2009 Montana Mining - Montana Mining Association

2009 Montana Mining - Montana Mining Association

2009 Montana Mining - Montana Mining Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Did you know that there are 9,000 pounds of copper, including<br />

632,000 feet of copper wire, in a 747-200 jet airplane? Or that<br />

a basic automobile contains about 50 pounds of copper? Copper<br />

plays an integral part in everyday life, yet many people don't appreciate<br />

it – unless you happen to be one of the 350 employees at<br />

<strong>Montana</strong> Resources in Butte, that is.<br />

<strong>Montana</strong> Resources operates an open pit copper and molybdenum<br />

mine. The operation comprises the Continental mine, crushers<br />

and a concentrator facility where thousands of tons of raw ore are<br />

processed into high-quality metal concentrates. The management of<br />

mining economies, adding control technology and production techniques,<br />

allows <strong>Montana</strong> Resources to competitively produce copper<br />

and molybdenum concentrates for a world market. <strong>Montana</strong><br />

Resources is the lowest grade copper mine operating in the world<br />

today. Head grades of copper ore average ¼ of one percent. The path<br />

for metal concentrates from earth to railcar involves many separate<br />

processes, mechanical and chemical, overseen by trained personnel.<br />

The copper mined at <strong>Montana</strong> Resources heads to China and to<br />

smelters in the U.S. and Canada. The molybdenum is shipped to a<br />

roasting plant in Pennsylvania, where it’s ultimately used in making<br />

stainless steel and other steel alloys.<br />

Environmental Stewardship<br />

<strong>Montana</strong> Resources is part of a modern generation of mine operators<br />

that strives to innovate processes and use more efficient technologies<br />

that lessen the impact of mining on the environment. They<br />

recognize the need to monitor water and air quality.<br />

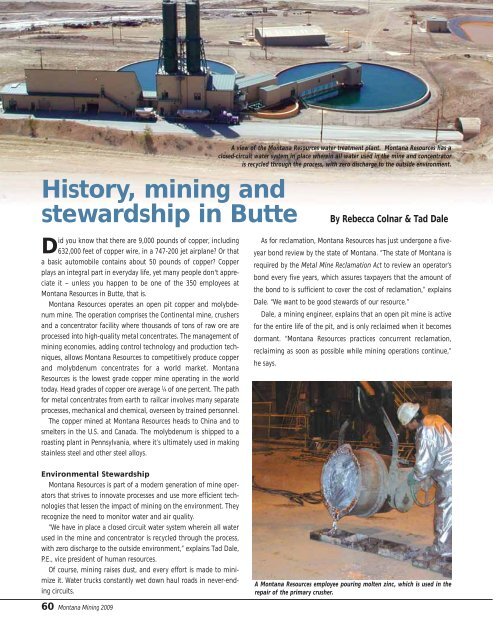

“We have in place a closed circuit water system wherein all water<br />

used in the mine and concentrator is recycled through the process,<br />

with zero discharge to the outside environment,” explains Tad Dale,<br />

P.E., vice president of human resources.<br />

Of course, mining raises dust, and every effort is made to minimize<br />

it. Water trucks constantly wet down haul roads in never-ending<br />

circuits.<br />

60 <strong>Montana</strong> <strong>Mining</strong> <strong>2009</strong><br />

A view of the <strong>Montana</strong> Resources water treatment plant. <strong>Montana</strong> Resources has a<br />

closed-circuit water system in place wherein all water used in the mine and concentrator<br />

is recycled through the process, with zero discharge to the outside environment.<br />

History, mining and<br />

stewardship in Butte By Rebecca Colnar & Tad Dale<br />

As for reclamation, <strong>Montana</strong> Resources has just undergone a fiveyear<br />

bond review by the state of <strong>Montana</strong>. “The state of <strong>Montana</strong> is<br />

required by the Metal Mine Reclamation Act to review an operator’s<br />

bond every five years, which assures taxpayers that the amount of<br />

the bond to is sufficient to cover the cost of reclamation,” explains<br />

Dale. “We want to be good stewards of our resource.”<br />

Dale, a mining engineer, explains that an open pit mine is active<br />

for the entire life of the pit, and is only reclaimed when it becomes<br />

dormant. “<strong>Montana</strong> Resources practices concurrent reclamation,<br />

reclaiming as soon as possible while mining operations continue,”<br />

he says.<br />

A <strong>Montana</strong> Resources employee pouring molten zinc, which is used in the<br />

repair of the primary crusher.