UCAR® Latex DL 424 - Mielco

UCAR® Latex DL 424 - Mielco

UCAR® Latex DL 424 - Mielco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

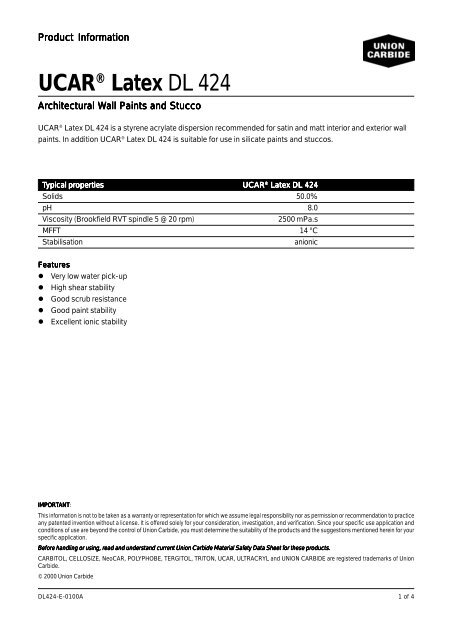

Product Product Information<br />

Information<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>424</strong><br />

Ar Ar Architectural Ar Ar chitectural W WWall<br />

W all Paints Paints and and Stucco<br />

Stucco<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>424</strong> is a styrene acrylate dispersion recommended for satin and matt interior and exterior wall<br />

paints. In addition UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>424</strong> is suitable for use in silicate paints and stuccos.<br />

Typical ypical pr properties pr properties<br />

operties UCAR <strong>UCAR®</strong><br />

<strong>Latex</strong> <strong>Latex</strong> <strong>DL</strong> <strong>DL</strong> <strong>424</strong> <strong>424</strong><br />

<strong>424</strong><br />

Solids 50.0%<br />

pH 8.0<br />

Viscosity (Brookfield RVT spindle 5 @ 20 rpm) 2500 mPa.s<br />

MFFT 14 °C<br />

Stabilisation anionic<br />

Featur Features Featur es<br />

l Very low water pick-up<br />

l High shear stability<br />

l Good scrub resistance<br />

l Good paint stability<br />

l Excellent ionic stability<br />

IMPOR IMPORTANT<br />

IMPOR IMPOR ANT ANT: ANT<br />

This information is not to be taken as a warranty or representation for which we assume legal responsibility nor as permission or recommendation to practice<br />

any patented invention without a license. It is offered solely for your consideration, investigation, and verification. Since your specific use application and<br />

conditions of use are beyond the control of Union Carbide, you must determine the suitability of the products and the suggestions mentioned herein for your<br />

specific application.<br />

Before Before Before handling handling or or using, using, using, read read and and understand understand understand current current Union Union Carbide Carbide Material Material Safety Safety Data Data Sheet Sheet for for these these products.<br />

products.<br />

CARBITOL, CELLOSIZE, NeoCAR, POLYPHOBE, TERGITOL, TRITON, UCAR, ULTRACRYL and UNION CARBIDE are registered trademarks of Union<br />

Carbide.<br />

© 2000 Union Carbide<br />

<strong>DL</strong><strong>424</strong>-E-0100A 1 of 4

Recommended Recommended formulations<br />

formulations<br />

Interior Interior matt matt wall wall wall paint paint MA MATT MA TT <strong>424</strong> <strong>424</strong><br />

Exterior Exterior wall wall paint paint EXT EXT <strong>424</strong><br />

<strong>424</strong><br />

Material Material<br />

weight<br />

weight<br />

Water 266.6<br />

CELLOSIZE QP30000H 5.0<br />

Ammonia (28%) 1.0<br />

Calgon N (10%) 10.0<br />

Dispex A40 (40%) 5.0<br />

Dehydran 1293 2.0<br />

Propylene Glycol 15.0<br />

Tiona RCL-535 100.0<br />

Finntalc M15 100.0<br />

Durcal 5 200.0<br />

Socal P2 120.0<br />

disperse to required Hegman<br />

Dowanol DPnB 10.0<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>424</strong> (50%) 60.0<br />

Dehydran 1293 2.0<br />

Acticide BX 2.0<br />

Acrysol TT-935 (30%) 8.2<br />

Water 93.2<br />

Total otal 1000.0<br />

1000.0<br />

PVC: PVC:<br />

85.5%<br />

85.5%<br />

Weight solids: 55.0%<br />

Volume solids: 34.1%<br />

Specific gravity: 1.52<br />

Krebs Stormer: 120 KU<br />

Viscosity (Brookfield RVT @20 rpm): 8100 mPa.s<br />

ICI Cone & Plate: 1.6 P<br />

Due to its excellent ionic stability UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>424</strong><br />

can be formulated in matt paints at PVC’s higher than<br />

80% (e.g. MATT <strong>424</strong> at 85.5%).<br />

Material Material<br />

weight<br />

weight<br />

Water 124.4<br />

Metatin K520 0.5<br />

Nopco 8034 FA 4.8<br />

Findet 1816/32E (20%) 24.1<br />

CELLOSIZE QP30000H 3.6<br />

AMP 90 1.4<br />

Dispex N40 (45%) 4.8<br />

Dowanol DPnB 19.3<br />

Durcal 5 170.2<br />

Micro-Mica W1 48.2<br />

Finntalc M15 40.5<br />

Tiona RCL-535 126.6<br />

disperse to required Hegman<br />

Propylene Glycol 30.0<br />

Metatin K520 0.5<br />

Metatin 55/64N 10.0<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>424</strong> (50%) 337.3<br />

Rheovis CR (30%) 5.8<br />

Nopco 8034 FA 1.9<br />

Water 46.1<br />

PVC: PVC:<br />

41.8%<br />

41.8%<br />

Weight solids: 55.0%<br />

Volume solids: 39.5%<br />

Specific gravity: 1.34<br />

Krebs Stormer: 112 KU<br />

Viscosity (Brookfield RVT @ 20 rpm): 10000 mPa.s<br />

ICI Cone & Plate: 1.0 P<br />

<strong>DL</strong><strong>424</strong>-E-0100A 2 of 4

Trowel owel stucco stucco TRST TRST <strong>424</strong>/3<br />

<strong>424</strong>/3<br />

Material Material<br />

weight<br />

weight<br />

Water 54.0<br />

Methocel J75MS 1.0<br />

Metatin K520 0.5<br />

Calgon N (10%) 10.0<br />

Dispex A40 (40%) 1.0<br />

Dowanol DPnB 4.0<br />

Byk 033 1.0<br />

Sodium hydroxide (10%) 2.0<br />

Tiona RCL-376 60.0<br />

Durcal 40 50.0<br />

Durcal 2<br />

disperse to required Hegman<br />

60.0<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>424</strong> (50%) 137.0<br />

Metatin 55-64N 10.0<br />

Metatin K520 0.5<br />

Quartz sand (0.1-0.45 mm) 489.0<br />

Quartz sand (0.4-2.0 mm) 120.0<br />

Total otal 1000.0 1000.0<br />

1000.0<br />

Weight solids: 86.0%<br />

Silicate Silicate Silicate paint paint SIL SIL <strong>424</strong><br />

<strong>424</strong><br />

Material Material<br />

weight<br />

weight<br />

Water 239.0<br />

CELLOSIZE QP30000H 1.0<br />

Rhodopol 50MD 1.0<br />

KOH (10%) 1.0<br />

Sapetin D20 2.0<br />

Foamex 1488 2.0<br />

Tiona RCL-535 100.0<br />

Hydrocarb 100.0<br />

Durcal 5 210.0<br />

Micro-Mica W1<br />

disperse to required Hegman<br />

52.0<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>424</strong> (50%) 72.0<br />

Dowanol DPnB 4.0<br />

Betolin P50 (29%) 205.0<br />

Dehydran 1293 2.0<br />

Water 9 .0<br />

Total otal 1000.0<br />

1000.0<br />

Roller Roller stucco stucco ROST ROST <strong>424</strong>/4<br />

<strong>424</strong>/4<br />

Material Material<br />

weight<br />

weight<br />

Water 40.0<br />

UCAR ® <strong>Latex</strong> <strong>DL</strong> <strong>424</strong> (50%) 209.5<br />

Metatin K520 0.5<br />

Byk 033 1.9<br />

Methocel J12MS 2.4<br />

Calgon N (10%) 9.5<br />

Dispex A40 (40%) 1.0<br />

Dowanol DPnB 9.0<br />

Propylene Glycol 14.3<br />

Kemira RDD 57.1<br />

Durcal 10 76.2<br />

Durcal 40 33.3<br />

Durcal 130 157.1<br />

disperse to required Hegman<br />

Metatin K520 0.5<br />

Byk 033 1.9<br />

Quartz sand (0.1-0.45 mm) 300.0<br />

Quartz sand (0.4-2 mm) 38.1<br />

Water 47.7<br />

Total otal 1000.0<br />

1000.0<br />

Weight solids: 76.7%<br />

SIL <strong>424</strong> shows good storage stability at ambient and<br />

at 50oC with a viscosity increase not greater than 30%,<br />

together with good application properties.<br />

<strong>DL</strong><strong>424</strong>-E-0100A 3 of 4

Raw Raw Material Material List<br />

List<br />

Acrysol TT-935 Acrylic thickener Rohm & Haas<br />

Acticide BX Preservative Thor Chemicals<br />

AMP 90 Base/dispersant Dow Chemical<br />

Byk 033 Defoamer Byk Chemie<br />

Betolin P35 Silicate Woellner Chemie<br />

Calgon N Dispersant BK Ladenburg<br />

CELLOSIZE QP30000H Cellulosic thickener Union Carbide<br />

China Clay B Clay English China Clay<br />

Dispex A40, N40 Dispersant Ciba Specialties<br />

Dehydran 1293 Defoamer Cognis<br />

Dowanol DPnB Coalescent Dow Chemical<br />

Durcal 2, 5, 10, 40, 130 Calcium carbonate Plüss Stauffer<br />

Findet 1816/32E Surfactant Kao<br />

Finntalc M15 Talc Finnmineral<br />

Foamex 1488 Defoamer Tego Chemie<br />

Hydrocarb Calcium carbonate Plüss Stauffer<br />

Kemira RDD Titanium dioxide Kemira<br />

Metatin K520 Biocide Acima AG<br />

Metatin 55-64N Fungicide Acima AG<br />

Methocel J12MS, J75MS Cellulosic thickener Dow Chemical<br />

Micro-Mica W1 Mica Norwegian Talc<br />

Nopco 8034 FA Defoamer Cognis<br />

Orotan 731 Dispersant Rohm & Haas<br />

Rheovis CR Acrylic thickener Ciba Specialties<br />

Rhodopol 50MD Xanthan Gum Rhône-Poulenc<br />

Sapetin D20 Dispersant Woellner Chemie<br />

Socal P2 Precipitated calcium carbonate Solvay<br />

Tiona RCL-535, RCL-376 Titanium dioxide Millenium<br />

Product Product Safety<br />

Safety<br />

When considering the use of any Union Carbide product in a particular<br />

application, you should review our latest Material Safety Data Sheets and<br />

ensure that the use you intend can be accomplished safely. For MSDSs and<br />

other product safety information, contact the Union Carbide Sales Office<br />

nearest you. Before handling any other products mentioned in the text, you<br />

should obtain available product safety information and take necessary steps<br />

to ensure safety of use.<br />

No chemical should be used as or in a food, drug, medical device, or<br />

cosmetic, or in a product or process in which it may contact a food, drug,<br />

medical device, or cosmetic until the user has determined the suitability<br />

and legality of the use. Since government regulations and use conditions are<br />

subject to change, it is the user's responsibility to determine that this<br />

information is appropriate and suitable under current, applicable laws and<br />

regulations.<br />

Union Carbide requests that the customer read, understand, and comply<br />

with the information contained in this publication and the current MSDS(s).<br />

The customer should furnish the information in this publication to its employees,<br />

contractors, and customers, or any other user of the product(s),<br />

and request that they do the same.<br />

<strong>DL</strong><strong>424</strong>-E-0100A<br />

Union Carbide Corporation<br />

UCAR Emulsion Systems<br />

Storage Storage and and Handling Handling - - <strong>Latex</strong>es<br />

<strong>Latex</strong>es<br />

Follow procedures typically recommended for polymer dispersions. Use<br />

corrosion-resistant storage tanks and piping. Air-operated diaphragm pumps<br />

are preferred. Avoid temperature extremes. Do not freeze; store above 5 ºC.<br />

For further information, refer to booklet "UCAR <strong>Latex</strong>es - Shipping, Storage,<br />

and Handling."<br />

Emergency Emergency Service Service for for Europe, Europe, Middle Middle East, East, and and Africa: Africa:<br />

Africa:<br />

Antwerp AIDE Centre of Union Carbide Benelux NV<br />

(+32) 3 5426906 or the nearest<br />

Poison Control Center<br />

European European Customer Customer Centre Centre Union Union Carbide Carbide Benelux Benelux NV<br />

NV<br />

Atlantic House<br />

Noorderlaan 147<br />

B-2030 Antwerp<br />

Tel.: (+32) 3 5434211<br />

Union Union Carbide Carbide (Europe) (Europe) S.A.<br />

S.A.<br />

7 rue du Pre-Bouvier<br />

CH-1217 Meyrin (Genève)<br />

Tel.: (+41) 22 9896111<br />

4 of 4