UCAR® Latex DL 420E - Mielco

UCAR® Latex DL 420E - Mielco

UCAR® Latex DL 420E - Mielco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Product Product Information<br />

Information<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>420E</strong><br />

Ar Ar Architectural Ar Ar chitectural W WWall<br />

W all Paints Paints and and Stucco<br />

Stucco<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>420E</strong> is a styrene acrylate dispersion recommended for both satin and matt, interior and exterior<br />

conventional wall paints. In addition UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>420E</strong> shows good performance in stucco formulations.<br />

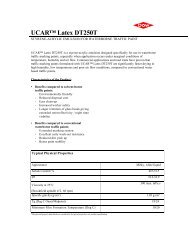

Typical ypical pr properties pr properties<br />

operties UCAR <strong>UCAR®</strong><br />

<strong>Latex</strong> <strong>Latex</strong> <strong>DL</strong> <strong>DL</strong> <strong>420E</strong><br />

<strong>420E</strong><br />

Solids 49.0%<br />

pH 8.5<br />

Viscosity (Brookfield RVT spindle 2 @ 50 rpm)

Recommended Recommended formulations<br />

formulations<br />

Interior Interior matt matt wall wall wall paint paint MA MATT MA MATT<br />

TT <strong>420E</strong> <strong>420E</strong><br />

Exterior Exterior wall wall paint paint paint EXT EXT <strong>420E</strong>/1 <strong>420E</strong>/1<br />

<strong>420E</strong>/1<br />

Material Material<br />

weight<br />

weight<br />

Water 270.0<br />

CELLOSIZE QP30000H 5.0<br />

Ammonia (28%) 1.0<br />

Calgon N (10%) 10.0<br />

Dispex A40 (40%) 5.0<br />

Dehydran 1293 2.0<br />

Propylene Glycol 15.0<br />

Tiona RCL-535 100.0<br />

Finntalc M15 100.0<br />

Durcal 5 200.0<br />

Socal P2 120.0<br />

disperse to required Hegman<br />

Dowanol DPnB 10.0<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>420E</strong> (49%) 90.0<br />

Dehydran 1293 2.0<br />

Acticide BX 2.0<br />

Acrysol TT-935 (30%) 9.2<br />

Water 58.8<br />

Total otal 1000.0<br />

1000.0<br />

PVC: PVC:<br />

80.0%<br />

80.0%<br />

Weight solids: 56.5%<br />

Volume solids: 34.1%<br />

Specific gravity: 1.52<br />

Krebs Stormer: 123 KU<br />

Viscosity (Brookfield RVT @20 rpm): 10000 mPa.s<br />

ICI Cone & Plate: 2.0 P<br />

Material Material<br />

weight<br />

weight<br />

Water 124.4<br />

Metatin K520 0.5<br />

Nopco 8034 FA 4.8<br />

Findet 1816/32E (20%) 24.1<br />

CELLOSIZE QP52000H 2.7<br />

AMP 90 1.4<br />

Dispex N40 (45%) 4.8<br />

Dowanol DPnB 19.3<br />

Durcal 5 170.2<br />

Micro-Mica W1 48.2<br />

Finntalc M15 40.5<br />

Tiona RCL-535 120.6<br />

disperse to required Hegman<br />

Propylene Glycol 30.0<br />

Metatin K520 0.5<br />

Metatin 55/64N 10.0<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>420E</strong> (49%) 344.2<br />

Rheovis CR (30%) 5.8<br />

Nopco 8034 FA 1.9<br />

Water 46.1<br />

Total otal 1000.0<br />

1000.0<br />

PVC: PVC:<br />

41.8%<br />

41.8%<br />

Weight solids: 50.0%<br />

Volume solids: 39.5%<br />

Specific gravity: 1.34<br />

EXT <strong>420E</strong> shows excellent application properties and<br />

exterior durability over a range of different wall surfaces.<br />

This product has a successful 15 years exposure history.<br />

<strong>DL</strong><strong>420E</strong>-E-0100A 2 of 4

Trowel owel stucco stucco stucco TRST TRST TRST <strong>420E</strong>/2<br />

<strong>420E</strong>/2<br />

Material Material<br />

weight<br />

weight<br />

Water 43.5<br />

CELLOSIZE QP30000H 1.5<br />

NaOH (10%) 2.0<br />

Calgon N (10%) 10.0<br />

Dispex N40 (45%) 1.0<br />

Foamex 1488 1.0<br />

Tiona RCL-535 60.0<br />

Durcal 40 50.0<br />

Durcal 2 60.0<br />

disperse to required Hegman<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>420E</strong> (50%) 143.0<br />

Dowanol DPnB 4.0<br />

Acticide BX 2.0<br />

Metatin 55/64N 2.0<br />

Quartz sand (0.1-0.45 mm) 500.0<br />

Quartz sand (0.4-2.0 mm) 120.0<br />

Total otal 1000.0 1000.0<br />

1000.0<br />

Weight solids: 86.0 %<br />

TRST <strong>420E</strong> gives excellent workability together with<br />

good adhesion to different wall surfaces.<br />

<strong>DL</strong><strong>420E</strong>-E-0100A 3 of 4

Raw Raw Material Material List<br />

List<br />

Acrysol TT-935 Acrylic thickener Rohm & Haas<br />

Acticide BX Preservative Thor Chemicals<br />

Calgon N Dispersant BK Ladenburg<br />

CELLOSIZE QP30000H, QP52000H Cellulosic thickener Union Carbide<br />

Dispex A40, N40 Dispersant Ciba Specialties<br />

Dehydran 1293 Defoamer Cognis<br />

Dowanol DPnB Coalescent Dow Chemical<br />

Durcal 2, 5, 40 Calcium carbonate Plüss Stauffer<br />

Findet 1816/32E Surfactant Kao<br />

Finntalc M15 Talc Norwegian Talc<br />

Foamex 1488 Defoamer Tego Chemie<br />

Metatin 55-64N, K520 Fungicide/biocide Acima AG<br />

Micro-Mica W1 Mica Norwegian Talc<br />

Nopco 8034FA Defoamer Cognis<br />

Orotan 731 Dispersant Rohm & Haas<br />

Rheovis CR Acrylic thickener Ciba Specialties<br />

Socal P2 Precipitated calcium carbonate Solvay<br />

Tiona RCL-535 Titanium dioxide SCM Chemicals<br />

Product Product Safety<br />

Safety<br />

When considering the use of any Union Carbide product in a particular<br />

application, you should review our latest Material Safety Data Sheets and<br />

ensure that the use you intend can be accomplished safely. For MSDSs and<br />

other product safety information, contact the Union Carbide Sales Office<br />

nearest you. Before handling any other products mentioned in the text, you<br />

should obtain available product safety information and take necessary steps<br />

to ensure safety of use.<br />

No chemical should be used as or in a food, drug, medical device, or<br />

cosmetic, or in a product or process in which it may contact a food, drug,<br />

medical device, or cosmetic until the user has determined the suitability<br />

and legality of the use. Since government regulations and use conditions are<br />

subject to change, it is the user's responsibility to determine that this<br />

information is appropriate and suitable under current, applicable laws and<br />

regulations.<br />

Union Carbide requests that the customer read, understand, and comply<br />

with the information contained in this publication and the current MSDS(s).<br />

The customer should furnish the information in this publication to its employees,<br />

contractors, and customers, or any other user of the product(s),<br />

and request that they do the same.<br />

<strong>DL</strong><strong>420E</strong>-E-0100A<br />

Union Carbide Corporation<br />

UCAR Emulsion Systems<br />

Storage Storage and and Handling Handling - - <strong>Latex</strong>es<br />

<strong>Latex</strong>es<br />

Follow procedures typically recommended for polymer dispersions. Use<br />

corrosion-resistant storage tanks and piping. Air-operated diaphragm pumps<br />

are preferred. Avoid temperature extremes. Do not freeze; store above 5 ºC.<br />

For further information, refer to booklet "UCAR <strong>Latex</strong>es - Shipping, Storage,<br />

and Handling."<br />

Emergency Emergency Service Service for for Europe, Europe, Middle Middle East, East, and and Africa: Africa:<br />

Africa:<br />

Antwerp AIDE Centre of Union Carbide Benelux NV<br />

(+32) 3 5426906 or the nearest<br />

Poison Control Center<br />

European European Customer Customer Centre Centre Union Union Carbide Carbide Benelux Benelux NV<br />

NV<br />

Atlantic House<br />

Noorderlaan 147<br />

B-2030 Antwerp<br />

Tel.: (+32) 3 5434211<br />

Union Union Carbide Carbide (Europe) (Europe) S.A.<br />

S.A.<br />

7 rue du Pre-Bouvier<br />

CH-1217 Meyrin (Genève)<br />

Tel.: (+41) 22 9896111<br />

4 of 4