UCAR™ Latex DT250T - Mielco

UCAR™ Latex DT250T - Mielco

UCAR™ Latex DT250T - Mielco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

UCAR <strong>Latex</strong> <strong>DT250T</strong><br />

STYRENE-ACRYLIC EMULSION FOR WATERBORNE TRAFFIC PAINT<br />

UCAR <strong>Latex</strong> <strong>DT250T</strong> is a styrene-acrylic emulsion designed specifically for use in waterborne<br />

traffic marking paints, especially when application occurs under marginal conditions of<br />

temperature, humidity and air flow. Commercial applications and road trials have proven that<br />

traffic marking paints formulated with UCAR <strong>Latex</strong> <strong>DT250T</strong> are significantly faster drying in<br />

high humidity, low temperatures and poor air flow conditions, compared to conventional water<br />

based traffic paints.<br />

Characteristics of the Product:<br />

• Benefits compared to solvent-borne<br />

traffic paints:<br />

Environmentally friendly<br />

- Reduced disposal cost<br />

- Easy clean-up<br />

- Increased worker safety<br />

- Longer retention of glass beads giving<br />

extended retroreflectivity / night time<br />

visibility<br />

• Benefits compared to conventional<br />

waterborne traffic paints:<br />

Extended marking season<br />

- Excellent early wash-out resistance<br />

- Reduced dirt pick up<br />

- Better paint stability<br />

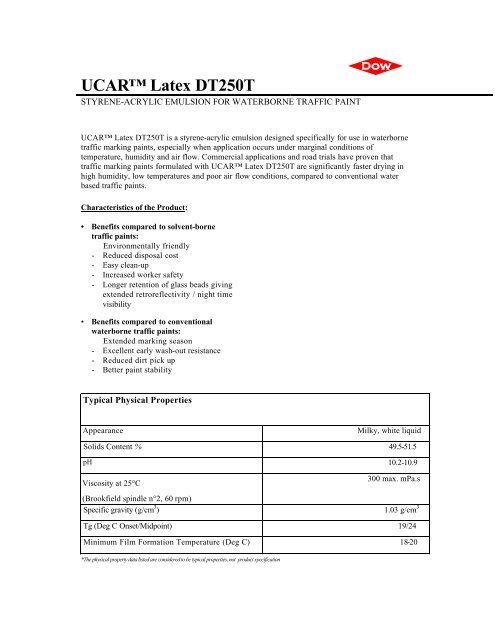

Typical Physical Properties<br />

Appearance Milky, white liquid<br />

Solids Content % 49.5-51.5<br />

pH 10.2-10.9<br />

Viscosity at 25°C<br />

300 max. mPa.s<br />

(Brookfield spindle n°2, 60 rpm)<br />

Specific gravity (g/cm 3 ) 1.03 g/cm 3<br />

Tg (Deg C Onset/Midpoint) 19/24<br />

Minimum Film Formation Temperature (Deg C) 18-20<br />

*The physical property data listed are considered to be typical properties, not product specification

UCAR <strong>Latex</strong> <strong>DT250T</strong><br />

STYRENE-ACRYLIC EMULSION FOR WATERBORNE TRAFFIC PAINT<br />

Formulating Guidelines<br />

Formulating waterborne traffic paints based on UCAR <strong>Latex</strong> <strong>DT250T</strong> is similar to<br />

formulating other common types of latex paints. No unusual techniques or equipment are<br />

required. However, as a result of the very fast drying characteristics of UCAR <strong>Latex</strong> <strong>DT250T</strong>,<br />

traffic paint manufacturers must adopt the following guidelines when formulating paints:<br />

1. pH:<br />

Maintain a pH of 10.2 or above at all times during the manufacture and storage of paints based<br />

on UCAR <strong>Latex</strong> <strong>DT250T</strong>.<br />

2. Neutralising Agent<br />

Use only ammonia to adjust the pH of the paint. Do not use less volatile amines or nonvolatile<br />

base.<br />

3. Grinding:<br />

Avoid excessive heating of the paint during manufacture. It is strongly recommended not to<br />

"grind" (disperse) at high speed (

UCAR <strong>Latex</strong> <strong>DT250T</strong><br />

STYRENE-ACRYLIC EMULSION FOR WATERBORNE TRAFFIC PAINT<br />

9. Wetting Agent:<br />

A surfactant is needed to facilitate wetting of the pigment particle surfaces. Triton X-405 has<br />

been found to be especially effective in reducing high viscosity.<br />

10. Defoamer:<br />

Excessive foam in the paint will increase the apparent viscosity and lead to problems with gel<br />

formation. Drewplus T-4201 is an example of an effective defoamer in this system.<br />

Alternatives should be evaluated for specific paint properties. It is important to carefully<br />

evaluate silicone based defoamers, as they may adversely affect the adhesion of the paint to<br />

the reflective glass beads.<br />

11. Rheology Modifiers:<br />

Although traffic marking paints based on UCAR <strong>Latex</strong> <strong>DT250T</strong> are less prone to pigment<br />

settling than conventional latex paints, a low level of rheology modifier can help to reduce<br />

pigment settling. Natrosol HBR 250 is recommended as it gives some structure to the paint,<br />

without negative effect on sprayability.<br />

12. Alcohol:<br />

Alcohols can be optionally added to paints based on UCAR <strong>Latex</strong> <strong>DT250T</strong> to impart freezethaw<br />

stability and to optimise "dry-to-no-pick-up" times. Care in method of alcohol addition is<br />

recommended as the alcohol may promote gel/particulate formation in the paint.<br />

13. Coalescents:<br />

Waterborne traffic marking paints based on UCAR <strong>Latex</strong> <strong>DT250T</strong> require the addition of<br />

coalescing solvents to obtain good film formation, particula rly at l ower ap plicat i on<br />

temperatures. We recommend 10% Texanol, calculated on polymer solids, to coalesce<br />

traffic marking paints based on UCAR <strong>Latex</strong> <strong>DT250T</strong> down to 5°C. Lower levels may<br />

compromise performance and durability, especially if the paints are applied at low road<br />

surface temperatures.<br />

Note these suggestions and data are based on information we believe to be reliable. They are offered in good<br />

faith but without guarantee as conditions and methods of use of our products are beyond our control. We<br />

recommend that the prospective user determines the suitability of our materials and suggestions before<br />

adopting them on commercial scale.

UCAR <strong>Latex</strong> <strong>DT250T</strong><br />

STYRENE-ACRYLIC EMULSION FOR WATERBORNE TRAFFIC PAINT<br />

Raw Materials<br />

UCAR <strong>Latex</strong> DT 250T Trademark of The Dow Chemical Company<br />

Drewplus T-4201 Trademark of Drew Ameroid Deutschland GmbH<br />

Hydropalat A Trademark of Cognis Deutschland GmbH & Co. KG<br />

Dispex A40 Trademark of Ciba Specialty Chemicals<br />

Ti-Pure R-900 Trademark of E.I. du Pont de Nemours and Company<br />

Omyacarb 5 Trademark of Omya AG<br />

Texanol Trademark of Eastman Chemical Company<br />

Natrosol HBR 250 Trademark of Aqualon-Hercules Inc.<br />

Versenol 120 Trademark of The Dow Chemical Company<br />

NOTICE: No freedom from any patent owned by Seller or others is to be inferred. Because use conditions and applicable<br />

laws may differ from one location to another and may change with time, Customer is responsible for determining whether<br />

products and the information in this document are appropriate for Customer's use and for ensuring that Customer's<br />

workplace and disposal practices are in compliance with applicable laws and other governmental enactments. Seller assumes<br />

no obligation or liability for the information in this document. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES<br />

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.<br />

Trademark of The Dow Chemical Company