You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

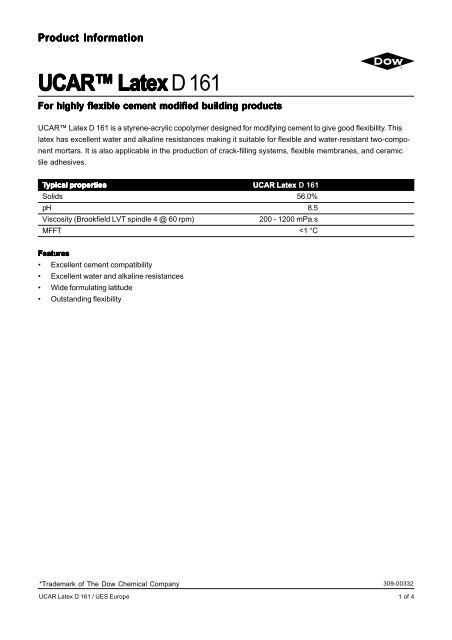

Product Product Information<br />

Information<br />

UCAR UCAR <strong>Latex</strong> <strong>Latex</strong> D <strong>161</strong><br />

For For highly highly flexible flexible cement cement modified modified building building products<br />

products<br />

UCAR <strong>Latex</strong> D <strong>161</strong> is a styrene-acrylic copolymer designed for modifying cement to give good flexibility. This<br />

latex has excellent water and alkaline resistances making it suitable for flexible and water-resistant two-component<br />

mortars. It is also applicable in the production of crack-filling systems, flexible membranes, and ceramic<br />

tile adhesives.<br />

Typical ypical ypical properties<br />

properties<br />

UCAR <strong>Latex</strong> DD D <strong>161</strong><br />

Solids<br />

56.0%<br />

pH<br />

8.5<br />

Viscosity (Brookfield LVT spindle 4 @ 60 rpm)<br />

200 - 1200 mPa.s<br />

MFFT

Recommended Recommended formulations<br />

formulations<br />

Flexible Flexible Flexible cementitious cementitious waterproofing waterproofing membrane membrane CWM991202<br />

CWM991202<br />

Material Material<br />

weight<br />

weight<br />

Dry premix<br />

Portland cement 50.00<br />

Calcium Carbonate (600 mesh) 40.00<br />

Sand 10.00<br />

Total otal 100.00<br />

100.00<br />

Aqueous phase<br />

UCAR <strong>Latex</strong> D <strong>161</strong><br />

Nopco NXZ 0.38<br />

Total otal 100.00<br />

100.00<br />

Mix the dry premix portion with the aqueous phase with agitation to obtain a homogenous slurry mixture<br />

Properties Properties Properties Properties Properties<br />

• Brookfield viscosity (spindle 4 @ 60 rpm): 8000 cps<br />

• Tensile strength (after 7 days ambient curing): 2.5 N/mm2 • Elongation at break (after 7 days ambient curing): 360%<br />

• Tear resistance (ASTM D-624): 9.8 KN/m<br />

• Water vapour permeability (based on ASTM E96, desiccant method at 90% R.H. at 38°C = 15g/m2 /day)<br />

• Adhesion to steel (pull-off strength), ASTM D-4541:4.5 N/mm2 This is a 2 component water proofing system consisting of latex and premixed powder which includes cement and sand. It is flexible<br />

and fills hairline cracks (up to 2 mm). It allows moisture vapour transmission or "breathing ability" which is necessary<br />

over fresh concrete or screeds. It has excellent adhesion to concrete, brick, screed, stone, wood, etc.<br />

It is easily applied using roller or stiff bristle broom/brush onto both horizontal and vertical surfaces.<br />

Formulation Formulation guidelines<br />

guidelines<br />

• A large amount of Portland cement in the dry mix results in a harder and less flexible membrane.<br />

• Larger amounts of filler such as calcium carbonate in the Portland cement give better tensile strength and<br />

elongation than coarse fillers such as sand.<br />

• Finer grades of calcium carbonate (e.g., 600 mesh) in the Portland cement give higher viscosity than coarser<br />

calcium carbonate (e.g., 325 mesh).<br />

• Larger amounts of UCAR <strong>Latex</strong> D <strong>161</strong> give better elongation, adhesion and waterproofing to the membrane.<br />

• Diluted acrylic thickener can be used to increase viscosity and give a shear-thinning rheology.<br />

• Typical ratio by weight of dry premix to aqueous phase ranges from 1:1 to 2:1.<br />

• Dry premix is added slowly into the aqueous phase with good agitation and this mixture must be applied within<br />

its potlife.<br />

• Usual application of this slurry mixture is by brushing or roller in at least 2 coats to give dry film thickness of<br />

about 1.5 - 2 mm.<br />

*Trademark of The Dow Chemical Company<br />

309-00332<br />

UCAR <strong>Latex</strong> D <strong>161</strong> / UES Europe<br />

99.62<br />

2 of 4

Exterior Flexible<br />

Exterior<br />

Flexible<br />

Exterior Flexible skim<br />

wall skim<br />

wall skim<br />

wall paint paint coat coat<br />

EXT EXT SC991202 SC991202<br />

30/1<br />

30/1<br />

Joint Joint compound compound JC991209 JC991209<br />

JC991209<br />

Material Material Material<br />

weight<br />

weight<br />

Aqueous Mix<br />

Water 21.70<br />

UCAR <strong>Latex</strong> D <strong>161</strong><br />

23.28<br />

Nopco NXZ 0.20<br />

Acticide EP-Paste 0.10<br />

Powder premix<br />

Calcium Carbonate (325 mesh) 16.78<br />

Talc 35.54<br />

UCAR POLYPHOBE TR-115 1.20<br />

Water 1.20<br />

Total otal otal 100.00<br />

100.00<br />

Premix the calcium carbonate and talc.<br />

Blend the aqueous mix.<br />

Load the dry premix powder to the aqueous mix.<br />

Add the solution of POLYPHOBE to the mixture.<br />

This is a pasty mixture used as skimming plaster for<br />

dry and damp interior and exterior, wall and ceiling<br />

surfaces. It has good adhesion over common<br />

substrates such as concrete gypsum board,<br />

masonry and cement backer board.<br />

The skim coat has good water resistance and<br />

alkali resistance compared to conventional skim coat.<br />

*Trademark of The Dow Chemical Company<br />

UCAR <strong>Latex</strong> D <strong>161</strong> / UES Europe<br />

Material Material<br />

weight<br />

weight<br />

Aqueous Mix<br />

Water 14.11<br />

TERGITOL NP-40 0.93<br />

Sodium Benzoate 0.07<br />

Acticide EP-Paste 0.08<br />

Propylene Glycol 0.22<br />

UCAR <strong>Latex</strong> D <strong>161</strong><br />

Powder premix<br />

13.69<br />

Calcium Di-Sulphate 2.94<br />

Calcium Carbonate 64.58<br />

Mica 2.19<br />

Attagel 40 0.40<br />

Talc 0.79<br />

Total otal 100.00 100.00<br />

100.00<br />

Load the ingredients in order for the aqueous mix.<br />

Add the powder mix to the aqueous mix.<br />

This mixture gives a smooth finish joint mixture which is<br />

able to seal the gaps and provide resistance to shrinkage<br />

Tile Tile converter converter TC991201<br />

TC991201<br />

under normal conditions.<br />

Material Material<br />

weight<br />

weight<br />

UCAR <strong>Latex</strong> D <strong>161</strong><br />

7.84<br />

Water 9.48<br />

TRITON X-405 0.20<br />

Portland cement 20.62<br />

Coarse sand (

Raw Raw Material Material List<br />

List<br />

Acticide EP-Paste Thor Chemicals<br />

Attagel 40 Lawrence Industries<br />

Nopco NXZ Cognis<br />

UCAR POLYPHOBE TR 115 The Dow Chemical Company<br />

TERGITOL NP-40 The Dow Chemical Company<br />

TRITON X-405 The Dow Chemical Company<br />

NOTICE NOTICE: NOTICE No freedom from any patent owned by Seller or others is to be inferred. Because use conditions and applicable laws<br />

may differ from one location to another and may change with time, Customer is responsible for determining whether products and<br />

the information in this document are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal<br />

practices are in compliance with applicable laws and other governmental enactments. Seller assumes no obligation or liability for<br />

the information in this document. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS<br />

FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.<br />

Published March 2004<br />

(Supersedes edition of September 2001).<br />

UCAR <strong>Latex</strong> D <strong>161</strong> / UES Europe<br />

*Trademark of The Dow Chemical Company<br />

309-00332<br />

4 of 4