ISOPRO® Type IPT - Spanelas

ISOPRO® Type IPT - Spanelas

ISOPRO® Type IPT - Spanelas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

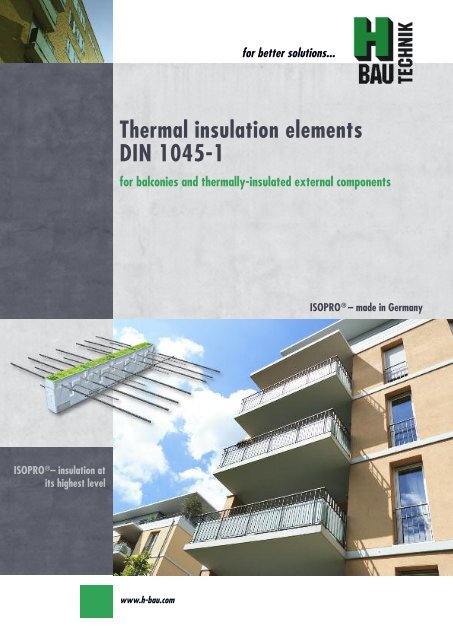

ISOPRO ® – insulation at<br />

its highest level<br />

Thermal insulation elements<br />

DIN 1045-1<br />

for balconies and thermally-insulated external components<br />

www.h-bau.com<br />

for better solutions...<br />

ISOPRO ® – made in Germany

H-Bau Technik GmbH<br />

Contact<br />

H-Bau<br />

Technik GmbH<br />

Head Office:<br />

Am Güterbahnhof 20<br />

79771 Klettgau<br />

Germany<br />

Tel. +49 (0) 77 42 / 92 15-20<br />

Fax +49 (0) 77 42 / 92 15-90<br />

eMail: export.klettgau@h-bau.de<br />

www.h-bau.com<br />

Production North-East:<br />

Brandenburger Allee<br />

14641 Nauen-Wachow<br />

Germany<br />

Tel. +49 (0) 332 39 / 775-20<br />

Fax +49 (0) 332 39 / 775-90<br />

eMail: export.berlin@h-bau.de<br />

Paul Rieger:<br />

Tel. +49 (0) 77 42 / 92 15-21<br />

Fax +49 (0) 77 42 / 92 15-93<br />

Mobil +49 (0) 171 / 864 72 61<br />

eMail: paul.rieger@h-bau.de<br />

Oliver Etzrodt<br />

Tel. +49 (0) 70 82 / 41 39 63<br />

Fax +49 (0) 70 82 / 79 33 00<br />

Mobil +49 (0) 171 / 864 72 60<br />

eMail: oliver.etzrodt@h-bau.de<br />

Rudolf Till<br />

Tel. +49 (0) 332 39 / 775-24<br />

Fax +49 (0) 332 39 / 775-90<br />

Mobil +49 (0) 172 / 993 70 50<br />

eMail: rudi.till@t-online.de

ISOPRO ®<br />

Balcony insulation elements<br />

Contents<br />

for better solutions...<br />

ISOPRO ® Thermal insulation elements<br />

General Overview of types 2-3<br />

Technical principles 4-6<br />

Building physics – Heat insulation 7<br />

Building physics – Fire protection 8<br />

Exposition class 9<br />

<strong>Type</strong> IP-<strong>IPT</strong> Examples 11<br />

Construction and dimensions 12-13<br />

Dimensioning table 14-15<br />

Special types 16-17<br />

On-site reinforcement and installation instructions 18-21<br />

Two-part elements 22-23<br />

Deflection and height offset 24-25<br />

Expansion joint spacing 26<br />

<strong>Type</strong> <strong>IPT</strong>-Corner Construction and dimensions/on-site reinforcement 27-29<br />

Dimensioning table 30<br />

<strong>Type</strong> IPH Technical principles 31<br />

<strong>Type</strong> IPE Technical principles 32<br />

Dimensioning table 33<br />

<strong>Type</strong> IPQ-IPQS Examples of shear force elements 34<br />

IPQZ Technical principles 35<br />

Construction and dimensions 36-37<br />

Dimensioning table 38<br />

On-site reinforcement 39-41<br />

<strong>Type</strong> IPQQ-IPQQS Construction and dimensions 42-43<br />

Dimensioning table 43<br />

On-site reinforcement 44-45<br />

Torque from eccentric connection 46<br />

<strong>Type</strong> <strong>IPT</strong>D Technical principles 47<br />

Construction and dimensions 48<br />

On-site reinforcement 49<br />

Dimensioning table 50-51<br />

<strong>Type</strong> IPA, IPF, IPO Technical principles 53<br />

<strong>Type</strong> IPA Construction and dimensional values 54<br />

On-site reinforcement and installation instructions 55<br />

<strong>Type</strong> IPF Construction and dimensional values 56<br />

On-site reinforcement and installation instructions 57<br />

<strong>Type</strong> IPO Construction and dimensional values 58<br />

On-site reinforcement and installation instructions 59<br />

<strong>Type</strong> IPS, IPW Technical principles 61<br />

<strong>Type</strong> IPS Construction and dimensional values 62<br />

On-site reinforcement and installation instructions 63<br />

<strong>Type</strong> IPW Construction and dimensional values 64<br />

On-site reinforcement and installation instructions 65<br />

Tender 66<br />

ISOPRO ® - insulation at its highest level<br />

1

2<br />

ISOPRO ®<br />

Overview of types<br />

www.h-bau.com<br />

ISOPRO ® type IP - page 12<br />

for freely-projecting balcony slabs.<br />

The element transfers negative bending moments<br />

and positive shear forces.<br />

ISOPRO ® type <strong>IPT</strong> - page 13<br />

for freely-projecting balcony slabs.<br />

The element transfers negative bending moments<br />

and positive shear forces.<br />

ISOPRO ® type <strong>IPT</strong>-Corner - page 27<br />

for freely-projecting external-corner balconies.<br />

The element transfers negative bending moments<br />

and positive shear forces.<br />

ISOPRO ® type IPQ - page 35<br />

for joint-supported slabs (e.g. balconies and<br />

loggia on supports).<br />

The element transfers positive shear forces.<br />

ISOPRO ® type IPQS - page 36<br />

for joint-supported slabs with selective force<br />

absorption.<br />

The element transfers positive shear forces.<br />

ISOPRO ® type IPQZ - page 36<br />

for joint-supported slabs with selective force<br />

absorption with zero stress.<br />

The element transfers positive shear forces.<br />

ISOPRO ® type IPQQ - page 42<br />

for joint-supported slabs.<br />

The element transfers positive and negative<br />

shear forces.<br />

ISOPRO ® type IPQQS - page 42<br />

for joint-supported slabs with selective force<br />

absorption.<br />

The element transfers positive and negative<br />

shear forces.<br />

Balkon Decke<br />

Balkon Decke<br />

Balkon Decke<br />

Balkon Decke<br />

Balkon Decke<br />

Balkon Decke<br />

Balkon Decke<br />

Balkon Decke

ISOPRO ®<br />

Overview of types<br />

ISOPRO ® type <strong>IPT</strong>D - page 47<br />

for re-entrant balcony slabs in the floor area.<br />

The element transfers positive and negative<br />

bending moments and shear forces.<br />

ISOPRO ® type IPH - page 31<br />

For selective absorption of horizontal forces in<br />

connection with cantilever slab or shear force<br />

connections.<br />

ISOPRO ® type IPE - page 32<br />

for selective absorption of horizontal forces<br />

and moments in conjunction with IP & <strong>IPT</strong> cantilever<br />

slab connections.<br />

ISOPRO ® type IPA - page 54<br />

for connection of fascias at storey floor level.<br />

The element is attached at selected points.<br />

ISOPRO ® type IPF - page 56<br />

for connection of projecting parapets at storey<br />

floor level.<br />

The element is attached at selected points.<br />

ISOPRO ® type IPO - page 58<br />

for connection of reinforced concrete consoles<br />

B<br />

at storey floor level.<br />

The element is attached at selected points.<br />

ISOPRO ® type IPS - page 62<br />

for connection of wall consoles and cantilever<br />

beams.<br />

The element transfers positive and negative<br />

shear forces.<br />

ISOPRO ® type IPW - page 64<br />

for connection of full-height wall panels.<br />

The element transfers bending moments and<br />

shear forces in both the vertical and horizontal<br />

direction.<br />

Konsole<br />

for better solutions...<br />

Balkon Decke<br />

Balkon Decke<br />

Balkon Decke<br />

Konsole<br />

Attika<br />

Brüstung<br />

B<br />

Decke<br />

Decke<br />

Decke<br />

Wandscheibe innen<br />

ISOPRO ® - insulation at its highest level<br />

3

4<br />

ISOPRO ®<br />

Technical principles<br />

The product<br />

ISOPRO ® is a thermally insulating,<br />

supporting, connection element between<br />

concrete construction components.<br />

Its excellent thermal insulation<br />

properties provide a reliable solution<br />

to the problems of building physics at<br />

the interface between external and internal<br />

construction elements.<br />

ISOPRO ® consists of an EPS insulating<br />

body 80 mm thick of the heat conduction<br />

group 035 together with a<br />

static rod framework that ensures effective<br />

transfer of the forces from BST<br />

500 in the area of the insulation and<br />

up to 100 mm to the side from BST<br />

500 NR.<br />

Elements made from high-performance<br />

specialty concrete or rods<br />

made from BST 500 NR are used in<br />

the compression zone.<br />

www.h-bau.com<br />

Features<br />

Approved and type-tested in accordance<br />

with DIN 1045-1<br />

Reduction of thermal bridges according<br />

to DIN 4108-2 and EnEV<br />

Avoids condensation and growth<br />

of mould<br />

Stainless steel construction provides<br />

corrosion protection<br />

Faster and more economical installation<br />

The consistently high quality standard<br />

of ISOPRO ® is maintained by<br />

continual in-house and third-party<br />

monitoring.<br />

Optimum absorption of shear<br />

forces and bending moments<br />

Application area<br />

Projecting balcony with ISOPRO ® type IP<br />

Supported balcony with ISOPRO ® type IPQ

ISOPRO ®<br />

Technical principles<br />

Installation locations for ISOPRO ® balcony insulation elements:<br />

for better solutions...<br />

ISOPRO ® in single-skin brickwork ISOPRO ® in single-skin brickwork with<br />

Thermal Insulation Bonding System<br />

ISOPRO ® in double-skin brickwork ISOPRO ® in double-skin brickwork with<br />

rear ventilation<br />

Order codes for ISOPRO ® balcony insulation elements:<br />

Order example 1:<br />

Freely-projecting balcony slab<br />

Slab thickness: h = 180 mm<br />

Concrete cover: c v = 35 mm<br />

m Ed = 31.6 kNm/m<br />

v Ed = 51.4 kN/m<br />

Fire protection requirement F90<br />

Order example 2:<br />

Supported balcony slab<br />

Slab thickness: h = 200 mm<br />

v Ed = 84,3 kN/m<br />

Fire protection requirement F90<br />

Additional identification for special element type IP:<br />

Downward curve in the wall ⇒ Var. l<br />

Upward curve in the wall ⇒ Var. ll<br />

Order example: IP 30 Var.l c v 35 h200<br />

IP 50 CV35 Q8 F90 h180<br />

<strong>Type</strong><br />

load bearing capacity<br />

concrete cover<br />

supplemented shear force<br />

fire protection class F90<br />

height of element<br />

IPQ 50 F90 h200<br />

<strong>Type</strong><br />

load bearing capacity<br />

fire protection class F90<br />

height of element<br />

Note:<br />

For types IPQ and IPQS no additional identification for the concrete covering c v is required.<br />

All of the special elements for types IP and <strong>IPT</strong> are shown on pages 16-17.<br />

Var. lll HV ⇐ ceiling offset upwards<br />

Var. lll UV ⇐ ceiling offset downwards<br />

ISOPRO ® 5<br />

- insulation at its highest level

6<br />

ISOPRO ®<br />

Component catalogue and test certificates<br />

Component catalogue ISOPRO ® elements<br />

Reinforcing steel: BSt 500 S<br />

Stainless steel: BSt 500 NR in accordance with general building authority approval Material<br />

No. 1.4571 or 1.4362<br />

Compression bearing: Pressure elements made from high tensile special concrete;<br />

BSt 500 NR in accordance with general building authority approval<br />

Insulation body: Rigid polystyrene foam of heat conduction group 035<br />

Fire protection slabs: Fibre-cement slab from construction material class A1<br />

Connecting structural components<br />

Concrete: Standard concrete according to DIN 1045-2 or DIN EN 206-1 with a dry bulk<br />

density of 2000 kg/m 3 to 2600 kg/m 3 (light concrete is not permitted)<br />

Reinforcing steel: BSt 500 M and BSt 500 S<br />

Test certificates<br />

Approvals: DIBt Berlin<br />

General building authority approval<br />

ISOPRO type IP Z-15.7-244<br />

ISOPRO type <strong>IPT</strong> Z-15.7-243<br />

type testing: State Office for Construction Engineering, Tübingen<br />

Test Report (type testing)<br />

ISOPRO type IP Prüf-Nr. 06/2<br />

ISOPRO type <strong>IPT</strong> Prüf-Nr. 08/5<br />

ISOPRO type IPQ Prüf-Nr. 08/6<br />

www.h-bau.com<br />

Minimum strength of concrete for external structural components:<br />

≥ C25/30 and dependent on the exposition classes according to DIN 1045-1<br />

Minimum strength of concrete for internal structural components:<br />

≥ C20/25 and dependent on the exposition classes according to DIN 1045-1

ISOPRO ®<br />

Building physics – Heat insulation<br />

Thermal bridge<br />

In the construction of buildings, unconsidered<br />

thermal bridges are a hidden<br />

risk. Thermal bridges are defined<br />

as locations in parts of a building in<br />

which heat transfer to the outside occurs<br />

more quickly than in other parts<br />

of the building.<br />

There is a difference between geometrical<br />

thermal bridges, in which, for<br />

the heat dissipation from the internal<br />

surface, there is an adjacent, larger,<br />

external surface (e.g. external corners<br />

of the building), and constructed thermal<br />

bridges, which create thermal<br />

bridges by the use of fixtures or materials<br />

with high heat conductivity or<br />

lack of thermal insulation. One example<br />

of constructive thermal bridges<br />

is reinforced concrete elements which<br />

penetrate external walls. At low outside<br />

temperatures, this increased heat<br />

flow leads to lower temperatures at<br />

the surface of the room wall. Problems<br />

of decreasing temperatures result<br />

from surface contact with the air<br />

in the room and its water retention capacity.<br />

Air humidity<br />

Air humidity (also air moisture) is defined<br />

as the proportion of water<br />

vapour mixed with gas (in this case in<br />

the room). The best known measure<br />

of humidity is the relative humidity,<br />

given as a percentage, which relates<br />

to the proportion of<br />

water vapour content in the air to the<br />

maximum possible content at any<br />

time. At lower temperatures the water<br />

retention capacity is lower than at<br />

higher temperatures, so that one<br />

cubic metre of air at 10ºC can absorb<br />

9.41 g of water.<br />

The same volume of air at 30ºC can<br />

absorb up to 30.38 g of water. This is<br />

known as saturation concentration.<br />

Due to fluctuating temperatures, for<br />

the same water concentration the relative<br />

humidity in the room also<br />

changes. Air, which is being cooled<br />

at the surface close to the thermal<br />

bridge, produces an increase in relative<br />

humidity until it reaches saturation<br />

concentration.<br />

Dew point temperature<br />

The temperature at which the water<br />

volume in the air is sufficient to cause<br />

saturation (relative humidity of 100%)<br />

is known as the dew point temperature,<br />

since a further decrease in temperature<br />

will cause excess humidity to<br />

be released from the air as condensate.<br />

This condensate attaches itself to<br />

the surface of the wall.<br />

Therefore, the higher the temperature<br />

and relative humidity levels in the<br />

dew point temperature [°C]<br />

20<br />

18<br />

16<br />

14<br />

12.6<br />

12<br />

10<br />

9.3<br />

8<br />

no risk *<br />

for better solutions...<br />

room are, the higher is the condensation<br />

point temperature and with it the<br />

increased risk of water condensation<br />

on the colder parts of the building surfaces.<br />

The assumed room climate is<br />

20ºC and 50% relative humidity. For<br />

these conditions the dew point temperature<br />

is 9.3ºC.<br />

The minimum heat insulation<br />

The hazard threat comes not only<br />

from humidity-related effects on construction<br />

elements and the associated<br />

damage to the building, but, more<br />

importantly, also from the health hazard<br />

due to mildew formation in these<br />

areas. The formation of mildew does<br />

not only start at the point when water<br />

condensation occurs, but already at<br />

the point when the surface temperature<br />

at the wall produces 80% relative<br />

air humidity. For normal climatic conditions<br />

in a room, the non-critical surface<br />

temperature is 12.6ºC. When<br />

this surface temperature is reached<br />

there is no further hazard risk.<br />

air temperature 22°C<br />

air temperature 20°C<br />

Relative humidity [%]<br />

air temperature 18°C<br />

* No risk of mildew formation from12.6ºC<br />

(DIN 4108-2 : 2001-03)<br />

6<br />

40 45 50 55 60 65 70 75 80 85 90<br />

Dependence of the dew point temperature on relative humidity and air temperature<br />

ISOPRO ® - insulation at its highest level<br />

7

8<br />

ISOPRO ®<br />

Building physics – Fire protection DIN 4109<br />

Fire-resistance class F 30<br />

All ISOPRO ® elements are categorised as fire protection class F30. The requirements to be met for the complete construction<br />

are illustrated in the following diagrams:<br />

F30 - wall area construction F30 - door area construction<br />

mineral-based mineral-based plaster plaster<br />

screeding / screeding plastering / plastering<br />

ISOPRO element ISOPRO element<br />

screeding / screeding plastering / plastering<br />

ISOPRO element ISOPRO element<br />

mineral-based mineral-based plaster plaster mineral-based mineral-based plaster plaster<br />

Fire-resistance class F 90<br />

All ISOPRO ® elements are also supplied to fire-resistance class F90, meeting the technical requirements for fire protection<br />

of balconies etc.<br />

The designation F90 is added to the element identification e.g. ISOPRO ® <strong>IPT</strong> 55 cv 30 F90.<br />

A1 material<br />

non-flammable<br />

The ISOPRO ® elements are fitted with fire protection plates attached to the top side and the under side.<br />

The construction can be seen in the sketch of the system below.<br />

detail 1<br />

detail 1<br />

A1 material<br />

non-flammable<br />

It is self-evident that to meet the requirements of the fire-resistance class F90, all other adjacent construction elements<br />

must also satisfy these requirements. For constructions with selected-point connections it is necessary to ensure that the<br />

intermediate insulation used also meets the fire-resistance requirements.<br />

www.h-bau.com<br />

100<br />

15<br />

15<br />

8<br />

F90 fire fire protection slab<br />

F90 fire fire protection slab

ISOPRO ®<br />

Exposition classes<br />

Exposition classes and concrete covering<br />

Reinforcement corrosion Minimum concrete<br />

strength class<br />

XC3 high humidity, outside<br />

construction elements,<br />

damp rooms<br />

XC4 alternating wet and dry,<br />

outside construction elements<br />

exposed to rain<br />

XD1 high humidity, area of<br />

spray water from road<br />

surface<br />

XS1 salt-laden air, outside<br />

construction elements<br />

near coasts<br />

Concrete attack Minimum concrete<br />

strength class<br />

XF1 high water saturation<br />

with no condensation<br />

source, outside construction<br />

elements<br />

Depth of concrete<br />

covering c nom<br />

Red. depth of concrete<br />

covering c v *<br />

C 20/25 c nom = 35 mm c v = 30 mm<br />

C 25/30 c nom = 40 mm c v = 35 mm<br />

C 30/37 c nom = 55 mm c v = 50 mm<br />

C 30/37 c nom = 55 mm c v = 50 mm<br />

C 25/30<br />

Concrete covering<br />

c v = degree of<br />

reinforcement corrosion<br />

* c v = a reduction of 5mm according to DIN 1045-1, 6.3 is taken into account<br />

DIN 1045-1 Concrete covering:<br />

for better solutions...<br />

Table for concrete covering<br />

This table for concrete covering is<br />

extracted from Tables 3 + 4 in DIN<br />

1045-1, 6.3<br />

The recommendations for external<br />

balconies are:<br />

in-situ concrete balconies, prefabricated<br />

balconies and filigree<br />

slabs with in-situ concrete covering<br />

and permanent sealing on<br />

the top surface:<br />

- concrete class C 25/30<br />

- exposition class XC4 with c v 30<br />

in-situ concrete balconies, prefabricated<br />

balconies and filigree<br />

slabs with in-situ concrete covering<br />

without permanent sealing:<br />

- concrete class C 25/30<br />

- exposition class XC4 with c v 35<br />

For constructions in accordance with DIN 1045-1 the most binding requirement is the issue of concrete covering (exposition<br />

class).<br />

The following concrete coverings (c v ) are frequently encountered:<br />

c v = 30mm<br />

c v = 35mm<br />

c v = 40mm<br />

c v = 50mm (second layer for c v = 30mm and c v = 35mm)<br />

Example: IP 12/10 c v 30 h = 180 mm<br />

Always include the element height!<br />

ISOPRO ® - insulation at its highest level<br />

9

10<br />

ISOPRO ®<br />

Dimensioning program ISOPRO ® DESIGN<br />

ISOPRO ® DESIGN dimensioning program<br />

With ISOPRO ® DESIGN we are passing on our many years of experience in the dimensioning of our ISOPRO ® thermal<br />

insulation elements for the most popular balcony systems.<br />

You can select from the popular balcony systems, e.g. cantilever balcony, supported balcony, loggia, internal corner balcony<br />

and external corner balcony, or using free inputs of known dimensional values work out the loading. After inputting<br />

the geometrical data and the effective loads, the relevant ISOPRO ® elements can be selected.<br />

The classification and the geometrical circumstances<br />

of the ISOPRO ® elements can<br />

be checked for feasibility in section and<br />

plan view and, if required, printed out as a<br />

formwork drawing or exported as a dxf file<br />

for further processing.<br />

Features<br />

all popular balcony systems can be selected<br />

installation languages German, English<br />

and Polish<br />

Dimensioning in accordance with German,<br />

Swiss or Polish standards (DIN,<br />

SIA, Eurocode)<br />

Dimensioning using FEM module<br />

Report output with verification<br />

CAD export<br />

www.h-bau.com<br />

ISOPRO ® DESIGN on CD or as free download at:<br />

Tel.: +49 (0) 77 42 / 92 15-20<br />

Fax: +49 (0) 77 42 / 92 15-90<br />

eMail: info@h-bau.de<br />

Internet: www.h-bau.com

IP / <strong>IPT</strong> 1st position<br />

ISOPRO ® <strong>Type</strong> IP / <strong>IPT</strong><br />

Examples<br />

IP / <strong>IPT</strong> 2nd position<br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong> IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong> IP / IP <strong>IPT</strong> / <strong>IPT</strong> IP / <strong>IPT</strong><br />

Freely-projecting balcony<br />

Side-separated internal corner balcony Internal corner balcony<br />

Internal corner balcony/loggia overlying on 3 sides,<br />

partially projecting<br />

<strong>IPT</strong> Corner IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

2nd position<br />

for better solutions...<br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong> 1st position<br />

1st position<br />

IP / <strong>IPT</strong> IP / IP <strong>IPT</strong>/ <strong>IPT</strong> IP / <strong>IPT</strong> 1st positionIP<br />

/ <strong>IPT</strong><br />

IP / <strong>IPT</strong> IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

1st position<br />

1st position<br />

IP / <strong>IPT</strong> 2nd position<br />

IP / <strong>IPT</strong> 2nd position<br />

IP / <strong>IPT</strong> 1st position<br />

IP / <strong>IPT</strong> 1st position<br />

IP / <strong>IPT</strong> 1st position<br />

IP / <strong>IPT</strong> 2nd position<br />

IP / <strong>IPT</strong> 2nd position<br />

IP / <strong>IPT</strong> 2nd position<br />

IP / <strong>IPT</strong> 2nd position<br />

IP / <strong>IPT</strong> 1st position<br />

IP / <strong>IPT</strong> 2nd position<br />

IP / <strong>IPT</strong> 2nd position<br />

IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

<strong>IPT</strong> Corner<br />

<strong>IPT</strong> Corner<br />

IP / <strong>IPT</strong> <strong>IPT</strong> Corner<br />

IP / <strong>IPT</strong> <strong>IPT</strong> Corner IP / <strong>IPT</strong> <strong>IPT</strong> Corner<br />

<strong>IPT</strong> Corner IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

2nd position<br />

External corner balcony<br />

IP / <strong>IPT</strong><br />

11<br />

ISOPRO ® - insulation at its highest level<br />

<strong>IPT</strong> Corner IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

2nd position<br />

<strong>IPT</strong> Corner IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

2nd position<br />

<strong>IPT</strong> Corner IP / <strong>IPT</strong><br />

IP / <strong>IPT</strong><br />

2nd position

12<br />

ISOPRO ® <strong>Type</strong> IP<br />

Construction and dimensions<br />

Section IP<br />

160 - 250<br />

Section IP - X<br />

160 - 250<br />

balcony side<br />

balcony side<br />

Configuration of the elements<br />

1000<br />

Dimensions type IP [length in mm]<br />

L ZB<br />

L ZB<br />

Top view<br />

L Q<br />

L Q<br />

80<br />

80<br />

80<br />

<strong>Type</strong> Length of element [mm] Tension rods Shear force rods Compression support<br />

L Q<br />

L ZD<br />

L ZD<br />

slab side<br />

slab side<br />

IP 10 1000 7 Ø 6 4 Ø 6 4<br />

IP 20 1000 7 Ø 8 4 Ø 6 4<br />

IP 25 1000 8 Ø 8 4 Ø 8 4<br />

IP 30 1000 4 Ø 8 + 4 Ø 10 4 Ø 8 6<br />

IP 40 1000 8 Ø 10 4 Ø 8 6<br />

IP 50 1000 10 Ø 10 4 Ø 8 8<br />

<strong>Type</strong><br />

Tension rods<br />

LZB LZD Shear force rods<br />

LQ LQ8 Supplemental shear force<br />

LQ10 LQ12 IP 10 370 430 250 615 - -<br />

IP 20 480 560 250 615 - -<br />

IP 25 480 560 280 615 615 745<br />

IP 30 590 690 280 615 615 745<br />

IP 40 590 690 280 615 615 745<br />

IP 50 590 690 280 615 615 745<br />

Expansion joint spacings for ISOPRO ® type IP can be found on page 26.<br />

www.h-bau.com<br />

Element classification<br />

see type test IP<br />

<strong>Type</strong> test<br />

Prüf-Nr. 06/2<br />

Approval<br />

Ap-No. Z-15.7-244

ISOPRO ® <strong>Type</strong> <strong>IPT</strong><br />

Construction and dimensions<br />

Section <strong>IPT</strong><br />

160 - 250<br />

160 - 250<br />

1000<br />

L ZB<br />

L ZB<br />

L Q<br />

L Q<br />

L D<br />

L D<br />

80<br />

balcony side slab side<br />

Section <strong>IPT</strong> - X<br />

Configuration of the elements<br />

80<br />

80<br />

balcony side slab side<br />

Dimensions type <strong>IPT</strong> [length in mm]<br />

Top view<br />

<strong>Type</strong> Length of element [mm] Tension rods Shear force rods Compression rods<br />

Tension rods Shear force rods Compr. rods Supplemental shear force<br />

<strong>Type</strong><br />

LZB LZD LQ LD LQ8 LQ10 LQ12 <strong>IPT</strong> 55 710 810 210 165 400 400 490<br />

<strong>IPT</strong> 60 590 690 210 165 400 400 490<br />

<strong>IPT</strong> 70 710 810 210 165 400 400 490<br />

<strong>IPT</strong> 80 710 810 210 165 400 400 490<br />

<strong>IPT</strong> 100 710 830 210 200 400 400 490<br />

80<br />

<strong>IPT</strong> 55 500 + 500 6 Ø 10 + 4 Ø12 4 Ø 8 6x2 Ø 10 + 4x2 Ø 12<br />

<strong>IPT</strong> 60 500 + 500 10 Ø 12 4 Ø 8 10x2 Ø 12<br />

<strong>IPT</strong> 70 500 + 500 10 Ø 12 4 Ø 8 7x2 Ø 14 + 3x2 Ø 12<br />

<strong>IPT</strong> 80 500 + 500 10 Ø 12 4 Ø 8 10x2 Ø 14<br />

<strong>IPT</strong> 100 500 + 500 10 Ø 14 4 Ø 8 10x2 Ø 14<br />

Expansion joint spacings for ISOPRO ® type <strong>IPT</strong> can be found on page 26.<br />

L D<br />

L D<br />

L Q<br />

L ZD<br />

L ZD<br />

for better solutions...<br />

Element classification<br />

see type test IP<br />

<strong>Type</strong> test<br />

Prüf-Nr. 08/5<br />

Approval<br />

Ap-No. Z-15.7-243<br />

IP / <strong>IPT</strong><br />

13<br />

ISOPRO ® - insulation at its highest level

14<br />

ISOPRO ®<br />

Dimensioning table for concrete ≥ C20/25<br />

Element height [mm]<br />

dependent on c v [mm]<br />

Dimensional values of the absorbable moments m Rd [kNm/m]<br />

30 35 40 45 50 IP 10 IP 20 IP 25 IP 30 IP 40<br />

- - - - 160 7.0 12.2 13.8 17.7 20.4<br />

- - - 160 - 7.4 13.0 14.6 18.8 21.7<br />

- - 160 - 170 7.8 13.8 15.5 19.9 23.0<br />

- 160 - 170 - 8.3 14.5 16.3 21.1 24.3<br />

160 - 170 - 180 8.7 15.3 17.2 22.2 25.5<br />

- 170 - 180 - 9.1 16.1 18.1 23.3 26.8<br />

170 - 180 - 190 9.6 16.8 18.9 24.4 28.1<br />

- 180 - 190 - 10.0 17.6 19.8 25.5 29.4<br />

180 - 190 - 200 10.4 18.4 20.6 26.7 30.7<br />

- 190 - 200 - 10.8 19.1 21.5 27.8 32.0<br />

190 - 200 - 210 11.3 19.9 22.4 28.9 33.3<br />

- 200 - 210 - 11.7 20.7 23.2 30.0 34.6<br />

200 - 210 - 220 12.1 21.4 24.1 31.1 35.9<br />

- 210 - 220 - 12.6 22.2 24.9 32.3 37.2<br />

210 - 220 - 230 13.0 22.9 25.8 33.4 38.4<br />

- 220 - 230 - 13.4 23.7 26.7 34.5 39.7<br />

220 - 230 - 240 13.9 24.5 27.5 35.6 41.0<br />

- 230 - 240 - 14.3 25.2 28.4 36.7 42.3<br />

230 - 240 - 250 14.7 26.0 29.2 37.9 43.6<br />

- 240 - 250 - 15.1 26.8 30.1 39.0 44.9<br />

240 - 250 - - 15.6 27.5 31.0 40.1 46.2<br />

- 250 - - - 16.0 28.3 31.8 41.2 47.5<br />

250 - - - - 16.4 29.1 32.7 42.3 48.8<br />

Dimensional values of the absorbable shear forces v Rd [kN/m]<br />

h = 160 - 250 [mm] 27.5 41.5<br />

<strong>Type</strong>s with supplemented shear force load bearing capacity<br />

<strong>Type</strong> IP 10 Q... IP 20 Q... IP 25 Q... IP 30 Q... IP 40 Q...<br />

Dimensional values of the absorbable shear forces v Rd [kN/m]<br />

Q8 (2Ø8/2Ø10) h ≥ 170mm 61.8* 79.2<br />

Q10 (4Ø10) h ≥ 170mm 96.6<br />

Q12 (4Ø12) h ≥ 180mm 139.1<br />

* (4 Ø8) h ≥ 160mm<br />

<strong>Type</strong>s with positive and negative shear force absorption<br />

Dimensional values of the absorbable shear forces v Rd [kN/m]<br />

<strong>Type</strong> IP 10 IP 20 IP 25 IP 30 IP 40<br />

Q8X (4Ø8/2Ø10) + 61.8 / - 48.8<br />

Q10X (4Ø10/2Ø12) + 96.6 / - 69.6<br />

Q12X (4Ø12/2Ø12) + 139.1 / - 69.6<br />

www.h-bau.com

ISOPRO ®<br />

Dimensioning table for concrete ≥ C20/25<br />

Dimensional values of the absorbable moments m Rd [kNm/m]<br />

IP 50 <strong>IPT</strong> 55 <strong>IPT</strong> 60 <strong>IPT</strong> 70 <strong>IPT</strong> 80 <strong>IPT</strong> 100<br />

27.0 28.3 31.9 35.2 36.8 43.9<br />

28.7 30.1 33.9 37.5 39.1 46.8<br />

30.4 31.9 36.0 39.7 41.5 49.7<br />

32.1 33.7 38.0 42.0 43.9 52.6<br />

33.8 35.6 40.1 44.3 46.3 55.5<br />

35.5 37.4 42.1 46.6 48.6 58.4<br />

37.2 39.2 44.2 48.9 51.0 61.3<br />

38.9 41.0 46.2 51.1 53.4 64.2<br />

40.6 42.8 48.2 53.4 55.8 67.1<br />

42.3 44.6 50.3 55.7 58.2 69.9<br />

44.1 46.4 52.3 58.0 60.6 72.8<br />

45.8 48.2 54.4 60.3 62.9 75.7<br />

47.5 50.1 56.4 62.5 65.3 78.6<br />

49.2 51.9 58.5 64.8 67.7 81.5<br />

50.9 53.7 60.5 67.1 70.1 84.4<br />

52.6 55.5 62.5 69.4 72.5 87.3<br />

54.3 57.3 64.6 71.7 74.9 90.2<br />

56.0 59.1 66.6 74.0 77.3 93.1<br />

57.7 60.9 68.7 76.2 79.6 96.0<br />

59.4 62.8 70.7 78.5 82.0 98.8<br />

61.1 64.6 72.8 80.8 84.4 101.7<br />

62.8 66.4 74.8 83.1 86.8 104.6<br />

64.5 68.2 76.9 85.4 89.2 107.5<br />

Dimensional values of the absorbable shear forces v Rd [kN/m]<br />

41.5<br />

IP 50 Q... <strong>IPT</strong> 55 Q... <strong>IPT</strong> 60 Q... <strong>IPT</strong> 70 Q... <strong>IPT</strong> 80 Q... <strong>IPT</strong> 100 Q...<br />

Dimensional values of the absorbable shear forces v Rd [kN/m]<br />

79.2<br />

96.6<br />

139.1<br />

Dimensional values of the absorbable shear forces v Rd [kN/m]<br />

IP 50 <strong>IPT</strong> 55 <strong>IPT</strong> 60 <strong>IPT</strong> 70 <strong>IPT</strong> 80 <strong>IPT</strong> 100<br />

+ 61.8 / - 48.8<br />

+ 96.6 / - 69.6<br />

+ 139.1 / - 69.6<br />

for better solutions...<br />

IP / <strong>IPT</strong><br />

15<br />

ISOPRO ® - insulation at its highest level

16<br />

ISOPRO ®<br />

Special types Valid for type series IP and <strong>IPT</strong> (analogously)<br />

Connection to a floor slab with a “small” step-up offset<br />

balcony<br />

wall<br />

slab<br />

balcony<br />

�<br />

For a step-up offset of less than 80 mm a standard element<br />

can also be used.<br />

� slab<br />

In balcony this case a stirrup reinforcement � wall with an upper leg<br />

balcony<br />

�<br />

length ≥ ls is required to deflect the tensile force towards<br />

the floor.<br />

�<br />

Dimensioning of the stirrup reinforcement � for cantilever<br />

wall<br />

effect and shear force on the � balcony slab.<br />

��<br />

balcony � wall<br />

balcony<br />

balcony<br />

balcony<br />

h ≤ 80<br />

h ≤ 80<br />

Connection to a vertical wall – connection downwards<br />

balcony<br />

�<br />

wall<br />

wall<br />

Connection to a vertical wall – �connection<br />

upwards<br />

balcony wall<br />

�<br />

balcony wall<br />

h ≤ 80<br />

The ISOPRO<br />

�<br />

® tension rods correspond to the required<br />

�<br />

overlap length ls in accordance with DIN 1045-1.<br />

See pages 18-21 for connection reinforcement to the<br />

balcony side.<br />

�<br />

balcony wall<br />

�<br />

≥ 220<br />

�<br />

�<br />

≥ 220<br />

�<br />

�<br />

�<br />

slab<br />

slab<br />

The ISOPRO<br />

slab<br />

balcony<br />

�<br />

�<br />

� slab<br />

® tension rods correspond to the required<br />

overlap length ls in accordance with DIN 1045-1.<br />

See pages 18-21 for connection reinforcement to the<br />

balcony side.<br />

www.h-bau.com<br />

�<br />

�<br />

�<br />

�<br />

�<br />

� upper reinforcement of steel bars or mesh<br />

� closed stirrup<br />

� lower reinforcement of steel bars or mesh<br />

� upper reinforcement of steel bars or mesh<br />

For connection reinforcement on the balcony side see<br />

� closed stirrup<br />

pages 18-21. � upper reinforcement of steel bars or mesh<br />

The necessary shear reinforcement in the overlap area<br />

must be proved in accordance with DIN 1045-1.<br />

Recommended joist width: � closed at least stirrup 200 mm.<br />

� lower reinforcement of steel bars or mesh<br />

Var. I<br />

insert stirrup<br />

�<br />

�<br />

insert stirrup<br />

� insert stirrup<br />

�<br />

� insert stirrup<br />

� insert stirrup<br />

� insert stirrup<br />

� upper reinforcement of steel bars or mesh<br />

� closed stirrup<br />

� reinforcement<br />

lower reinforcement of steel bars or mesh<br />

� reinforcement<br />

� reinforcement<br />

� reinforcement<br />

The necessary shear reinforcement in the overlap area<br />

must be proved in accordance with DIN 1045-1.<br />

The minimum wall thickness is dependent on the type.<br />

Var. II<br />

� reinforcement<br />

The necessary shear reinforcement in the overlap area<br />

� upper reinforcement of steel bars or mesh<br />

must be proved � lower in accordance reinforcement with of steel DIN bars 1045-1. or mesh<br />

The minimum wall thickness is dependent on the type.<br />

� closed stirrup<br />

� upper reinforcement of steel bars or mesh<br />

� angled reinforcement<br />

� closed stirrup<br />

� reinforcement

�<br />

balcony wall<br />

ISOPRO ®<br />

Special types Valid for type series � IP and <strong>IPT</strong> (analogously)<br />

�<br />

balcony wall<br />

Connection to a floor slab with a step-up offset<br />

balcony<br />

≥ 220<br />

�<br />

balcony<br />

�<br />

Dimensioning of the stirrup reinforcement for cantilever<br />

�<br />

moment and shear force for the balcony slab.<br />

The <strong>ISOPRO®</strong> tension rods correspond to the required<br />

overlap length ls in accordance with DIN 1045-1.<br />

balcony<br />

On-site connection reinforcement see pages 18-21.<br />

Connection to a floor slab with step-down offset �<br />

�<br />

balcony<br />

≥ 220<br />

�<br />

�<br />

�<br />

≥ 220<br />

�<br />

≥ 220<br />

�<br />

slab<br />

slab<br />

Dimensioning of the stirrup reinforcement for cantilever<br />

moment and shear force for the balcony slab.<br />

The <strong>ISOPRO®</strong> tension rods correspond to the required<br />

overlap length ls in accordance with DIN 1045-1.<br />

On-site connection reinforcement see pages 18-21.<br />

�<br />

Var. III HV<br />

slab<br />

slab<br />

�<br />

�<br />

�<br />

Var. III UV<br />

For further solutions please contact our applications engineering department.<br />

Tel.: +49 (0) 77 42 / 92 15-70<br />

Fax: +49 (0) 77 42 / 92 15-96<br />

�<br />

�<br />

� upper reinforcement of steel bars or mesh<br />

�<br />

� closed stirrup<br />

� reinforcement<br />

� lower reinforcement of steel bars or mesh<br />

� closed stirrup<br />

The required shear reinforcement in the overlap area<br />

must be proved in accordance with DIN 1045-1.<br />

� angled reinforcement<br />

Recommended minimum beam width: at least 220 mm<br />

closed stirrup<br />

closed stirrup<br />

� insert sti<br />

� upper reinforcement of steel bars or mesh<br />

�<br />

� insert stirrup<br />

� lower reinforcement of steel bars or mesh<br />

� upper reinforcement of steel bars or mesh<br />

� angled reinforcement<br />

� insert stirrup<br />

� lower reinforcement of steel bars or mesh<br />

� upper reinforcement of steel bars or mesh<br />

� insert stirrup<br />

for better solutions...<br />

� reinforcement<br />

� lower reinforcement of steel bars or mesh<br />

The required shear reinforcement in the overlap area<br />

must be proved in accordance with DIN 1045-1.<br />

Constructive angled reinforcement item 3.<br />

Recommended minimum beam width: at least 220 mm<br />

�<br />

IP / <strong>IPT</strong><br />

17<br />

ISOPRO ® - insulation at its highest level

alcony slab<br />

ny slab<br />

�<br />

balcony slab<br />

ISOPRO ® ny <strong>Type</strong> IP slab<br />

balcony slab<br />

� �<br />

ny slab<br />

�<br />

balcony slab<br />

� �<br />

balcony slab<br />

A<br />

�<br />

� �<br />

�<br />

� �<br />

concrete ≥ 25/30 concrete ≥ 20/25<br />

ny slab<br />

18<br />

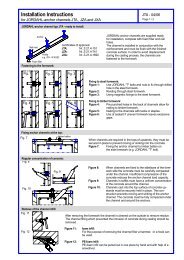

ISOPRO ® <strong>Type</strong> IP<br />

On-site reinforcement and installation instructions<br />

�<br />

A<br />

ISOPRO ® type IP with on-site mesh support<br />

The mesh support replaces the suspension reinforcement.<br />

It should be installed at a distance of ≤ 100 mm from the<br />

insulation and raised up until it is immediately below the<br />

tension reinforcement. The diameter of the diagonals must<br />

be at least 5 mm. The transverse force rod can be positioned<br />

above or below the mesh support.<br />

www.h-bau.com<br />

ISOPRO ® <strong>Type</strong> IP<br />

ny slab<br />

�<br />

A<br />

�<br />

te ≥ 25/30 concrete ≥ 20/25<br />

A<br />

�<br />

�<br />

�<br />

�<br />

�<br />

Section A - A<br />

Section A - integral A suspension reinforcement<br />

integral suspension � reinforcement<br />

�<br />

�<br />

�<br />

ISOPRO tension rods<br />

� insert edging according to DIN<br />

� � lower reinforcement<br />

� ISOPRO transverse force rods ISOPRO compression support � distribution rods Ø 8<br />

� lower reinforcement<br />

ISOPRO transverse force rods<br />

Installation instructions<br />

Lay the lower reinforcement � for the floor and balcony<br />

slab.<br />

Install ISOPRO ® IP and align. The direction of alignment<br />

(arrow symbol on top of element) must be followed.<br />

Insert the balcony-side edging � in accordance with<br />

DIN 1045-1 and connect to the ISOPRO ® tension rods.<br />

The ISOPRO ® tension rods and the support reinforcement<br />

are at the same level. If required. the binder on<br />

the tension rod level can be cut through.<br />

Lay the distribution rods. one Ø 8 top and bottom item<br />

�.<br />

In the case of indirect support, lay the floor-side edging<br />

� according to DIN 1045-1 and distribution rods �<br />

Ø 8.<br />

Insert the upper slab reinforcement � and bind together<br />

with the ISOPRO ® tension rods. The ISOPRO ®<br />

tension rods and the support reinforcement are at the<br />

same level.<br />

It is necessary when concreting to fill and pack uniformly<br />

on both sides in order to prevent movement of<br />

the ISOPRO ® elements<br />

balcony<br />

Mesh support<br />

ISOPRO tension rods<br />

ISOPRO compression support<br />

100<br />

� upper reinforcement<br />

� upper reinforcement<br />

� insert edging according to DIN<br />

� distribution rods Ø 8<br />

slab

ISOPRO ® <strong>Type</strong> IP<br />

On-site connection reinforcement<br />

On-site connection reinforcement for ISOPRO ® type IP<br />

<strong>Type</strong><br />

as,erf *<br />

[cm²/m]<br />

for better solutions...<br />

Recommendation for on-site connection reinforcement<br />

Concrete reinforcing steel<br />

rod BSt 500 S<br />

Concrete steel mesh<br />

BSt 500 M<br />

ISOPRO ® elements are supplied as standard from the factory with the required balcony-side suspension reinforcement.<br />

On the end-face side of the slabs to be connected, distribution rods of at least 2 Ø 8 are to be arranged on-site.<br />

In the case of indirect support of the elements it should be noted:<br />

A suspension reinforcement is required on the floor side that is dimensioned for V Rd . Distribution rods of at least 2 Ø 8<br />

are to be arranged on the end-face side of the slabs.<br />

The required steel cross-section for the suspension reinforcement per metre can be taken from the table:<br />

Concrete steel mesh<br />

+ reinforcing steel rod<br />

IP 10 1.98 Ø 8 / 200 Q257A / R257A -<br />

IP 20 3.52 Ø 10 / 170 Q424A / R424A Q188A + Ø 6/150<br />

IP 25 4.02 Ø 10 / 150 Q424A / R424A Q257A + Ø 6/150<br />

IP 30 5.15 Ø 10 / 110 Q524A / R524A Q188A + Ø 8/150<br />

IP 40 6.28 Ø 10 / 100 Q636A Q335A + Ø 8/150<br />

IP 50 7.85 Ø 12 / 100 - Q 524A + Ø 8/150<br />

* The required connection reinforcement A s,erf applies to fully-loaded ISOPRO ® elements. For lower loading, these can<br />

be reduced correspondingly.<br />

Note:<br />

For proof of the shear force load bearing capacity of the slabs without web reinforcement. DIN 1045-1. Section 10.3.3<br />

applies. For proof of the shear force load bearing capacity of the slabs with web reinforcement DIN 1045-1. Section<br />

10.3.4 applies. The maximum shear force transferable across the joint is limited to 0.3 · V Rd.max .<br />

Suspension reinforcement for ISOPRO ® type IP<br />

<strong>Type</strong> Standard Q8 Q10 Q12<br />

IP 10 Q...<br />

IP 20 Q...<br />

IP 25 Q...<br />

IP 30 Q...<br />

IP 40 Q...<br />

IP 50 Q...<br />

a s,erf [cm²/m] 0.63 1.42 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

a s,erf [cm²/m] 0.63 1.42 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

a s,erf [cm²/m] 0.95 1.82 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

a s,erf [cm²/m] 0.95 1.82 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

a s,erf [cm²/m] 0.95 1.82 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

a s,erf [cm²/m] 0.95 1.82 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

IP / <strong>IPT</strong><br />

19<br />

ISOPRO ® - insulation at its highest level

20<br />

ISOPRO ® <strong>Type</strong> <strong>IPT</strong><br />

On-site reinforcement and installation instructions<br />

balcony slab<br />

ny slab<br />

�<br />

balcony slab<br />

ISOPRO ® ny <strong>Type</strong> <strong>IPT</strong>slab<br />

balcony slab<br />

� �<br />

ny slab<br />

�<br />

�<br />

balcony slab<br />

� �<br />

balcony slab<br />

A<br />

�<br />

� �<br />

�<br />

� �<br />

concrete ≥ 25/30 concrete ≥ 20/25<br />

ny slab<br />

A<br />

www.h-bau.com<br />

ISOPRO ® <strong>Type</strong> <strong>IPT</strong><br />

ny slab<br />

�<br />

A<br />

�<br />

te ≥ 25/30 concrete ≥ 20/25<br />

A<br />

�<br />

�<br />

�<br />

�<br />

�<br />

Section A - A<br />

Section A - integral A suspension reinforcement<br />

integral suspension � reinforcement<br />

�<br />

�<br />

�<br />

� upper reinforcement<br />

ISOPRO tension rods � upper reinforcement<br />

ISOPRO tension rods<br />

� insert edging according to DIN<br />

� � lower reinforcement<br />

� ISOPRO transverse force rods ISOPRO compression support � distribution rods Ø 8<br />

� lower reinforcement<br />

ISOPRO transverse force rods<br />

ISOPRO compression support<br />

Installation instructions<br />

� insert edging according to DIN<br />

� distribution rods Ø 8<br />

Lay the lower reinforcement � for the floor and balcony<br />

slab.<br />

Install ISOPRO ® <strong>IPT</strong> and align. The direction of alignment<br />

(arrow symbol on top of element) must be followed.<br />

Insert the balcony-side edging � in accordance with<br />

DIN 1045-1 and connect to the ISOPRO ® tension rods.<br />

The ISOPRO ® tension rods and the support reinforcement<br />

are at the same level. If required, the binder on<br />

the tension rod level can be cut through.<br />

Lay the distribution rods, one Ø 8 top and bottom item<br />

�.<br />

In the case of indirect support, lay the floor-side edging<br />

� according to DIN 1045-1 and distribution rods �<br />

Ø 8.<br />

Insert the upper slab reinforcement � and bind together<br />

with the ISOPRO ® tension rods. The ISOPRO ®<br />

tension rods and the support reinforcement are at the<br />

same level.<br />

It is necessary when concreting to fill and pack uniformly<br />

on both sides in order to prevent movement of<br />

the ISOPRO ® elements

ISOPRO ® <strong>Type</strong> <strong>IPT</strong><br />

On-site connection reinforcement<br />

On-site connection reinforcement for ISOPRO ® type <strong>IPT</strong><br />

<strong>Type</strong><br />

as,erf *<br />

[cm²/m]<br />

for better solutions...<br />

Recommendation for on-site connection reinforcement<br />

Concrete reinforcing steel rod<br />

BSt 500 S<br />

Concrete steel mesh<br />

+ reinforcing steel rod<br />

<strong>IPT</strong> 55 8.34 Ø 12 / 125 Q335A + Ø 10 / 150<br />

<strong>IPT</strong> 60 9.40 Ø 12 / 100 Q335A + Ø 10 / 125<br />

<strong>IPT</strong> 70 10.50 Ø 12 / 100 Q335A + Ø 12 / 150<br />

<strong>IPT</strong> 80 11.00 Ø 12 / 100 Q335A + Ø 12 / 125<br />

<strong>IPT</strong> 100 13.16 Ø 14 / 100 Q524A + Ø 12 / 125<br />

* The required connection reinforcement A s,erf applies to fully-loaded ISOPRO ® elements. For lower loading, these can<br />

be reduced correspondingly.<br />

Note:<br />

For proof of the shear force load bearing capacity of the slabs without web reinforcement, DIN 1045-1, Section 10.3.3<br />

applies. For proof of the shear force load bearing capacity of the slabs with web reinforcement DIN 1045-1, Section<br />

10.3.4 applies. The maximum shear force transferable across the joint is limited to 0.3 · V Rd,max .<br />

Suspension reinforcement for ISOPRO ® type <strong>IPT</strong><br />

ISOPRO ® elements are supplied as standard from the factory with the required balcony-side suspension reinforcement.<br />

On the end-face side of the slabs to be connected, distribution rods of at least 2 Ø 8 are to be arranged on-site.<br />

In the case of indirect support of the elements it should be noted:<br />

A suspension reinforcement is required on the floor side that is dimensioned for V Rd . Distribution rods of at least 2 Ø 8<br />

are to be arranged on the end-face side of the slabs.<br />

The required steel cross-section for the suspension reinforcement per metre can be taken from the table:<br />

<strong>Type</strong> Standard Q8 Q10 Q12<br />

<strong>IPT</strong> 55 Q...<br />

<strong>IPT</strong> 60 Q...<br />

<strong>IPT</strong> 70 Q...<br />

<strong>IPT</strong> 80 Q...<br />

<strong>IPT</strong> 100 Q...<br />

a s,erf [cm²/m] 0.95 1.42 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

a s,erf [cm²/m] 0.95 1.42 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

a s,erf [cm²/m] 0.95 1.42 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

a s,erf [cm²/m] 0.95 1.82 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

a s,erf [cm²/m] 0.95 1.82 2.22 3.20<br />

selected 4 Ø 6 4 Ø 8 4 Ø 10 4 Ø 12<br />

IP / <strong>IPT</strong><br />

21<br />

ISOPRO ® - insulation at its highest level

22<br />

ISOPRO ® <strong>Type</strong> IP & <strong>IPT</strong><br />

Two-part elements installation instructions<br />

In type IP pre-cast units In type <strong>IPT</strong> pre-cast units<br />

≤100<br />

≥ 100<br />

�<br />

�<br />

�<br />

≤100<br />

�<br />

On-site type IP On-site type <strong>IPT</strong><br />

≥ 100<br />

�<br />

�<br />

www.h-bau.com<br />

�<br />

�<br />

≤100<br />

�<br />

≥ 180* *<strong>IPT</strong> 100 ≥ 215<br />

�<br />

�<br />

≤100<br />

�<br />

≥ 180* *<strong>IPT</strong> 100 ≥ 215<br />

In pre-cast units<br />

Arrange the lower reinforcement layer including the<br />

mesh support as per structural design. Distance to insulation<br />

joint ≤ 100 mm.<br />

Install lower section �. The last transverse rod in the<br />

mesh must be placed as close as possible to the insulation,<br />

observing the required concrete covering.<br />

For IP: the transverse force rod can be under or on top<br />

of the mesh support. The mesh support should be lifted<br />

until it is underneath the tension reinforcement.<br />

Concreting the slab element.<br />

Locate and fix the associated upper section � and,<br />

where required, intermediate section �.<br />

<strong>Type</strong> IP is supplied with suspension reinforcement as standard<br />

On-site<br />

Lay the necessary on-site reinforcement on the floor<br />

side. (See pages 18-21)<br />

Lay the slab element on the timber beams prepared for<br />

it.<br />

Lay the necessary on-site reinforcement on the balcony<br />

side. (See pages 18-21)<br />

Attach the upper section � and, where required, intermediate<br />

section �. Bind the tensioning rods to the onsite<br />

reinforcement.<br />

Note:<br />

For an element height h = 210 to 250 mm fit additional insertion<br />

stirrups Ø 6/200 or stirrup mesh Q188A on the<br />

balcony side.<br />

Important note:<br />

The type identification for lower and upper sections must match (see also colour identification). The direction of installation<br />

(on the balcony side) must be observed.

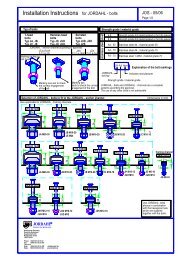

ISOPRO ® <strong>Type</strong> IP & <strong>IPT</strong><br />

Two-part elements<br />

Construction<br />

<strong>Type</strong> IP <strong>Type</strong> <strong>IPT</strong><br />

upper section<br />

middle section<br />

lower section<br />

for better solutions...<br />

upper section<br />

middle section<br />

lower section<br />

balcony slab balcony<br />

slab<br />

General notes<br />

All ISOPRO ® elements of types IP and <strong>IPT</strong> can be supplied as two-part elements<br />

The permitted section sizes can be found in the tables on pages<br />

14 and 15 of this technical information.<br />

Intermediate sections can be supplied for height offset compensation<br />

in 20 and 40 mm thicknesses.<br />

<strong>Type</strong> IP: If the mesh supports are placed with a spacing of<br />

≤ 100 mm from the insulation joint, no additional suspension<br />

reinforcement is required. Instead a suspension reinforcement<br />

dimensioned for VRd should be located along the insulation<br />

joints.<br />

For information regarding the required formwork height offset<br />

and the maximum spacing of expansion joints, refer to pages<br />

24-26.<br />

The adhesive labels (type designation) for the upper and lower<br />

sections must be identical. Follow the instructions for the balcony<br />

side and the floor side.<br />

The following elements also have an additional<br />

colour coding:<br />

ISOPRO ® type Colour code<br />

IP 20 green<br />

IP 30 blue<br />

IP 40 yellow<br />

IP 50 white<br />

The continuity of the colour coding through<br />

the elements ensures correct matching every<br />

time, even for short sections.<br />

IP / <strong>IPT</strong><br />

23<br />

ISOPRO ® - insulation at its highest level

24<br />

ISOPRO ® <strong>Type</strong> IP & <strong>IPT</strong><br />

Deflection and camber<br />

Freely cantilevered slabs made from<br />

concrete experience a sinking of the<br />

edge when they are stripped. This displacement<br />

is a combination of a deformation<br />

of the balcony insulation<br />

element used and a bending of the<br />

slab itself.<br />

Cambering the balcony slab<br />

www.h-bau.com<br />

These two deformations are superimposed<br />

and offset by cambering the<br />

formwork.<br />

From the calculation shown below the<br />

required formwork camber on the<br />

cantilever arm end is derived resulting<br />

from the ISOPRO ® elements at<br />

100% loading.<br />

Element heigh h [mm] IP 10<br />

Concrete covering c v<br />

30 35 40 45 50<br />

IP 20<br />

IP 25<br />

IP 30<br />

IP 40<br />

IP 50<br />

To obtain the total camber, the slab<br />

deformation according to DIN 1045-<br />

1 is added. For the total camber to be<br />

specified by the structural designer in<br />

the construction drawings the direction<br />

of the scheduled water run-off<br />

must be considered when making the<br />

camber.<br />

<strong>IPT</strong> 55<br />

<strong>IPT</strong> 60<br />

<strong>IPT</strong> 70<br />

<strong>IPT</strong> 80<br />

<strong>IPT</strong> 100<br />

160 0.51 0.59 0.92 1.06<br />

160 0.48 0.56 0.87 1.00<br />

160 170 0.45 0.53 0.82 0.94<br />

160 170 0.43 0.50 0.77 0.89<br />

160 170 180 0.41 0.47 0.73 0.84<br />

170 180 0.39 0.45 0.70 0.80<br />

170 180 190 0.37 0.43 0.67 0.79<br />

180 190 0.35 0.41 0.64 0.73<br />

180 190 200 0.34 0.39 0.61 0.69<br />

190 200 0.33 0.38 0.59 0.67<br />

190 200 210 0.31 0.36 0.56 0.64<br />

200 210 0.30 0.35 0.54 0.62<br />

200 210 220 0.29 0.34 0.52 0.59<br />

210 220 0.28 0.33 0.50 0.57<br />

210 220 230 0.27 0.31 0.49 0.55<br />

220 230 0.26 0.30 0.47 0.53<br />

220 230 240 0.26 0.29 0.46 0.52<br />

230 240 0.25 0.29 0.44 0.50<br />

230 240 250 0.24 0.28 0.43 0.49<br />

240 250 0.23 0.27 0.42 0.47<br />

240 250 0.23 0.26 0.40 0.46<br />

250 0.22 0.25 0.39 0.45<br />

250 0.21 0.25 0.38 0.43

ISOPRO ® <strong>Type</strong> IP & <strong>IPT</strong><br />

Deflection and camber<br />

Determination of the balcony slab camber<br />

ü [mm] = value in the table · (m Ed /m Rd ) · l k [m] · 10<br />

m Ed<br />

mRd lk for better solutions...<br />

Bending moment for determining the camber resulting from the ISOPRO ® element.<br />

The decisive load combination is decided by the designer.<br />

Design moment of the ISOPRO ® element in accordance with the dimensioning tables on pages 14 and 15.<br />

Cantilever length in [m]<br />

Example:<br />

Cantilever length: l k = 1.80 m<br />

Slab thickness: h = 180 mm<br />

Dead weight (slab and covering): g = 6.0 kN/m 2<br />

Edge load (parapet): F = 1.5 kN/m<br />

Traffic loading: q = 4.0 kN/m 2<br />

Concrete cover: c v = 30 mm<br />

Dimensioning:<br />

m Ed = (g + q) x l k 2 / 2 + F x lk = (6.0 · 1.35 + 4.0 · 1.5) · 1.8 2 / 2 + 1.5 · 1.8 · 1.35 = 26.5 kNm/m<br />

v Ed = (g + q) x l k + F = (6.0 · 1.35 + 4.0 · 1.5) · 1.8 + 1.5 · 1.35 = 27.4 kN/m<br />

Selected: ISOPRO ® IP 30 c v 30 h = 180 mm m Rd = 26.7 kNm/m v Rd = 41.5 kN/m<br />

Selected load combination in the determination of the camber resulting from the ISOPRO ® element:<br />

m Ed = (g + q/3) · l k 2 /2 + F · lk= (6.0 · 1.35 + 4.0/3 · 1.5) · 1.8 2 / 2 + 1.5 · 1.8 · 1.35 = 20.0 kNm/m<br />

ü = 0.39 · (20.0 / 26.5) · 1.80 · 10 = 5.3 mm<br />

This camber results from the deformation of the ISOPRO ® elements at 100% loading and is to be superimposed by<br />

the slab deformation in accordance with DIN 1045-1.<br />

IP / <strong>IPT</strong><br />

25<br />

ISOPRO ® - insulation at its highest level

spacing e<br />

26<br />

ISOPRO ® <strong>Type</strong> IP & <strong>IPT</strong><br />

Expansion joint spacing<br />

Expansion joint spacing ISOPRO ®<br />

The external concrete components must have expansion joints at right angles to the insulation layer in order to limit the<br />

stress caused by changes in temperature. The spacing of the joints e is given in the following table:<br />

expansion joint spacing e<br />

balcony<br />

Expansion joint spacing for ISOPRO ® type IP and <strong>IPT</strong><br />

Rod diameter [mm] ≤ 10 12 14 16 20<br />

Joint spacing e [m] 13.00 11.30 10.10 9.20 8.00<br />

For corner constructions, the maximum rod leg length is e/2<br />

www.h-bau.com<br />

expansion joint dowelling<br />

expansion joint e.g. HED-S + plastic sleeves<br />

expansion joint<br />

ISOPRO ISOPRO<br />

expansion joint<br />

expansion joint spacing e<br />

ISOPRO <strong>Type</strong> <strong>IPT</strong> Corner<br />

e /2<br />

balcony<br />

e /2<br />

ISOPRO <strong>Type</strong> <strong>IPT</strong> Corner<br />

expansion joint<br />

e /2<br />

balcony

ISOPRO ® <strong>Type</strong> <strong>IPT</strong> Corner<br />

Construction and dimensions<br />

ISOPRO ® type <strong>IPT</strong> Corner 20<br />

690 80<br />

690<br />

3 Ø 8<br />

SECTION<br />

690<br />

580<br />

1st layer c v 30<br />

2nd layer c v 50<br />

5 Ø 10<br />

1st layer<br />

80<br />

80<br />

balcony side<br />

2nd layer<br />

slab balcony<br />

On-site reinforcement <strong>IPT</strong> Corner 20<br />

<strong>IPT</strong> Corner 20 1st layer<br />

� 5 Ø 10<br />

� 5 Ø 10<br />

slab<br />

� 5 Ø 10<br />

<strong>IPT</strong> Corner 20 2nd layer<br />

580<br />

1st + 2nd layer c v 30<br />

3 Ø 8<br />

690<br />

� 5 Ø 10<br />

balcony<br />

5 Ø 10<br />

� 5 Ø 10<br />

� 5 Ø 10<br />

Notes:<br />

for better solutions...<br />

Corner element comprises 2 elements<br />

1st and 2nd layer<br />

Element height h ≥ 180 mm<br />

810<br />

CORNER<br />

<strong>IPT</strong><br />

3 Ø 10<br />

1s<br />

Special elements h = 160 mm 700<br />

possible<br />

8 Ø 12 Spacing between the floor-side<br />

filigree slabs and the insulation<br />

body ≥ 100 mm<br />

4<br />

80<br />

810<br />

SECTION<br />

slab<br />

On-site connection reinforcement<br />

A s,erf = 3.92 cm²<br />

recommended structural components<br />

catalogue:<br />

� Connection reinforcement<br />

1st layer 5 Ø 10 / 100<br />

l = balcony cantilever length -<br />

70 mm<br />

� Connection reinforcement<br />

2nd layer 5 Ø 10 / 100<br />

l = balcony cantilever length -<br />

70 mm<br />

� Supplementary reinforcement<br />

5 Ø 10 / 100<br />

l = 2 x balcony cantilever<br />

length<br />

� Supplementary reinforcement<br />

5 Ø 10 / 100<br />

l = 2 x balcony cantilever<br />

length<br />

810 80<br />

1st layer c v 30<br />

2nd layer c v 50<br />

<strong>IPT</strong> Corner 30 1st layer<br />

slab<br />

� 6 Ø 12 � 6 Ø 12<br />

� 6 Ø 12<br />

27<br />

ISOPRO ® - insulation at its highest level<br />

7 Ø<br />

80

5 Ø 10<br />

ny<br />

28<br />

ISOPRO ® <strong>Type</strong> <strong>IPT</strong> Corner<br />

Construction and dimensions<br />

ISOPRO ® type <strong>IPT</strong> Corner 30<br />

810<br />

80<br />

810<br />

3 Ø 10<br />

SECTION<br />

www.h-bau.com<br />

700<br />

balcony side<br />

810 80<br />

810<br />

1st layer c v 30<br />

2nd layer c v 50<br />

7 Ø 12<br />

1st layer<br />

8 Ø 12 4 Ø 14<br />

80<br />

slab balcony<br />

On-site reinforcement <strong>IPT</strong> Corner 30<br />

<strong>IPT</strong> Corner 30 1st layer<br />

� 6 Ø 12<br />

� 6 Ø 12<br />

slab<br />

� 6 Ø 12<br />

<strong>IPT</strong> Corner 30 2nd layer<br />

8 Ø 12 4 Ø 14<br />

700<br />

1st layer c v 40<br />

2nd layer c v 20<br />

2nd layer<br />

3 Ø 10<br />

7 Ø 12<br />

� 6 Ø 12<br />

balcony<br />

� 6 Ø 12<br />

� 6 Ø 12<br />

830<br />

80<br />

830<br />

Notes:<br />

Corner element comprises 2 elements<br />

1st and 2nd layer<br />

Element height h ≥ 180 mm<br />

SECTION<br />

slab<br />

4 Ø 10<br />

Special elements h = 160 mm<br />

700<br />

possible<br />

Spacing between the floor-side<br />

filigree slabs and the insulation<br />

body ≥ 100 mm<br />

830 80<br />

1st layer c v 30<br />

2nd layer c v 50<br />

6 Ø 14<br />

1st layer<br />

6 Ø 14 6 Ø 14<br />

On-site connection reinforcement<br />

A s,erf = 6.41 cm²<br />

recommended structural components<br />

catalogue:<br />

� Connection reinforcement<br />

1st layer 6 Ø 12 / 100<br />

l = balcony cantilever length -<br />

70 mm<br />

� Connection reinforcement<br />

2nd layer 6 Ø 12 / 100<br />

l = balcony cantilever length -<br />

70 mm<br />

� Supplementary reinforcement<br />

6 Ø 12 / 100<br />

l = 2 x balcony cantilever<br />

length<br />

� Supplementary reinforcement<br />

6 Ø 12 / 100<br />

l = 2 x balcony cantilever<br />

length<br />

80<br />

balcony sid<br />

6 Ø 14 6 Ø 14<br />

700<br />

1st layer c v 40<br />

2nd layer c v 20<br />

<strong>IPT</strong> Corner 50 1st layer<br />

slab<br />

� 6 Ø 14 � 6 Ø 14<br />

� 6 Ø 14

7 Ø 12<br />

balcony<br />

ISOPRO ® <strong>Type</strong> <strong>IPT</strong> Corner<br />

Construction and dimensions<br />

ISOPRO ® type <strong>IPT</strong> Corner 50<br />

830<br />

80<br />

830<br />

4 Ø 10<br />

SECTION<br />

700<br />

balcony side<br />

830 80<br />

830<br />

1st layer c v 30<br />

2nd layer c v 50<br />

6 Ø 14<br />

1st layer<br />

6 Ø 14 6 Ø 14<br />

80<br />

slab balcony<br />

On-site reinforcement <strong>IPT</strong> Corner 50<br />

<strong>IPT</strong> Corner 50 1st layer<br />

� 6 Ø 14<br />

� 6 Ø 14<br />

slab<br />

� 6 Ø 14<br />

<strong>IPT</strong> Corner 50 2nd layer<br />

6 Ø 14 6 Ø 14<br />

700<br />

1st layer c v 40<br />

2nd layer c v 20<br />

2nd layer<br />

4 Ø 10<br />

6 Ø 14<br />

� 6 Ø 14<br />

balcony<br />

� 6 Ø 14<br />

� 6 Ø 14<br />

Notes:<br />

for better solutions...<br />

Corner element comprises 2 elements<br />

1st and 2nd layer<br />

Element height h ≥ 180 mm<br />

Special elements h = 160 mm<br />

possible<br />

Spacing between the floor-side<br />

filigree slabs and the insulation<br />

body ≥ 100 mm <strong>IPT</strong> CORNER<br />

On-site connection reinforcement<br />

A s,erf = 7.27 cm²<br />

recommended structural components<br />

catalogue:<br />

� Connection reinforcement<br />

1st layer 6 Ø 14 / 100<br />

l = balcony cantilever length -<br />

70 mm<br />

� Connection reinforcement<br />

2nd layer 6 Ø 14 / 100<br />

l = balcony cantilever length -<br />

70 mm<br />

� Supplementary reinforcement<br />

6 Ø 14 / 100<br />

l = 2 x balcony cantilever<br />

length<br />

� Supplementary reinforcement<br />

6 Ø 14 / 100<br />

l = 2 x balcony cantilever<br />

length<br />

29<br />

ISOPRO ® - insulation at its highest level

30<br />

ISOPRO ® <strong>Type</strong> <strong>IPT</strong> Corner<br />

Dimensioning table<br />

Dimensioning table for concrete ≥ C20/25<br />

Element height [mm]<br />

dependent on c v [mm]<br />

www.h-bau.com<br />

Dimensional values for the absorbable moments M Rd [kN]<br />

30 35 <strong>IPT</strong> Eck 20 <strong>IPT</strong> Eck 30 <strong>IPT</strong> Eck 50<br />

- 180 19.5 25.9 28.8<br />

180 - 20.3 27.3 30.4<br />

- 190 21.2 28.7 32.0<br />

190 - 22.0 30.1 33.5<br />

- 200 22.9 31.5 35.1<br />

200 - 23.7 32.9 36.7<br />

- 210 24.6 34.3 38.3<br />

210 - 25.4 35.7 39.9<br />

- 220 26.3 37.1 41.5<br />

220 - 27.1 38.5 43.0<br />

- 230 28.0 39.9 44.6<br />

230 - 28.8 41.3 46.2<br />

- 240 29.7 42.7 47.8<br />

240 - 30.6 44.1 49.4<br />

- 250 31.4 45.5 50.9<br />

250 - 32.3 46.9 52.5<br />

Dimensional values for the absorbable shear forces V Rd [kN]<br />

h = 180 - 190 [mm]<br />

72.6 96.8<br />

46.5<br />

h = 200 - 250 [mm] 104.6 118.1<br />

Dimensioning table for concrete ≥ C25/30<br />

Element height [mm]<br />

dependent on c v [mm]<br />

Dimensional values for the absorbable moments M Rd [kN]<br />

30 35 <strong>IPT</strong> Eck 20 <strong>IPT</strong> Eck 30 <strong>IPT</strong> Eck 50<br />

- 180 19.5 29.4 33.2<br />

180 - 20.3 31.0 35.0<br />

- 190 21.2 32.6 36.8<br />

190 - 22.0 34.2 38.7<br />

- 200 22.9 35.8 40.5<br />

200 - 23.7 37.4 42.3<br />

- 210 24.6 38.9 44.1<br />

210 - 25.4 40.5 46.0<br />

- 220 26.3 42.1 47.8<br />

220 - 27.1 43.7 49.6<br />

- 230 28.0 45.3 51.4<br />

230 - 28.8 46.8 53.2<br />

- 240 29.7 48.4 55.1<br />

240 - 30.6 50.0 56.9<br />

- 250 31.4 51.6 58.7<br />

250 - 32.3 53.2 60.5<br />

Dimensional values for the absorbable shear forces V Rd [kN]<br />

h = 180 - 190 [mm]<br />

72.6 96.8<br />

46.5<br />

h = 200 - 250 [mm] 104.6 118.1

ISOPRO ® <strong>Type</strong> IPH<br />

Technical data<br />

Notes<br />

for better solutions...<br />

The ISOPRO ® elements type IPH for absorption of horizontal forces must only be used together with ISOPRO ® cantilever<br />

slabs or shear-force connections.<br />

The number of IPH elements to be configured is taken from the data provided by the structural designer. See page 26<br />

for the configuration of expansion joints.<br />

When using ISOPRO ® IPH elements note that the force absorption of the line connection is reduced by the percentage<br />

length ratio of the IPH elements to the total connection length.<br />

Plan view Section<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

100<br />

balcony balcony<br />

slab<br />

balcony slab<br />

balcony slab<br />

balcony slab<br />

IPH 1 for absorption of horizontal forces parallel to the expansion joint.<br />

balcony balcony<br />

slab<br />

balcony slab<br />

balcony slab<br />

balcony slab<br />

IPH 2 for absorption of horizontal forces at right-angles to the expansion joint.<br />

balcony balcony<br />

slab<br />

balcony slab<br />

balcony slab<br />

balcony slab<br />

Dimensioning table, type IPH for concrete ≥ C20/25<br />

c v - independent<br />

balcony balcony<br />

balcony<br />

balcony<br />

balcony<br />

220<br />

220<br />

220<br />

220<br />

220<br />

220<br />

220<br />

220<br />

Reinforcement Element length<br />

HRd [kN]<br />

Shear force Horizontal<br />

[mm]<br />

Vertical Horizontal<br />

IPH 1 2 x 1 Ø 8 - 100 ± 7.4 kN -<br />

IPH 2 - 1 Ø 10 100 - ± 18.1 kN<br />

IPH 3 2 x 1 Ø 8 1 Ø 10 100 ± 7.4 kN ± 18.1 kN<br />

80<br />

80<br />

80<br />

80<br />

250<br />

80<br />

250 80<br />

250 80<br />

250 80<br />

250<br />

80<br />

250 80<br />

250 80<br />

250 80<br />

IPH 3 for absorption of horizontal forces parallel and at right-angles to the expansion joint.<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

250<br />

slab<br />

slab<br />

slab<br />

slab<br />

balcony balcony<br />

slab<br />

balcony slab<br />

balcony slab<br />

balcony slab<br />

balcony balcony<br />

slab<br />

balcony slab<br />

balcony slab<br />

balcony slab<br />

On-site reinforcement<br />

The installation of the ISOPRO ® IPH elements takes place analogously to the installation of the ISOPRO ® cantilever slabs<br />

or shear-force connections.<br />

The number and position of the elements is taken from the statics data. The elements are to be fixed in their positions.<br />

IPH / IPE<br />

31<br />

ISOPRO ® - insulation at its highest level

32<br />

100<br />

ISOPRO ® <strong>Type</strong> IPE<br />

Technical data<br />

Notes<br />

The ISOPRO ® elements type IPE for absorption of horizontal forces parallel and at right-angles to the insulation level<br />

must only be used together with ISOPRO ® cantilever slabs or shear-force connections. Moments generated for example<br />

from the effects of earthquakes can only be absorbed with the ISOPRO ® type IP/<strong>IPT</strong> elements.<br />

The number of IPE elements to be configured is taken from the data provided by the structural designer. See page 26<br />

for the configuration of expansion joints.<br />

When using ISOPRO ® HRd ||<br />

MRdy ZRd ⊥<br />

balcony slab<br />

IPE elements note that the force absorption of the line connection is reduced by the percentage<br />

length ratio of the IPE elements to the total connection length.<br />

100<br />

balcony slab<br />

balcony slab<br />

ISOPRO ® type IPE 1<br />

100<br />

100<br />

740 80<br />

740<br />

ZRd ⊥<br />

balcony slab<br />

www.h-bau.com<br />

balcony slab<br />

Construction and dimensions<br />

Z Rd ⊥<br />

550 80<br />

740 80<br />

H Rd ||<br />

H Rd ||<br />

balcony slab<br />

M Rdy<br />

550 80<br />

Z Rd ⊥<br />

balcony slab<br />

M Rdy<br />

H Rd ||<br />

balcony slab<br />

ISOPRO ® type IPE 2<br />

Examples of IPE elements<br />

M Rdy<br />

550<br />

IPQQ IPQQ IPE IPE IPQQ IPQQ IPE IPE IPQQ IPQQ<br />