />

Orotan 731A-<strong>ER</strong> (25%) 13.0 11.8<br />

Tego® Foamex 1495 1<br />

2.0 2.0<br />

Tioxide TR92 2<br />

Durcal 2 3<br />

Calibrite SL 3<br />

Talc AT-1 4<br />

Interior / Exterior Solvent Free Matt Formulation<br />

based on <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (PVC 50%)<br />

M-<strong>016</strong>-50-01<br />

170.0 42.5<br />

50.0 18.2<br />

90.0 33.3<br />

40.0 13.8<br />

Acrysol RM-8W (21.5%) 4.0 3.8<br />

Grind Sub-total 493.5 249.9<br />

Let Down<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (50.5%) 320.0 303.0<br />

Ropaque Ultra E (30%) 70.0 68.3<br />

Biocide* 2.0 2.0<br />

Acrysol RM-5000 (18.5%) 21.0 20.1<br />

Acrysol RM-8W (21.5%) 23.6 22.7<br />

Water 69.9 69.9<br />

Totals 1000.0 735.9<br />

(*) : Kathon LXE (1.5%) was used in this formulation<br />

Paint Properties Film Properties<br />

Volume Solids : 40% Gloss (100 µm, on glass) :<br />

Weight Solids : 55% Gloss 20° : 2-3<br />

Density : 1.360 Gloss 60° : 8-9<br />

pH : ~ 9.2 Sheen 85° : 5-6<br />

Dispersant (active based on total powders) : 0.9%<br />

Coalescent (based on polymer solids) : 0.0% Contrast ratio :<br />

Calculated VOC* content (g/L of wet paint) : < 0.1 CR at 150 µm wet: 95.9%<br />

Viscosities Wet scrub resistance (200 scrubs):<br />

Krebs Stormer (KU) : 115 - 125 Loss of thickness (µm) 3.4<br />

ICI (Poise) : 1.6 - 2.0 ISO 11998 :<br />

Class 1<br />

tested in Rohm and Haas laboratory (**)<br />

Suppliers<br />

1<br />

Tego Chemie Service GmbH, Essen, Germany<br />

3<br />

Omya UK Ltd, Dorking, UK<br />

2<br />

Hunstman Tioxide, London, UK<br />

4<br />

Talc de Luzenac, Toulouse, France<br />

(*) VOC: Amount in g/L of organic compounds having an initial boiling point<br />

less than or equal to 250°C measured at a standard pressure of 101.3 kPa.<br />

(**) Rohm and Haas Valbonne laboratories are not allowed to give official certifications<br />

14.8%<br />

6.3%<br />

11.6%<br />

4.8%<br />

49.9%<br />

KATHON, MAINCOTE, MULTILOBE, OROTAN, PARALOID, PRIMAL, ELASTENE, AVANSE, ROPAQUE, ROVACE,<br />

SKANE, ACRYSOL, RHOPLEX and TAMOL (in certain countries) are trademarks of Rohm and Haas Company, or of its<br />

subsidiaries or affiliates. The same goods may be marketed in other countries under other Company trademark designations.<br />

These suggestions and data are based on information we believe to be reliable. They are offered in good faith, but without<br />

guarantee as conditions and methods of use of our products are beyond our control. We recommend that the prospective<br />

user determine the suitability of our materials and suggestions before adopting them on a commercial scale.<br />

Suggestions for uses of our products or the inclusion of descriptive material from patents and the citation of specific patents in<br />

this publication should not be understood as recommending the use of our products in violation of any patent or as permission<br />

or license to use any patents of the Rohm and Haas Company.<br />

PVC<br />

12.4%<br />

July 2008 4/9

ROHM AND HAAS PAINT AND COATINGS MAT<strong>ER</strong>IALS<br />

Material Name Kilograms Liters<br />

Grind<br />

Water 148.0 148.0<br />

Orotan 731-A <strong>ER</strong> (25%) 15.0 13.6<br />

Potassium Hydroxide (10% in water) 3.0 3.3<br />

Tego® Foamex 1495 1<br />

2.0 2.0<br />

Tioxide TR92 2<br />

Durcal 2 2<br />

Calibrite SL 3<br />

Talc AT-1 4<br />

160.0 40.0<br />

70.0 25.4<br />

140.0 51.9<br />

40.0 13.8<br />

Acrysol RM-8W (21.5%) 5.0 4.8<br />

Grind Sub-total 583.0 302.8<br />

Let Down<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (50.5%) 240.0 227.3<br />

Water 30.0 30.0<br />

Texanol 3.6 3.8<br />

Ropaque Ultra E (30%) 70.0 68.3<br />

Biocide* 2.0 2.0<br />

Acrysol RM-12W (19%) 1.4 1.4<br />

Acrysol RM-5000 (18.5%) 20.5 19.7<br />

Acrysol RM-8W (21.5%) 20.5 19.7<br />

Water 29.0 29.0<br />

Totals 1000.0 704.0<br />

(*) : Kathon LXE (1.5%) was used in this formulation<br />

Paint Properties Film Properties<br />

Volume Solids : 40% Gloss (100 µm, on glass) :<br />

Weight Solids : 57% Gloss 60° : 2-3<br />

Density : 1.420 Sheen 85° : 6-7<br />

pH : ~ 9.0<br />

Dispersant (active based on total powders) : 0.9% Contrast ratio :<br />

Coalescent (based on polymer solids) : 2.5% CR at 150 µm wet: 95.1%<br />

Calculated VOC* content (g/L of wet paint) : < 0.1<br />

Viscosities<br />

Krebs Stormer (KU) : 115 - 125<br />

ICI (Poise) : 1.5 - 1.9<br />

Suppliers<br />

1 Tego Chemie Service GmbH, Essen, Germany<br />

2 Hunstman Tioxide, London, UK<br />

Exterior Masonry Formulation<br />

based on <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (PVC 61%)<br />

Mas-<strong>016</strong>-61-01<br />

(*) VOC: Amount in g/L of organic compounds having an initial boiling point<br />

less than or equal to 250°C measured at a standard pressure of 101.3 kPa.<br />

3 Omya UK Ltd, Dorking, UK<br />

4 Talc de Luzenac, Toulouse, France<br />

14.6%<br />

9.3%<br />

18.9%<br />

5.0%<br />

KATHON, MAINCOTE, MULTILOBE, OROTAN, PARALOID, PRIMAL, ELASTENE, AVANSE, ROPAQUE, ROVACE,<br />

SKANE, ACRYSOL, RHOPLEX and TAMOL (in certain countries) are trademarks of Rohm and Haas Company, or of its<br />

subsidiaries or affiliates. The same goods may be marketed in other countries under other Company trademark designations.<br />

These suggestions and data are based on information we believe to be reliable. They are offered in good faith, but without<br />

guarantee as conditions and methods of use of our products are beyond our control. We recommend that the prospective<br />

user determine the suitability of our materials and suggestions before adopting them on a commercial scale.<br />

Suggestions for uses of our products or the inclusion of descriptive material from patents and the citation of specific patents in<br />

this publication should not be understood as recommending the use of our products in violation of any patent or as permission<br />

or license to use any patents of the Rohm and Haas Company.<br />

July 2008 5/9<br />

PVC<br />

13.0%<br />

60.8%

ROHM AND HAAS PAINT AND COATINGS MAT<strong>ER</strong>IALS<br />

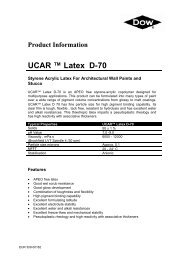

Material Name Kilograms Liters<br />

Grind<br />

Water 150.0 150.0<br />

Orotan N-4045 (45%) 9.0 6.9<br />

Potassium Hydroxide (10% in water) 3.0 2.8<br />

Triton DF-16 1<br />

2.0 1.9<br />

Acrysol DR-73 <strong>ER</strong> (30%) 5.0 4.7<br />

Tego® Foamex 1495 2<br />

2.0 2.0<br />

Tioxide TR92 3<br />

Durcal 2 4<br />

Durcal 5 4<br />

P-820 5<br />

Talc AT-1 6<br />

150.0 37.5<br />

70.0 25.4<br />

140.0 50.9<br />

30.0 13.6<br />

50.0 17.2<br />

Grind Sub-total 611.0 312.9<br />

Let Down<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (50.5%) 170.0 161.0<br />

Ropaque Ultra E (30%) 60.0 58.5<br />

Biocide* 2.0 2.0<br />

Acrysol DR-73 <strong>ER</strong> (30%) 9.0 8.5<br />

Acrysol DR-72 (30%) 2.0 1.9<br />

Potassium Hydroxide (10% in water) 12.0 11.0<br />

Water 134.0 134.0<br />

Totals 1000.0 689.8<br />

(*) : Kathon LXE (1.5%) was used in this formulation<br />

Paint Properties Film Properties<br />

Volume Solids : 38% Gloss (100 µm, on glass) :<br />

Weight Solids : 56% Gloss 60° : 3-4<br />

Density : 1.450 Sheen 85° : 5-6<br />

pH : ~ 9.2<br />

Dispersant (active based on total powders) : 0.9% Contrast ratio :<br />

Coalescent (based on polymer solids) : 0.0% CR at 150 µm wet: 99.1%<br />

Calculated VOC* content (g/L of wet paint) : < 0.1<br />

Wet scrub resistance (200 scrubs):<br />

Viscosities Loss of thickness (µm) 17.0<br />

Krebs Stormer (KU) : 113 - 123 ISO 11998 :<br />

Class 2<br />

ICI (Poise) : 1.5 - 1.9<br />

tested in Rohm and Haas laboratory (**)<br />

Brookfield (spindle 4 / 60 rpm) (mPa.s) :<br />

Brookfield (spindle 4 / 6 rpm) (mPa.s) :<br />

Suppliers<br />

3 Hunstman Tioxide, London, UK<br />

Interior Solvent Free Matt Formulation<br />

based on <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (PVC 70%)<br />

4400 - 5400<br />

10000 - 12000<br />

1 Dow Chemical Co ltd, West Drayton, UK<br />

2 Tego Chemie Service GmbH, Essen, Germany<br />

M-<strong>016</strong>-70-01<br />

(*) VOC: Amount in g/L of organic compounds having an initial boiling point<br />

less than or equal to 250°C measured at a standard pressure of 101.3 kPa.<br />

4<br />

Omya UK Ltd, Dorking, UK<br />

5<br />

Degussa Huels AG, Francfort, Germany<br />

6<br />

Talc de Luzenac, Toulouse, France<br />

(**) Rohm and Haas Valbonne laboratories are not allowed to give official certifications<br />

14.9%<br />

10.1%<br />

20.3%<br />

5.4%<br />

6.9%<br />

69.7%<br />

KATHON, MAINCOTE, MULTILOBE, OROTAN, PARALOID, PRIMAL, ELASTENE, AVANSE, ROPAQUE, ROVACE,<br />

SKANE, ACRYSOL, RHOPLEX and TAMOL (in certain countries) are trademarks of Rohm and Haas Company, or of its<br />

subsidiaries or affiliates. The same goods may be marketed in other countries under other Company trademark designations.<br />

These suggestions and data are based on information we believe to be reliable. They are offered in good faith, but without<br />

guarantee as conditions and methods of use of our products are beyond our control. We recommend that the prospective<br />

user determine the suitability of our materials and suggestions before adopting them on a commercial scale.<br />

Suggestions for uses of our products or the inclusion of descriptive material from patents and the citation of specific patents in<br />

this publication should not be understood as recommending the use of our products in violation of any patent or as permission<br />

or license to use any patents of the Rohm and Haas Company.<br />

July 2008 6/9<br />

PVC<br />

12.1%

ROHM AND HAAS PAINT AND COATINGS MAT<strong>ER</strong>IALS<br />

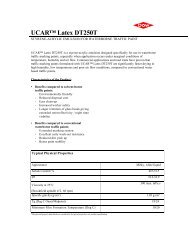

Material Name Kilograms Liters<br />

Grind<br />

Water 150.0 150.0<br />

Orotan N-4045 (45%) 12.0 9.2<br />

Potassium Hydroxide (10% in water) 2.8 2.6<br />

Triton DF-16 1<br />

2.0 1.9<br />

Tego® Foamex 1495 2<br />

2.0 2.0<br />

Tioxide TR92 3<br />

Durcal 2 4<br />

Durcal 5 4<br />

Socal ® P2 5<br />

Talc AT-1 6<br />

110.0 27.5<br />

100.0 36.3<br />

210.0 76.3<br />

60.0 22.2<br />

40.0 13.8<br />

Acrysol DR-72 (30%) 3.0 2.8<br />

Grind Sub-total 691.8 344.6<br />

Let Down<br />

<strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (50.5%) 120.0 113.6<br />

Ropaque Ultra E (30%) 60.0 58.5<br />

Biocide* 2.0 2.0<br />

Acrysol DR-73 <strong>ER</strong> (30%) 8.0 7.5<br />

Acrysol DR-72 (30%) 1.2 1.1<br />

Potassium Hydroxide (10% in water) 11.2 10.3<br />

Water 105.8 105.8<br />

Totals 1000.0 643.4<br />

(*) : Kathon LXE (1.5%) was used in this formulation<br />

Paint Properties Film Properties<br />

Volume Solids : 42% Gloss (100 µm, on glass) :<br />

Weight Solids : 61% Gloss 20° : 2-3<br />

Density : 1.550 Gloss 60° : 4-5<br />

pH : ~ 9.5 Sheen 85° : 4-5<br />

Dispersant (active based on total powders) : 1.0%<br />

Coalescent (based on polymer solids) : 0.0% Contrast ratio :<br />

Calculated VOC* content (g/L of wet paint) : < 0.1 CR at 150 µm wet: 99.6%<br />

Viscosities Wet scrub resistance (200 scrubs):<br />

Krebs Stormer (KU) : 118 - 128 Loss of thickness (µm) 26.5<br />

ICI (Poise) : 1.3 - 1.7 ISO 11998 :<br />

Class 3<br />

Brookfield (spindle 4 / 60 rpm) (mPa.s) : 5300 - 6300<br />

tested in Rohm and Haas laboratory (**)<br />

Brookfield (spindle 4 / 6 rpm) (mPa.s) : 11500 - 14000<br />

Suppliers<br />

1<br />

Dow Chemical Co ltd, West Drayton, UK<br />

2<br />

Tego Chemie Service GmbH, Essen, Germany<br />

3 Hunstman Tioxide, London, UK<br />

Interior Solvent Free Matt Formulation<br />

based on <strong>Primal</strong> <strong>SF</strong>-<strong>016</strong> <strong>ER</strong> (PVC 79%)<br />

M-<strong>016</strong>-79-01<br />

(*) VOC: Amount in g/L of organic compounds having an initial boiling point<br />

less than or equal to 250°C measured at a standard pressure of 101.3 kPa.<br />

(**) Rohm and Haas Valbonne laboratories are not allowed to give official certifications<br />

10.6%<br />

14.0%<br />

29.3%<br />

8.5%<br />

5.3%<br />

11.7%<br />

4<br />

Omya UK Ltd, Dorking, UK<br />

5<br />

Solvay Chemicals Ltd, Hemel Hempstead, UK<br />

6<br />

Talc de Luzenac, Toulouse, France<br />

KATHON, MAINCOTE, MULTILOBE, OROTAN, PARALOID, PRIMAL, ELASTENE, AVANSE, ROPAQUE, ROVACE,<br />

SKANE, ACRYSOL, RHOPLEX and TAMOL (in certain countries) are trademarks of Rohm and Haas Company, or of its<br />

subsidiaries or affiliates. The same goods may be marketed in other countries under other Company trademark designations.<br />

These suggestions and data are based on information we believe to be reliable. They are offered in good faith, but without<br />

guarantee as conditions and methods of use of our products are beyond our control. We recommend that the prospective<br />

user determine the suitability of our materials and suggestions before adopting them on a commercial scale.<br />

Suggestions for uses of our products or the inclusion of descriptive material from patents and the citation of specific patents in<br />

this publication should not be understood as recommending the use of our products in violation of any patent or as permission<br />

or license to use any patents of the Rohm and Haas Company.<br />

July 2008 7/9<br />

PVC<br />

79.4%

Storage and handling<br />

ROHM AND HAAS PAINT AND COATINGS MAT<strong>ER</strong>IALS<br />

Most emulsions from Rohm and Haas<br />

have excellent storage stability, so<br />

agitation is not needed unless the<br />

products are held static for six weeks or<br />

more, which may occur in an extended<br />

shutdown. Though not absolutely<br />

necessary, intermittent agitation may be<br />

used when the tank is heated to hold the<br />

temperature constant, but take care to<br />

avoid excessive foam formation. It is<br />

highly desirable that the air space over<br />

the emulsion in the tank is humidified to<br />

limit skin formation. A regular injection of<br />

steam can efficiently maintain a water<br />

saturated or humid condition. A coarse<br />

filter (400 – 800 µm) positioned in the<br />

transfer line is also recommended to<br />

remove any skin or grit.<br />

When tanks are located at sites (inside or<br />

outside), in which freezing temperatures<br />

may exist continuously for 12 hours,<br />

insulation and heating must be provided<br />

to prevent freezing of the emulsion. As a<br />

general rule, emulsions should always be<br />

stored at temperatures above 5°C and<br />

below 30°C. Most polymer emulsions<br />

cannot tolerate repeated freezing and<br />

thawing. Primarily, we recommend<br />

vertical tanks constructed from thinwalled,<br />

reinforced stainless steel.<br />

July 2008 8/9

SAFE HANDLING<br />

INFORMATION<br />

Rohm and Haas<br />

Company maintains<br />

comprehensive and<br />

up-to-date material<br />

safety data sheets<br />

(MSDS) on all of its<br />

products. These<br />

sheets contain<br />

pertinent information<br />

that you may need to<br />

protect your<br />

employees and<br />

customers against any<br />

known health or safety<br />

hazards associated<br />

with our products.<br />

Rohm and Haas<br />

Company recommends<br />

that you obtain copies<br />

of our material safety<br />

data sheets from your<br />

local Rohm and Haas<br />

representative on each<br />

of our products prior<br />

to its use in your<br />

facilities. We also<br />

suggest that you<br />

contact your supplier<br />

of other materials<br />

recommended for use<br />

with our products for<br />

appropriate health and<br />

safety precautions<br />

prior to their use.<br />

ROHM AND HAAS PAINT AND COATINGS MAT<strong>ER</strong>IALS<br />

European Headquarters for<br />

Paint and Coatings Materials Europe :<br />

Rohm and Haas Europe Sarl<br />

Lake Geneva Center<br />

7 route de la Longeraie<br />

1110, Morges<br />

Tel: 41-21-805 9000<br />

Rohm and Haas Europe Trading ApS<br />

France succursale<br />

La Tour de Lyon<br />

185 rue de Bercy<br />

75579 Paris Cedex 12, France<br />

Tel: +33-(0)1 40 02 50 00<br />

Fax: +33-(0)1 40 43 45 28 19<br />

Rohm and Haas Europe Service ApS<br />

France succursale<br />

371 rue L.V. Beethoven<br />

Sophia Antipolis 1<br />

06560 Valbonne, France<br />

Tel: +33-(0)4 93 95 53 53<br />

Fax: +33-(0)4 93 65 30 16<br />

For further details, please contact your local Account<br />

Manager or use our numbers below:<br />

Belgium:<br />

080049939<br />

Denmark:<br />

80881706<br />

Finland:<br />

0800116231<br />

France:<br />

0805639694 or 0805639695<br />

Greece:<br />

800985899 or 800126422<br />

Ireland:<br />

1800992563 or 1800992564<br />

Israel:<br />

18009214285<br />

Italy:<br />

800985898<br />

Netherlands:<br />

8000203356<br />

Germany:<br />

+49-(0) 69 789 960<br />

Norway:<br />

80013879<br />

Poland:<br />

008001211387<br />

Portugal:<br />

800812052<br />

Russia:<br />

7095 726 5929<br />

Sweden:<br />

0200880380 or 0200880391<br />

Spain:<br />

800099519<br />

Turkey:<br />

90262 754 1752<br />

UK:<br />

08009012195 or 08009012196<br />

South Africa:<br />

0800995774<br />

Also visit Rohm and Haas Website:<br />

www.rohmhaas.com<br />

Subsidiaries of Rohm and Haas Company, Philadelphia, USA<br />

July 2008 9/9<br />

These suggestions<br />

and data are based<br />

on information we<br />

believe to be reliable.<br />

They are offered in<br />

good faith, but<br />

without guarantee, as<br />

conditions and<br />

methods of use of our<br />

products are beyond<br />

our control.<br />

We recommend that<br />

the prospective user<br />

determines the<br />

suitability of our<br />

materials and<br />

suggestions before<br />

adopting them on a<br />

commercial scale.<br />

Suggestions for uses<br />

of our products or the<br />

inclusion of<br />

descriptive material<br />

from patents and the<br />

citation of specific<br />

patents in this<br />

publication should not<br />

be understood as<br />

recommending the<br />

use of our products in<br />

violation of any<br />

patent or as<br />

permission or license<br />

to use any patents of<br />

the Rohm and Haas<br />

Company.